Why do you need a punched tape

Due to its many positive qualities, polycarbonate sheathing has found its application in various fields of activity, including agriculture. Cellular polycarbonate is a hollow plastic sheet with thin bridges inside.

Moisture trapped inside the hollow cells of honeycomb polymer plastic settles in the form of condensation, resulting in mold. The accumulation of dust and dirt leads to the loss of the original physical properties and qualities of the material. However, there is a solution to this problem - we are talking about punched tape.

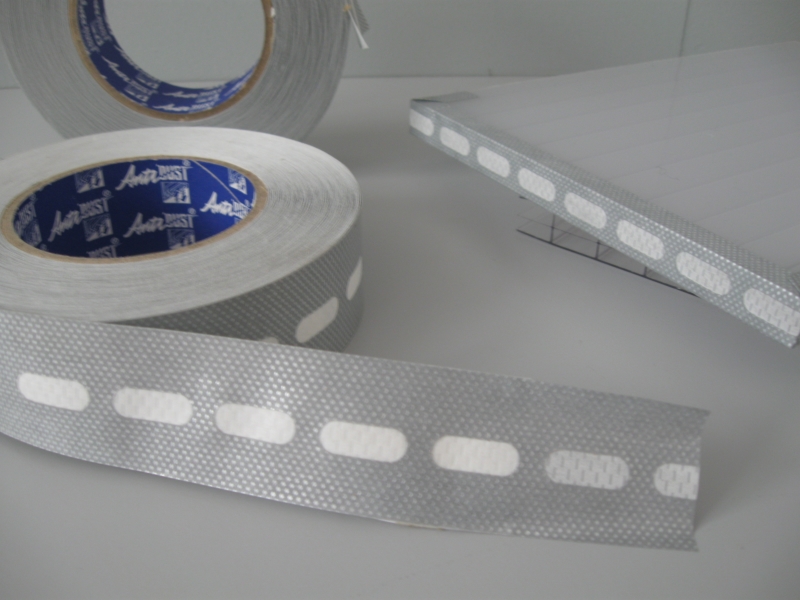

Punched tape helps protect polycarbonate from moisture

Perforated tape, often referred to as an adhesive-backed anti-dust or anti-condensation film, is made from an elastic polymer.

The advantages of punched tape include:

- strength, elasticity and high wear resistance;

- protection against the penetration of dust, small debris and insects;

- excellent moisture resistance;

- ensuring air circulation and, accordingly, eliminating condensate;

- the presence of an antibacterial protective coating;

- ease of installation and further maintenance;

- resistance to weather conditions and temperature changes.

Punched tape has a high coefficient of linear expansion. Thus, with insignificant deformation of panels and joint seams, the perforated tape can expand by 10-15%.

Where is punched tape used?

Perforated polycarbonate tape is used when assembling any suspended structures, for example, an air duct. Such perforated strips are used when installing a warm floor. They are used to attach a cable that heats the floor.

When constructing structures made of polycarbonate sheets, perforated strips are an auxiliary element with which they increase the strength of the fixing unit. Punched tape is successfully used in the installation of truss systems. It is effectively used for vertical glazing. The tape is attached to the surface of the sheet and is closed from above with a profile.

When building any semblance of an arch, you need to close the polycarbonate sheets from both ends with punched tape.

Dignity

Punched tape has the following advantages:

- It can be operated in conditions of high air humidity.

- She has high strength.

- It is distinguished by its resistance to corrosion.

- It is characterized by precision and ease of assembly.

- This tape has a high tensile strength.

- Its service life is quite long.

- The tape is used very widely.

