Glass wallpaper adhesive Quelyd

Quelyd is another brand that sells both ready-made glue and dry mix for glass wallpapers. Packing of dry mix - 500 g, ready-made glue is sold in 5 and 10 kg (in plastic buckets).

The properties and features of Quelyd Glass Wallpaper or Quelyd Murale, as indicated by the manufacturer, are encouraging to buyers.

- In order for the finished mixture to be applied to the wall evenly and easily, chalk is added to the composition.

- Also in the composition there are fungicides that prevent the development of fungi and mold.

- Suitable for both manual and machine application.

- Swelling occurs within 15 minutes.

- Working properties are retained for about 10 days.

- Colorless after drying.

- Does not react with paints.

- Final drying takes about 48 hours.

- For greasing joints, it is recommended to purchase special Quelyd Raccord tubes to ensure reliable fixation when gluing the sheets "joint to joint".

The opinion of those who used such an adhesive mixture fully meets the declared characteristics.

Composition

As you know, the main component of any glue is starch. Modified starch is now being produced, which has greater properties than conventional starch. It has excellent adhesion resistance. To regulate the web during gluing, latex is added to the composition. In addition to starch and latex, antiseptic and fungicides are added to the glue to prevent mold and mildew. The concentration of these substances is small to cause harm to humans, but sufficient for high-quality pasting. Methylcellulose retains water. The composition includes enzymes for quick drying, and also imparts moisture resistance and frost resistance to the adhesive composition.

Technology of use

A relatively flat surface must be primed. Oscar has a range of primer mixes that you can use. After the wall has completely dried, a composition 1–1.5 mm thick is applied to the base (ceiling, wall, etc.) with a roller or a large wide brush. The area covered with glue should be slightly larger than the width of the canvas so that subsequent adjustments can be made directly on the surface. Further, like other wallpapers, the fiberglass is leveled with a spatula to remove excess glue under the canvas.

Experts recommend following these recommendations when using Oscar glue:

- for a stronger bond, the room temperature should be at least +10 degrees, but not more than +23 degrees;

- humidity should be less than 70%;

- during the pasting of surfaces, as well as the drying of the mixture, there should be no draft in the room;

- do not expose packaging and finishing to direct sunlight during drying;

- shelf life unopened up to 2 months.

- the glue dries completely after 2 hours. For subsequent staining, it is necessary to withstand a day.

How to glue fiberglass?

The technology is simple enough to be straightforward. Who knows how the wallpapering process takes place can easily figure out this operation. In order for the work to take place without delay, first prepare everything you need. This list includes:

- fiberglass in rolls;

- ready-made adhesive composition;

- a small container (cuvette) for it;

- brushes of different sizes;

- long-handled roller;

- stepladder (table);

- regular wide and plastic wallpaper spatula;

- painting knife, ruler;

- pencil (marker);

- cutter.

To prepare glue from a dry mixture, you will need a bucket, a drill with a mixer attachment, or a small wooden stick (narrow rail). In addition, they purchase in advance means for reliable protection against glass - glasses, gloves, a respirator.It is best to work with long sleeves.

Preparatory activities

They, as always, consist in the preliminary preparation of the surfaces.

- They are completely cleaned of the previous coating, then large defects, for example, cracks, are necessarily putty. Determine the necessity of the operation by checking their size. Such a test is done with a spatula: if the crack is wider than its blade, then it is necessary to fix it.

- When the spatula refuses to fit into the hole, no putty is needed. The surfaces are cleaned of dust, then the walls (ceilings) are primed with a deep penetration compound, or with glue, not too diluted with water. Waiting for the surfaces to dry.

- The bases are marked for the dimensions of the sheets, leaving a small allowance for overlapping joints. Use a pencil or marker. Rolls are unrolled with the seamy (rough) side up.

Then the elements for the ceiling and floor are carefully cut out of the fiberglass in accordance with the measurements taken. The size of the canvases can be arbitrary: the one with which it is more convenient to work. For walls, they can be cut to the full height at once, for ceilings there is a limitation: it is extremely difficult to handle segments exceeding 2 meters in length even with two people. On a horizontal surface, the canvases are placed along the room.

