Stamps

There are times when, in order to save money, the craftsmen use the usual or silicone adhesive for tiles. However, many formulations are unsuitable for such work in their consistency, since they will be too thick or, conversely, liquid. In the latter version, the canvas simply does not hold on to the base, and the presence of aggressive substances in the composition can harm the decorative material.

Therefore, for working with mosaics, it is necessary to purchase only specialized compositions from well-known manufacturers, for example, domestic Unis or Italian Litokol K55, Lacrysil, Mosaik products. The leaders in this segment are the Ceresit and Knauf brands.

However, an important nuance is still the purchase of products that will not represent a low-quality fake under a well-known brand.

The packaging of the composition contains information indicating the scope of use of the glue, which relates to the possibility of working with transparent or translucent mosaics, as well as the use of products in residential premises, for outdoor cladding, in conditions of high humidity or in direct contact with water. Manufacturers of mosaic adhesives offer customers a wide range of quality products for all types of substrates and tile sheets made from a variety of materials.

For a test review of Plitonit glue for mosaic tiles, see the video below.

Preparing the plywood surface for tiling

The strength and durability of the mosaic finish is equally dependent not only on the correct choice of adhesive, but also on the careful preparation of the substrate. In your case, it is necessary to completely remove the varnish from the plywood and sand the surface. Several coats of primer must be applied to the substrate before applying the adhesive.

Before applying the LITOKOL K55 glue to the plywood, several coats of PRIMER C should be applied to the surface to form a strong waterproof film on it.

The primer PRIMER C of the same brand is perfectly combined with the LITOPLUS K55 glue you already have. It is designed for loose and porous surfaces, penetrates deep into them and creates a strong waterproof film on the surface and increases the adhesion of the base with the glue.

We hope that our tips will help you create a beautiful and durable arch mosaic.

Reactive adhesives from LITOKOL

Two-component adhesives for tiles Litokol are composed of an epoxy-polyurethane base with organic additives. Therefore, they are thixotropic.

Suitable for finishing work with various coatings. Withstand high loads, thanks to this they are used in places with a large passage of people.

Two-component adhesive LITOELASTIC

Two-component reactive adhesive Litokol for white tiles. The first component is an inert filler epoxy. The second component is a special hardener. To obtain a ready-made glue mass, it is required to combine the two components and mix thoroughly.

Suitable bases:

- Various types of plaster.

- The walls are made of concrete, bricks, foam blocks.

- Laying on old tiles.

- Metal, plastic, glass.

- Plywood, fiberboard.

- Cement screeds with an installed "warm floor" system.

Characteristics of Litokol two-component adhesive:

- High elasticity.

- Resistance to prolonged exposure to moisture, temperature extremes.

- Withstands heavy loads, frequent vibrations.

- After drying, such a composition does not shrink.

Conclusion

Let's summarize. Litokol adhesives for tiles are in steady demand. They have their advantage in the construction market.A wide variety of products allows you to choose an adhesive mixture that is suitable even for laying a new layer of tiles on old tiles. The manufacturer offers a range for all work surfaces and various bases. There is a choice both for difficult conditions with high indoor humidity and for unfavorable effects for outdoor cladding.

How to use?

Before proceeding with the installation of any of the selected tiles, it is recommended to thoroughly clean the entire surface. The base should be free of dust, dirt, small debris and everything that will impede high-quality adhesion. Another important point is that the surface must be completely dry. Otherwise, the adhesion will be poor.

If the glue is to be applied to a plaster surface, it must first be primed. The gypsum structure has the ability to absorb moisture. And if there is no primer on the surface, the glue mixture will simply be absorbed, the result of laying will not be of high quality. In addition, the plaster surface must be sanded.

In the event that the installation must be carried out on a cement or other porous surface, the usual primer for preliminary preparation of the base will not work. It is recommended to choose a deep penetration mixture, and only then use Litokol K55.

If the glue is to be used for lining the pool, then the waterproofing must be done carefully first.

For those who will lay the tiles during the installation of the "warm floor", it is recommended to remember that it is possible to apply glue to such floors only after two weeks.

When laying conventional ceramic tiles, it is important to apply the adhesive directly to the surface. Try to apply the mixture only to the area of the working area that you can coat within the next 10-15 minutes.

An adhesive is applied to the reverse side if the work is carried out with:

- large format tiles;

- variety for lining the inside of the pool;

- material for "warm floor".

For the installation of mosaic tiles, almost all of the above recommendations apply. The surface must be clean and level. It is recommended to apply the composition with a toothed instrument. The reverse side of the tile itself must be thoroughly cleaned to obtain a high-quality result. When working with Litokol K55, it is recommended to remember that the mixture is made on the basis of cement.