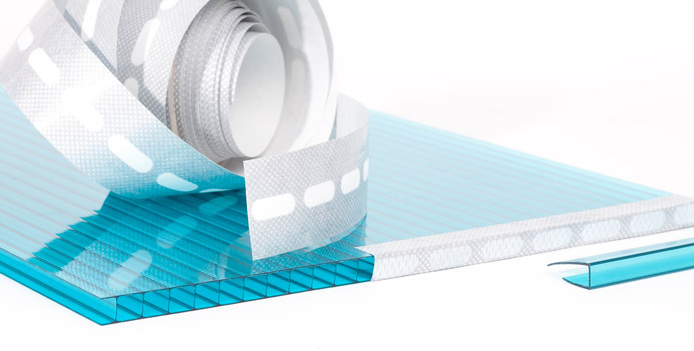

Punched tape for cellular polycarbonate has a microfilter and is called anti-dust. It is designed to protect longitudinal honeycombs from moisture and dust. It is an affordable and practical tape that adheres easily and can withstand a very wide temperature range. With its help, the necessary microclimate is created inside the honeycomb. It also prevents friction when mounting the profile along the edge.

A perforated tape is produced from very thin low-carbon steel, which is galvanized, which allows the tape to not lose its properties in high humidity conditions.

The tape can easily withstand such difficulties during operation as high or, conversely, low temperatures, ultraviolet radiation, high humidity, mold, and so on. She has served for quite a long time, more than a dozen years.

The perforated tape that protects the bottom edge of the polycarbonate sheet has air filter pores forty microns in size. They do not let dust and various insects inside the honeycomb. At the same time, the condensate formed inside is released through them.

