Applications

The use of hammer paint is possible in most areas:

- for the processing of various metals. Suitable for coating equipment and metal products made of steel, copper, iron, aluminum, etc .;

- in construction it is used for painting most metal structures;

- application is often carried out on doors, safes and certain types of furniture for industrial use;

- in the automotive industry it is used to cover the body and disks;

- intended for application to forged products;

- used to create an interesting effect in the interior, the substance gives the feeling of antiquity;

- in the advertising direction it is used to cover glass and plastic.

Popular paints for metal

Many products have appeared on the building materials market that greatly facilitate painting work. For example, the popular "3 in 1" paint, which combines 3 components - a rust converter, a primer with high adhesion and an enamel coating.

It is the optimal composition for corroded metals. You just need to take into account that large flakes of rust still have to be cleaned, but you do not need to touch the rest of the layer: the enamel will lie flat and cover all errors and defects. Let's list the main paints used:

- Hammerayt for rust. This paint is very popular. It prevents dirt from retaining on the metal structure, it can be matte and glossy. It is used in private housing construction, industry, agricultural equipment. Rust removal is not required for its application. The temperature range at which the composition retains the specified properties is from -20 to +80 degrees.

- Ground enamels. They successfully destroy corrosion, prime the surface, and act as a decorative paint. To apply them, the surface must be cleaned of dirt, degreased, cleaned traces of rust. Ground enamels are applied in 2 layers. The time between application of layers is indicated in the instructions and ranges from 30 minutes to 5-6 hours. This interval must be strictly observed, otherwise the metal can be covered with a second layer only after a month.

- Rust-eater paint. A universal composition that acts both as a primer and as a paint composition. It is an enamel in combination with a primer that can be used for both indoor and outdoor use. Protects metal from rust in adverse conditions, stops corrosion of various alloys. The paint can be applied on concrete and wood surfaces. The temperature range without loss of quality is from -60 to +100 degrees.

- Quick-drying alkyd paint "Nerzhamed". It also dries very quickly, alkyd and polymer modifiers are introduced into its composition. Suitable for application on corroded surfaces without additional cleaning of the substrate.

- TICIANA alkyd enamel primer creates a surface that does not corrode. Rust does not spread under its layer. Can be used both indoors and outdoors.

- Enamel Poly-Hammer (POLI-HAMMER) also prevents the spread of corrosion, and even has excellent decorative properties. Painted with this enamel, the metal surface takes on a stylish vintage look.

- Hammer effect paint. This composition is the dream of all motorists, it is also used in shipbuilding, in industries associated with exposure to chemicals. Its distinctive feature is unique water resistance and inertness to salt and other aggressive media. The elastic composition is able to mask all irregularities, has high adhesion to metal, is able to create structural patterns on the surface of metal structures, dries quickly and does not allow air to pass through.

Popular rust paints

Among the many brands of special rust paints, there are those that are especially popular. It is determined not only by positive customer reviews, but also by sales.

