The nuances of the selection of paint in spray cans

The first step is to know what type of plastic your parts are made of, since the further choice of the properties of the dye and the technology of its application depends on the material itself.

- ABS (Acrylonitrile Butadiene Styrene) - from it are made, cases of household and computer equipment, mobile phones and much more.

- PVC (Polyvinylchloride) - window constructions, floor coverings, children's toys and goods, some types of household containers.

These two types of plastics differ in that when they are painted, a prerequisite is the application of a primer. Its presence gives high-quality adhesion of paint to the surface, which excludes subsequent peeling and cracks. If you don't know what kind of plastic you are holding, there is a simple method to check.

Fill a container with water that will fit your plastic part (excluding large items). Dip the item into the water. If the plastic sinks, then no primer is required. You can apply paint directly to the surface. If your part remains welded, you will need to purchase a primer spray. Without it, the paint will not last long.

The best paints for rust and metal TOP 5

Consider paints that are used to paint a variety of metal surfaces.

Epoxy enamel

This type of paint for various metal surfaces contains silicone resins. This coating is used to preserve industrial pipelines. The main purpose of epoxy enamels is to protect metal structures from high temperatures. Due to the toxicity of the components that make up it, enamel is rarely used for domestic purposes. Also, this type of paint does not guarantee long-term protection against corrosive processes.

Oil paint

It contains natural oils, and linseed oil is used as a binder. Due to its low resistance to temperature extremes, the paint is intended for interior repair and finishing work - for example, for painting pipes that are located indoors. Oil paints do not provide the necessary anti-corrosion protection and this is the reason for the limitation on their use as a material for external repair and finishing works. Also, such paint is characterized by a rapid loss of color brightness and cracking; it does not withstand temperatures above 80 ° C.

Alkyd paint

The main area of application for alkyd paints is the treatment of galvanized metal surfaces. Among all paints for metal, alkyd paint has the best adhesion to the work surface. However, it is not able to withstand high temperatures and it is not recommended to use it for metal structures that are very hot, because the paint ignites easily.

Hammer paint

This paint creates a rough, specific hammer-like finish with a metallic sheen. This effect is achieved due to the components contained in the paint - alkyds, aluminum powder, acrylic, epoxies. Semi-matt and glossy tones can also form. The first layer of paint acts as a primer, the next layer is anticorrosive, and the third one acts as an enamel. However, the paint is not suitable for metal objects heated above 150 ° C.

Acrylic paint

This type of paint and varnish material has recently appeared on the market, but has already gained popularity among buyers. And this is due to a complex of functional characteristics. Acrylic paints provide the best long-term corrosion protection. They are suitable for interior and exterior decoration and renovation work, becausedo not fade or crack. The paint is immune to high temperature indicators - it can withstand more than 120 ° C. And this makes it possible to use acrylic paint for painting heating elements and highly heated objects. The paint is water-soluble and therefore non-toxic and non-flammable.

Coating options

Chrome paint is made with different effects. Reflective compositions (white specular luster) resemble polished stainless steel, molten silver. Pigment dyes are not added to such a mixture, the base becomes transparent.

Reflective compositions (white specular luster) resemble polished stainless steel, molten silver.

Yellowish, yellow-orange metallic shades are created through the use of ground copper alloys: brass, bronze. The effect is visible only after the base has dried. Coloring pigments are introduced into high-temperature coatings, achieving the required shade.

Yellowish, yellow-orange metallic shades are created through the use of ground copper alloys: brass, bronze.

The matt paint creates a brushed metal effect that does not show minor scratches.

Classic version of painting with chrome

Mirror compositions are created for the restoration of chrome parts, they return them to their former shine and attractiveness. Spray cans are used to decorate photo frames, exotic bottles. Aerosols are produced with pigment dyes.

Powder can paint is used in auto repair shops to create a silver tint with a mirror finish. On a resinous or acrylic basis, finely dispersed aluminum powder is diluted, which, after the paint layer dries, refracts and reflects light rays.

