How to make EDC glue with your own hands

For gluing plastic with dichloroethane, you can prepare the glue yourself. To do this, you need to complete several steps according to the instructions below:

- For the substance, a glass container is taken with the possibility of a hermetic closure, this is required due to its rapid evaporation.

- Plastic shavings are added to the substance, or finely chopped plastic elements, they must be immersed in the solution as a whole.

- After the container is closed tightly, it is removed to a dark place so that ultraviolet light does not fall on it, the place should be inaccessible to children.

- When the plastic material is completely dissolved in the liquid, the resulting solution can be used.

The amount of plastic depends on the desired thickness of the resulting glue, the more of it, the thicker the mass will be. You can also use plexiglass, the ratio should be 1:10.

Before use, the product is checked on a small piece of material that will stick together.

Before use, the product is checked on a small piece of material that will stick together.

Adhesive self-adhesive films

Self-adhesive tapes are a good alternative for repairing plexiglass products. Their undoubted advantage is the ability to glue both two plexiglass parts and plexiglass with other materials.

There are three main types of such films on the market:

- Baseless adhesive films. In fact, it is a thin layer of adhesive several tens of microns thick. It is stored between two transport polyethylene films, which are removed just before gluing. Such adhesive films can bond smooth, perfectly flat parts with a low coefficient of thermal expansion.

- Films with a thin transparent base, several hundredths of a millimeter thick. Also requires a smooth surface, but the requirements are somewhat lower. The connection turns out to be less strong and theoretically detachable - you can try to remove the film.

- Films with a thin foamed base, similar to the so-called double-sided tape. The base thickness ranges from tenths to several millimeters. Plexiglass can be glued with such films, even if the surfaces are not very even, but the bond strength is very low. Suitable for structures that are not subject to heavy loads.

Adhesive tape

Requirements for surface preparation and the maximum loads that the joint can withstand are specified in the manual enclosed with the specific film.

How to glue plexiglass to metal and wood

Than you can glue plexiglass to metal and wood, for this purpose you can choose Moment glue, liquid nails and Glue88. "Moment" known to many is capable of gluing plexiglass, both with wood and with metal. Coupling is fast, so the location of the parts must be correctly positioned immediately.

"Moment" known to many is capable of gluing plexiglass, both with wood and with metal.

Glue88 is universal and can be applied to different materials. Unlike the previous type, it makes it possible to adjust the position of materials after installing them end-to-end. Creates a secure grip.

Glue 88 is universal, it can be used for different materials.

Liquid nails are the most reliable option among those presented. They stand out for their fast setting, can be used for thick plexiglas, for a firm setting you need to wait 24 hours.

They stand out for their fast setting, can be used for thick plexiglas.

The better to glue plexiglass

Both for repairing broken parts and for assembling new products, a suitable adhesive should be used.

How to glue plexiglass:

Specialized compounds for gluing plexiglass are of two types:

- Compositions based on acrylic fillers and strong organic solvents. In composition, they are very close to the substance of plexiglass, which makes it possible to obtain a homogeneous and sufficiently strong connection.

- Epoxy based adhesives are great for filling and repairing cracks, the joint takes a long time to harden, but the epoxy can bond tightly.

In addition, plexiglass can be dissolved, which means it can be glued with strong acids:

- acetic;

- formic;

- some others.

It will not be possible to glue the plexiglass with food vinegar (acetic acid with a concentration of 7-9%), you will need at least 70% vinegar essence. Acetic acid does not dissolve the entire surface layer of the material, but only softens it, so the parts will have to be strongly compressed and held for a long time.

Security measures

Regardless of what kind of adhesive and in what amount is supposed to be used, it is necessary to understand that all means intended for this have high chemical activity and are harmful to humans with prolonged contact.

It is recommended to carry out all work related to the bonding process in the fresh air or in well-ventilated rooms. In any case, goggles, rubber gloves, a respirator or a normal medical mask should be used. If the adhesives come in contact with the skin, rinse the area with water as quickly as possible.

Varieties and properties of adhesives based on dichloroethane

Adhesive for EDC plastic has several types, they differ in their properties, in order to choose the right option for a particular material, the characteristics of each should be studied. Then it will be easier to decide which of them is best suited for a specific purpose, and the result will be optimal.

EDC plastic adhesive has several types, they differ in their properties.

EDC plastic adhesive has several types, they differ in their properties.

Liquid

The liquid form is prepared using water and thinner. During the setting process, the solvent dichloroethane evaporates, and the glue layer hardens, and reliable adhesion is obtained. Can be used on porous surfaces: fabric, wood, plastic. It is not able to adhere sealed materials, it hardens on them.

Can be used on porous surfaces: fabric, wood, plastic.

Can be used on porous surfaces: fabric, wood, plastic.