Instructions - correctly glue the mosaic on the mesh in the bathroom

Work on laying mosaic tiles is carried out in the following sequence:

1. Preparation of the base. Glue the mosaic on the mesh on the bathroom wall or on the kitchen backsplash only after thorough preparation of the base.

It is necessary to clean the surface from dirt and dust, old peeling coatings - everything that can impair the adhesion of materials.

If the surface of the wall is not completely flat, it should first be sanded with a grinder or grinder with a disc for stone or ceramics.

If the unevenness on the base exceeds 2-3 mm, it is recommended to level the surface using leveling compounds. Absolutely dry, durable, clean and even surface - ideal for laying mosaic on mesh.

2. Markup. It is recommended to apply markings on the prepared surface, which will help to gently glue the mosaic canvases.

First, the sheets of tiles are laid out on the floor in such a way that the distance between the canvases corresponds to the gap between the tiles themselves.

After that, measurements are taken and the entire scheme is transferred to the wall, not forgetting to control the vertical and horizontal position of the canvases with the help of the building level. Correct markup allows you to hide the clipped areas.

3. Preparation of the glue. The properties of any glue are guaranteed by the manufacturer only on condition that the proportions and technology for preparing the solution are strictly observed.

The principle of preparing glue from different manufacturers is the same: the building mixture is poured into a clean dry container, filled with water in the specified proportion and mixed with a drill mixer until a homogeneous creamy consistency is obtained.

The finished solution is left for a few minutes, after which it is mixed again.

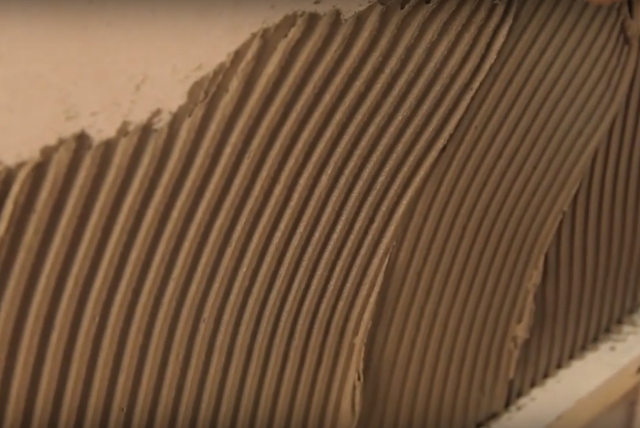

4. Application of glue. The adhesive solution is applied to the wall evenly with a notched trowel, while the surface area should not exceed the area of the number of mosaic sheets that can be laid within 3-5 minutes (otherwise the glue will dry out).

The optimal thickness of the glue layer is 2-3 millimeters. If there is more glue, then when the mosaic is pressed in, the excess mortar will fill the seams between the tiles, which will complicate the grouting process in the future.

5. Laying mosaic tiles. The prepared mosaic canvases are applied to the marked area with a mesh base. Carefully, without undue pressure, level the canvas on the surface.

All prepared canvases are laid in the same way. For splitting the material, if necessary, use special tongs.

6. Grouting. After 24 hours after laying the mosaic, you can start grouting. To do this, use a rubber float, with which the grout is rubbed into the seam spaces with smooth movements.

Excess material is removed with a damp sponge. After the grout has dried, the surface is polished with a felt cloth.

VIDEO INSTRUCTION

Useful styling tips

Here are some practical tips to help you lay your mosaic better:

- When choosing an adhesive, consider the type of substrate to which it will be applied.

- Check the consistency of the adhesive to avoid shifting the mosaic sheets during installation. Too thick glue dries quickly, which complicates the workflow.

- It is recommended to prepare glue in small portions, taking into account a low consumption (about 2 kg per square meter). It is not recommended to try to dilute the thickened glue residues, since its properties have already been lost.

- During installation, the glue should not be allowed to flow out of the seams - this will complicate their grouting in the future.

- The optimum temperature for laying mosaics on a grid is 15-25 C.

Types and composition

A wall in a room, lined with mosaics, or a whole pool - in any case, the result from the use of such products will exceed all expectations. Moreover, the laying of the tiles can be entrusted to the master, or you can do it yourself. But in order for the work to be carried out efficiently, a suitable adhesive composition is needed. Most modern and domestic manufacturers of building materials offer the consumer special adhesives for these works.

It is quite difficult to select the highest-quality adhesive composition that will save on consumption for 1 m2 of working area, since each type of product has individual characteristics and properties.

Mosaic adhesives are classified based on their composition. There are three main types of products.