Mirror compositions are created for the restoration of chrome parts, they return them to their former shine and attractiveness.

Black chrome

There is a nitro paint in cans and cans, designed to paint objects black. This is an alternative to Kuzbasslak. The two-pack black chrome can paint produces a wear-resistant film. Nitro paint in spray cans has to be refurbished more often.

Aerosol black chrome dries the fastest.

Colored chrome plating

The introduction of a certain amount of pigment into the lacquer base does not affect the quality of the formed film, the gloss, the metallic effect is preserved. Manufacturers produce annual colored paints and varnishes and transparent, amenable to tinting. You can achieve the desired shade in car body repairs.

Pigments in liquid chromium should be translucent, refracting the light flux, and not absorbing light of a certain wavelength. There are dyes with a scattering effect, they are added to matte chrome used for household items, making souvenirs.

You can achieve the desired shade in car body repairs.

How to paint the plastic of the car interior

- Sand it.

- Degrease.

- Find out whether it needs to be primed or not.

- Restore texture if needed.

- Paint in the desired color.

Than sanding

For matting salon plastic under the ground, red tape-bright is usually sufficient. It is a felt-backed abrasive material, similar to the hard side of a dishwashing sponge. The advantage over fine-grained sandpaper is its softness, which allows this tool to efficiently process various bends and depressions.

How to degrease

Painters with experience are advised to use only anti-silicone. The fact is that classic solvents in the form of white spirit or solvent can ruin the plastic unit. For example, after using organic matter, stains are formed that are difficult to hide even by painting. By the way, we have already recommended giving up white spirit when performing a technology describing how to remove tar from a car body without damaging the paint.

Do you need a primer for plastic or not

The reason for the crumpling and peeling of fresh paint is that no primer has been previously applied.This is a composition with a special formula of various additives and plasticizers, which improves the adhesion of paint to the surface. However, not all plastics need to be primed. To establish whether to prime the salon plastic or not, it is necessary to carry out two experiments:

- Set fire to a piece of the workpiece.

- Submerge the part in water.

If the plastic smokes and sinks, it is not necessary to use a primer over the plastic. When the plastic element burns like a wax candle and floats on water, you cannot do without a primer.

It is important to correctly approach the choice of soil. So ordinary car compositions are not suitable - the paint peels off in an instant

We need a special primer designed specifically for plastic.

When structural paint is needed

If you've ever fingered a black plastic bumper or dark side mirror in an inexpensive car, you probably felt that the touchable surface was covered with small bumps. The matte rough effect is a structural plastic. The paint under study reproduces the same result and is commonly used to mask scuffs and light scratches.

What's with the paint itself

First, decide what kind of coverage you want. Here are some examples:

- Soft-Touch. Usually used for dashboards. The surface is slightly silky and rubberized. This coating is applied to the panel from the factory.

- Normal, rough. Applied to hard plastic. For example, the side parts of the center console, the lower trims for the door cards or the handles for closing the doors.

- Glossy. Used to trim the interior levers for opening the door.