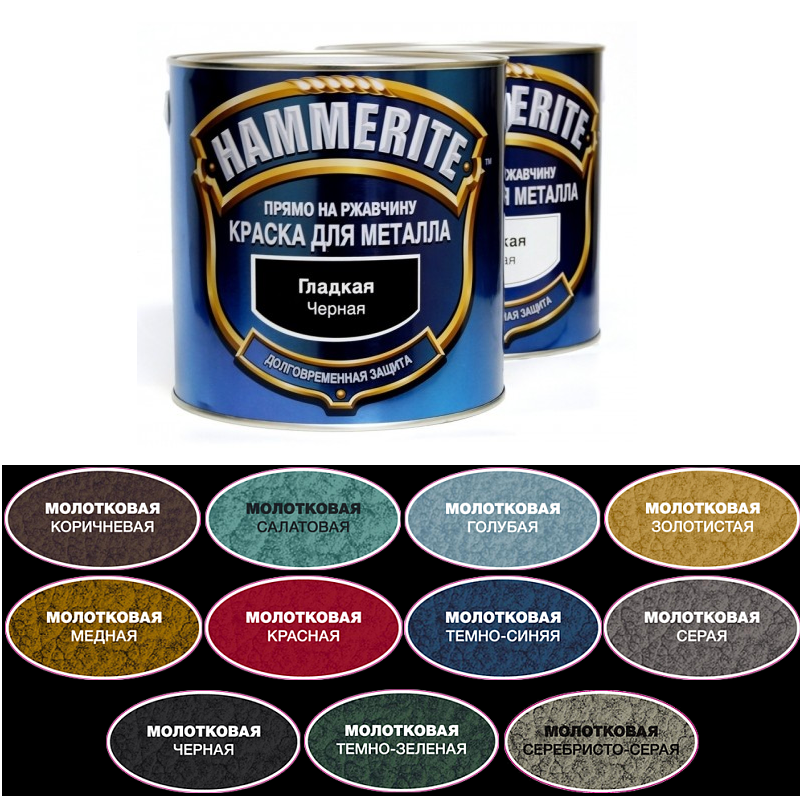

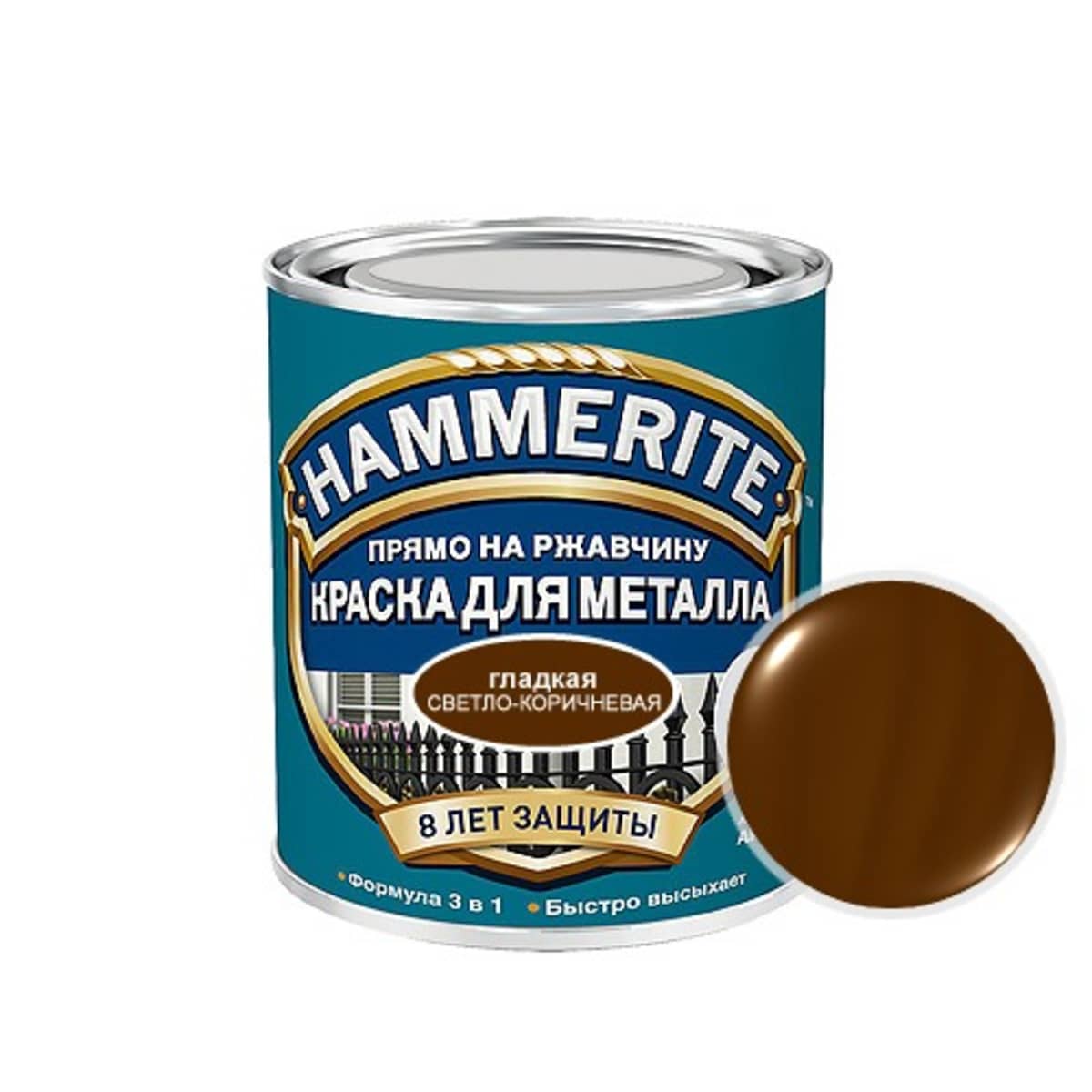

Hammerite

This brand is confidently leading, despite the rather decent cost.This is due to the quality of the coating, its durability, beautiful texture and versatility. Hammerayt anti-corrosion paints are used for decorative finishing of ferrous, galvanized and non-ferrous metals, wood, plastic. They are used for finishing external and internal structures. Apply to new and previously painted surfaces with a different paint.

Hammerite paints

Hammerite paints

When choosing a paint of this brand, you should pay attention to the series.

-

Hammered are hammer paints that create a hammer effect on the painted surface. It turns out to be shiny, but textured and rough, which perfectly masks minor defects. This effect is achieved by adding aluminum powder and fine fractions of glass to the composition. Hammer compounds are ideal for painting ferrous metal.

-

Smooth - a series that forms smooth glossy or semi-matt films. In addition to ready-made paints of standard shades, you can purchase a base composition for tinting in your own color.

"Lacra" Hammer Effect

Another effective protective agent with a hammer consistency. Made on an alkyd-styrene base, it has a low price and good adhesion to metal surfaces with a rusty layer thickness of up to 0.1 mm. It can also be used for painting wooden structures, creating a coating on them with a metallic sheen.

"Lacra" Hammer Effect

"Lacra" Hammer Effect

Alpina Direkt Auf Rost

Universal paint from the well-known company Caparol for decorating metal surfaces indoors and outdoors. Differs in ease of application and good resistance to fading.

Alpina Direkt Auf Rost

Alpina Direkt Auf Rost

"Nerzhamet"