Contact

This type in the composition may contain a hardener, it can be made without it. It is applied to both parts, they wait a little for seizure to occur, then the parts are pressed against each other to ensure better fixation, a weighting agent is applied on top.

Complete solidification occurs after 24 hours.

Complete solidification occurs after 24 hours.

Hot glue

Before gluing the plastic with hot-melt dichloroethane, it is heated. Under the influence of temperatures, the substance becomes liquid, then cools down again and becomes hard. Designed for gluing large items.

Designed for gluing large items.

Designed for gluing large items.

Reactionary

It happens one and two-component

The gluing process takes place in a matter of seconds, therefore it is important to connect the parts immediately in the correct position. You can use a one-component composition right away, a two-component one must first be diluted with water

The gluing process takes place in a matter of seconds, therefore it is important to connect the parts immediately in the correct position.

Adhesive self-adhesive films

When the question arises of how to glue the plexiglass tightly, the master can use good glue, also a homemade adhesive, or use a self-adhesive film. The main advantage of such a connecting device is the ability to glue the same and different materials. Three types of films can be found on the market:

- Material without base. It is a film with a thickness of less than 1 mm. Before gluing the working surfaces, the protective sheets used during transportation are removed from it. Suitable for joining perfectly flat surfaces.

- Films with a thin base. The base reaches several hundredths of a mm. It is transparent, visually does not stand out after connection. Requirements for a flat surface are slightly lower than those of the previous material.

- Foam base film. It is a thin double-sided tape that is sold in large rolls. Any surfaces can be glued with such a film, however, the bond strength is low due to the foamed base.

How to glue plexiglass at home

When it is not possible to buy a specialized composition, but glue plexiglass at home you need, you can use the means at hand. When working with homemade compounds, you need to know the safety rules so as not to harm yourself, to preserve the integrity of the material.

The composition of plexiglass, what is it

Another name for the material is plexiglass, acrylite or metaplex. It is a synthetic polymer based on acrylate resin. Plexiglass is only conventionally called glass, in fact, it is a hot-melt transparent plastic and has the following characteristics:

- Lower density compared to ordinary glass (almost twice).

- Scratch sensitivity.

- Easy to process.

- High impact resistance.

- The ability to transmit UV rays.

- Resistant to moisture, bacteria and fungal deposits.

- Environmental friendliness.

- Melts at temperatures above 100˚С.

It is used in the following industries:

- Contact lens manufacturing.

- Lighting devices (shades, diffusers, lampshades).

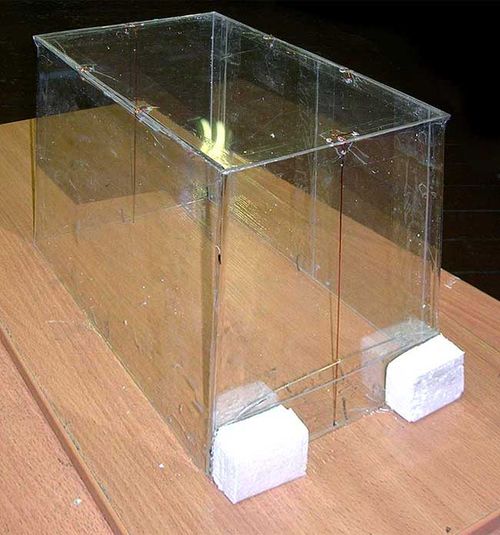

- Aquarium equipment.

- Showcases, transparent fences.

- Shower screens, bathtubs.

- Transparent inserts in interior doors.

- Cabinet doors, coffee tables, computer tables.

How to glue plexiglass: types and brands of the best products

If you do not have reliable information about the type of polymer, we will select an adhesive for plexiglass with the expectation that it is really PMMA. In principle, if you have already dealt with gluing plastic, then there will be no intrigue in the question of how to glue plexiglass for you: the guarantee of the strength of the seam is still in solvents.

A small educational program for those who have not previously dealt with gluing plastics: the most reliable option for gluing polymers is to dissolve the edges to be glued to a viscous state using solvents and dock them until they dry. Thus, the product is essentially monolithic, and the seam holds even when the product begins to crack and break in other places.

How to glue plexiglass so that you are pleased with the result? There are several options here.

Factory glue

Of course, the most convenient formulations for working with plexiglass are various types of factory glue. Indeed, why look for something to glue plexiglass, and invent something when everything has already been invented for us?

- Artifix is a reactive adhesive, which is currently considered the highest quality and most convenient when working with plexiglass. The seam obtained with its help is strong, transparent and durable, and the toxicity is lower than the toxicity of solvents if there is no dichloroethane in the composition (there are variations without its addition). True, it is better to use this glue for plexiglass if you have a small production: it is not very profitable to lay out about 6-8 thousand rubles per liter package to glue the model. The most commonly used numbers are 116, 117, 106 and 190, depending on the degree of viscosity you want.