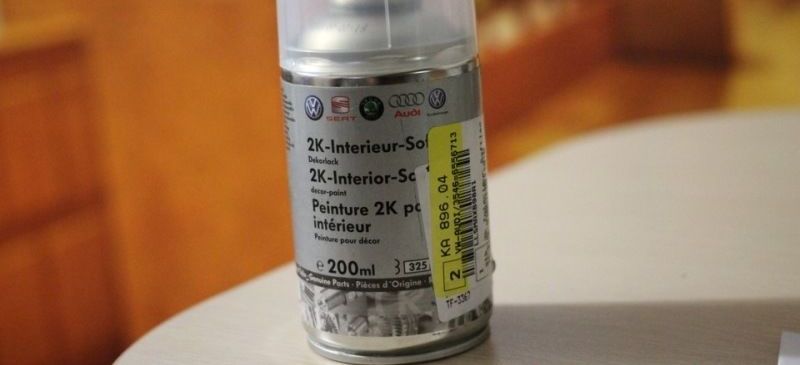

Then find out for yourself which shade to give preference to. If painting the interior is planned exclusively in a restoration style, then take the trouble to find a corporate catalog with the distribution of the colors of the insides and exteriors by VIN numbers. The original paint, selected from the factory catalog (for example, for VW it is ETKA), will preserve the monotony of the overall picture of the interior. This will be due to the fact that there will be no noticeable difference between the painted and unpainted parts.

If we carry on the conversation in the plane of the above examples, then it is precisely the Soft-Touch aerosol can to be purchased through the official line. To get a regular rough layer, it is enough to use a classic paint paired with a structured one. Here are examples for common shades:

- Black. VAZ Black Space (code 665) will do.

- Gray. The VAZ decorant (graphite), intended for bumpers, fits perfectly.

However, the color and origin of paint are purely individual things and are selected exclusively according to their own preferences. Continuing the conversation about rough coatings, it is appropriate to mention the well-known RAPTOR U-POL, a protective coating for the exterior of a car, and its similarity - HB BODY.

Glossy objects are regular paint with multiple coats of varnish. The latter is recommended to be purchased in aerosol cans. There are no strict requirements for this component.

We recommend painting the plastic parts of the car interior only with a spray can. When applying the enamel with a brush, there is a risk of sagging. In addition, such a layer dries much longer, which means that the probability of catching dust particles is much higher.

Types of colorful aerosols and tips for choosing

The range of aerosol paints is very wide: from universal to specialized, as well as creating special decorative effects.

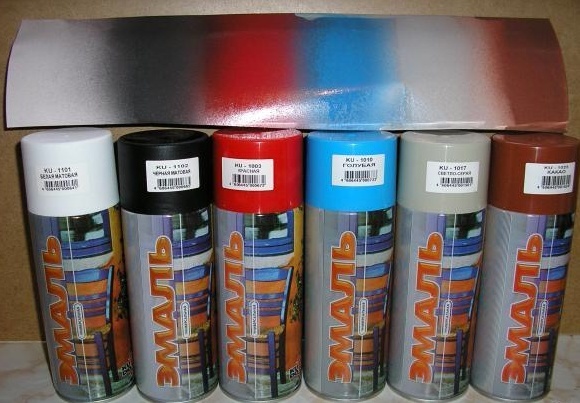

Universal

Among the most popular are universal alkyd-based decorative enamels and acrylic enamels. They are suitable for both outdoor and indoor use. The finished coating protects the painted surfaces from weathering for a long time, and, in addition, has a high resistance to impact, bending and other mechanical influences. The manufacturer tints the enamels (matte, glossy, with a metallic effect) in accordance with the European RAL color standard. They are applied to a previously prepared and primed base.

ShutterStock

If you spray water in the room before painting, dust particles and other airborne debris will not settle and remain on the painted surface. To avoid clogging of the spray head, after operation, the cylinder is turned upside down and the composition is sprayed until a clean propellant gas starts to come out.

"Spectrum"

When choosing a heat-resistant spray paint, pay attention to the operating temperature range of the coating and the anti-corrosion properties of the composition, which are especially important for metal products operated in high humidity conditions.