Alkyd paint Stainless steel is available in the usual form and in aerosol cans. It contains polymer inclusions, is very easy to apply, dries quickly and adheres well to rusty surfaces, forming a hard semi-glossy film. Its service life without the need to renew the coverage is six years.

Anti-corrosion paint for metal

Anti-corrosion paint for metal

"Prestige". Primer-enamel

Another inexpensive domestic product, characterized by a high drying rate, high resistance to moisture and other aggressive media, and an economical consumption of a maximum of 120 grams per square meter. It is diluted with solvents such as xylene or P-4 to the desired consistency.

"Prestige". Primer-enamel

"Prestige". Primer-enamel

This paint is widely used for finishing galvanized metal roofs, external pipelines and fences.

"Stop rust"

Like most other alkyd enamels, this composition can be applied in any way. Available in packaging of different sizes: buckets, cans, aerosol cans. It is used to paint external structures made of steel and cast iron, including those with an old paintwork. It penetrates well into the decaying structure of the metal and blocks the spread of rust.

"Stop rust"

"Stop rust"

"Cycrol"

Even galvanized steel under the influence of precipitation, sunlight and corrosive impurities contained in the air corrodes over time. For its protection, a special 3-in-1 "Cycrol" product has been developed, which has high adhesion to such surfaces.

High-quality anticorrosive primer-enamel based on acrylic resins with polymer additives in organic solvents

High-quality anticorrosive primer-enamel based on acrylic resins with polymer additives in organic solvents

It contains acrylic resins, organic solvents and additives that increase the resistance of the enamel to wear, moisture, low temperatures, corrosion and other atmospheric influences. It is characterized by good hiding power, water repellency and the ability to dry quickly after application.