- Colacril is a slightly more budgetary replacement for the previous glue, but judging by the reviews, Artifix cannot be outdone. The most commonly used numbers are 20 and 30. Different numbers can be mixed to obtain the desired viscosity.

- Cosmofen for acrylic glass is a cyanoacrylate-based superglue, also called liquid plastic. That is, a monolithic connection will be obtained only if the acrylic of the glue matches the acrylic from which the plexiglass is produced. Most often it is used when working with plastic windows: there it fits perfectly.In other cases, you will still get a pretty strong and durable seam, and for not the most money. Please note that Cosmofen may require UV curing!

Solvents

You can make your own glue with a completely identical polymer, and this can be done using solvents. Yes, it will set a little slower, but the result will not be worse!

- How to make the perfect glue at home? Dissolve some of your plexiglass shavings in dichloroethane! Yes, the substance is quite toxic and it is better to work with it in the fresh air, but the parts will stick to each other just tightly!

- If EDC is not found, you can look for tetrohydrofuran. Depending on the nuances of the composition, it glues some types of plexiglass even better than the famous dichloroethane.

- In desperate situations, you can glue the pieces together with formic acid, glacial acetic acid, or even ordinary vinegar essence. Not with table vinegar, but with concentrate.

In general, you can glue the parts without diluting the chips - if you apply a solvent to both parts, connect them and fix them until dry, the seam will again turn out to be monolithic.

Contact adhesive

What about the other options? There are a lot of other types of glue, which, no, no, yes, they will advise on some resource. Unfortunately, you shouldn't count on a really high-quality seam and gluing "for centuries" with them, and that's why.

- Sometimes epoxy resin is recommended for gluing plexiglass, because it really holds the joint well, and even completely transparent. But it just connects the two parts of the plexiglass, without turning them into a monolith.

- Adhesives like "Super Moment" do not change the structure of the material and create a very fragile seam: they can only be used for gluing together the elements of the product, which is practically unloaded. In addition, when using them, the plexiglass becomes cloudy and the seam becomes very noticeable.

- The usual "Moment" and similar compositions will not last long either: they can only glue what you are not going to actively use, and that will hold up mediocre.

How to glue plexiglass, which adhesives are suitable

Before you start gluing plexiglass, you need to understand the features of the material. Depending on the type, the cooking process includes casting or extrusion. It is a synthetic material that is made from acrylic resins by adding a number of other elements to it. The result is a reliable, durable and transparent material. But, despite the high indicators of strength, objects from it can break, due to active use. Therefore, it is worth knowing the better to glue the acrylic.

Plexiglass is a synthetic material that is obtained from acrylic resins, adding a number of other elements to it.

Plexiglass is a synthetic material that is obtained from acrylic resins, adding a number of other elements to it.

Types and brands of glue

The glue for acrylic glass is chosen based on the needs of the master. There are 2 types of adhesive solutions for gluing plexiglass:

- Mixtures of acrylic with thinner. Suitable for professionals. The composition acts on the material, as a result, the top layer melts and a strong connection of the parts occurs. However, this view is intended only for certain types of material;

- Two-component composition based on epoxy or cyanoacrylate. Helps to glue individual elements, can be used for gluing small items.

If the work is carried out at home, you can choose how to glue the plexiglass from 2 options for the principle of operation:

- Active substances, the principle of their work is to melt plexiglass. And the connection is performed at the moment of its liquid state, they help to glue the parts tightly;

- Adhesives that create a film between parts, this method does not provide as high reliability as the previous one.

The glue for acrylic glass is chosen based on the needs of the master.

The glue for acrylic glass is chosen based on the needs of the master.

Plexiglass can be glued with products of the following brands:

-

Glue "Sekunda" is a two-component solution, components are produced in syringes, before work they must be mixed together. Differs in fast setting and viscosity, it can fill cracks, it does not spread, the composition will not be visible. Withstands exposure to water, acetone, gasoline, oils;

-

Rexant glue dichloroethane, produced in China. It has a transparent consistency, dissolves the material on which the parts are then glued. Does not require preliminary degreasing of the surface, withstands the influence of water, does not change the color of the material;

-

ACRIFIX 1S 0116, when joining, it is not necessary to squeeze the elements to be glued, viscous, cannot cope with filling the entire depth of the crack, air may remain inside the product. The initial setting occurs in a minute and a half;

-

Sika Sikaflex-295 UV is a mastic used for the assembly of acrylate glazing. Cures when exposed to ambient humidity and is used as a sealant for sealing imperfections in maritime transport.

