Mounting types

There are many different foam block anchors. It will be more convenient to decide on the assortment if you subdivide fasteners by means of dowels into three main types.

Metal dowel

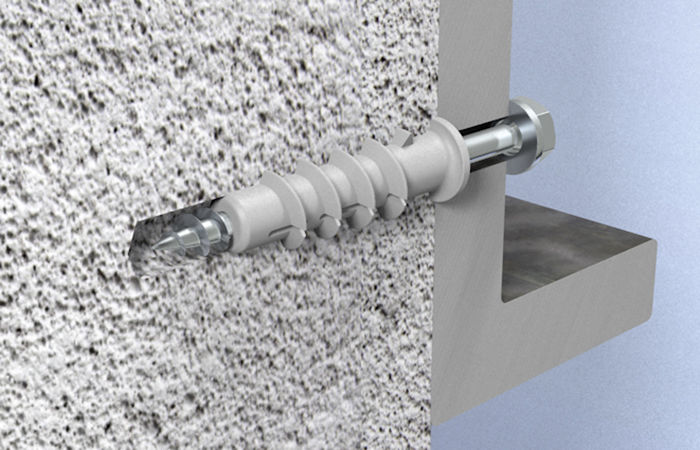

The fasteners used are four spacer parts with external spikes, which ensure a strong fastening of the product to the foam concrete wall.

It evenly distributes the pressure in the block, and therefore the fastening connection reliably withstands high mechanical loads.

It can be used for hanging:

- shelves;

- kitchen cabinets;

- lamps;

- shells.

The product is based on galvanized steel, which is a stable material under any load. Metal rods are used in rooms with a high degree of fire hazard and are the best option for this.

When screwing in, the dowel evenly penetrates the porous material and is firmly held by the corrugated surface. Sharpened spikes guarantee a secure connection of the dowel with the foam block.

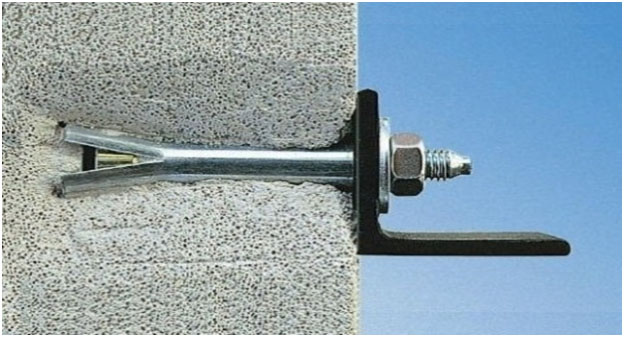

Expansion metal anchor

Expansion metal anchor

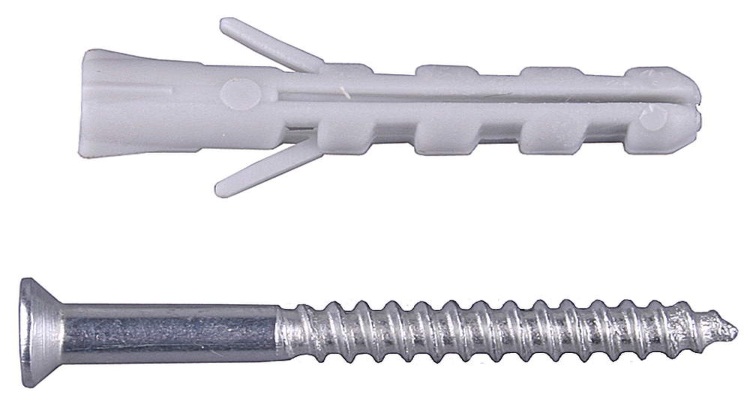

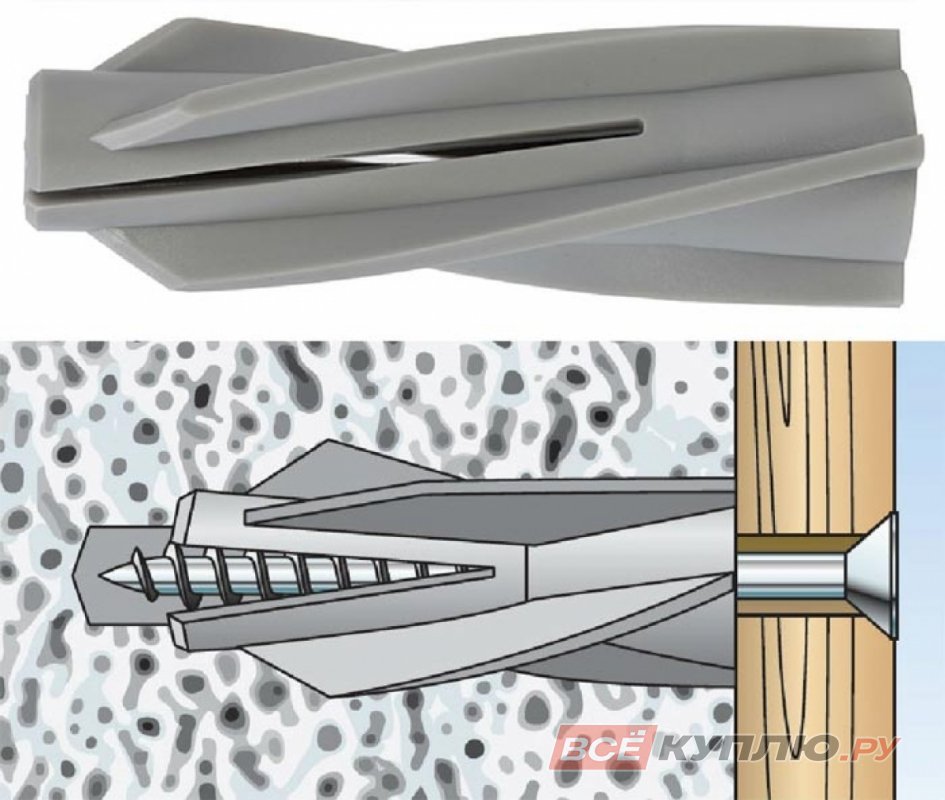

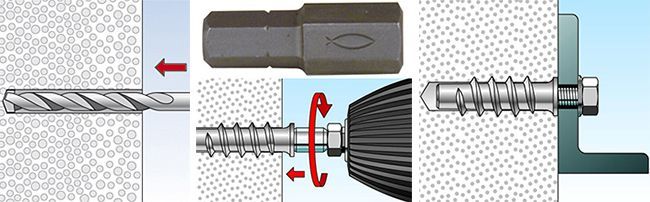

Nylon fasteners

They are mainly used in a domestic environment. Plastic products are stable for a long time, therefore, the fastening reliability is high.