Vixen

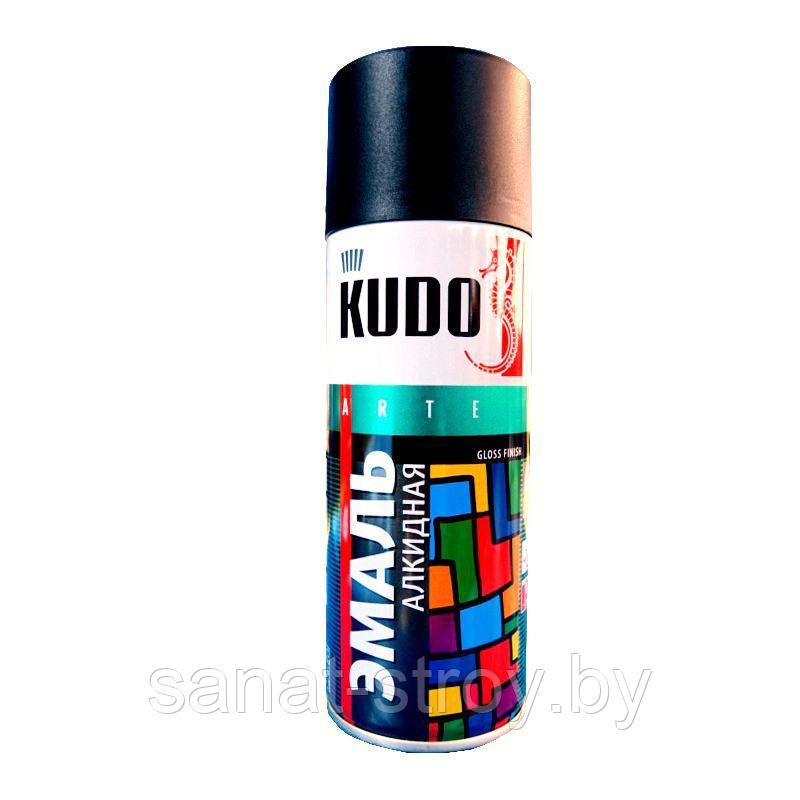

Kudo

Heat resistant

Heat-resistant aerosol compositions are intended for painting heating metal surfaces: elements of exhaust systems of cars, pipelines and steam lines, various parts of water-heating and boiler equipment, fireplaces and stoves, barbecues. The thermal resistance of the protective and decorative film starts from 80 ° С, as in Alkyd enamel for radiators (Kudo), and reaches extreme 1000 ° С, as in matte Certa enamel (Spectrum) for barbecues, stoves, fireplaces and metal structures.

With an unusual effect

Among aerosols with unusual effects, we note luminous ones: phosphorescent and fluorescent. The former absorb the light energy of ultraviolet rays, incandescent lamps and then slowly release it, which is manifested by a glow in the dark. Moreover, it resumes an unlimited number of times after repeated exposure to the light source. Such paints are useful for decorating Christmas tree decorations, toys, clocks, etc. Fluorescent aerosols are highly reflective. When exposed to sunlight or ultraviolet rays, their brightness increases many times. And this is often used by designers when decorating interiors and exteriors.

ShutterStock

The glow brightness of the phosphorescent paint will be maximized if it is applied on a white ground.

Bosny

Reflective paints are used to obtain signal effects on steps, enclosing elements, for original decor.

Vixe

Kudo

Decorix

Spray paints with craquelure effect will give a touch of noble antiquity to furniture items, architectural decor. It is obtained by successively applying two coats. The base is applied first, which will subsequently show through the cracks, and after it dries, the finishing one. A network of small cracks appears on its uniformly thin layer. To form larger craquelures, without waiting for the first finishing layer to dry, apply a few more (one or three).

Enamel KUDO fluorescent

Among the unusual decorative effects that aerosol paints can create, there are many others. This is, for example, an imitation of an aged metal surface, with natural oxides, as well as the chameleon effect, when the coating changes color depending on the angle of incidence of light (it is especially pronounced on objects with smooth bends), or the effect of frost, which is very useful on New Year's Eve. of the year.

"Spectrum"

Think in advance how to turn the object during staining, in what places to intercept it.

"Spectrum"

Lightweight items, including picture frames, can be hung for easy handling.