What glue to glue plexiglass at home

Consider several options for glue for reliable bonding of organic glass parts:

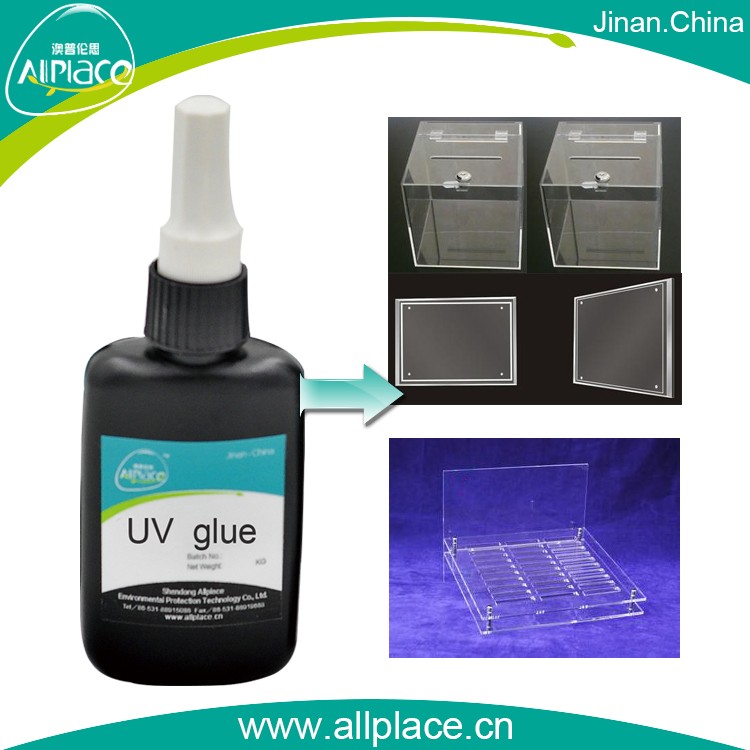

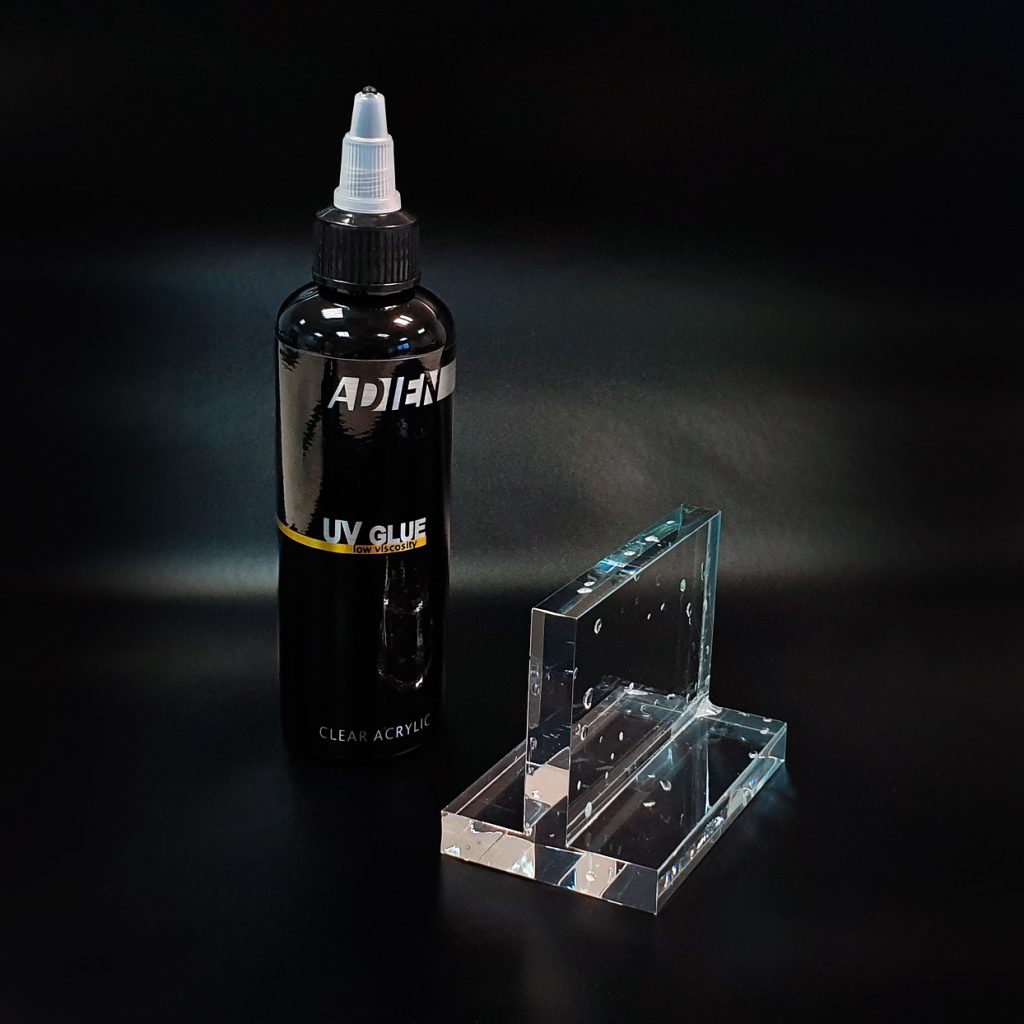

UV glue for plexiglass and plastics is one of the latest developments in the chemical industry.