What are the features of this work?

How to glue fiberglass? This operation differs little from working with wallpaper. In the same way as in the case of conventional wall materials, drafts should not be allowed in the room. But the process itself is somewhat simpler due to the fact that the adhesive is spread directly on the bases.

- Glue is applied to a section of a wall or ceiling with a roller. In corners and other hard-to-reach places, brushes are used. A piece of cobweb is glued. To avoid the formation of bubbles, the surface is carefully ("herringbone") smoothed with a wallpaper spatula.

- The excess is cut off from the glued canvas, if any, then it is impregnated with glue again. Again, they are passed over the surface with a spatula to ensure good impregnation with the composition. The finished sheet should darken slightly.

- The adjacent piece is glued with an overlap, the overlap is from 30 to 40 mm. Then, at the junction of two canvases, a ruler (or a wide spatula) is applied, along which an incision is made through both layers. Excess tapes are removed, and the seam is again coated with glue.

- Do the same in the corners. The first sheet is bent 40-50 mm, the next - in the opposite direction. In the middle (in the corner), the fiberglass is cut, and then the strips are removed.

- Each new canvas and joints must be treated with glue. Its excess is removed with a spatula located almost at right angles. The surfaces are freed from excess adhesive with a soft cloth.

An additional layer of glue in this case acts as a primer, but the application of the original primer before the next operation is still required in most cases. After the surfaces have dried (but not earlier), you can proceed to further work, which depends on the chosen topcoat.

Not all surfaces are pasted over in this way, with the exception of drywall. In this case, the sheets of fiberglass are placed only end-to-end. The reason is the upper paper layer of the gypsum board, it is easy to damage it, and the defect will inevitably lead to cracking of the gypsum "filling". There is a way to avoid an emergency - blunt the tip of the blade against brick or concrete. Such a knife will not touch the cardboard, but it will calmly cut the fiberglass.

Adhesives for fiberglass

Before studying the topic of how to glue fiberglass, it is better to get acquainted with the features of adhesive mixtures for it.

Types of adhesive

Building materials stores sell 2 types of such compounds: ready-made, packaged in plastic buckets, and dry powders in paper bags.

- Ready-made glue (5, 10 l or larger). When buying it, you must check the date of manufacture on the container. Otherwise, you can purchase expired goods, and the result of the work will be the appearance of bubbles.Another potential nuisance is web flaking due to poorer adhesion. It is recommended to use open containers in the near future, since there is no guarantee that the composition will not lose its characteristics.

- Dry powder. This is a more practical option, since this type of glue costs less, but it allows dosed use - only in the right amount. Prepare the glue in strict accordance with the instructions on the package. Unless otherwise indicated, the powder is poured into warm water, stirring constantly. The prepared composition is kept for about 10-15 minutes, because it should swell. Then the glue is stirred again.

The third possible option is PVA, but with only one condition. The fiberglass has a rather low density, so the glue will soon turn yellow in the light. This color change will definitely affect the light finish. If the choice fell on PVA, it is better to choose paint in dark tones. However, special mixtures are better: they contain additional additives that give the material maximum strength.

Glass-breaking adhesives

Since fiberglass can be glued with the same compositions as fiberglass, the assortment for choice is wide enough. The most popular brands are mixtures of several manufacturers.

- Quelyd is a French brand. A large number of various adhesives for wallpaper, liquids for their removal, sealants and mastics are produced under it. The most popular product for glass fiber wallpapers is Optima.