In most cases, they are used for hanging products from which the fasteners do not experience special stress:

- Lattices;

- Shelf;

- Pipes;

- Pictures;

- Carpets.

The wavy thread inside allows the dowel to be inserted into the foam concrete without visible damage to the material. In domestic conditions during work, most often choose Ø4-12 mm fasteners, into which hardware (screws, self-tapping screws) are already directly screwed in.

Plastic anchor for foam concrete

Plastic anchor for foam concrete

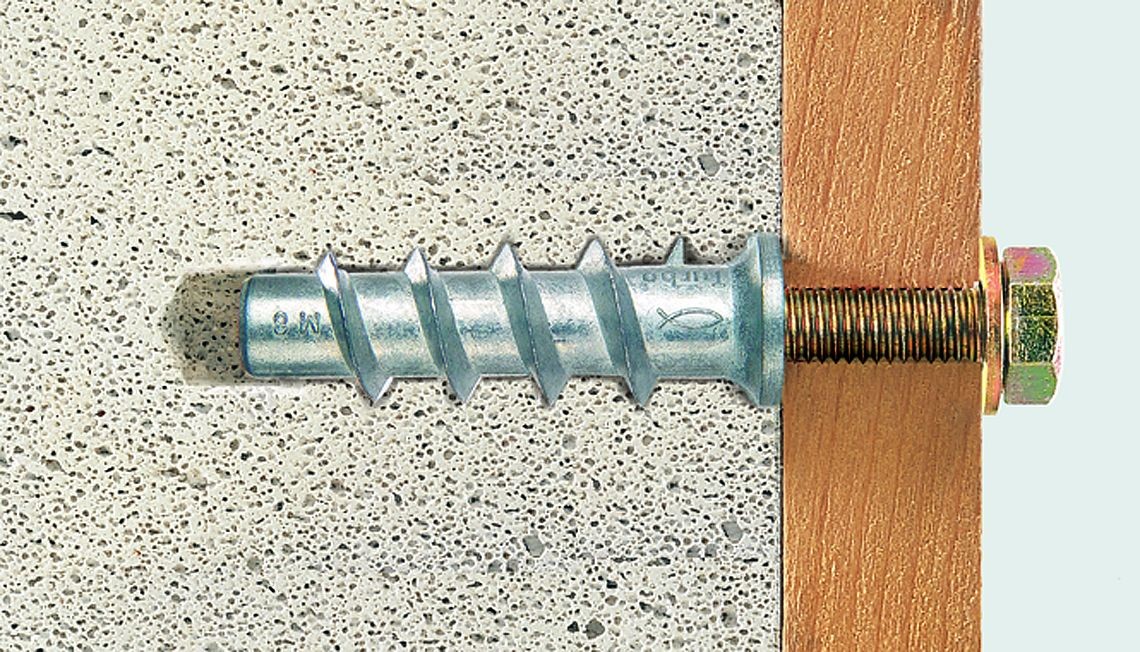

Dowels for fastening frames

Both types of dowels can be used with a special design, which allows fixing structures with the greatest efficiency.

Such equipment includes frame dowels: their length of fastening hardware is often equal to the width of the foam block.

As a result of the uniform distribution of the load over the entire plane of the block, door and window frames or similar similar structures can be fixed to the wall using frame dowels.

Universal frame rod

Universal frame rod

Chemical anchor fasteners

It is currently the most popular compound in foam blocks. The composition of the preparation consists of two component mixtures - cement and resin. Mineralite in this case, when filling the hole, forms a reliable adhesion to the base of the block.

The resin of the chemical anchor acts as a hardener, it accelerates the "setting" of the cement and at the same time enhances its bond. Both components are placed in two chambers of the cylinder and, when squeezed out, spontaneously mix in the required proportions.

The vessel is placed in a standard press gun for various adhesives and sealants. Chemical anchors can be used as fasteners for any structure.