This is a special group of one-component glue that hardens when exposed to ultraviolet radiation (sunlight or UV lamp).

It is a transparent liquid of low viscosity.

Time for fitting and precise assembly of the joint will be sufficient, since the adhesive will not cure without UV irradiation.

For gluing plexiglass, UV glue of the brands SM 301, Kafuter K-303, 3M UV-301, etc. is suitable.

The only drawback of UV glue is the high price.

ACRIFIX 116 (117) is a specialized one-component adhesive.

This transparent plexiglass adhesive does not harden under the influence of ultraviolet radiation, but due to the evaporation and absorption of the solvents included in the adhesive on the surfaces of the parts to be joined. Acrifix 117 is a low viscosity formulation, 116 is a more viscous formulation.

Cosmofen PMMA glue is a transparent one-component adhesive designed for fast structural bonding of acrylic parts.

It is enough to clean and degrease the surfaces to be glued, apply a thin layer of glue to them and bond tightly for 45 seconds.

Cosmofen PMMA is characterized by excellent temperature stability and is completely unaffected by UV rays.

Seconds glue moment and Cosmofen can glue plexiglass

There are two well-known adhesives that can be purchased at any hardware store or hardware store. Both names are similar in their action, since they contain cyanoacrylate. They have a number of strengths, and of course weaknesses. Use as a last resort.

Advantages:

- Low cost.

- Availability.

- Ease of use.

Disadvantages:

- Low strength index.

- The seams turn white after drying, which degrades the appearance of the transparent garment.

It is recommended to use these types of adhesives when gluing Plexiglas products that will not be subjected to stress.

DIY plexiglass glue

Above, this process was described a little. So, in order to repair sheet materials, you can make an adhesive composition with your own hands. If a novice master does not know what kind of glue to glue plexiglass, this option is considered one of the best.

To make a homemade product, you need to prepare consumables:

- Plexiglass sawdust.

- Dichloroethane.

- Organic solvent.

Mix solvent with dichloroethane in one container. While stirring the solution with a metal wire, sprinkle with small portions of Plexiglass sawdust. Their number is set depending on the required consistency. You can do it by eye, nothing terrible will happen.

What is the glue for plexiglass

Plexiglass glue is chosen depending on the wishes of the consumer himself.

new one-component Wiko Plexy adhesive for plexiglass (plexiglass)

There are two types of glue used to repair, restore the integrity of products:

An adhesive mixture of acrylic with a solvent, used for extrusive (cast) acrylic (it is also plexiglass, plexiglass). Professional glue. During the connection of two identical components under the influence of the third active substance, a strong connection of the bases occurs due to the dissolution of the surface molecular layer of plexiglass. The gluing is monolithic. There are some nuances. Although this group is intended directly for bonding plexiglass (plexiglass), not all adhesives in this group will be able to bond all types of these materials.

This is very important, there are exceptions, so you need to be careful when choosing a composition for certain brands of PLEXIGLAS, which is the general name of the trademark.

Two-component adhesive based on epoxy resin or cyanoacrylate. With their help, you can quickly glue individual parts

Suitable in some cases, and can be used for a small area of work.

Household adhesives for joining plexiglass are divided into two groups according to the principle of action:

- The former include active substances that are applied to the joints before gluing. The surfaces are melted. The master glues them while the material is liquid. After drying, a monolithic seam is formed.

- Compositions forming a connecting layer between the individual parts. A less durable seam is formed than during the melting of the surfaces to be joined.

In order not to be mistaken during the selection, it is necessary to consider the most popular products for gluing plexiglass.

new two-component adhesive Wiko Dual Glue for plexiglass (plexiglass)

Acrifix 116 glue

Acrilfix plexiglass adhesive, which produces high-quality substances that are used when joining various materials. Product 116 is a transparent formulation, a thick mixture (more viscous than Acrifix 117), which is similar in consistency to a flowing resin. Packaged in 100 ml tubes.

Used for gluing rough parts with uneven edges. Effectively fills in the voids caused by chips, creates a homogeneous surface. One component adhesive. It hardens by evaporation and absorption of solvents by the parts to be joined.

Acrifix 117

If a person does not know how to glue plexiglass, any experienced craftsman will call him Acrilfix 117 glue. This mixture is considered the best for gluing acrylic-based materials. He has a number of strengths and weaknesses.

Advantages:

- High strength of the finished seam.

- Dries quickly.

- The lowest level of toxicity compared to analogues.

- Long shelf life.

- Penetrates small cracks, fills them to the ground.

- The transparent seam is practically invisible on the total area of the glued surface.

Disadvantages:

- Very high price.