"Spectrum"

A dramatic sense of mystery will help create the Cobweb effect (Condor Foto). Thanks to him, any objects and surfaces will be covered with thin dusty threads. They look so realistic that they cannot be distinguished from the real web. For a more cheerful, festive picture, the Snow Spray (Kaemingk) artificial snow comes in handy. It lays down voluminously, like a real snow cover, and looks spectacular on spruce branches, in decorative compositions.

Condor Foto

A "good" web is obtained if, pressing the spray, vigorously shake the Cobweb effect balloon (Condor Foto).

Condor Foto

The creamy texture of Snow Spray (Kaemingk) becomes crumbly over time.

Kaemingk

Stages of work

When enamel is sprayed from a cylinder, a suspension of tiny paint particles is formed in the air, which can get on the skin and into the respiratory tract

Therefore, it is important to put on glasses, work gloves and a respirator (if possible) before starting work.

Surface preparation process

Before proceeding directly to staining, the plastic must be prepared in a certain way.

- First, the product must be cleaned with a stiff brush and detergent, then rinsed with water and allowed to dry completely.

- After that, the product is sanded with a "sandpaper", smoothing out all the irregularities. If the defects are too deep, you can use a special plastic primer and level the surface.

- Then the plastic must be treated with a degreaser, and then you can proceed with the primer, if it is necessary for this type of material.

- If there are doubts about the type of material, then it is better to put a primer in any case. It will not be superfluous, but it will provide a more reliable adhesion of the paint and the surface of the plastic.

For information on how to properly prepare plastic for painting, see the next video.

Painting

Spray painting takes place in several stages:

- First, it is necessary to cover all areas not intended for painting with cardboard, film or an unnecessary piece of cloth. Very small areas can be sealed with tape (use masking tape, as ordinary tape can damage the old coating when it is removed). If the product is small, it is advisable to lay it horizontally on some surface over which paint will be sprayed.

- Shake the can of paint for 30-40 seconds to mix the dye evenly.

- Remove the spray cap from the top of the can. Apply paint to the plastic with constant smooth movements, without holding your hand in one place to avoid drips.

- The hand with the spray must be kept at a distance of at least, but not more than 20-30 cm from the surface to be painted.

- After applying the first layer, let the paint dry for 30-40 minutes. Then you can apply a second layer and let it dry as well. If necessary, it is permissible to apply additional layers according to the same algorithm.

- Despite the fact that the paint itself dries quickly enough, it is not recommended to use the painted product for one day. During this time, the dyes are finally polymerized, so the surface will be reliably protected from various damages.

Getting a mirror finish

To achieve the effect of polished metal of silver or gold color, the plastic is covered with a special paint, and the process itself is called chrome plating.

The price for this service is quite high, so working independently with such a dye is a great opportunity to save money.

In general, the process of working with chrome paint is carried out in the same way as with any mixture for plastic in a cylinder, only a spray is applied to the surface already pre-painted with black paint. Without preparatory staining in black, creating a mirror effect at home simply will not work.

There are several more subtleties of staining for chrome:

- It is better not to pursue cheapness and purchase proven formulations from foreign manufacturers.

- It is more difficult to apply such an aerosol than regular paint, so it is worth pre-practicing on various surfaces and areas.

- If the product will be varnished, it is necessary to first check the compatibility of the purchased paint and varnish. Some types of varnish mixtures can destroy even a correctly applied chromium layer.

It is necessary to be prepared for the fact that paint from a balloon and chrome plating with your own hands does not always give the effect of salon coloring, but the prospects for development in this direction are quite high.

Subtleties of wood processing

Due to its characteristics, wood requires special processing. The safety of the material during operation depends on a number of factors, including:

- precipitation;

- temperature drops;

- exposure to sunlight, etc.

Without proper treatment from such aggressive effects, wood can deteriorate: crack, dry out or rot. To provide a reliable hydrophobic coating on lumber products, oil or alkyd enamel paints are usually used.