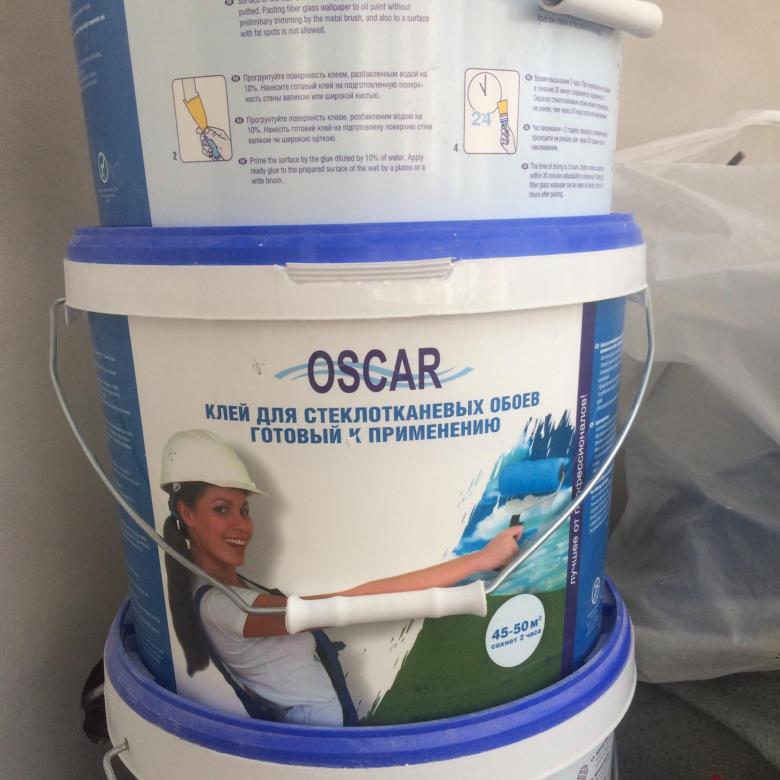

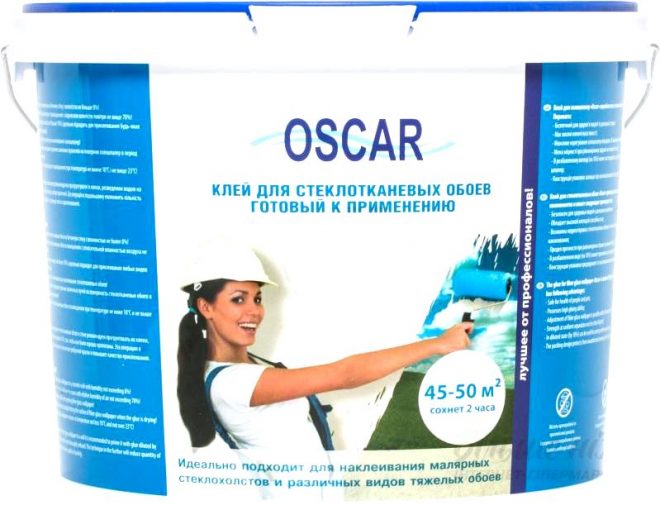

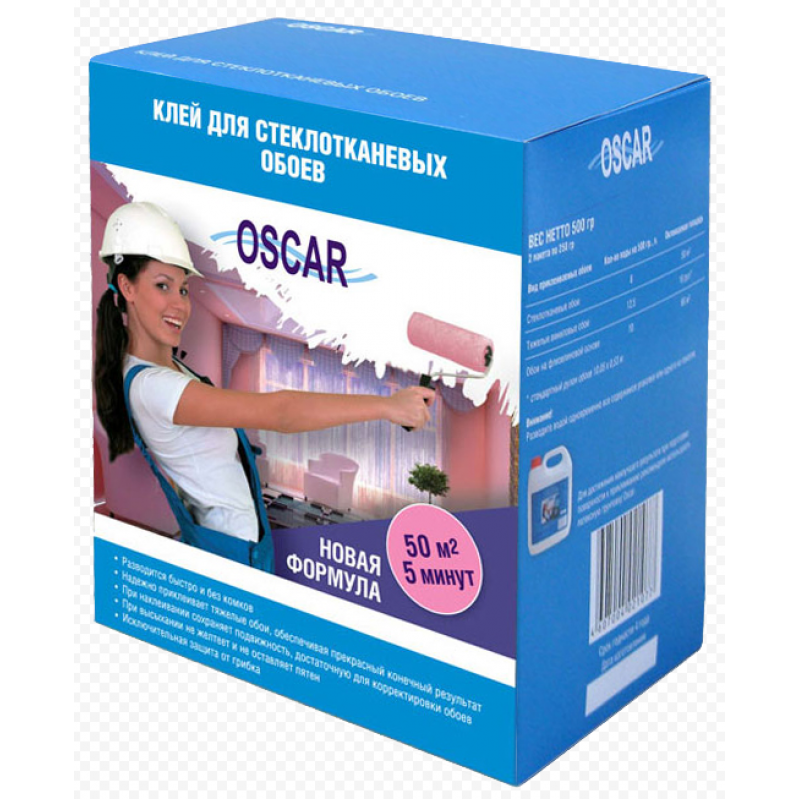

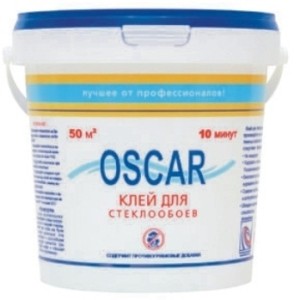

- Oscar is a Swedish brand, the compositions are produced in Russia. The adhesive, ready-made or dry, is characterized by minimal consumption and high strength. Additionally contains fungicides that prevent the formation of mold.

