Advantages and disadvantages

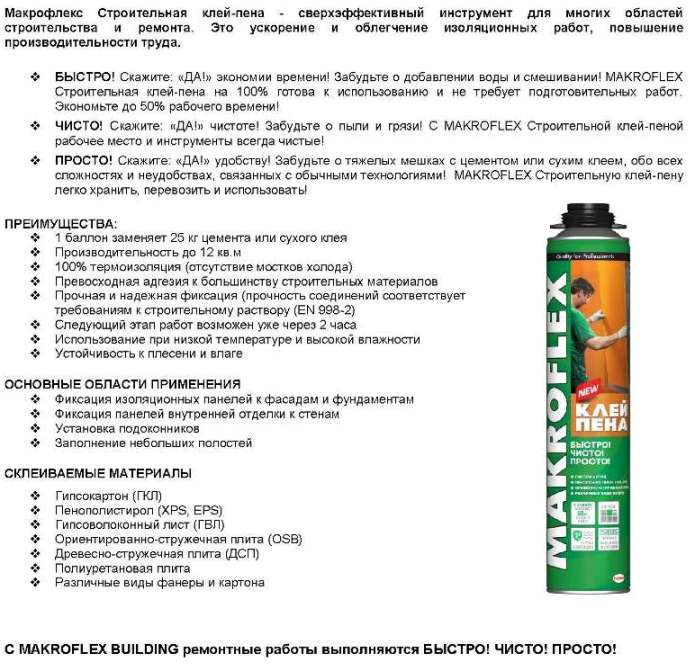

Advantages of using Macroflex foam:

- Foam is a finished product. The work does not require preliminary preparatory work.

- Super versatile foam can be used not only for laying materials, but also for gluing them and sealing seams and cracks.

- Simplicity and ease of use.

- The company's products are characterized by an affordable price.

- Due to its composition, the foam provides reliable protection against moisture.

- The hardening of the material is faster than the hardening of the cement mixture.

- Macroflex foam can be used with various materials: wood, stone, concrete, metal coatings, PVC, chipboard.

- The temperature range for working with special assembly mixture varies from -5 to +35 degrees.

- Working with polyurethane foam eliminates the formation of dust and various contaminants, which makes it possible to reduce the period of cleaning the premises after construction procedures.

Disadvantages:

- Under the influence of ultraviolet rays, the destruction of the foam occurs over time. To protect the material, paint products based on an aqueous emulsion, the composition of a sealing special material, a mixture of cement, and gypsum are used.

- Installation is carried out only with special protective equipment. Mounting tape affects the respiratory organs, skin, mucous membranes of the eyes.