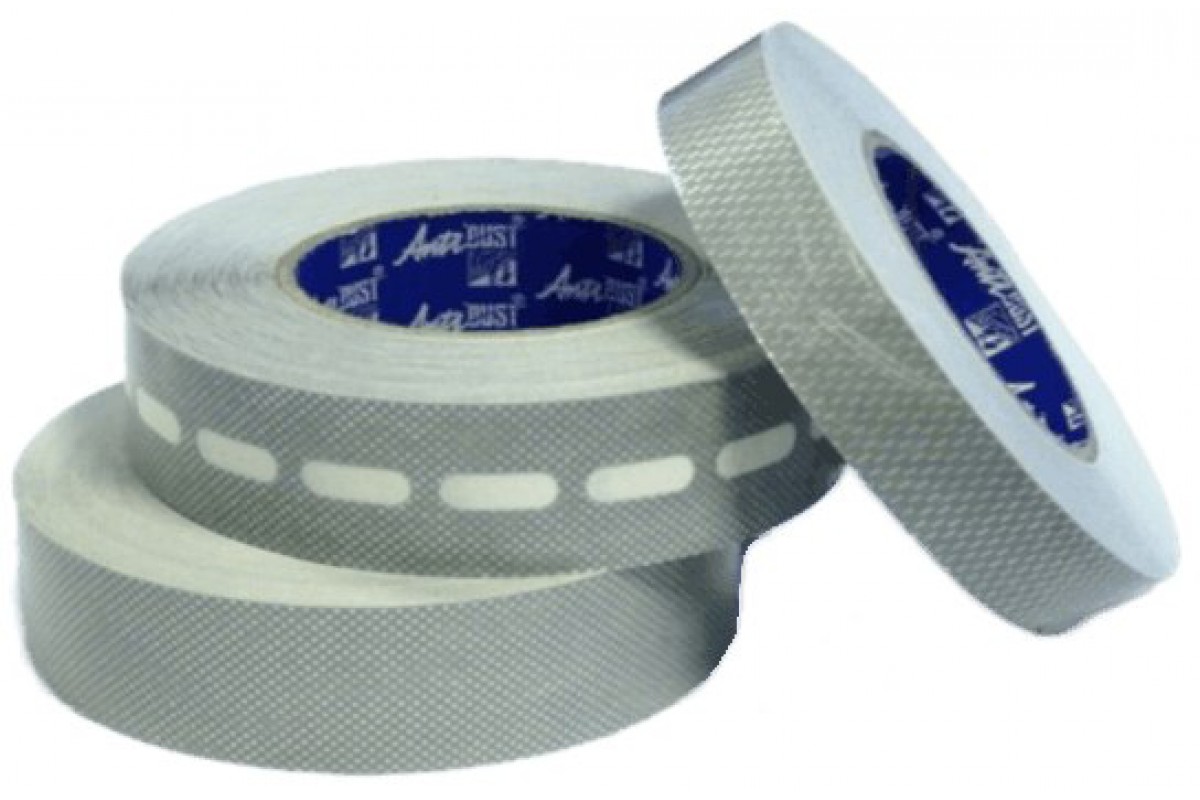

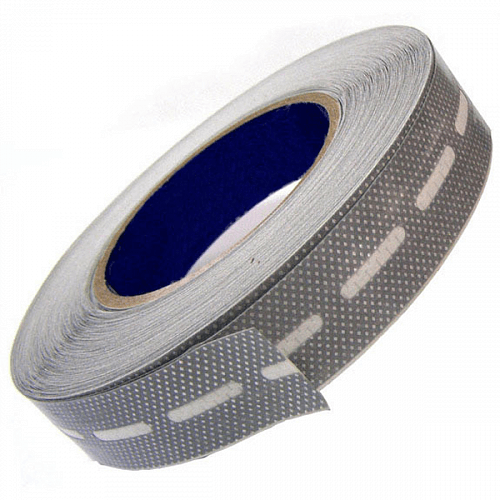

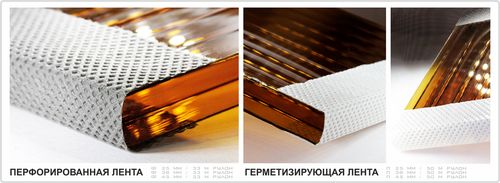

Externally, the tape looks like a self-adhesive base with silver perforation. The adhesive layer has a high adhesive strength. At the same time, it is balanced so that, if necessary, the tape can be re-glued. The adhesive force of the adhesive is able to counteract the shear generated by the different coefficients of thermal expansion of the profile and sheet.

To protect the tape from harmful factors, it is closed from above with an end profile, polycarbonate or aluminum. It is selected so that the color of it and the ribbon matches. Small holes are made in it through which condensate is removed from the honeycomb. For this, a gap of two millimeters is left between the polycarbonate sheet and the end profile.

You cannot cover up any end of the sheet with ordinary tape. Because of this, moisture can accumulate in the honeycomb, which can lead to deterioration of the polymer panels.

Sizes of the produced punched tape

The width of the perforated tape depends on the thickness of the polycarbonate with which it is planned to be used.

- sheets up to six millimeters thick are covered with punched tape, twelve millimeters wide;

- for polymer sheets with a thickness of eight to ten millimeters, a twenty-five millimeter tape is used;

- polycarbonate panels, having a thickness of sixteen to twenty-five millimeters, are covered with a tape, the width of which is thirty-eight millimeters;

- finally, for panels thirty-two to forty millimeters thick, use a tape fifty millimeters wide.

Usually, perforated polycarbonate tape, the price of which per running meter is much higher than hermetic tapes, is produced in rolls with a length of thirty-three meters. The sealing tape is produced in rolls of fifty meters.

The cost of a roll of hermetic tape twenty-five millimeters wide is four hundred and eighty rubles, thirty-eight millimeters wide - six hundred and sixty rubles. A roll of perforated tape of the same width costs nine hundred and sixty and one thousand and eighty rubles, respectively.

Rubric: About the material.

How to choose?

The choice of tape for polycarbonate should be approached as carefully and responsibly as possible. At the same time, experts advise taking into account several key parameters.

- Appointment. Initially, you need to figure out what purpose you will use the tape for. What type and size of material you choose depends on this decision. Accordingly, you must make this choice even before purchasing the material.