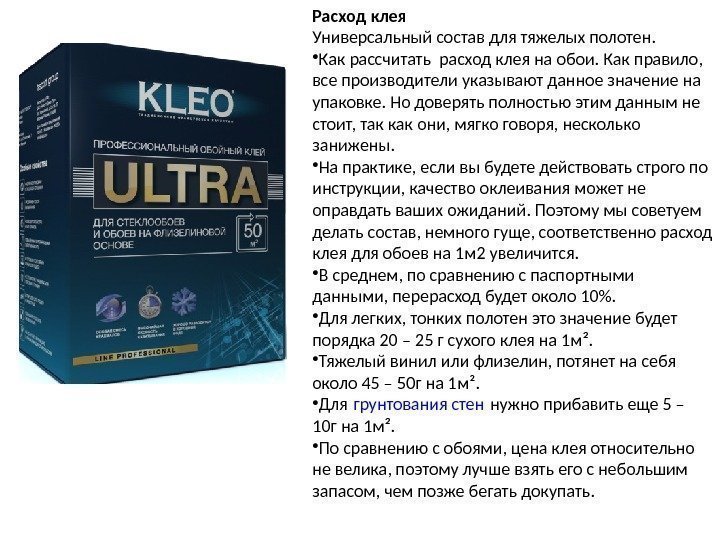

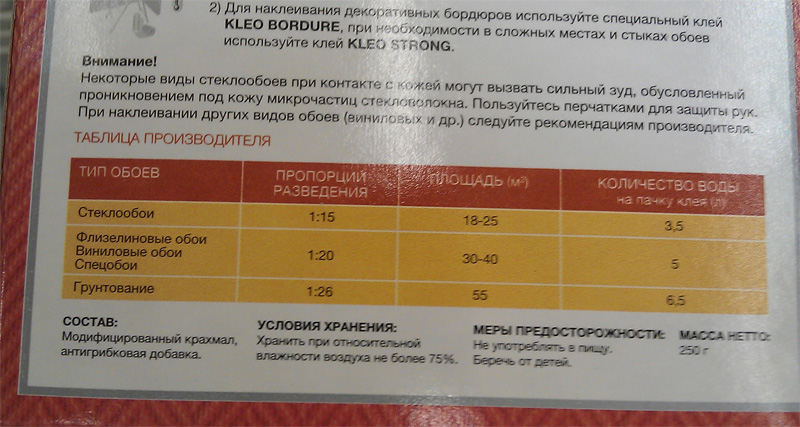

- Kleo is another Frenchman. This company specializes in the production of dry adhesives for glass fiber wallpaper and fiberglass. The products are distinguished by high quality, but reasonable price, quick preparation of the mixture, the same drying.