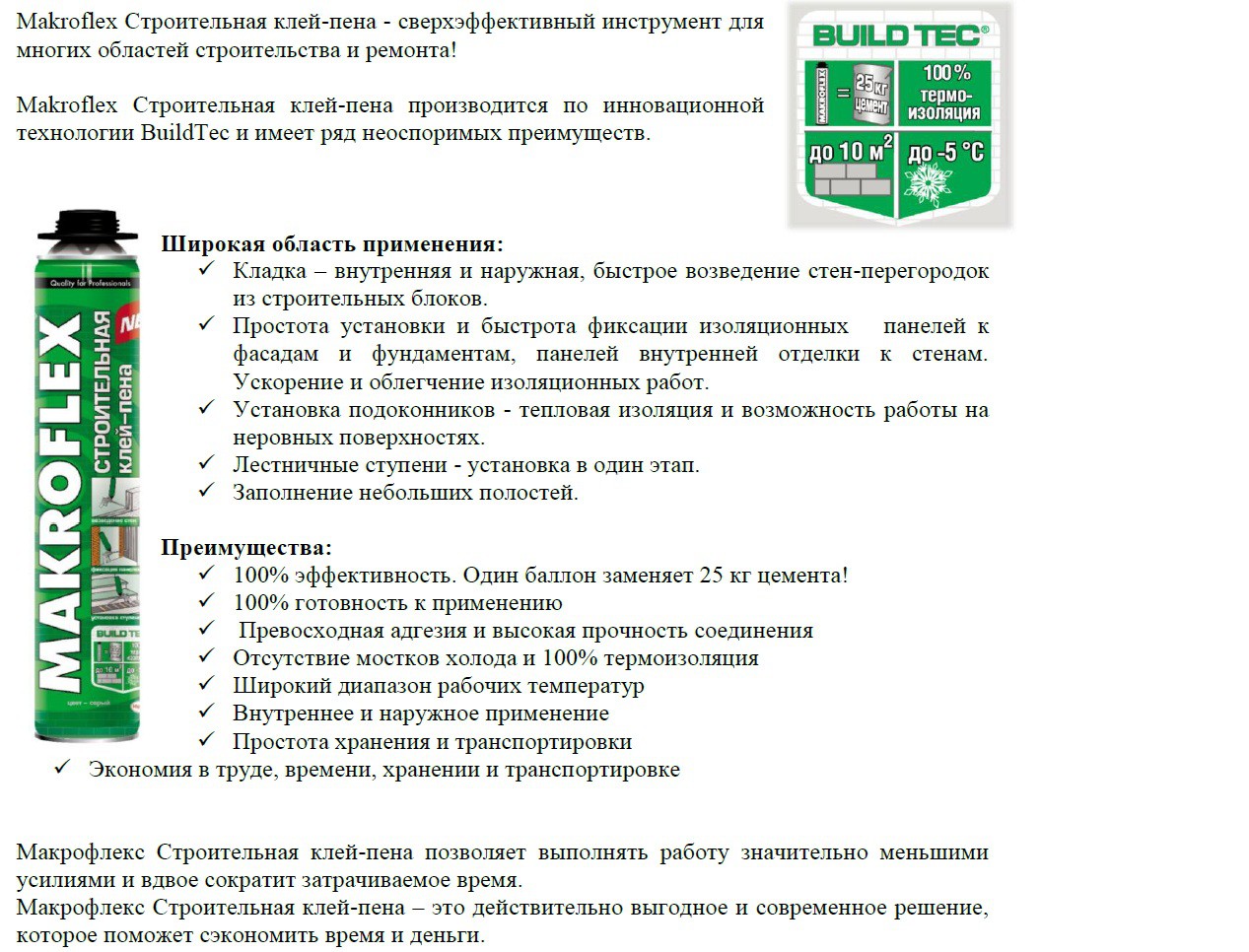

Polyurethane foam Makroflex: technical characteristics and scope

Macroflex is a one-component polyurethane polyurethane foam in cylinders. Consumption corresponds to the figure declared by the manufacturer. According to customer reviews, the foam of this brand is enough for an area twice as large as that of analogues of another manufacturer in a similar 750 ml cylinder. Note that the one-component foam hardens when it interacts with moisture. Therefore, air humidity plays an important role here.

Seeing Makroflex products:

- high yield foam (65);

- professional editing room marked "PRO";

- fireproof FR77;

- 2x2 with combined adapter;

- professional winter with the mark "Siberian", which allows you to work at - 18 ° C;

- a range of products labeled "Premium";

- foam cement, available in 850/1000 ml packs.

Features of Makroflex 750 ml:

- high density - 25-35 kg / m³;

- strength and resistance to compression - 3 N / cm²;

- high adhesion to wood, metal, glass, concrete, stone and other common building materials.

Makroflex 750 ml is fireproof, as it contains substances capable of self-extinguishing, in terms of fire resistance it belongs to class E (according to EN 13501) and to B3 (according to DIN 4102).

High adhesion makes the material versatile

High adhesion makes the material versatile

Primary hardening occurs within 60 minutes, primary expansion - 2 times. They work with Makroflex foam at wide ambient temperature ranges: from -10 to +25 degrees. She is able to provide heat and sound insulation. Professional Makroflex repels moisture, prevents mold.

Among the disadvantages, there is a poor tolerance of ultraviolet rays. Therefore, at the end of the work, cover the filled joint with putty, sealant or special paint that protects against ultraviolet radiation.

Views

The range of products from Makroflex contains an extensive list of substances of various quality and applicability.

- Makroflex Shaketec (Winter) is an all-season foam used in dry and cool conditions (-10 ° C - + 25 ° C). Provides reliable sound insulation, is able to completely fill voids when repairing roofs, installing doors and window openings.

- Makroflex Premium based on polyurethane belongs to the type of professional assembly tools. When applied, it increases its volume by about 2 times. It is applied to the surface to be treated with a pistol.The high degree of adhesion of the substance allows it to be used in work with wet structures. It is sold in 750 ml cylinders.

- Makroflex Premium Mega is a professional-grade winter remedy. Used at a temperature of -15 ° C, it provides a reliable degree of adhesion to various building materials.

- Makroflex Pro is applied using a special device, the practical material yield reaches 65 liters. The composition does not contain chloride, fluoride or carbon inclusions, it is used for insulating windows and doors, filling various kinds of voids. As a sealant it is used for insulation of premises.

An independent product category is made up of Makroflex sealants:

Makroflex TA145 is a super heat-resistant material used in conditions of high temperatures or sharp temperature changes (ovens, ceramic panels of kitchen stoves). The solidification of the TA-145 substance is facilitated by a humid environment. The composition does not contain solvents, the product is odorless and dries up within 1-2 days.