Dry composition

It is produced when white or gray cement is included in the mixture, due to which its color is set. Cement glue for work must be prepared - in the specified proportion, the powder is mixed with water or latex. The composition can be elastic, highly elastic and rigid. Each of the above adhesive solutions has a narrow scope of application, based on the type of surface from which it is necessary to fix the tile.

A hard mixture is used when working with an even mineral base; it can safely be used to process brick or plastered walls, foam blocks, concrete surfaces. Dry mixes have a positive feature that concerns their low cost. For non-standard cases, experts prefer to choose mixtures with good elasticity.The use of such products makes sense in those situations when it is required to lay mosaics on surfaces that do not absorb moisture and have little resistance to temperature fluctuations, for example, for facing "warm" floors.

Dispersion adhesives

This mixture can be used immediately after purchase for mosaic work. It is a one-component adhesive, the main advantage of which is ease of use. It is convenient to apply the mixture to substrates in residential premises, since it does not generate any waste or dust when performing the assigned tasks. For surface treatment, you do not need a lot of funds, the mixture does not dry out and does not lose its properties, it does not need to be kneaded, since the glue in the container is already completely ready for use. After finishing the lining, the container with glue must be tightly closed with a lid. Ease of use of the product more than pays for its cost.

Two-component adhesive

The reactive composition includes a hardener and a base, which react with each other, due to which the product acquires the ability to reliably fix the tile. More in demand are products where the basis is an epoxy or polyurethane component.

The mortar is needed to perform the laborious tasks associated with mosaic tiling.

It is also successfully used for glass, wood and plastic products.

To work properly with such glue, you need some experience - it is applied to a small area with quick and clear movements, since the mixture instantly hardens, after which it will no longer be possible to use it.

Styling nuances

Laying the mosaic is not as difficult as it might seem at first glance. However, without preliminary preparation of the base, the result will be much worse.

Surface preparation

Before starting any tiling work, we recommend that you carry out the correct surface preparation. First, the surface must be cleaned of debris and small dust particles. This can be done with a paint brush or any large brush.

Lay the mosaic on an extremely flat surface. To achieve this, you need to remove the old coating. Then the base is leveled, getting rid of potholes, chips, pits and even small cracks. They can also affect the final look of the finished cladding. After the starter coat is dry, it is trimmed and covered with a layer of primer. It is needed to enhance the adhesion of the mosaic to the prepared substrate.

If the surface requires special leveling, the plaster mixture is applied in several layers. In an attempt to save time, quality training can be lost. A thick layer of plaster will fall off along with the mosaic in the first year after the renovation. In addition, it will crack, which will lead to the question of dismantling the mosaic.

How to glue it correctly?

Fragments of small mosaics are often held on a grid

This process is especially required when the mosaic has a certain pattern. We'll have to glue fragment by fragment to the surface. The technique of gluing the mosaic is painstaking and requires care.

When there is a grid, the workflow is simplified. Usually it represents squares assembled on a silicone base. It remains for the master to apply glue to the base, then apply, observing the level of adhesion.

You can also stick such tiles on drywall, wooden surface, chipboard base, window sill or plywood. The main thing is that the base is prepared, primed and cleaned. Glue the mosaic starting from the bottom. It is not necessary to smear the back of the tile. The glue on the wall is enough. In no case should you press down from above, trying to secure it better. If you have to cut the mosaic, try to use these fragments in laying corners and other places that are not so visible.

Finishing

After you complete the mosaic laying process, you can proceed to the finishing.Thoroughly clean the surface from glue residues. It is recommended to let the surface dry a little and only then proceed to the final stage: grouting

Tiling technology

If you understand the technology of mosaic laying, then it will not be difficult to do all the work. Of the tools you will need:

- Paint brush.

- The spatula is simple and notched.

- Mixer.

- Container for glue.

Before starting work, you need to prepare the surface of the wall. The old coating is removed, the surface is cleaned of dirt, leveled and sanded. The wall is primed and immediately tiled. Further actions:

- Using the instructions on the package, we make the adhesive mixture. The instructions indicate the exact proportions required to mix the mixture.

- Cover the back side of the mosaic and the wall with a fixer. On the surface of the wall, the adhesive is applied evenly with a notched trowel.

- The tile is glued to the surface and lightly pressed with a spatula. With the help of the building level, the correct installation is simultaneously checked. Vertical and horizontal lines must be accurate. By the same principle, the rest of the picture is glued.

- Residues of the mixture from the tile surface are removed with a damp cloth. This must be done within 30 minutes, otherwise it will harden and it will be problematic to remove it.

- Grouting on the panel is done in two days. Using a rubber trowel, the seams are covered with a trowel. For the kitchen, choose an epoxy-based grout. It is waterproof. For the rest of the rooms, a composition based on latex, liquid glass or Portland cement is suitable.