Chemical anchor

Chemical anchor

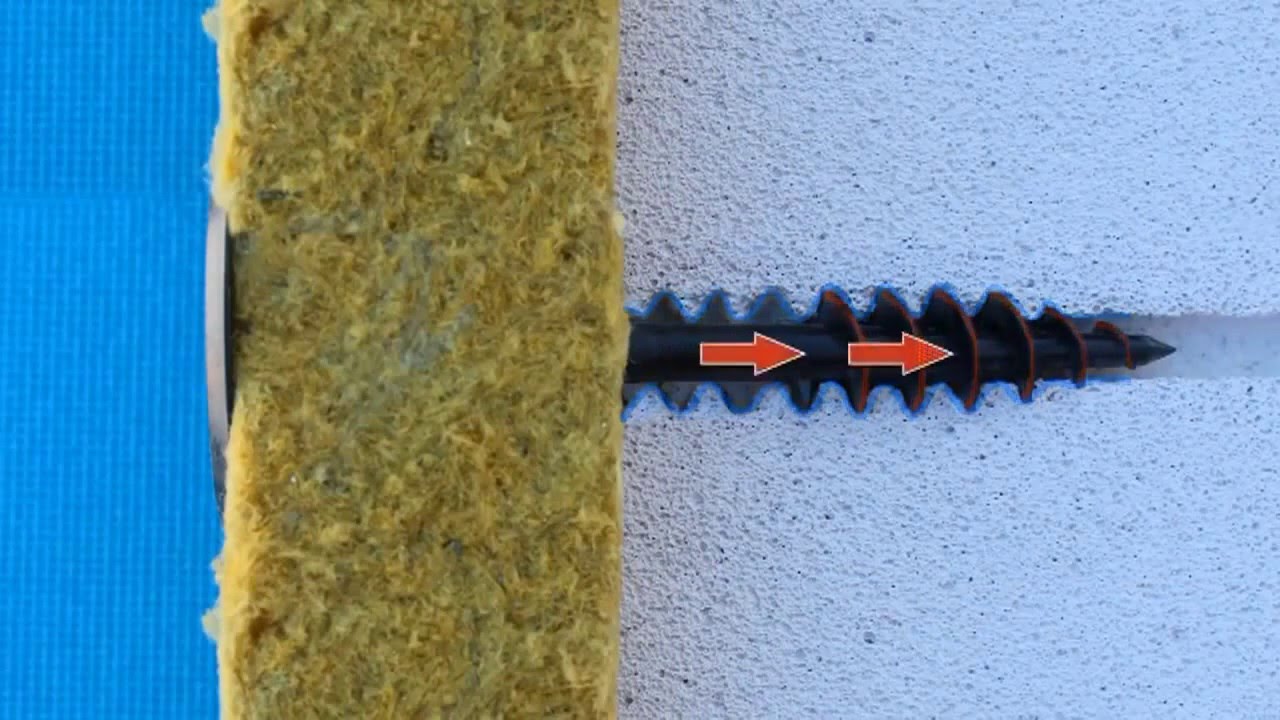

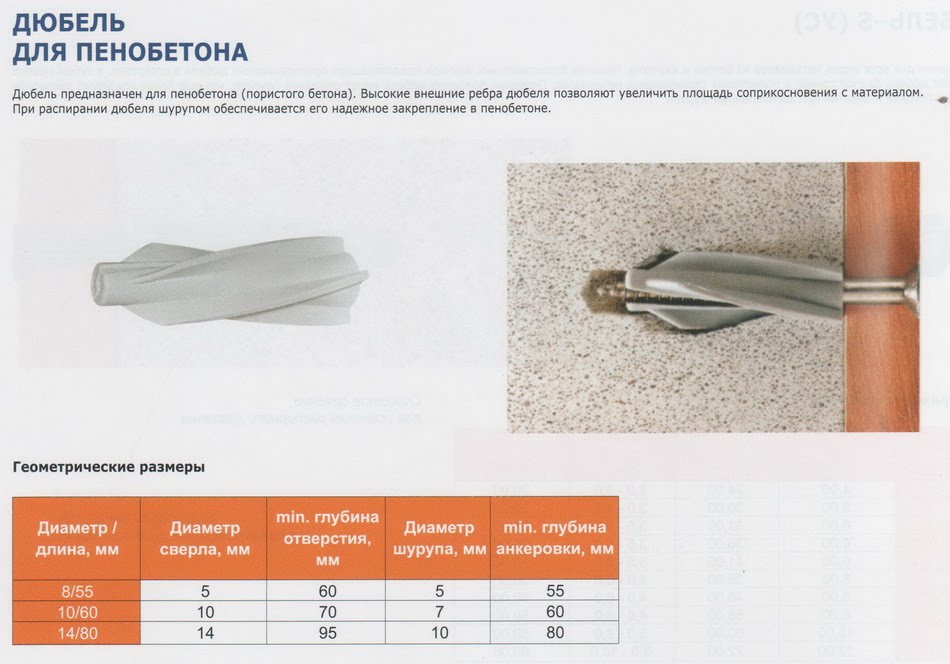

Screw-in dowels for fixing in aerated concrete

Conventional dowels used for hard concrete are not suitable for a foam block, as they do not provide sufficient bearing capacity. A fairly common type of fasteners for foam blocks is twisted metal or plastic dowels. The shape and size of the teeth, as well as the anchorage depth, ensure a secure attachment under heavy loads. The outer part of the dowel is made in the form of a special self-tapping thread, as a result of which the dowel has a tight fit during installation. Large screw teeth ensure a secure connection between the dowel and the base. The geometry of the product allows for practically expansion-free anchoring.

Bolts or studs with threads from M6 to M10 are used as a fastener for metal dowels. For plastic (nylon) models, either wood screws or bolts or studs with threads from M4 to M10 are used.

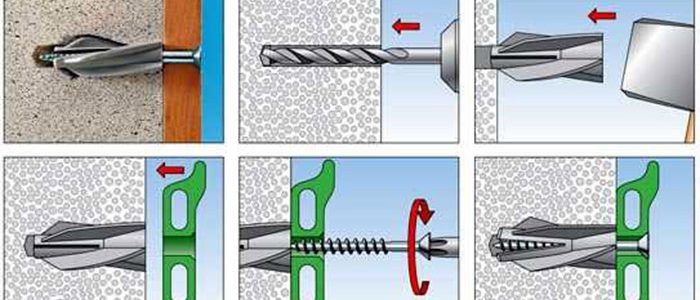

The installation of such products is quite simple:

- First, a hole of the required diameter and depth is drilled in the foam block (in accordance with the installation dimensions of the dowel).

- Then a dowel is installed in the hole using a screwdriver and an appropriate bit (or manually).

Attention! When installing with a screwdriver, start with a low torque. After that, the necessary element is fixed with a screw or screw (hooks for a shelf, brackets for a built-in cabinet, a chandelier, etc.)

After that, the necessary element is fixed with a screw or screw (hooks for a shelf, brackets for a built-in cabinet, a chandelier, and the like).

Important! The dimensions and material of the fastening dowel are selected depending on the expected load. The most famous manufacturers of this category of hardware for fixing to foam block walls are Fischer (Germany), Sormat (Finland) and Mungo (Switzerland)

The price for such products, depending on the material, size and manufacturer: from 16 ÷ 22 rubles for nylon (M4⨯10) to 220 ÷ 260 rubles for metal (M10⨯70)

The most famous manufacturers of this category of hardware for fixing to foam block walls are Fischer (Germany), Sormat (Finland) and Mungo (Switzerland). The price for such products, depending on the material, size and manufacturer: from 16 ÷ 22 rubles for nylon (M4⨯10) to 220 ÷ 260 rubles for metal (M10⨯70).