Comparative studies show that Makroflex sealant has a number of advantages over conventional sealants. In case of fire, the material burns without forming cracks, where combustion products can penetrate. The finished coating can withstand from -65 ° C to + 315 ° C.

Makroflex AX104 is a highly versatile silicone-based sealing substance used for self-sealing of building elements during work in closed conditions and outdoors. It has excellent adhesion to glass, ceramic and aluminum materials. The product contains anti-fungal components.

The substrate is resistant to the influence of ultraviolet radiation. Favorable temperature for installation - + 5 ° С - + 40 ° С in the absence of moisture. Stored up to 18 months.

- Makroflex NX108. It is characterized by high adhesion to wood, glass, metal, ceramic, plastic, concrete surfaces. The product is resistant to rust and ultraviolet radiation. The advantage of the substrate is that it can be used in high humidity conditions (for example, in a bathroom).

- Makroflex FA131 is an effective frost-resistant polyacrylic product. It is used in the processing of seam elements and structural defects, internal and external work. The material is resistant to sudden changes in temperature. It is not recommended to use it in high humidity conditions. The main functionality is the processing of seam elements and defects in concrete, brick, wood and other types of coatings.

- Makroflex SX101. It has a sanitary function as it contains antifungal fungicides. Used in high humidity conditions. Substance is white or colorless.

It should not be used on aquariums as the substrate contains antiseptics. Stains may appear on contact with a stone. Application is limited by temperature conditions - + 5 ° С - + 40 ° С.

Makroflex MFf190 is a powerful extra strong white adhesive based on an aqueous dispersion of polymers. It is used in the process of gluing plastic and wood products for internal and external work. Acts quickly and efficiently.

There is a certain classification that divides foam into household and professional products. When sealing cracks small sizes, installation of small products, it is irrational to purchase professional foam. In addition, household level foam increases in volume to a greater extent than professional foam.

It is important to know that the shrinkage of professional foam is small (within 0-3%), for household foam this parameter is up to 5%. Shrinkage should not exceed 5%, since such an excess leads to deformation of the substance, and sometimes to unwanted ruptures.

Based on this, professional Makroflex foam 750 ml is used in more demanding cases, for example:

- thermal insulation of heating networks, roofs;

- filling various voids;

- construction of insulating bulkheads;

- erection of fire-resistant structures (fire-resistant Makroflex FR77).

The right choice of polyurethane foam

To avoid mistakes and alterations during repair and installation work, choose the right polyurethane foam. First, decide on the tasks of applying the sealant. What are you planning to pop? Where will the work take place - outdoors or indoors? At what temperature? Calculate the approximate amount of material required based on the specifications. Consider which cleaner to prepare.

Strengthening the window frame

Strengthening the window frame

Requirements for Macroflex, as well as for other types of polyurethane foam (for example, Soudal), include the following specifications and properties:

- Flame retardant packaging and aerosol sales;

- When applied to the surface, polymerization and hardening should occur within the time indicated on the package;

- The required level of adhesion (adhesion) to ensure installation work;

- When drying, the foam should be elastic, not crumble or collapse;

- The secondary expansion coefficient must correspond to that indicated in the certificate and on the packaging.

Makroflex: household or professional

There is an opinion that beginners should use household foam in their work. This is partly true. For such work as sealing small cracks, installing small products, household foam is used. It makes no sense to buy a professional one for this type of work. As for professional foam, it is applied to the surface by means of a pistol, which allows more accurate metering of the volume and control of the substance consumption.

The main difference between household and professional foam is shrinkage.

The main difference between household and professional foam is shrinkage.

Household foam doubles in volume. As for the secondary expansion of the professional, it is practically absent. The coefficient of shrinkage of professional foam is minimal: from 0 to 3%, which cannot be said about household foam, where the indicated indicators are 5-7%. Household is used once, professional - more than once.

Professional foam Makroflex 750 ml is used for:

- thermal insulation of roofs, heating systems or walls;

- filling cavities;

- creating partitions with soundproofing properties;

- in fire-resistant structures, as fire protection (Makroflex FR77 fire-resistant).

It should be remembered that the substance hardens in about 24 hours. In view of this, large voids cannot be filled in one go. Use multiple balls.

Specifications

The official manufacturer declares the following technical parameters of Makroflex products, which in most cases corresponds to reality:

- The final hardening time of the used substance is exactly one day. At temperatures above + 20 ° C, the solidification time is reduced to 1.5-2 hours.