Rust paints and enamels

Rust paints and enamels

Anti-corrosion compounds for cars

Usually the car is coated with anti-corrosion compounds during the production phase. But it happens that some parts of the body rust under the influence of adverse weather conditions. In this case, anti-corrosion mixtures will come to the rescue.

They are of two types: in the form of an aerosol, for hard-to-reach places of the car, and applied with a brush. It is enough to lightly clean the area affected by corrosion in order to then apply a product that will create an even and smooth painted surface.

But you cannot use anti-corrosion mixtures for those parts that are heated to a temperature of more than 150 degrees. Here it is already better to entrust the work to specialists.

Of course, this is not a complete list of anti-corrosion paints used to prevent rust in metal structures. New formulations are being developed, already tested paints are being modified.

The choice is wide, therefore, with the correct use of anti-corrosion agents, metal structures and parts will serve for a long time and delight the eye with a beautiful appearance.

We also recommend reading:

Choosing the best paint for metal

Of all the dyes previously listed, hammer effect coatings have the highest performance in terms of basic quality criteria. In terms of external characteristics, the coating has similar features to rubber dyes, since both have a similar consistency. However, these materials have completely different compositions, and a different binder component was used for their manufacture.

In order to protect forged products from the effects of atmospheric agents, it is worth choosing the right paint for metal

The significant disadvantages of hammer paint include only the high price. Its use will be profitable only if a small surface is processed, because the application of this composition is accompanied by a high consumption. If, in financial terms, there are no restrictions, then it is hammer paint that can be considered as an ideal option for finishing metal surfaces in the open air.

Important! Hammer paints must be used in combination with the same brand of primer. Provided that this requirement is maintained, the service life of the coating will be at least 20 years.

Comparative characteristics of dyes

| Characteristic | Types of dyes | ||||

| Aerosol | Alkyd | Rubber | Powder | Molotkovaya | |

| UV resistant | 1 | 2 | 2 | 3 | 4 |

| Moisture resistance | 1 | 2 | 3 | 3 | 4 |

| Resistance to mechanical stress | 1 | 1 | 2 | 3 | 4 |

| Adhesion level | 1 | 2 | 2 | 3 | 4 |

| Price | 1 | 1 | 2 | 3 | 4 |

The table clearly shows the advantages and disadvantages of various types of dyes according to the main parameters, where 1 is the lowest and 4 is the highest.

Regardless of the type of paint chosen, the surface should be pre-cleaned from the top layer of rust and dirt

Popular paints for galvanized metal

Not every type of dye is suitable for finishing galvanized metal surfaces. That is why there is a separate category of materials designed for these purposes. Moreover, such paints are produced both in the form of a powder, which needs to be diluted, and in the form of a ready-made mixture. The composition, which does not require preliminary preparation, is packaged in cans, buckets and aerosol cans.

According to consumer reviews, Cycrol paint for galvanized metal is the most demanded in this category. Customers appreciate the ease of use and high quality of the coating on any application, including brush, roller and airless.

Zinccomet compositions are no less in demand, which are noted by users as easy-to-use dyes with optimal parameters and cost. The only drawback is the only limitation for application to coatings at low temperatures, but most users on the forums consider this nuance insignificant.

Due to its anti-corrosion properties, metal paint is able to protect the roof of a private house from negative external factors.

Basic colors are presented in a small number of shades, which, as a rule, include white, silver, black, brown and green.A separate place is reserved for anti-corrosion silver paint for metal, the price of which is more than affordable.

Possibilities of Hammerayt hammer paint for metal

Among hammer coatings, Hameright metal paints from the manufacturer Akzo Nobel are especially popular, which offers customers a lot of advantages:

- protection of metal surfaces from corrosion damage both indoors and outdoors;

- spectacular appearance is provided by an unusual texture and a variety of colors, including standard and exclusive shades;

- a high level of adhesion even over rust and maintaining an attractive appearance for at least 8 years;

- operating temperature range in the region from -20 to + 85 ° С.