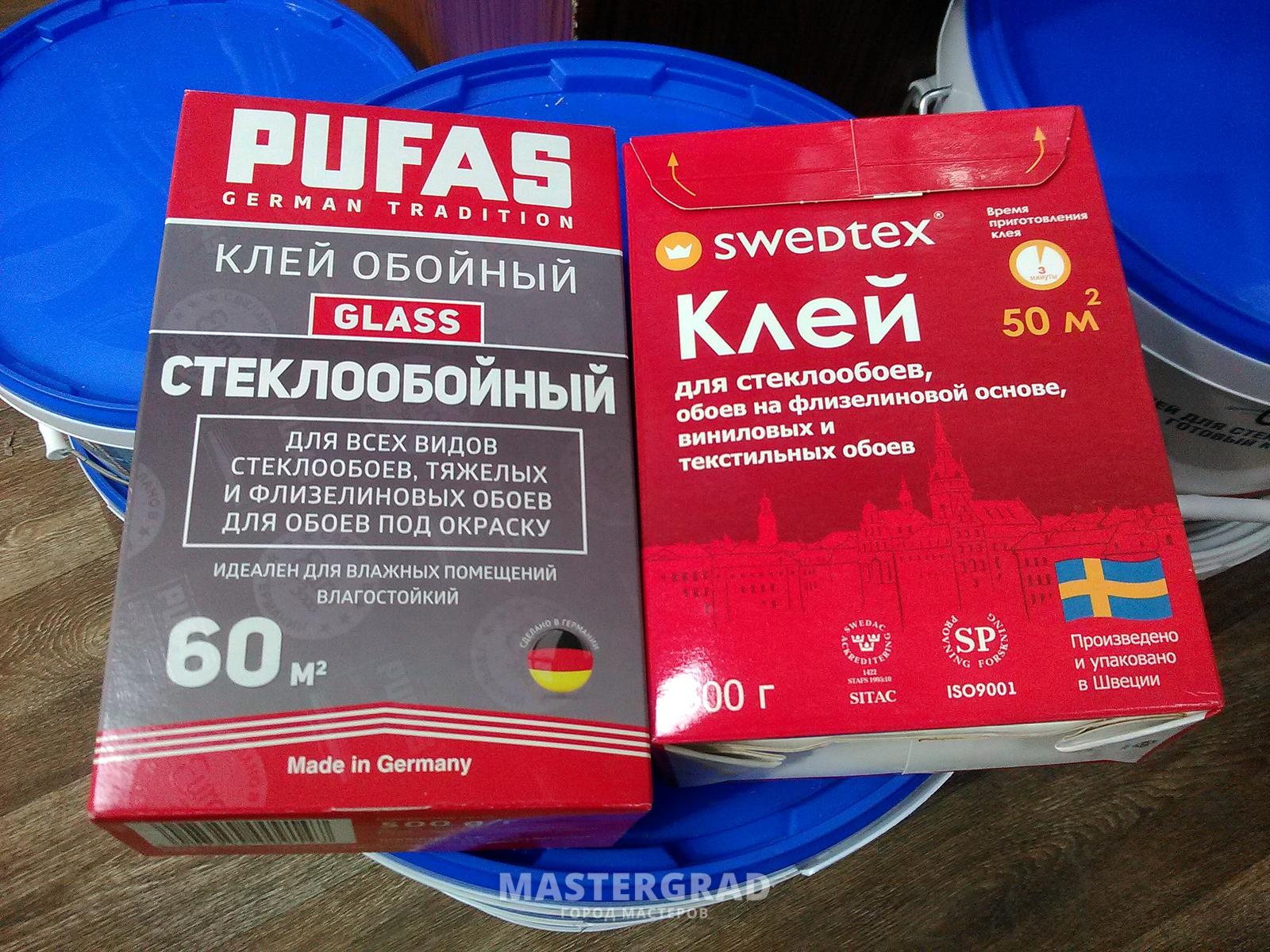

- Pufas is a German candidate for surface repair. The manufacturer produces paints and varnishes, adhesives, primers. The product for glass wallpaper is famous for its excellent adhesion properties.

- Bostik is another brand from France. The company produces various adhesives, but the best known is the parquet mix. Despite the low price, the adhesive mixtures for the canvas guarantee the reliability of the coating, easy joining of the canvases.