- Rarely comes across on the shelves of hardware stores.

- It is impossible to buy a small capacity. The standard package size is 1 liter.

Experienced craftsmen recommend mixing Acrilfix 117 with 116 (10/1) in order to reduce the consumption of expensive glue. In addition to this, the mixture better fills the voids of microcracks. The quality of the seams does not deteriorate.

Colacril 20 glue

When gluing plexiglass, craftsmen often use Colacril products. It costs less than Acrilfix, however, its properties are close to expensive mixtures. Item 20 is a flowable adhesive that can be used to make transparent, strong, durable seams. Similar in its actions to the previous brand, but cheaper.

Colacril 30

It differs from the name 20 - in consistency. It is thicker, so that 30 is mixed with 20 to get the desired thickness of the adhesive. The lack of adhesives from this company is that they crack at the bend. This violates the integrity of the connection, degrades the appearance.

BRAUBERG glue

This transparent adhesive is universal for a large number of different materials, differing in their structure. Sold in a package called a show box. Glues and joins wood, metal, PVC of any hardness, polystyrene, porcelain, ceramics, plexiglass, glass. Also glues rubber, felt and leather.

Advantages:

- Versatility.

- Water resistance.

- Elasticity of the sealed seam.

- Bonds porous materials.

- Glues plexiglass and plain glass.

- A symbolic price.

We glue acrylic

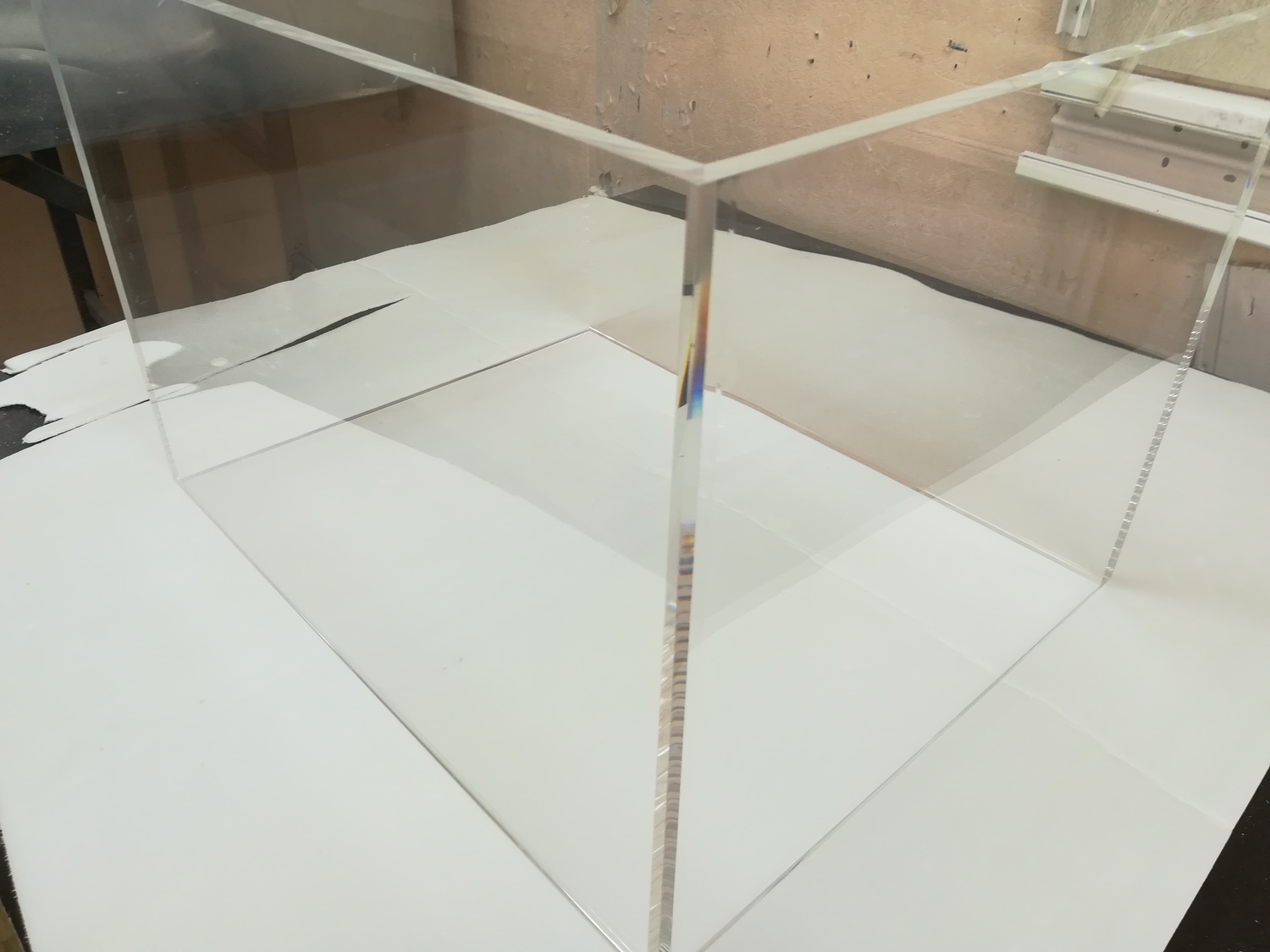

You can glue the acrylic canvas: butt joint, overlap, overlapping (when creating a two-layer material), butt end.