A thin coat of hammer paint can be used to create an interesting effect on metal fittings.

Under the condition of a short exposure to high temperatures, the coating will retain its attractiveness (up to + 150 ° C). For at least 5 years, the finish will not undergo any changes in shade under the influence of UV. These and many other benefits have made Hammerayt so popular in the market.

The modern range of paints and varnishes offers hundreds of quality finishes. However, there is no universal composition. When choosing a finish, first of all, you should be guided by the type of material of the surface to be treated, the budgetary possibilities and the advantages that the dye can offer.

How Hammerayt paint is applied to a metal surface

Prior to application, surface treatment with a primer is optional. But if you want, you can do it. The effect of adhesion of paint to metal will only intensify. To do this, apply Hammerite No. 1 Anti-Rust.

If there are areas of well-adhered old paint on the surface, do the following. Apply Hameright to it in a test spot. Let dry for 30 minutes and inspect. If the coating is intact and even, then the composition of the previous paint allows you to apply a new one to it.

Hammerite coating colors

The composition is applied to the surface in the following main ways:

- paintbrush or roller;

- using paint spray in a special canister;

- using air spray (compressor with spray gun).

Consider the features of the application of each of the methods.

The first is with the use of a brush, when Hameright paint is applied on medium-sized surfaces and on objects with complex elements and shapes.

- Assess the viscosity of the paint before use. Generally no additional thinning is required. If it has thickened, it must be thinned. To do this, add 1 part Hammerite Brush Cleaner & Thinners to 9 parts of paint and mix thoroughly.

- Use good quality brushes made from natural bristles. This will ensure an even coating from the first pass. Do not use brushes, the fluff of which remains on the surface during the painting process.

- Dip your brush into Hammerite paint no more than half the size of your work surface. This will make it possible to use paint sparingly and without smudges.

Brushing Hammerite Paint

Move the brush preferably in one direction, overlapping each subsequent stroke by half with the previous one. This will ensure the uniformity of paint application. Be sure to carefully apply Hammerite to areas of the product to be painted, where access is inconvenient and difficult. This is your special focus area

It is imperative that the composition gets there in the required quantity. Otherwise, these untreated parts of the surface will become hotbeds of developing rust.

Painting is done in at least 2 and no more than 3 layers. Coating in one layer will not provide the desired effect.Applying more than 3 coats will result in unnecessary consumption of paint material. Painting vertical metal surfaces requires special attention. This is due to the fact that, being at such an angle, the applied paint can drain and form smudges. Continuously monitor the condition of previously applied layers. If necessary, without letting them dry out, immediately correct this area of the surface with a brush. Before applying the next layer, it is necessary to withstand a time of at least 3 hours for the previous one to dry. You shouldn't be in a hurry. This will destroy the previously applied coating.

Part painted with Hammerite paint

The second is using a roller. The basic requirements for the preparation of the paint composition remain the same as when using a paint brush.

The peculiarities include the method of dipping the roller into a special container for applying paint to its working surface. Do this evenly over the entire fleecy area. Performing such an operation will ensure the application of the Hamerayt composition evenly and without gaps.

Painting with a roller

The third is by air spraying. The paint composition is applied from an aerosol can or a compressor with a spray gun.

Large areas are painted with a compressor and spray gun. In this case, it is imperative to meet the requirements for the viscosity of the paint. It is necessary to prepare the composition in a ratio of 2 parts paint and 1 part Hammerite Brush Cleaner & Thinners. If this ratio is violated, the spraying process will be difficult or impossible. The thick compound will not spray normally from the spray gun nozzle. Excessively thinned will cause smudges or an unacceptably thin coating.

Paint application by air spray

The paint is applied in 3-4 layers with intervals between applications in 30 minutes.

Hammerayt paint for rust is a good solution for metal painting. It will provide time and labor savings in surface preparation, coating durability during operation.

