Production technology

Fibreboards are made from wood. To be more precise, not from solid wood, but from waste remaining when processing wood at sawmills and other wood processing industries. Additionally, the structure of the material can include used paper and its waste, other products containing cellulose. After crushing the components, the material is compressed into slabs and dried. To make the board resistant to moisture, various suspensions and precipitants are added to the fibrous semi-finished product.

The fiberboard manufacturing process is divided into several stages:

- shredded wood waste is washed, after which garbage and sand are removed from them by means of absorption plants;

- then, on disc centrifuges using electromagnets, metal elements are removed from the structure of the mixture;

- then the chips are sent for grinding, which can be both large and small, based on the conditions of use of laminated fiberboard;

- in the defibrator, kneading is carried out with the addition of resins, polymers and paraffins.

Upon completion of these activities, the creation of laminated fibreboard can be carried out dry or wet. In more modern industries, the dry method is practiced, only it is less environmentally friendly than the wet one. This is associated with an increased formaldehyde content in the binder mixture.

The lamination procedure has a number of features.

- After surface preparation work, the slabs are sent to a hot pressing machine, in which heated mineral oil is constantly circulated to maintain the temperature regime.

- Attached to the press is a form with a textured pattern that determines the type of future embossed print (wood pores, skin roughness, brick texture, etc.).

- Fiberboard sheets are covered with a specialized melamine film with a low degree of hardening, after which a hot press imprints it on the surface of the fiberboard.

- Under the influence of pressure and high temperature, fragmented melting of melamine-based resins is carried out, which diffuse into the surface of the material, sticking to it without the use of any adhesive

- ... If necessary, fiberboard can be laminated on both sides.

This impregnation method guarantees moisture resistance of the material, a very attractive exterior and excellent functional and performance characteristics.

Fiberboard production

The increase in the cost of resources and concern for the ecological state of the environment forces many manufacturers to invent new building materials and introduce technologies that can significantly save raw materials without much damage to the quality of the final product. A striking indicator of such changes is the sphere of furniture production, where various synthetic materials have replaced natural solid wood.

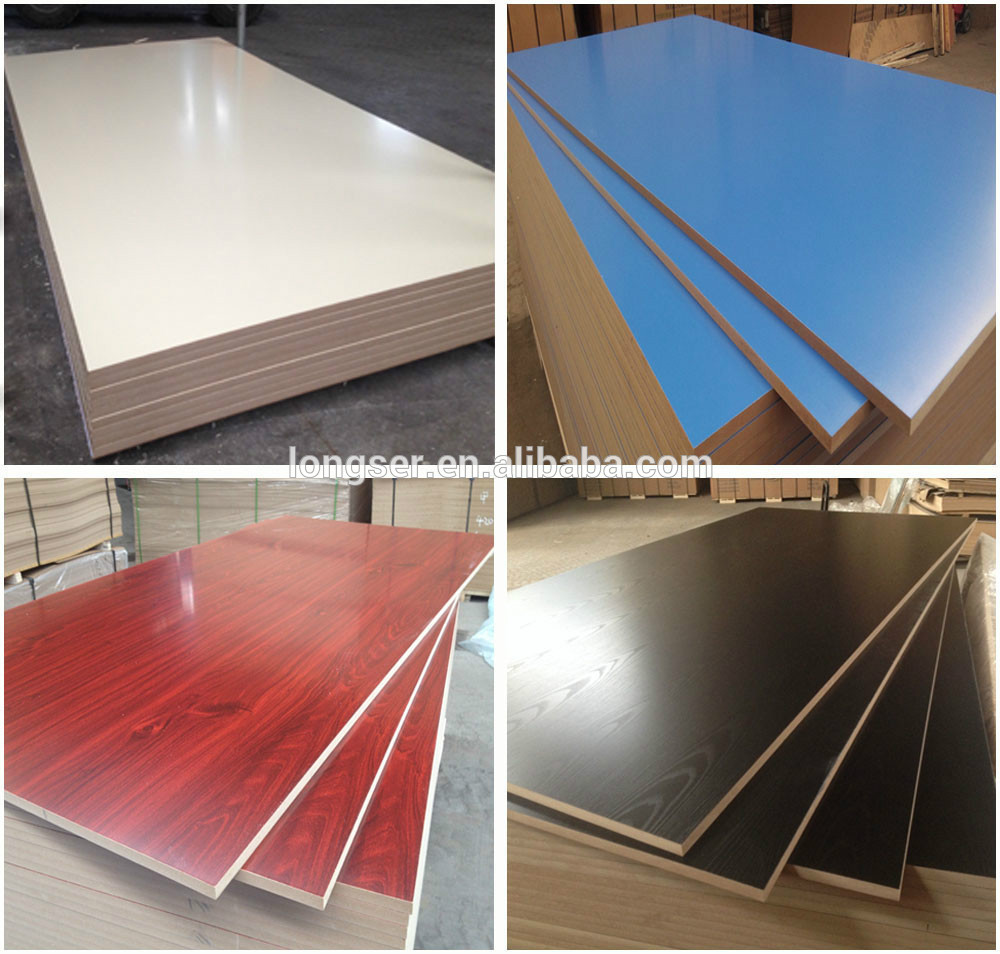

Fiberboard sheets are widely used in furniture production

The first imported furniture, which was imported into our country in the second half of the twentieth century, with its aesthetic and durable design, showed that wood processing waste can be used for manufacturing. Further development of fiberboard production technology made it possible to bring the appearance of the material closer to natural wood, ennobling the slabs with a special film, similar in texture to wood. The production of laminated fiberboard has grown exponentially.Today this material can be purchased at a very affordable price. Sizes of a sheet of laminated fiberboard are different and will satisfy any, even the most non-standard, consumer request.

Where can you buy quality building material?

Today, there are a huge number of retail outlets in the country where you can purchase building materials for any request. Each store tries to expand its assortment, according to the requirements of the consumer and the emergence of new products on the market.

It is more profitable to buy fiberboard panels in bulk than by the piece

Repair and construction work is a very responsible and painstaking undertaking. It is necessary to approach the choice of the necessary materials with all responsibility and care. Having studied in detail the pricing policy of construction stores, you can choose the most acceptable option for yourself.

One of such large hypermarkets is the Epicenter store, which offers a wide range of goods covering all spheres of human life. The products are categorized and clearly displayed in sales areas. Additionally, you can order goods that are missing at this time.

In the Epicenter network, the price for a fiberboard sheet is optimal, and the availability of positions from different manufacturers makes it possible to choose the desired product in one place, which will save time.

The price of fiberboard is influenced by the size and thickness of the sheet.

The modern range of fibreboard is very diverse. Everyone can choose a worthy option for themselves, based on their scope of fiberboard application and their own financial capacity. If you correctly approach the choice of this building material, having previously studied the pricing policy for your region, you can get a good product for a very reasonable fee.

But do not forget that the better the raw materials, additional components and the more reliable the level of pressing, the better the quality of the final product and, accordingly, the higher its cost.