Recently, there has been a trend towards painting wood with aerosol paints. This is due to the fact that when working with spray paints you will not have to face application problems inherent in conventional formulations:

- the difficulty of applying a layer of the same thickness on the entire surface of the product;

- smudges;

- long drying time;

- the need for special painting tools (rollers, brushes, etc.)

In addition, when choosing paint in spray cans, there is no need to select a special composition for wood, since most aerosols are suitable for processing wood materials.

Dyeing plastic at home

It is possible to cope with painting of plastic materials on your own, this will largely save the budget. Turning to professionals is a very expensive business. To carry out the work at home yourself, you will need to take care of your own safety by preparing protective equipment, also prepare all the necessary tools (listed above), and perform all stages of the work. They will be discussed in detail later.

It is possible to cope with painting of plastic materials on your own, this will largely save the budget.

Painting methods

The paint coat is available either in cans or in aerosols. Which option to choose depends on the size of the product and the experience of the person who will carry out the painting work.

-

Spray cans are more appropriate for a small object to be painted, it is not difficult to work with them, but before starting, you should try it by sprinkling a little paint on an unnecessary surface, this will help you understand how best to spray in order to get the desired result. In general, the aerosol method will give a good even coverage. This method does not allow mixing tones, and thus it will not work to apply clear color boundaries.

-

A can of a larger volume than a can, but storage in it is possible only for a short time. For this reason, it is more often used for a large amount of work. It should also be taken into account that working with a brush is much more difficult and requires skill. Otherwise, an ugly trace of bristles may remain on the product, and stains, the coating will be uneven and aesthetically unkempt.

The use of a spray gun can facilitate the process; a roller is rarely used. For a beginner, the spray method will be more suitable.

Preparing plastics for painting

As mentioned earlier, you should carefully prepare the product before starting work in order to get an excellent result. This stage includes the following steps:

- Get rid of the previous cladding, you can use sandpaper, solvent, construction hairdryer.

- Get rid of contamination.

- The product must be degreased using a solvent.

- Treat the product with an antistatic agent.

- If required, apply a putty.

- To ensure good adhesion, the surface is treated with no more than 180 sandpaper, after the completion of this stage, the object is again cleaned and dried.

- Degreasing is carried out again.

- Carry out priming work, if required.

- Rub and clean again.

The product must be degreased using a solvent.

Plastic dyeing technology

Having chosen the type of coloring agent, it is worthwhile to understand the method of work. The article will discuss two technologies: painting with a brush, and application with an aerosol.

They work with a brush, making wide straight strokes, initially move the brush gently, then press harder, so the coating will become thinner, and the finishing stroke is also done softly to align. If everything is done correctly, then a one-time work with a brush is enough.

General recommendations:

- The brush should not be dipped whole, the tip is enough;

- You should strive to make the layer as thin as possible by pressing on the bristles;

- Maintain a slope in the working position of the hand.

They work with a brush, making wide straight strokes, initially move the brush gently, then press harder.

Spray operation process:

- They put the product on a flat surface, for example, on a chair, mark the part to be painted with paper tape, close the lying objects (with film, newspaper, paper);

- You must first shake the aerosol;

- There should be 20-30 centimeters to the subject;

- Spray paint smoothly in one layer, keeping the balloon straight;

- For complete coloring, it is worth making two or three layers;

- Wait for the time indicated on the package between the application of layers until it dries;

- After completion of the work, the tape is immediately removed.

Once dry, you can varnish the item to increase durability. Acting in the same way as when painting.

Spray paint smoothly in one layer, keeping the balloon straight.

Plastic paint is a great option to freshen up old items and give them new life. The presence of a wide variety of colors allows you to come up with various solutions for decoration. Before painting the plastic, they include all the imagination, they take the tools necessary for this process, as a result, you can perfectly decorate your home yourself.