Popular brands

- Enamel with the effect of embossing ML 165 is popular. Like all hammer compounds, it is distinguished by its strength and moisture resistance, and pronounced anti-corrosion properties. Feature - higher heat resistance. The maximum allowable operating temperature reaches 130 ° C. The composition is universal, has no restrictions on the type of surface and operating conditions. If you need to remove a layer of enamel of this brand, you can use xylene solvent.

- If it is necessary to obtain color, it is recommended to use EP-1323 ME enamel, which can be applied to rust. It allows you to prime and decorate surfaces. It is mainly used for applying on the surface of automotive elements, parts of forklifts (body), gates, fences. Compositions 648 and 667 are recognized as an effective solvent for the material.

- Among the enamels of the premium segment, it is worth noting the products of the Hammerite brand. It is distinguished by high resistance rates, which means that even rusty substrates can be painted.

If you are looking for an inexpensive composition, take a look at NC-221. However, it should be borne in mind that this is rather a decorative coating, it should not be applied over rust.

Indicators of moisture and heat resistance of the composition do not exceed similar values of conventional dyes for metal. Enamel "Prestige" has the same characteristics.

Hammer compositions for metal products have a different form of release, however, aerosol enamels are the most convenient for use. The leading manufacturer of such products is the Bosny brand. The highest quality paint and a convenient, economical, well-thought-out design of the spray can - this is what determines the demand for products.

It is important that the composition does not contain mercury and other toxic elements.

An interesting effect is provided by the Hammerite effect enamel aerosol.Painted bases acquire a pronounced pebbled effect, a noble matte shine

The composition is allowed to be applied over rusty substrates, however, if we are talking about a thick layer of loose rust, it is recommended to clean it off.

- If you need to apply a thin layer of enamel on uneven surfaces, products with many small details, choose products from the Italian manufacturer Maimeri Idea Spray. Thanks to high-quality spraying and a special concentration of enamel, good coverage and adhesion of the product are achieved.

- Dali 3in1 hammer enamel, reviews of which are mostly positive, is also suitable for application over rust, as well as on new and already painted surfaces. It does not require special preparation, even when used on surfaces made of colored, galvanized and stainless materials. Good hiding power and economical consumption help to simplify the painting process and reduce costs.

- The 3 in 1 formula (that is, high rheological performance, protective and decorative effect) is also characteristic of the Molotex composition. It is convenient that the product is produced in containers of different volumes; to achieve the strength of the layer, its thickness of 80 microns is sufficient.

Features of paint application

The first step is to choose a tool that will be used to paint. Traditionally, a brush, roller, spray gun, or spray cans are used. When choosing, you need to be guided by the type of surface, if the surface is flat, then a roller and a spray gun will do, if there are many complex transitions on it, then they resort to a brush. Small objects are painted with spray cans.

The first step is to choose a tool that will be used to paint.

Brush

The brush should be chosen with natural bristles, the application on the surface is carried out in 2-3 layers, the processing is especially careful on the curly elements, corners. In this case, the thickness of one layer should not be more than 100 microns.

The brush should be chosen with natural bristles; application on the surface is carried out in 2-3 layers.

Roller

A roller is best suited with a short nap made of wool or fur. Working with a roller allows you to quickly paint even surfaces, parts with corners, irregularities are better processed with a brush. The first coat should be applied using a solvent of the same brand for the paint.

A roller is best suited with a short nap made of wool or fur.

Spray gun

When choosing a spray gun, you need to have the skills to apply coloring compositions using it. The paint is diluted to obtain the desired viscosity, the surface must be smooth and clean.

Hammerite paint for metal the instructions describe the proportion of the addition of Brush Cleaner & Thinners, it is equal to 2/1. Dilution will provide the required viscosity.

When choosing a spray gun, you need to have the skills to apply coloring compositions using it.

Spray can

Before spraying, thoroughly shake the aerosol, apply from a distance of 15-20 centimeters, you need to make 3-4 layers, from the thinnest to the densest. The 2nd layer can be applied after 2-3 minutes, 3 and 4 after 15-20 minutes.