- Heat resistance of the product - from -50 ° С to + 100 ° С.

- The density of the hardened substance is 25-35 kg / m3.

- The ignition temperature of the foam is about 400 ° C.

- The degree of fire resistance of the hardened product is from B1 (fire resistant) to B3 (combustible).

- Foam yield - from 25 to 50 liters, depending on the volume of the package. With similar characteristics, Makroflex brand products provide a substance yield about 10% higher than that of analogues of other brands.

Reliable level of strength - up to 3 N / cm² in compression and tension.

The storage time of the product in the package is up to 15 months (it is better to store the tube vertically to maintain tightness). Storage temperature - not lower than + 5 ° С. It is strictly forbidden to store the product directly under sunlight.

Foam performance is limited by ambient temperature. The product shows its best qualities at temperatures not lower than + 5 ° С. A special compound has been developed and is being sold for work in winter.

Nevertheless, it is important to know that at low temperatures the foam hardens longer, and accordingly, its filling properties also decrease.

Purpose of Macroflex foam

Polyurethane sealant, as you can also call polyurethane foam, is available in cylinders of various capacities. The constituent parts of the sealant are prepolymer and propellant gas. When the prepolymer leaves the balloon, it solidifies as a result of interaction with air. The result of solidification is the formation of a fairly rigid polyurethane foam that has penetrated into cracks, recesses, holes. Hence, the purpose of the Macroflex foam follows:

- Sealing joints, cracks, holes.

- Filling voids in the material.

- Bonding several materials together.

- Thermal insulation and sound insulation of various surfaces and rooms.

There are several types of Macroflex foam. Foam for household use has an attachable plastic tube through which it exits the container. The professional version has a special outlet for attaching an assembly gun. In addition, professional foam has a higher yield of the finished composition, and it is more expensive.

Macroflex foam properties

The following properties and features of Macroflex 750 ml foam can be distinguished:

- Excellent adhesion to all solid materials. Best of all, the liquid composition interacts with concrete, brick, wooden surfaces, glass, plastic, metal, cellular concrete.

- To obtain the most reliable connection, it is advisable to dust the work surface. For example, moisten it. However, the presence of ice or frost on the surface will negatively affect the quality of the connection.

- Any atmospheric influences cannot harm the hardened Macroflex foam. Only UV radiation acts negatively on it, under the influence of which the polyurethane foam gradually collapses and begins to crumble. From here comes a prerequisite that must be observed when installing external structures. Stuck seams must be closed with some kind of material. These can be metal, wood, plastic trims or corners, as well as plaster, cement mortar or paint.

- It is recommended to use Macroflex to fill gaps, not less than 0.5 cm and not more than 8 cm. In too narrow gaps, the composition may not penetrate to the required depth, and the walls of too wide gaps will not be able to hold a heavy viscous mass.

- Liquid, just applied foam has a slight polyurethane odor. There are no odors after hardening.

- The solidified mass is sensitive to high humidity. Water absorption of Macroflex 750 ml is 10%. That is, when it is in water for a long time, the material is saturated with water, which gradually penetrates into the cells and destroys them.

- Cured Macroflex foam is not toxic and harmful to humans. Extraneous discharge from its surface is absent.

Additional tips and tricks

The optimum temperature of the working mass inside the cylinder is 23 ° C. To achieve it, it is recommended to keep it at 22-25 ° C for about 12 hours before starting work. Use the product as follows:

- shake the balloon 20 times;

- remove the protective cover;

- attach the gun.

During these operations, keep the cylinder upside down. Carrying out the main work (applying glue), hold it upside down. The foam output speed can be adjusted in standard ways using the screw on the gun and the trigger. Shake the can regularly during work.

To prevent the foam from hardening, adhere to the following rules for using the gun:

- do not remove it while there is foam in the container;

- when the glue runs out, quickly disconnect the empty bottle, replacing it with a new one;

- after completion of work, clean the device with a special liquid (Premium Cleaner);

- Remove the hardened mass mechanically.

It is recommended to store glue cylinders for no more than 15 months, observing a storage temperature of 5-25 ° C. In this case, put them strictly vertically, the valve should look up. When transporting the product, wrap it in a cloth. Carry in the trunk. Observe safety precautions when working. Do not smoke, do not light a fire nearby.A supply of fresh air must be provided in the room. Protect the skin of the hands with gloves, eyes with goggles. Do not inhale vapors.

2> Specifications Macroflex 750 ml

We list the characteristics corresponding to the Macroflex 750 ml polyurethane foam:

- The use of Macroflex is limited to temperature conditions. It is recommended to use foam if the air temperature is at least +5 degrees. You can use a special compound for winter work, but it must be borne in mind that at low temperatures Macroflex hardens for a long time and fills a smaller volume.