Metallic and plastic types

Dowel-nails for a foam block are usually metal or plastic. The metal dowel is notable for the fact that it contributes to an even distribution of pressure in the building material. Therefore, it can withstand heavy mechanical stress. Such fasteners need to be purchased when it is necessary to fix hinged shelves, cornices, kitchen modules on the wall.

For the manufacture of such dowels, zinc-coated steel is used. It differs in that  able to tolerate well the effects of temperature changes. This mounting option is best suited for those rooms for which the highest fire safety requirements are imposed.

able to tolerate well the effects of temperature changes. This mounting option is best suited for those rooms for which the highest fire safety requirements are imposed.

When the metal dowel is screwed in, it smoothly penetrates the porous structure and is firmly fixed thanks to the ribbed surface.

The advantages of these fasteners include, above all, durability. They are usually used to fix not very massive objects. For example, with the help of plastic dowels, gratings, consoles, pipes are installed.

Thanks to the embossed thread available on such fasteners, the process of inserting the dowel into the cellular building material is simplified. This does not damage the plaster layer on the wall.

Dismantling features

When choosing which dowel is good and which one is not suitable for the task at hand, it is necessary to take into account the possibility of dismantling. If there is a possibility that the mount will need to be removed in the future, it is advisable to think about it before installing it.

To quickly and correctly perform dismantling, you will need a variety of tools that are usually in the arsenal of any master. Some types of dowels (chemical, for example) cannot be dismantled).

How to dismantle the dowel:

- To remove an ordinary plastic dowel, it is enough to find a self-tapping screw of the appropriate size. The self-tapping screw is screwed 2/3 into the dowel itself, the screw head is carefully clamped with pliers, then pulled out of the monolith together with the dowel. In some cases, a corkscrew will suffice.

- The head of the self-tapping screw, which is inserted into the dowel, can be pry off with a nail puller. Here you need to ensure that the working part of the self-tapping screw fits snugly in the hole itself.

- Homemade wood dowels are taken out in parts - first, a piece of wood (easiest along the grain) is crushed into separate pieces using a chisel (preferably with a thin blade) and a hammer. After the dowel is destroyed, it is pryed off with an awl, sharp knife or nail and pulled out of the nest.

- In some cases, the dowel firmly sitting in the monolith is easier not to dismantle at all - it is better to cut off the part that comes out to the surface, carefully cover the depression with plaster of paris and carefully align.

- If part of the screw is stuck in the dowel, you will need a heated soldering iron. First, the plastic base of the dowel melts gently, then the fragment of the fastener is pry off with round-nose pliers or nippers and removed.

- A metal dowel, which was hammered into concrete with a construction gun, is first processed with strong, frequent blows of a hammer, acting on the protruding part of the product from different sides. Usually, the anchor plug will loosen during the process and can be easily removed. If it is difficult to loosen, you can make a groove nearby with a drill with a hard alloy tip or a metal punch. Thanks to the circular funnel, the area of adhesion of the fasteners to the wall will decrease, and it will be easier to remove it.

Dowels for concrete today in the construction market of Moscow and the region, other regions are presented in a wide variety, therefore, it will not be difficult to find fasteners that exactly meet the requirements and operating conditions. The main thing is to choose reliable suppliers and focus on product quality.

Types and scope of application

As a mass, which is used to fill a hole for an anchor or chemical-type dowel, substances based on the following types of resins are used:

- epoxy;

- epoxyacrylate;

- polyester;

- vinyl ester.

Resin for chemical anchors can be in capsules or tubes

Certain types of adhesives (for example, those based on vinyl ester resin) can be used to form anchoring joints that are operated at low temperatures. The convenience of using glue based on such a resin also lies in the fact that it can be used to fix even in wet holes, while no internal stresses are created in the material of the building structure. Such anchors can be equally successfully used for mounting threaded and smooth rods in aerated concrete.

It is also important that there is no styrene in vinyl ester resins - a substance harmful to human health.

Adhesives based on epoxy resins are very popular among specialists. Such compositions are used for fixing anchor bolts in aerated concrete, the class of which exceeds C20 / 25. The most common areas of their application, in addition to the device of reinforcement outlets, include installation:

- various objects on walls, beams and road barriers made of concrete blocks;

- screens performing noise protection functions;

- technological equipment for various purposes.

A two-part epoxy adhesive capsule is intended for use with a dispenser when installing threaded rods or fittings

Distinctive features of epoxy based adhesive are:

- the ability to use in conditions of high humidity and even under water;

- application for the installation of anchors both inside the building and on external building structures;

- the ability not to create internal stresses inside the building material;

- no toxic styrene;

- the possibility of using for the installation of both threaded and smooth fasteners.

For professional use, it is recommended to purchase a special kit that includes everything you need to install chemical anchors.

Along with all the advantages of the listed types of adhesives, materials based on epoxyacrylate resins are also distinguished by a high fire resistance limit - R120.This parameter indicates that even if there is direct exposure to fire on a fastener fixed with such an adhesive, nothing will happen to it within 120 minutes.

The adhesives are also distinguished by the different period required for their setting and complete hardening. So, the setting / hardening time is for compositions:

- epoxy - 7-180 minutes / 7-48 hours;

- based on polyester resins - 2-30 minutes / 25-180 minutes;

- vinyl ester - 2-60 minutes / 15 minutes - 24 hours;

- epoxyacrylate - 2-24 minutes / 15-180 minutes.

If you wish, you can make glue for mounting a chemical anchor in aerated concrete with your own hands, the main thing is to strictly observe the proportions of all its components.