Other worthy contenders include products from Spektrum (Sweden), Nortex, Wellton, Bolars (Russia).

Popular alternative

There is a recipe for making a decent adhesive with your own hand. To do this, mix:

- 1 pack of regular (cheap) dry wallpaper glue;

- 1 kg PVA;

- 5 liters of warm water.

First, dry glue is mixed with water to obtain a homogeneous, lump-free composition. After that, PVA is poured in. This sequence avoids lumps of PVA and dry undiluted powder.

Adhesive selection

For fiberglass it is necessary to choose a suitable adhesive. Below are the requirements that apply to such adhesive mixtures, and companies that produce such products.

Types of mixtures

Two types of adhesive mixtures are used to apply fiberglass:

- dry;

- ready.

Finished products do not need to be prepared in advance - they are initially ready for use

However, when choosing such an adhesive solution, you need to pay attention to its shelf life. As a rule, it is indicated on the container in which the glue is located.

It is worth considering that an expired product can cause a lot of inconvenience during the pasting process, for example, it starts to bubble and flake off.

If the bucket is already open, it is recommended to use the glue as soon as possible. You always need to measure the amount of adhesive with the planned production of the product. For this, knowledge of the consumption rate of the adhesive mixture, which is indicated on the package, is useful.

Dry mixes are good because they can be prepared in the volumes that are needed at the moment.Such formulations should be prepared for work, strictly following the instructions. The recipes for the preparation of these adhesive mixtures are of the same type, however, there are options with some nuances that must be followed.

Many consumers are wondering whether it is possible to install fiberglass on the popular PVA glue. According to experts, this composition can be used when working with such finishing materials.

Composition requirements

A high-quality adhesive solution for fiberglass should contain a number of special components.

- plasticizer - it is this ingredient that makes the adhesive base elastic even after it has completely dried, so cracks and other damage do not appear on it;

- polyvinyl acetate is a special polymer that is known to most consumers as PVA, is a versatile adhesive that does not have toxic constituents and is suitable for many different substrates;

- fungicidal additives - these components prevent the destruction of materials applied during the repair process by bacteria;

- modified starch;

- bactericidal components.

Sometimes a special glue is included with the fiberglass. Such products can be used for finishing a wide variety of areas: a bathroom, kitchen, loggia or balcony, as well as other equally important places.

Glue - choose and not be mistaken

Composition

One type of glue for glass wallpaper

The classic mixture is not much different from the familiar paste, which was cooked at home in Soviet times. However, the main constituent element, starch, has undergone some changes.

Today, modified starch is used in production, which has increased adhesive qualities.

In addition, the mixture contains fungicides and an antiseptic, which prevent the formation of mold and the activity of biological parasites.

Some mixes contain chemical additives that reduce drying time and increase swelling rate.

More expensive glue for fiberglass differs only in the rate of swelling in water, the main element, starch, is the same for everyone.

Classification

Ready glue

On the construction market, you can now find many different options for glue, but not all of them are suitable for pasting walls with fiberglass.

Due to their characteristics, fiberglass weighs a lot and will not stick to the surface with a paper finishing compound.

Suitable formulations:

- Universal. It can be used for all kinds of roll-to-roll finishing materials, it is tough enough to hold the glass wallpaper on the walls.

However, it is not recommended to use it for pasting the ceiling. Purchase Oscar special glass wallpaper glue. - Heavy. Used for pasting surfaces with textured, photo and textile fabrics.

They are based on PVA, which has high adhesive properties and reliably adheres the canvas to the surface. - Dispersive. This variety is intended for textiles and fiberglass.

Such a composition is characterized by increased strength, therefore, when removing the finish, the use of special removers will be required.

Pay attention to the content of various chemical additives. For fiberglass, formulations with additives that increase moisture resistance and reduce the drying time of the adhesive layer are suitable

Release form and types

|

Release form |

|

|

Dry mix |

Ready mix |

|

Dry Oscar, 800 g (bucket) |

Ready Oscar, 10 kg (bucket) |

|

Dry Oscar, 400 g (bucket) |

|

|

Dry Oscar, 400 g (pack) |

Ready Oscar, 5 kg (bucket) |

|

Dry Oscar, 200 g (pack) |

The dry mixture is diluted with water and turns into a ready-made mixture within 5 minutes, while no lumps are formed. For mixing large volumes, a mixer or drill with a special attachment is usually used. A pack of 400 grams is designed for 50 squares of fiberglass.