Before spraying, the aerosol is thoroughly shaken, the application is carried out from a distance of 15-20 centimeters.

Surface preparation

Before starting work, the surface should be cleaned or thoroughly wiped. For this, a variety of solvents, acetone or "white spirit" are used. The degree of readiness of the surface is easy to check if you run a sheet of thin paper over it - there should be no traces. If they are, cleaning should be repeated.

Sometimes a metal brush helps a lot, because by cleaning the surface with such a tool, you can significantly increase the adhesion coefficient. The substance adheres well to old paint and varnish material, which is not necessarily cleaned off to the base, it is enough to just remove the "burrs" with sandpaper.

Manufacturers

On the market for anti-corrosion paint for cars, there are several of the most popular brands:

Hammerite.Suitable for direct application to rust (ideally, you can clean the surface from the loose layer). That is, there is no need for a preliminary primer. The product converts the foci of corrosion into a water-repellent film. Thus, the paint acts as a topcoat, with the help of which the machine can be given the desired color - there are enough shades in the palette, among which there are probably the most popular;

Hammerite Rust Paint

Hammerite Rust Paint

"Special Forces". The product from this company will replace the primer, anticorrosive and ordinary enamel. The composition protects the car from mechanical and chemical influences, and also prevents water from getting on the metal, which prevents its oxidation and the formation of plaque. The versatility of the product is achieved through a combination of water and dirt-repellent properties, mechanical strength, anti-rust and decorative coating. It can be used both at the starting and at the finishing stage of the surface treatment of a rusty car. The manufacturer recommends applying it, first of all, to the fenders and the bottom of the car, which are most often in contact with the external environment;

Anti-corrosion paint "Spetsnaz"

Anti-corrosion paint "Spetsnaz"

"Nerzhamet". This paint is made on the basis of alkyd-type resins with the addition of polymers and organic solvents. Replaces primer, car enamel and anticorrosive agent. Suitable for use on both cleaned and unpolished rusty automotive surfaces. Suitable as a finishing decorative coating, as the product is presented in a wide range of colors;

Stainless steel aerosol - anticorrosive aerosol enamel in color

Stainless steel aerosol - anticorrosive aerosol enamel in color

- "Unicom". The product also belongs to special paint 3 in 1 and is a uralkyd enamel with priming properties. It protects the car surface not only from rust, but also from aggressive chemicals. Resistant to UV rays, fuel and grease, temperature extremes. It is operated in the temperature range from -60 to +60 degrees, and it can be applied at temperatures from +10 to +40 degrees. Product consumption is about 1 kg per 3-6 square meters. m. car surface in single layer application;

- "PF-132 Ferrocor". Can be used as a stand alone coating or base for coloring. Contains a corrosion modifier, has the properties of a soil and paintwork.

Peculiarities

The characteristics of the hammer coating may vary from manufacturer to manufacturer, but on average they look like this:

- density - 1 kg / l;

- diluted with white spirit solvent;

- the binder is an alkyd resin;

- the remainder on the surface - 48% of the volume;

- dries for at least two hours;

- each subsequent layer is applied after five hours;

- stored in containers for up to two years;

- resistance to temperatures up to 80 degrees Celsius;

- gloss level - 66;

- consumption - on average 1 liter per 9-10 square meters (one layer).

Main advantages:

- before processing with such a paint, the metal surface does not need to be thoroughly cleaned of rust;

- the coating layer tolerates vibration, atmospheric phenomena well;

- the coating effectively protects metals from rust;

- the treated surface does not require re-painting for up to ten years;

- the coating resists high temperatures, therefore such a paint and varnish material is often used to paint fireproof cabinets and bank safes;

- hammer substance does not contain toxins that have a detrimental effect on the human body;

- the coloring matter does not have repulsive pungent odors, it can be used even in those rooms where the airflow is not very good;

- rich variety of shades;

- a layer of hammer coating after application for a long time "keeps" the color and does not fade;

- dirt and dust will not stick to the painted surface.