- Manufacturer. Preference should be given only to those products that are produced by manufacturers who enjoy the confidence of consumers. This is due to the fact that only such a tape will meet all the necessary requirements, and its production will comply with generally accepted (state and international) standards.

- Place of purchase. You should buy polycarbonate tape only in specialized hardware stores, where you can get qualified advice from sellers and managers.

- Reviews. Before purchasing a feed, you need to carefully study user reviews and comments. In this case, you will be sure that the quality declared by the manufacturer will fully correspond to the real state of affairs. Given these characteristics, you can purchase a tape that will 100% meet your needs and perform well its functions.

How to use?

Of particular importance is not only the choice of a suitable type of polycarbonate tape (in terms of variety and size), but also the correct use of the material.Experienced builders recommend adhering to simple instructions in the process of using the material and compulsorily following the recommendations of specialists.

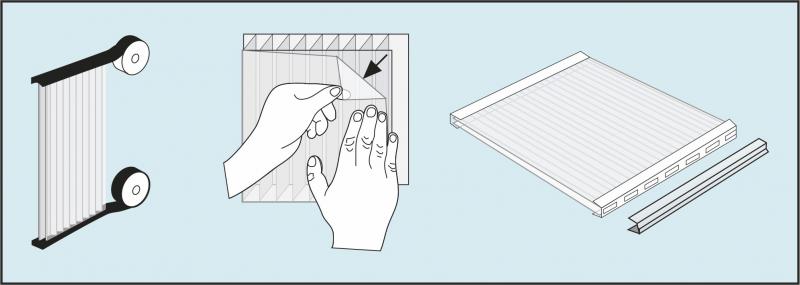

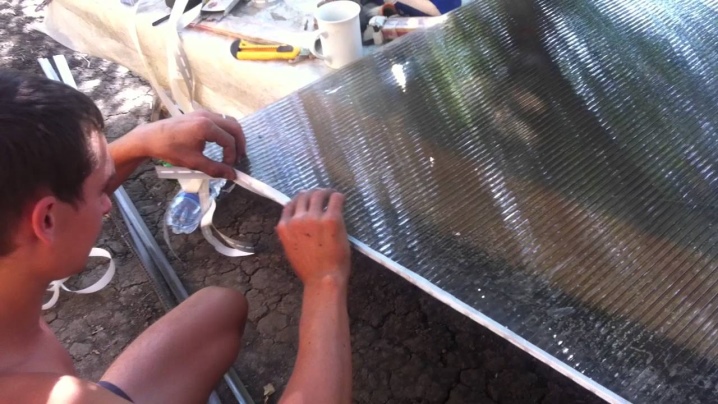

First of all, it is necessary to prepare polycarbonate panels. They need to be cut to size (which is relevant in a particular case), then holes are made specifically for thermal washers. After that, it is necessary to start the honeycomb blowing process. Only after the completion of these processes, you can proceed to the direct gluing of the tape.

Before gluing the tape, you need to carefully process the polycarbonate

It is important to remove any existing bumps, scratches and any other defects. This will allow the tape to be glued to the surface as accurately as possible, respectively, the tape will effectively perform its tasks.

In those areas where the tape will be glued in the future, you need to remove the protective film from the polycarbonate.

At this stage, you can proceed to the direct application of the tape to the ends of the polycarbonate

It is important to pay attention to the fact that the edges of the tape are neatly and evenly distributed over the polycarbonate. To ensure this effect, it is necessary to stretch it during the application of the tape (however, this must be done in such a way as not to break the material). In addition, in the process of gluing the tape, you need to pay attention to the fact that folds do not appear on the surface of the material.

In addition, in the process of gluing the tape, attention must be paid to ensure that no folds appear on the surface of the material.

After you have attached the tape, press down the edges using a soft felt cloth. In this case, one should not exert excessive pressure on the material, so as not to spoil or destroy it. After completing the above steps, the end profiles should be installed over the material. At the same time, remember to keep a small gap (2-3mm). Such a gap is a drainage one, since it is used to drain condensate.