Sequencing:

- Apply glue to the bonding area. Solvent-based solutions are spread over the surface until the top layer begins to melt.

- The parts are pressed tightly against each other and kept for 2–4 minutes.

- Fill the joints with a thin layer of adhesive (this will make the seam stronger).

Wait for the final adhesion (at least a day).

When joining the acrylic sheet with self-adhesive films:

- Wipe and degrease the surface thoroughly.

- Spread the foil evenly over the element's attachment point.

- Remove the protective strip and attach the second plate.

- Press the elements together and leave for a few hours.

We recommend watching the video:

The main problem when gluing plexiglass

When the result of gluing is far from what they would like to see, people in most cases blame the glue for it. Because of this, on the forums for working with plexiglass, you can stumble upon real verbal skirmishes! But the fact that the glue advised by someone did not suit you is the last indication that glue - the only variable that is 100% identical in your cases - is the culprit of the failure.

When we talk about a thing that it is "plastic", in fact, plastic may be one of hundreds of polymers or their mixtures - we have the same situation with plexiglass. Depending on the composition of this plastic, the same glue will give different results, therefore, unfortunately, there is no escape from the share of risk, experimentation and selection of the ideal glue empirically.

General technology and principles of gluing at home

To obtain a strong bond, it is necessary to prepare the surfaces to be bonded. If it is plexiglass, the places where the glue is applied are wiped with a rag dipped in gasoline and alcohol. The metal is cleaned of rust, degreased with alcohol. Wooden surfaces are wiped with a damp cloth and dried.