The dry mix is cheaper than the ready-made mix, therefore it is more popular even among professionals.Dry Oscar is considered quite economical, 200 grams of glue requires 5 liters of water, 400 grams - 11 liters, 800 grams - 22 liters. It is necessary to pour the powder into the water while stirring. Pouring water into a dry mixture is prohibited due to technical indicators.

The ready-made mixture is intended for fiberglass wallpaper or for conventional heavy non-woven wallpaper. For gluing the latter, the solution must be diluted with water to create a less thick consistency. The consumption of ready-made glue is 1 kg per 5 m² of "cobweb".

Instructions for use

A person interested in quality learns the rules for the preparation of the mixture and the application of the adhesive composition. Before starting work, prepares tools:

- A container in which the required amount of glue is diluted.

- Roller or wide brush for applying the composition.

- Wooden spatula.

- A clean rag to wipe off excess glue.

- Spatulas: wide metal - for leveling the surface before pasting, and plastic - for smoothing glued glass wallpaper.

- A utility knife to cut off any leftover wallpaper.

- Convenient step-ladder.

Important! Work with Oscar glue in protective gloves

Preparing the walls

Before applying the ready-made adhesive, the surface:

- thoroughly cleaned with water from dirt, dust;

- remove the remnants of old wallpaper, peeling plaster, whitewash;

- cracks, seams, irregularities are cleaned with sandpaper;

- a shiny smooth surface is brought to a matte state;

- align the walls using gypsum plaster, then putty and polish them.

Finally, the walls or ceiling are primed with diluted Oscar wallpaper glue or latex primer. The procedure fixes weak, chalky or crumbling substrates. After applying the primer, the wall or ceiling is allowed to dry for about 2 hours.

Preparation of the composition

Prepare a working mixture as follows:

- The required amount of cold clean water is poured into a clean plastic container.

- Stirring continuously, in a thin stream, a dry composition is poured into the center of the funnel formed during stirring.

- Leave the glue mixture to swell.

- Stir again after 5-10 minutes until a homogeneous thick mass is formed.

Proceed to pasting the surface with fiberglass or fiberglass.

On a note! If a ready-made adhesive mixture is used for work, the composition must also be mixed before gluing the surfaces.

Glue application

"Oscar" is applied with a roller or a wide brush, evenly spreading over the surface to be decorated, wall, ceiling. Make sure that the adhesive layer is:

- sufficiently thick (at least 0.5 mm);

- wider than the sheet to be glued.

The glass fabric is glued to the surface immediately after application and distribution of the composition. After that, within 20 minutes, you can correct the position of the canvas on the wall or ceiling. The canvases are leveled using a spatula from the middle of the strip to the edges in a herringbone motion. Glass fiber has a porous structure, so the glue "seeps" through the canvas. The leaked excess is evenly distributed over the canvas with a clean cloth. Fiberglass is glued end-to-end.

Prerequisites for gluing fiberglass:

- The room should not be too humid.

- The work is carried out at temperatures from +10 to +23 degrees.

- Do not allow drafts.

- Protect the surface from direct sunlight until the Oscar glue dries.

On a note! If the glass cloth is glued for further staining, then before starting painting work, wait at least 3 days for the glue to dry out.

Popular manufacturers

Currently, the market for building and finishing materials has a large number of large and well-known manufacturing companies that produce high-quality and popular products. Below are the most popular brands offering modern consumers durable and practical adhesive mixtures for fiberglass.

Quelyd is a renowned French brand that produces high quality adhesive mixes that form a universal joint called BluTack. This substance has many functions and allows different materials to reliably adhere.

The assortment of this large manufacturer contains different types of adhesives designed for various wallpapers, as well as sealants, cloth removers, mastics, bleaching and protective complexes and gypsum putties.