4 We mount the dowel-nail for aerated concrete correctly

Faced for the first time with the installation of such a mount, home craftsmen make some mistakes, which in the future, and sometimes immediately, lead to poor-quality installation and the lack of the ability of the mount to hold something. In order to avoid such troubles, we suggest that you familiarize yourself with the instructions for correct in porous materials.

As an auxiliary tool, we will use an electric drill or hammer drill, a concrete drill for a drill or for a hammer drill, a hammer and, without fail, a Phillips screwdriver. Also, you should immediately choose one of the types of fasteners, plastic or metal. Both of these types will be discussed in our step-by-step instructions.

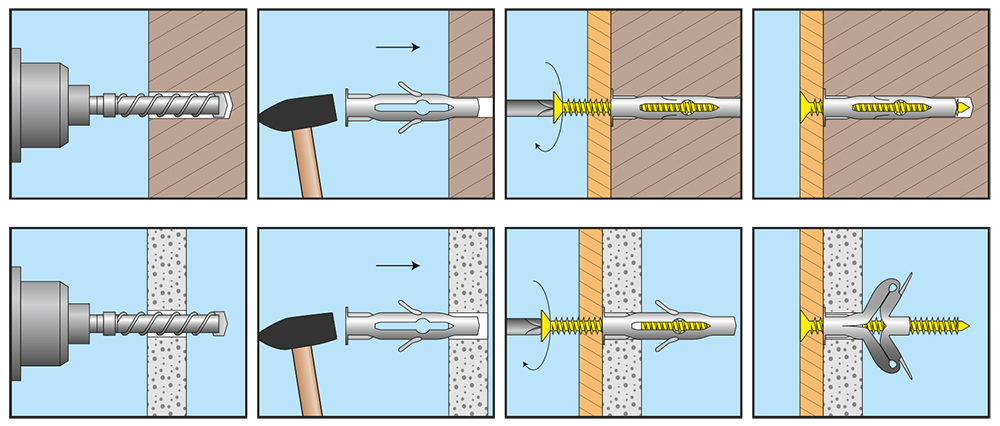

Installing fasteners into the wall

Installing fasteners into the wall

The next step will be to install the fasteners into the finished hole, we will start with the plastic version. In order for the mount to hold tightly to the wall, it must be carefully screwed onto the installation site. To do this, take a screwdriver and twist it all the way, there are special slots on the mount for both a Phillips and slotted screwdriver. We mount the metal product in a different way, we simply insert it into the bore and carefully hammer it with a hammer until it stops, while trying not to distort the fasteners.

Step 3:

We tighten the self-tapping screw

Now that our dowel is installed, you can safely tighten a self-tapping screw or a universal mounting bolt. To do this, you should also use a screwdriver and tighten the self-tapping screw to the depth that you need.

It is categorically not recommended to use an electric tool, since, through negligence, mechanical impact can damage your mount, turning it around its axis, which is not recommended

Aerated concrete is a light and warm material, this explains its popularity both in the construction of residential buildings and in the construction of non-residential premises. Alas, lightweight concrete, which includes aerated concrete, gas silicate and foam concrete, has its drawbacks. The main one is that fasteners intended for other materials, such as wood or brick, do not hold well in the aerated concrete wall.

It is often required to ensure reliable fastening of heavy objects to aerated concrete, these can be boilers, sinks, furniture items, etc. In these cases, it is necessary to provide a secure fit. Some builders use conventional anodized self-tapping screws, but alas, the self-tapping screw can be easily pulled out of lightweight concrete. Ordinary dowel-nails also do not provide reliable fastening, since they are securely held only in walls made of solid materials, for example, from silicate bricks.

For these reasons, special anchors and dowels are used for fastening to lightweight concrete.

Anchors and dowels work according to the same principle - they are securely fixed in the wall due to expansion. It will be conventionally considered that the anchor is made of metal and is an independent element. The dowel, most often, is made of nylon and is a "plug" into which a screw or self-tapping screw can be screwed. In Soviet times, such corks were made of wood.

Fastening methods

The principle of operation of an anchor for aerated concrete can be mechanical or chemical, depending on the type of material from which the building object is made, as well as on a number of other factors.