Thus, we can conclude that the tape for polycarbonate, despite the fact that it is an auxiliary building element, plays a very important role. Its use will significantly increase the strength and reliability of the structure. In this case, it is worthwhile to carefully approach the choice of material and take into account all its characteristics, so as not to regret the purchase made in the future.

For information on how to seal the ends of polycarbonate with different types of tapes, see the next video.

Views

Polycarbonate tapes are available in several types. The first is perforated. The name itself indicates the structure of the material. Such tapes have the smallest pores with a special filter that does not allow moisture to penetrate, while providing sufficient ventilation for the tunnels of cellular polycarbonate. In addition, such tapes do not interfere with the removal of condensate.

The second type of sealing tape is a solid material that works well for open edges. For example, roof edging. Non-perforated sealing tapes do not allow anything at all inside. But they also do not allow condensate to escape. In sunny weather inside the leaf, this can cause a "greenhouse effect" that will encourage mold growth. Therefore, it is ideal to use both types of sealing tapes. For example, for edges that are at a junction with each other, it is better to use perforated adhesive tape, which will provide sufficient ventilation for the tunnels, and a continuous sealing tape around the edges.

Adhesive recommendations

- The sharp edges of the sheet must be removed.

- The ends of the sheet are cleaned, the protective film and a possible layer of glue remaining after it are removed. If this is done with soapy water, the sheets should be dry afterwards.

- The sealing tape is applied without unnecessary effort and stretching so that it is centered on the end face and is released from the backing. For this, of course, a size similar to the sheet thickness is chosen.

- The tape takes root tightly, after which it is smoothed with rubbing movements.

As a result, a smooth, beautiful joint is obtained, with positive qualities for the further operation of the sheet. In the photo and live, the design with such decorated edges of the sheets looks complete and beautiful. Therefore, even for the aesthetic component, tapes will be needed. For monolithic polycarbonate, such tapes are not used, because its one-piece structure excludes the ingress of any particles into the material. The tape is needed exclusively for the honeycomb type of sheets.

Ribbon material

Good adhesive tapes to improve the quality of polycarbonate are made from special polymeric materials with a good level of elasticity. For the manufacture of their sticky base, special acrylic glue is used (providing high adhesion), and the thickness is sufficient to ensure a good impermeable seam.

The qualities of polymer adhesive tapes:

- Thermal stability - usually the operating temperature range ranges from -30 to 80 degrees Celsius, which allows the material to retain its shape even in "aggressive" weather.

- High degree of strength (elongation in the region of 10-13%, good tensile strength).

- A similar coefficient of linear expansion with the polycarbonate sheets themselves.

Sealing instructions

Now let's move on to step-by-step instructions for using perforated tape to cover a greenhouse with cellular polycarbonate:

- Remove the protective film from the cellular polycarbonate, which is necessary during the transportation and storage of the material.

- Work the end of the plastic with a sharp construction knife. Remove bumps and burrs. The line should be as flat and smooth as possible.

- Clean the polycarbonate from dust, small debris and glue residues from the protective film. If moisture gets inside, dry the cells with a construction or ordinary household vacuum cleaner.

- Degrease the end and surface of the blade.

- Lay the sheet on the work surface, fix it. Measure the length and thickness of the polycarbonate sheet with a construction tape.

- Select the appropriate perforated tape size. Cut off the tape with a sharpened knife. Remove the protective strip.

- Place one edge of the punched tape against the end of the polycarbonate. Thoroughly flatten and smooth the sealing strip, removing air and unevenness.

- Align the base of the perforated tape with the end of the polycarbonate. Glue the second edge. Remove excess air.

- Carefully work the edges of the sealing strip with a stitching roller.

For better fixation of punched tape on sheets of cellular polycarbonate, a rolling roller is used