The most popular today are adhesive mixtures for glass wallpaper from the Optima line, which are sold in a plastic container of 15 liters and have a low consumption per 1 m2. These types of glue can be used in damp rooms. In addition, Quelyd products contain bactericidal and fungicidal components.

The time for complete drying of such glue is 24-48 hours. Coloring of the finished base can be done after a day. Quelyd adhesive can be applied both by hand (with a roller) and by machine.

The renowned Oskar brand produces high quality adhesives (dry and ready-made) for the application of fiberglass. The products of this popular manufacturer are famous for their performance characteristics, low consumption and high adhesive properties.

Many consumers opt for Oskar adhesives, as they are safe and harmless - they do not contain hazardous chemicals. Branded products meet all sanitary requirements. In addition, Oskar adhesives prevent mildew and mildew from forming under decorative surfaces.

Pufas is another popular and large brand from Europe with a representative office in Russia. The products of this manufacturer are manufactured using the latest technologies. The Pufas assortment is very rich and varied - it is represented by various types of paints and varnishes, primers and adhesives.

Pufas ready-made fiberglass adhesive is in great demand as it is relatively inexpensive and has excellent adhesive properties. Such products of the German brand are completely ready for use. As a rule, they contain antifungal components. Also, Pufas adhesive mixtures for glass fiber wallpaper are not afraid of frost and temperature extremes.

The international Bostik network offers high-quality adhesive mixtures for working with fiberglass at the choice of consumers. Many of them contain binders such as PVA and starch. It is recommended to apply them on certain bases with a roller or a special brush. Such mixtures acquire full strength after 7 days.

It is recommended to apply Bostik glass mat adhesive to substrates in dry rooms. On such coatings, you can lay not only fiberglass, but also various types of fabrics, as well as paper and vinyl wallpaper.

Kleo is another well-known manufacturer from France that produces dry adhesives for glass fiber installation. The products of this brand are distinguished by reliability, drying in a short time, affordable cost and ease of preparation at home.

Kleo adhesive mixtures remain transparent after drying. They can be divorced easily and quickly without forming hard lumps. There are no dangerous and harmful substances in their content, therefore, such compositions can be safely called absolutely safe for both people and animals. In the finished state, Kleo glass fiber glue can be stored for up to 10 days.

What should you choose?

Which is better - Oscar or Kelid, Pufas or Cleo? On this issue, the opinions of professionals differ. However, they all agree on one thing - these brands are definitely better than the rest. As can be seen from the review of adhesive mixtures for well-known brands, the difference in their properties is almost imperceptible, therefore, the question of choosing between them is more a matter of taste than performance and ease of use.But in addition to the brands described, a wide variety of products of this type are presented in the markets and in stores.

Sometimes in the markets you can find, according to the assurances of sellers, "super-quality glue" from America or Europe without any translation. To buy a mixture suitable specifically for fiberglass or fiberglass, you can focus on the marking.

Designations of polymer adhesives in different languages:

- in English (EN) - dispersion adhesive;

- in German (DE) - dispersionsklebstoff;

- in French (FR) - adhésif en dispersion.

If there is such a mark, the purchase can be made. Another point affecting the choice of glue is its consumption.

It is important to know this parameter in order to calculate how many buckets / packs you need to buy.

Fiberglass and finishing

The fiberglass cloths take a day to dry. After that, they move on to putty. Sometimes this stage is skipped: walls or ceilings are painted immediately. In this case, the painted surface will have an interesting "spider-like structure".

If the owners do not set such a goal, then leveling with a finishing putty is mandatory. It is recommended to apply two thin layers - from 1.5 to 2 mm. Each of them should dry for 12 hours. Then the surfaces are sanded, primed, guaranteeing the reliability of the base and better adhesion, which means less material consumption.

The last stage is painting or wallpapering. In the second case, putty is also required, since heavy materials - vinyl, non-woven - do not really like such a surface. They do not hold well on it. The second reason is the overconsumption of wallpaper glue due to the high absorption of moisture by reinforced bases.