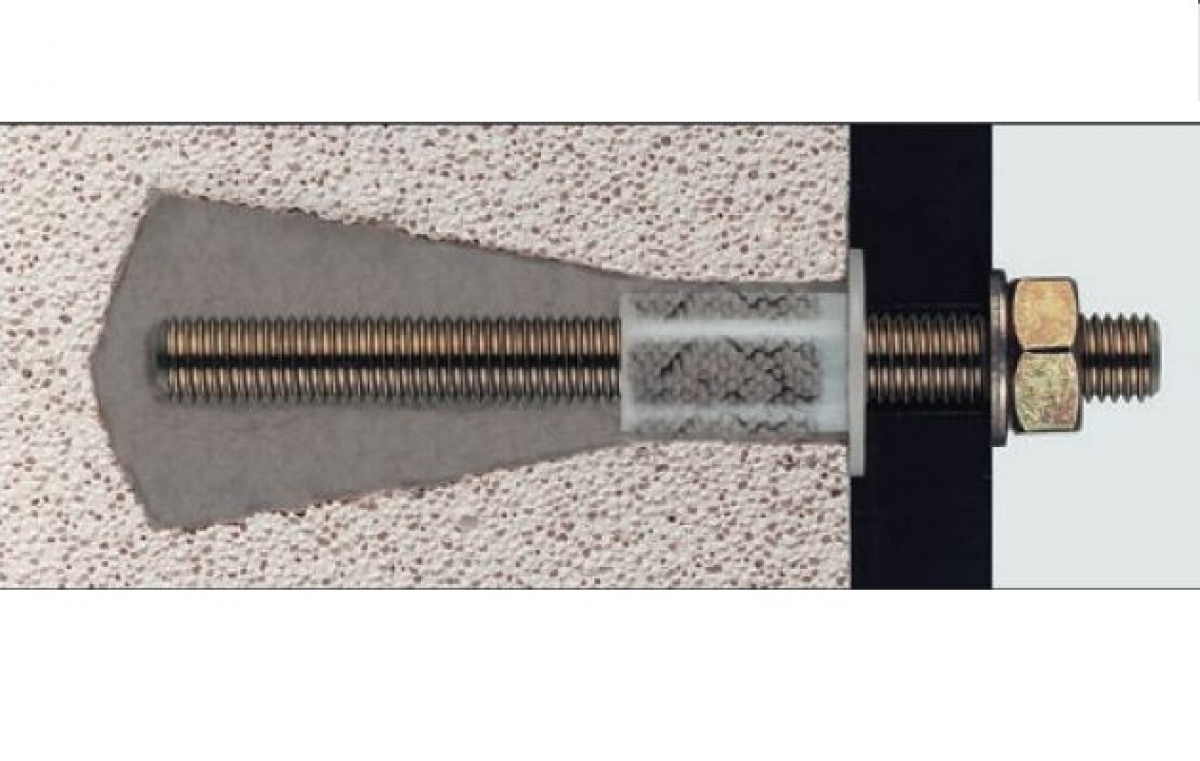

Anchors designed for aerated concrete and working according to the mechanical principle are rigid metal rods that are driven or screwed into a structure, on the surface of which a certain object must be fixed. The device of such anchors, which is noticeable even from the photo, ensures their reliable fixation even in such a porous material as aerated concrete. In this case, the load taken by the fastener is distributed almost evenly over the entire area of its outer surface.

Anchor placement in aerated concrete

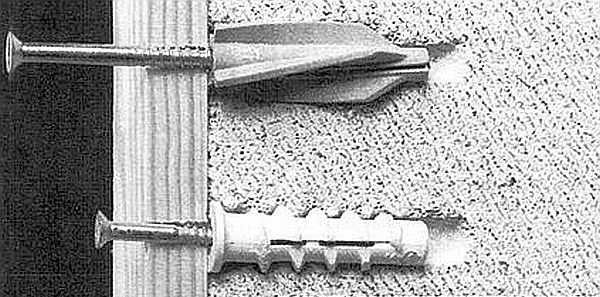

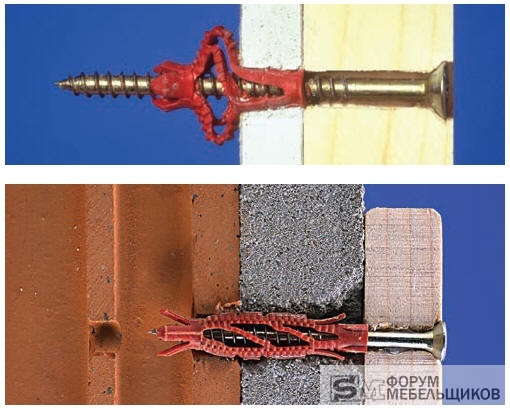

A mechanical anchor used for installation in aerated concrete, aerated concrete and other porous materials is often called a "butterfly" due to the peculiarities of its design. The working end of such a fastener, which is mounted in the hole, splits into separate petals during the screwing in of the threaded element, which makes the anchor look like a butterfly (this is clearly visible from the photo) and contributes to its reliable fixation in the previously prepared hole.

A bolt or threaded rod that is screwed into the expansion part of such an anchor can damage the hole made in the gas silicate block or foam block. To prevent this from happening, for aerated concrete, working according to the mechanical principle, it has a special collar or border that prevents its threaded element from being pushed through. Mechanical anchors of the "butterfly" type can be equally successfully used for reliable fastening of various objects to structures made of foam concrete, gas silicate blocks, as well as from other materials with a porous structure.

The choice of anchor depends on the load

are used in cases where the object, fixed on a structure made of foam concrete or gas silicate blocks, has a significant weight, which mechanical fasteners are not able to withstand

It is important that such an anchor works on the principle of a mechanical anchor bolt and at the same time is mounted in the prepared hole using a special adhesive. Such fastening methods used in the installation of chemical anchors allow them to be securely fixed in porous materials (foam concrete blocks, gas silicate walls, porous bricks, etc.)