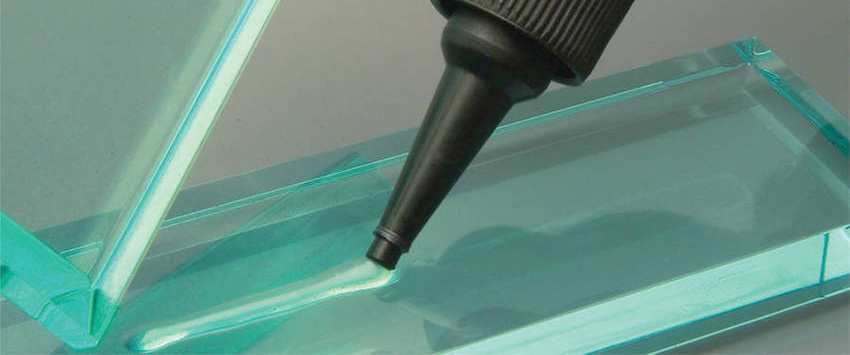

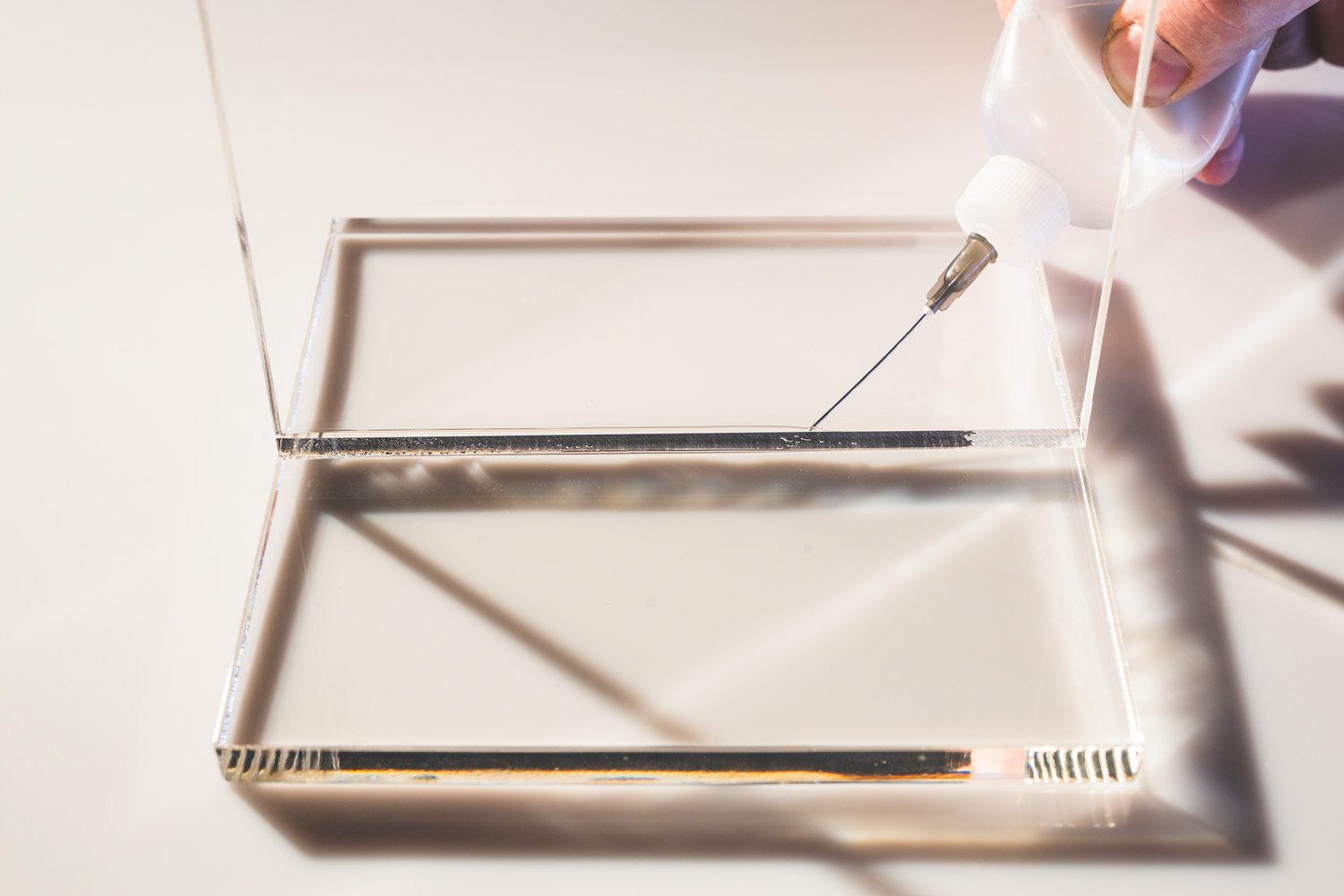

When gluing plexiglass, a small gap is left between the edges, which is filled with an adhesive composition, and then pressed tightly against each other. To obtain a neat seam, use a syringe with a sharpened needle. The setting time depends on the composition used.

Plexiglass gluing to metal, wood must be carried out according to the manufacturer's instructions: application method, holding time. Adhesives leave traces when dry. To protect surfaces from contamination, it is recommended to cover them with paper tape or tape.

Adhesive self-adhesive films

If you want to quickly and efficiently glue plexiglass, then this method is just for such a case. The tape is applied directly from the roll, you only need to press two canvases, and they stick together. If you decide to choose a suitable film, then be guided by the instructions that come with the tape. On sale today you can find such films in three versions.

What is the best way to glue plexiglass?

If you plan to glue an organic glass item, then you need to decide on the type of glue. We sweep away the silicate glue immediately, it is too liquid for these purposes. You can use the following types:

- Solvent-based acrylic adhesive is just perfect for bonding acrylics.It turns out that two identical substances are linked by a third, similar in composition, so it turns out that all three components merge into one whole.

- Epoxy resin. It is used to repair cracks, it sets quickly.

But it is better to use special formulations for polymer glass. What requirements should such glue meet. According to the principle of operation, two types of glue are distinguished: glue that does not dissolve the material of the adhesive surface and dissolving.

- In the first case, an intermediate layer is formed between the parts, which, drying out, connects the adhesion of the two surfaces. It just turns out that it makes no sense to connect the surfaces of plexiglass with such glue, there are no pores in the surface, the glue simply has nothing to cling to.

- A second type of adhesive that dissolves surfaces before gluing. And the molecules of one part interact with the second, forming one monolithic seam. It turns out that the parts can stick together due to the adhesion of the molecules of the substance. The seam turns out to be as strong as the material itself, and also invisible. This connection is sometimes referred to as "cold welding".

Today, the solvents for artificial glass are formic acid, methyl alcohol, dichloroethane, glacial acetic acid. The only drawback of dichloroethane is that it is in the company of harmful substances.

You can even glue plexiglass with vinegar essence, which, moreover, does not dissolve the layer of organic material, but simply softens it.

Conclusion and conclusions

You won't have a problem if you haven't heat-treated the plexiglass. This includes work with a grinder, laser, jigsaw, etc. If the technology is violated, then when the glue gets on the cut areas, then the marriage in the form of sprawling microcracks is inevitable.

Not many novice craftsmen know how to glue plexiglass. Strong gluing is possible only when using a specialized adhesive, correctly performed work. To do this, just read the step-by-step instructions, prepare consumables, parts to be connected.

One of the few best options is when internal stress is relieved, i.e. use plexiglass annealing. You will need a heating cabinet or a thermal oven for "tempering", like metal.