Composition and specifications

White spray paint or another color can be produced with a slightly different composition. It all depends on the material for which it is intended. It is usually distinctive to add special components that provide the necessary protection for the material. For example, spray paint in metal cans must have anti-corrosion properties. The following popular components can be distinguished, which are included in the composition of aerosol paints:

- Acrylic;

- Epoxy resins;

- Oil elements;

- Water components;

- Dyes, fillers.

The technical characteristics of paint products in sprays may also vary. The following inherent characteristics are noted:

- Resistance to moisture, vapors, chemical elements;

- High temperature resistance;

- High degree of wear resistance;

- Abrasion resistance;

- Environmental friendliness;

- Average consumption is 150-200 grams per square meter of surface.

Spray paint in metal cans must have anti-corrosion properties.

How to paint salon plastic so that the paint does not peel off

Let's start with the analysis of the main mistake: why does the enamel layer peel off? The reason is that the material has nothing to catch on, that is, poor adhesion of the paint layer to the ground or to the plastic.

The fact is that before applying any type of paintwork on the surface to be treated, it is necessary to create small grooves and scratches, that is, to grind. This improves the adhesion of the new coating to the base, making it durable and resistant to abrasion. What else is sanding useful for? During the treatment with tape-bright, stubborn dirt is removed, which is difficult to remove with anti-silicone.

Hard plastic painting technology

We have already outlined the main stages of restoration work in the selection of materials. Now let's deal with the technical part of each operation.

- Sand it. In terms of painting terminology, this transition would be correctly called matting. The bottom line is that the red bright tape must be moistened with anti-silicone and rubbed with the plastic part.

- Degrease. Soak a cloth in anti-silicone and walk over the treated surface.

- Prime. Apply 3-4 coats of special primer for plastic and wait until it dries.

- Sand it. Treat the primed surface with adhesive tape.

- Paint. Apply 2-3 coats of paint in the desired color. If there is a need to restore the structure, then structural enamel is applied before the main painting. The places of its spraying are determined in place: this is either the entire surface of the part, or some of its sections. If the goal is to obtain a varnished surface, then in 20-30 minutes after receiving the painted coating, varnish is applied in 1-2 layers.

When painting salon plastic, follow the well-known rules for working with aerosol cans:

- Place the part in a closed room with an exhaust hood so that dust does not enter the processing area.

- Cover untreated surfaces with newspaper, cardboard or thick cloth, securing it around the perimeter with masking tape.

- Shake the can for 1 minute in order to obtain an even layer.

- Try to spray paint on some kind of cardboard. Check the color match and prepare the can to spray evenly.

- Apply paint / primer to the surface with quick but smooth and non-stop longitudinal movements. Drying time between layers at + 25 ° C is on average 20-30 minutes. Complete polymerization occurs in 24 hours. Shake the bottle periodically when painting.

- Flip the can and press the button. Relevant if paint remains in the container. This is to prevent the material from hardening in the sprayer.

Working with Soft-Touch coating

We have already noted that the above painting technique is relevant for hard salon plastic. Soft coated plastics such as dashboards or door cards need special treatment:

- The old soft-touch layer must be completely removed. If this is not done, then the new paint will peel off again. To easily remove the coating, the part should be soaked in 646th solvent.

- When using original Soft-Touch paints, plastic is usually not primed, and one layer of coating is enough to successfully close the issue of restoration of interior elements.

Chrome effect paints

Paintwork materials that create the effect of chrome or nickel plating are available in cans and aerosol cans. According to experts, canned compositions are more difficult to apply, but the paint film is more similar to a natural metal coating. Perfect aesthetic resemblance can be achieved. It is better to paint a self-restored disc or headlight contour with canned paint. Aerosol cans are purchased by beginners who find it difficult to apply professional formulations in an even layer.

Aerosol cans are purchased by beginners who find it difficult to apply professional formulations in an even layer.

Composition and characteristics

In terms of their component content, paints and varnishes differ due to the base. A binding film-forming base is added to the metal crushed to a powder state. Alkyd, acrylic, resinous or nitrocellulose compounds help to distribute the powder evenly. After drying, the base becomes transparent, metal particles are clearly visible, it is the powders that create a mirror-like, reflective surface.