Placement of a chemical anchor in aerated concrete

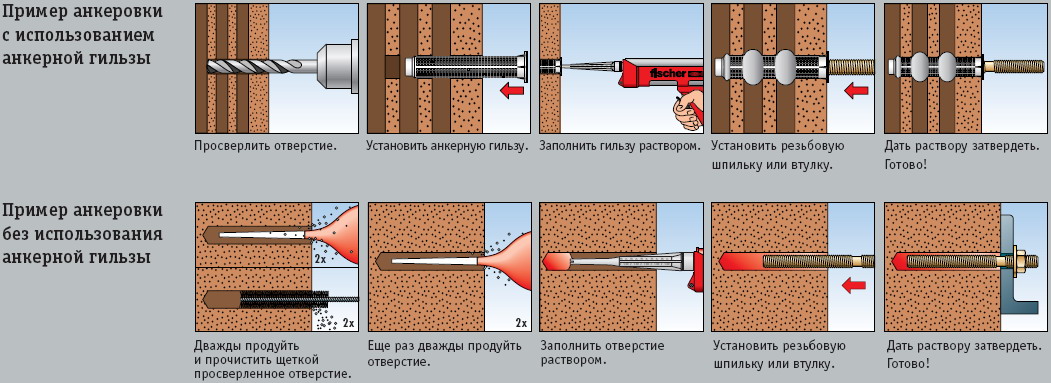

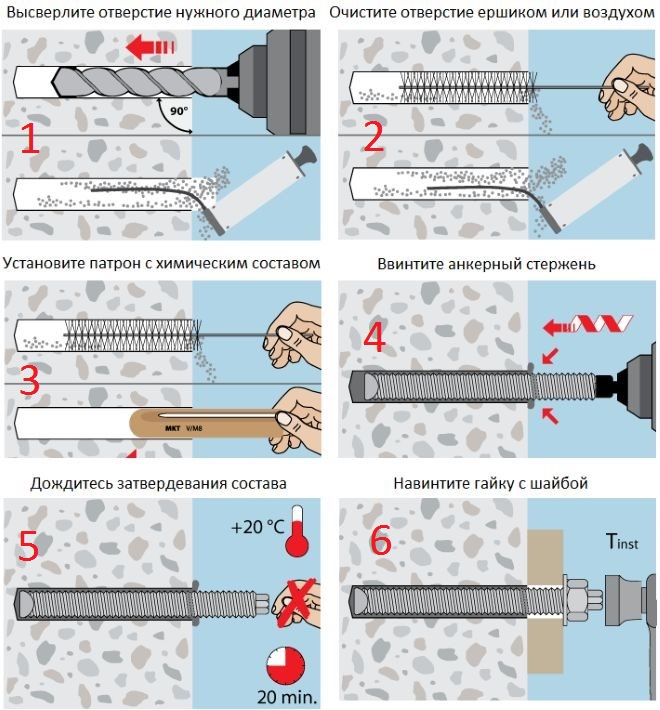

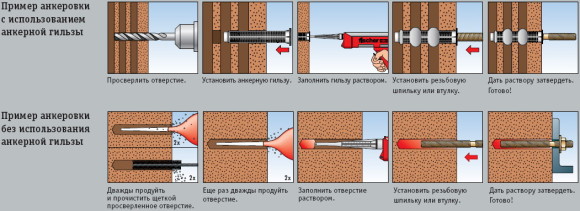

Installation of anchor bolts or chemical dowels, which form almost permanent connections with building structures, consists of such steps as:

- preparation of the bore hole (a conventional electric drill can be used for this);

- cleaning the hole from construction dust and pieces of building material that has crumbled into its internal cavity (to perform this procedure, you can use an ordinary medical pear or a brush of the appropriate diameter);

- installation of a special capsule with an adhesive mass into a prepared hole or pumping glue from a tube;

- installation of a dowel with a threaded element or, as it is correctly called, a chemical anchor into the hole;

- complete curing of the adhesive, which can take up to 48 hours (the time required for the complete curing of the glue used during installation depends not only on the composition of the adhesive, but also on the ambient temperature and a number of other external factors).

Procedure for installing a chemical anchor

It is obvious that the installation of such fasteners is easy to perform even with your own hands, without involving qualified specialists to solve this problem. For the manufacture of chemical dowels, depending on their purpose, you can use both metal alloys with anti-corrosion coatings and polymer compositions.

Advantages and disadvantages

Foam blocks are widely used in construction, and differ from many other popular building materials in porosity. Their main components are the same substances that are used to prepare concrete mixtures: sand, water and cement.

The difference between the foam block and ordinary cement-sand mortar and concrete is that, in addition to these three materials, a special substance is added to it, due to which numerous pores are formed, which are so important for heat and sound insulation. This substance is called a foaming agent.

Foam concrete has many advantages:

- It has low thermal conductivity, therefore it retains warm air well inside the room and does not allow cold air to penetrate into the room.

- It is a good sound insulator. Loud noises coming from the street or from neighbors' houses will not be heard.

- It is lightweight, so it is convenient to work with.

The most serious drawback of foam blocks is their low strength. It is for this reason that builders face difficulties in the installation of engineering parts.

With their help, you can quickly and reliably fix decorative elements of almost any shape and weight on the walls of the foam block. In modern hardware stores, you can find many different options for such products.

Chemical anchor

This type of fastening, as a chemical anchor, is a fairly new and already in demand method. The builders appreciated it. Chemical anchoring has its advantages and disadvantages.

The advantages of a chemical anchor include:

- high load capacity factor for fasteners;

- compliance with GOST, chemical composition is safe, environmentally friendly;

- versatility, it is used for any building material;

- high resistance to weather fluctuations, low temperatures;

- low price when compared with steel anchors.

The disadvantages include:

- strict adherence to technology;

- purchase of special equipment, namely, a brush, pump, gun and drills;

- additional time for solidification of the chemical solution.

Chemical fasteners for foam concrete include a threaded steel stud, maybe a special rod, a chemical mixture, additional bushings.

Sequence of attachment of chemical anchor

- Using a drill, make a cylindrical hole. Then it needs to be shaped into a cone with an expansion in depth.

- The finished hole is thoroughly cleaned. You can use a pump for this.

- A centering sleeve is inserted into the base.

- A chemical solution is poured into the hole through the sleeve; a construction gun is used for this.

- The threaded rod (stud) is screwed in.

- We leave time until the chemical solution completely solidifies.

The set of the chemical anchor includes an easy-to-use package with a dispenser. Installation is easy and high structural strength is achieved.

Fastening chemical anchors

And so, for fastening light structures, decorative elements, ordinary self-tapping screws are quite suitable. They can be designed for woodworking or aerated concrete. Aerated concrete nails should have a wedge-shaped or curved tip inside the concrete cavity.

For heavy structures, such as plumbing, kitchen cabinets, boilers, it is worth using fasteners for foam concrete, with wedging dowels. Reliable fixation is carried out precisely thanks to the internal stop. All hardware must be corrosion resistant. This is especially true for external wall mountings.

More recently, it was quite problematic to install fasteners in porous materials. Today the situation has changed dramatically, the dowel for aerated concrete has made a breakthrough in fastening technology, but let's talk about everything in order.

Views

On the shelves of hardware stores, you can purchase several types of fasteners:

- dowel;

- dowel nail;

- simple anchor;

- chemical anchor;

- screw M4;

- self-tapping screws;

- anchor bolt.

The dowel is the most demanded type of fastening material. The main feature is the creation of internal support when expanding inside the work surface.

Construction department consultants can offer dowels made of plastic or metal. Before buying, you must consider the type of finishing work. The assembly of consumables is carried out using a screwdriver, the regulator of which must be set to low speed.

The dowel nail is a fastening material used when working with dense blocks for walls. Feature - fast and reliable fixation of structures made of wood, metal and aluminum to the aerated concrete work surface. Dowel nails have a unique ribbed surface, which makes it possible to increase the level of fixation and distribute the load within the block. This feature of the details allows for facade work and the manufacture of suspended ceilings.