- The maximum time for complete solidification of the applied composition is 24 hours. At temperatures above +20 degrees, the setting time can be reduced to 1.5 hours.

- Heat resistance of the foam - 55 +100 degrees.

- The density of the hardened composition is 25-35 kg / cubic meter.

- Combustion temperature Macroflex - 400 degrees.

- Fire resistance of cured polyurethane foam - B3 (according to DIN 4102).

- Foam yield - 20-50 liters, depending on the weight of the contents. It is calculated that, with equal characteristics, Macroflex products are capable of providing a foam yield by 10% more than similar products from other companies.

- Tensile and compressive strength - 3 N / cm².

- Shelf life in a cylinder is no more than 15 months. It is recommended to store foam only in an upright position in order to avoid loss of tightness of the cylinder. Storage temperature is not less than +5 degrees. Storage of cylinders in direct sunlight is prohibited.

Main characteristics of Macroflex 750

Polyurethane foam Macroflex is one-component in structure. It cures quickly and has excellent adhesion (adhesion, adhesion) to wood, metal and concrete surfaces. Macroflex has good heat and sound insulation, moisture resistance and durability.

Macroflex is used for the installation and repair of window openings, door frames, for sealing cavities, seams, joints and cracks. It is used in the construction of screens for sound insulation and thermal insulation, helps with the installation of building parts and seals the joints.

When squeezed out of the 750 ml can, in which the foam is stored and sold, the material expands, reaching 100% of its original volume and gradually hardens. This achieves the sealing of joints, cavities and cavities during the installation of door and window openings. Having doubled during hardening, the foam is capable of deforming structures if they are made of a soft material. Consider this nuance while working.

Another important characteristic of the foam is that this material does not tolerate solar radiation, therefore, it is necessary to protect the filled areas in order to avoid the destruction of the sealant.

The material is also suitable for harsh weather conditions

The material is also suitable for harsh weather conditions

Soudal

Special mention should be made of the Soudal super-frost-resistant foam. Which successfully promotes its product to the Russian market, since such a sealant is in demand in cold conditions. Unique characteristics of "Soudal", with the help of which construction and installation work, replacement of windows and doors at temperatures up to minus 25 ° C are performed.

This material is durable, tensile and compressive resistance. The adhesive properties of the foam to basic materials (stone, metal, concrete and wood), even at extremely low temperatures, comply with European requirements. This type of sealant is fire-resistant, and in terms of other characteristics, Soudal doubles the requirements for such materials existing today.

Technical characteristics of Macroflex 750 ml polyurethane foam

The main feature of Macroflex is its properties. They are determined by the characteristics that the manufacturer says on the package. In fact, the material is polyurethane, initially represented by a viscous mixture, which becomes foam at the exit, then hardens due to the influence of moisture.

When solidified, the substance has a certain smell, which then disappears.The finished solidified product has absolutely no aroma. If the air temperature is on average + 20 degrees, and the humidity is not higher than 30%, then the polyurethane will fully fulfill its function within fifteen minutes, after which there is no adhesion effect. However, it is important to maintain the required hardening time. It completely depends on humidity, for example, if it tends to 100%, then solidification will take place within an hour. The maximum full hardening occurs after 24 hours.

When solidified, the substance has a certain smell, which then disappears.The finished solidified product has absolutely no aroma. If the air temperature is on average + 20 degrees, and the humidity is not higher than 30%, then the polyurethane will fully fulfill its function within fifteen minutes, after which there is no adhesion effect. However, it is important to maintain the required hardening time. It completely depends on humidity, for example, if it tends to 100%, then solidification will take place within an hour. The maximum full hardening occurs after 24 hours.

In addition, the following technical parameters are characteristic of polyurethane foam:

- Expansion pressure: 1.5 MPa or less.

- The size can change its stability, but not more than 5%.

- Heat resistance of Macroflex on average varies from - 55 to 90 degrees.

- The ignition temperature of the material should reach 400 degrees.

- The recommended shelf life in liquid form is considered to be 15 months.

- The density of the material ranges from 25 to 35 kg / cubic meter.

As technical characteristics, manufacturers also declare the ability to adhere perfectly to any surfaces. However, this property only applies to unfrozen surfaces. In this case, the primary treatment can be carried out within an hour after applying "Macroflex" to the surface.

Regarding humidity, one can also make one remark that directly relates to the technical characteristics of the polyurethane foam. The approximate moisture absorption of the finished foam is 10%, respectively, if you leave this foam on a surface with higher moisture, there is a risk of destruction of its structure.