Manufacturers offer a large assortment of paintwork materials with a metallic sheen for metal, plastic, wood. Chrome paint is:

- One-component, these are aerosol containers, nitro-paint in the middle price category;

- Two-component based on acrylic or epoxy resin, it is highly resistant to moisture, dirt, is not afraid of the effects of detergents (car shampoos, non-aggressive household chemicals).

To improve the visual effect, lacquer is additionally used, it strengthens the film layer.The wood looks like metal under the chrome paint. Heat-resistant powder coatings are bred in a special way, they are more complex in structure. They form coatings closer to natural chrome plating - resistant, bright.

To improve the visual effect, lacquer is additionally used, it strengthens the film layer.

To improve the visual effect, lacquer is additionally used, it strengthens the film layer.

Dyes are available in different colors:

- Silver, imitating nickel, chrome;

- Gold with powder from non-ferrous alloys, reaching a noble yellow hue;

- Dark - black, blue, other shades.

All chrome-plated paints are shiny, with good reflectivity, forming a protective film in the form of a mirror.

All chrome-plated paints are shiny, with good reflectivity, forming a protective film in the form of a mirror.

Advantages and disadvantages of spray cans

The main advantage of chrome paint in spray cans is the ability to apply without the use of a brush, hands will remain clean. The main disadvantage is that the balloon holds a little paintwork.

With the help of aerosols, they hide small defects on the metal, powder paints perfectly mask rust.

Other pluses of chrome paint in spray cans:

- The aerosol is ready to work, for painting it is enough to remove the lid from the can, press the spray;

- Versatility, mixtures are designed for coloring various materials, including plastic;

- No tools or accessories are required for work;

- An aerosol can is a sealed container, the paint is well preserved in the package, does not lose its original properties;

- Manufacturers offer a varied palette of colors, you can easily choose the desired shade;

- When sprayed, the layer dries quickly;

- No special preparation is required for coating.

Now about the disadvantages:

- It is difficult to handle large areas;

- With painting of some types of polymers, problems are possible, with glossy plastics, the layer is scratched.

An aerosol can is a sealed container, the paint stays well in the package, does not lose its original properties.

An aerosol can is a sealed container, the paint stays well in the package, does not lose its original properties.

Tips for selection and use

If you are planning to go to the store for the first time for acrylic paint in spray cans, we recommend that you familiarize yourself with the tips for choosing products. Experts identify the following rules:

Consumption

Be sure to pay attention to paint consumption. The solution in cylinders must be applied in several layers, the optimal number is 2-3

Knowing the consumption rate, you can correctly calculate the required amount of products.

Texture and aesthetic properties. The decorative aspect is as important as the technological one. The final effect after drying will change the interior. It can be metallic, gold plated, chrome or any color from the spectrum. To make your choice more convenient, use the special tones catalog.

Additional element. If you want to fully reveal the color, you will need white paint. An achromatic color is preliminarily applied, and on top of it - the main one. White is the best canvas for any shade.

Material. While most spray products are versatile, you need to consider the material you intend to paint. Some manufacturers make specialized formulations designed exclusively for specific surfaces.

Storage. Because of the easy access to the contents of the spray can, store the paint in a closed pantry or out of the reach of children and animals.

Acrylic paint in spray cans appeared on the domestic market for a long time, and since then interest in this product has not faded away. Abroad, such paint is also in great demand due to its convenience and other advantages. On the vastness of the worldwide network, many reviews have been collected characterizing acrylic paint in a special format.

Positive reviews (about 90% of them) indicate that this is a quick, convenient and profitable way to carry out local repairs, and a huge variety of colors with expressive aesthetic properties makes it possible to translate the most daring ideas of decorators into reality.

You will learn how to make the "Craquelure" effect with acrylic paint in a spray can in the following video.