A simple anchor is a fastening element consisting of a spacer or a plastic dowel. Conventional anchors cannot be used for aerated concrete due to the porous structure of the building material.

Chemical anchor is an innovative type of fastening that has universal application.

The adhesive composition of a chemical anchor consists of several components:

- cement mortar;

- organic resin.

Fastening material advantages:

- high level of strength and reliability;

- resistance to low temperatures and atmospheric fluctuations;

- long period of operation;

- environmental Safety;

- ease of installation;

- universal application.

The disadvantages include the high price range.

Screw M4 - an iron fastener with a spreading element made of metal. This mount can be used not only for foam concrete blocks, but also for a work surface made of dense aerated concrete.

Self-tapping screws for wood are simple and inexpensive fixing parts that allow you to fix objects with light weight.

Anchor bolt - an iron rod with a special thread and a fixing device. It is used to perform work of increased complexity.

Particular attention should be paid to high-quality German products of the Fischer trademark. Fasteners from this manufacturer are made on innovative equipment from modern metal and plastic

Fischer is the first manufacturer of consumables for this type of work. German fasteners are universal parts with a wide range of applications, including for foam block 10x60 cm, and foam concrete 6x52 cm.

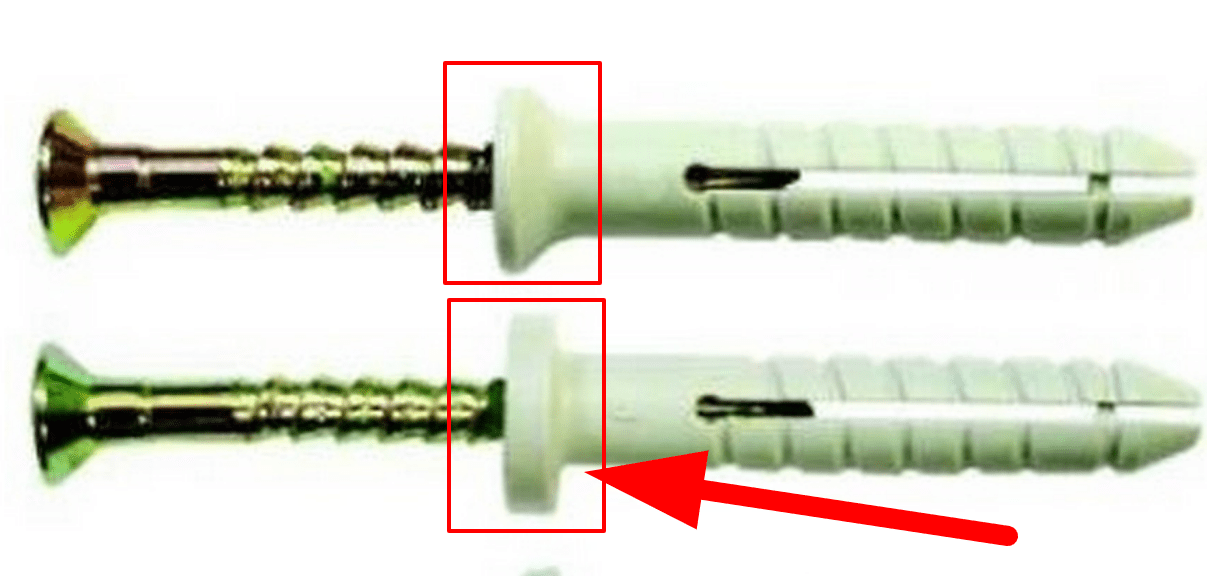

Dowel characteristics

The main components of the fasteners for the foam block are a screw, a ring, a half-ring, a hollow sleeve. It also has a countersunk head and 4 fixation segments. The destruction of the wall during drilling is prevented by an element called a side. Due to the sharp protrusions, called teeth, the load-bearing capacity is increased. They also prevent turning during installation.

The length of the anchor for foam concrete can be different, this also applies to their thickness. Standard fasteners are approximately 45 mm long and 5 to 10 mm thick. In the domestic sphere, dowels with a thickness of about 8 mm are usually used to attach certain decorative elements in a room, and hardware is screwed into them with a screwdriver.

For example:

- If it is necessary to carry out the facade finishing of the building from foam blocks, then it is recommended to use metal fasteners with the so-called drop-down "skirt".

- To fix a photo frame or a small painting on the wall, you can use a nail-shaped dowel.

- If you need to place an opening for a door or window in a foam block wall, then you can purchase special frame dowels for this. A characteristic feature of such fasteners is the presence of a through hole and a large length. It is thanks to this that it is able to withstand high loads.

Sold in packs of several tens or hundreds each. You can purchase a package containing only 25 dowels. You can also find such a package, where there are 500 of them.

Self-tapping screws for aerated concrete and gas silicate

Self-tapping screws for lightweight concrete must provide a secure grip. As a rule, this is ensured by a coarse thread.

Self-tapping screw for lightweight concrete

The video below shows how to fix a wooden batten to a wall made of expanded clay concrete blocks and a wall made of aerated concrete blocks using SORMAT KBRM screws.

Please note that the screw must fit at least 60 mm into the wall, i.e. not the entire thread length

When screwing in screws, it is necessary to use a tool that allows you to control the tightening force. If you overtighten the screw, it will not stick firmly to the wall. As a last resort, in order not to overdo it, you can use a screwdriver.

Aerated concrete is a convenient material in many aspects. The main difficulty in the operation of aerated concrete blocks is the difficulty of fixing fasteners in it in the usual way. The gas block has a cellular structure, which means that you need a special dowel for aerated concrete, which will firmly hold in the wall.

Dowels are bushings with four "petals", which, when the self-tapping screws are driven or twisted in them, expand in the cellular structure of aerated concrete and are firmly fixed. The surface of the petals is rough - with teeth and incisors, which also contributes to the reliability of the fastener. The teeth can go in a spiral, which increases the reliability of the fastening.