At the end of the work, the tiles are wiped with a damp cloth.

What should be the surface for laying

What surface can the mosaic be glued to? The facing material is small in size. Therefore, all the unevenness of the base will be emphasized by the facing material. If so conceived by the designer, then you should choose an adhesive with high adhesion rates and a short curing time. The thickness of the mosaic adhesive is small to avoid floating of the tile

It is also important to take into account the fact that the seams must be unfilled until the glue is completely dry.

When designing a plane, the surface must be pre-leveled. Mosaic mortars can have filling capacity without shrinkage, but leveling the mosaic with a large adhesive layer will be inconvenient. It is worth noting that cheap materials, during drying, lose the volume specified by the master. This leads to the fact that the tile will not give an even plane.

This is interesting: How to use the sealant gun correctly?

Step-by-step instruction

In order for the mosaic to serve for a long time, the laying is carried out sequentially in the following order:

- The glue is first applied to the surface with an even layer of 3-5 mm. Then the mass is leveled with a notched trowel to give grooves. The larger the elements, the greater the height of the teeth.

- The mixture can be applied not only to the base, but also to the mosaic itself. In this case, the thickness of the glue is 2-3 mm.

If you have no experience with self-installation, spread the glue over an area of 3-4 plates, no more. In order to take your time and prevent the top layer from drying out.

- After applying the glue, the mosaic is applied to the plane and tapped with a rubber mallet to release excess air.

- To make the tile lie flat, roll the top with a plastic roller.

- After half an hour, the excess glue is removed from the surface of the mosaic with a brush with stiff bristles or a match.

- Paper sheets are pre-moistened with water and peeled off from the front side.

- After the glue has completely dried, grout the inter-seam space using special materials. Spread the grout evenly between the chips with a rubber spatula.

- The color of the grout is chosen depending on the shade of the decorative coating.

- Excess grout is removed with a wet sponge and wiped with a lint-free soft cloth.

Interesting video on the topic:

How to choose glue for gluing mosaic on plywood

Glass mosaic adhesive must meet the following requirements:

- it is imperative to be white so that the color and structure of the base do not shine through through the transparent and translucent tiles;

- be marked "for working with glass, translucent and transparent mosaic tiles";

- have a mark on the place of use on the label: facade work; Living spaces; bathrooms and pools; decoration of furniture and interior items.

All of the above criteria are fully met by three types of bites for working with glass mosaics.

Cement-based white adhesives

These are well-proven dry mixes of Italian production LITOPLUS K55, CERESIT CM 115, IVSIL Mosaic (MOSAIK) and some others.

When gluing glass mosaic tiles on a plywood base, dry cement-containing mixtures can be used if:

- the size of mosaic fragments does not exceed 5x5 cm;

- instead of water, a liquid latex additive from the same manufacturer is used as a diluent.

In your case, the dry component of the LITOPLUS K55 glue should be diluted with the liquid latex additive Latexkol-m. It will significantly improve the adhesion of the adhesive to the base, make the adhesive layer elastic and give it the necessary water resistance.

Cement-based latex additive improves elasticity, water resistance and adhesion of cement-based adhesive

Reactive epoxy and polyurethane adhesives

These are ready-made two-component polyurethane adhesives LIIELASTIC and Mapei Keralastic T, two-component epoxy adhesive Sopro DBE 500 and others. The whole group of reactive adhesives is distinguished by high elasticity, water resistance, and the ability to level surfaces. They are suitable for gluing glass mosaics to any surface, including wood, plywood, rubber, etc. The only drawback is the high price, often twice or three times the cost of dry mixes.

Two-component reactive polyurethane and epoxy adhesives are suitable for gluing mosaics to all types of substrates, but are expensive

Liquid Nails

Adhesives of the "liquid nails" group are not cheap materials, but they are a universal means for gluing any materials on any substrate, including wood and plywood. For facing small surfaces with glass mosaic such adhesives of this type as Kerabond T, Universal Moment and Liquid Nails LN 604 are suitable. The time for complete curing of "liquid nails" depends on the layer thickness, room temperature and is 12-24 hours.

Universal liquid nail glue can also be used for gluing glass mosaics to plywood

Cement mosaic adhesive

Cement glue is a universal option for laying glass mosaics. Moreover, manufacturers offer special compositions for this - white. Semi-transparent elements of a delicate pastel palette and bright colors, folded into original patterns and ornaments, will look more attractive on a white background. Whereas the gray glue layer neutralizes the colorful effect and makes the picture dimmer.

Photo: Onix

Glass mosaic is extremely hygienic: microbes do not multiply on it

But this is not the only distinguishing feature of glass tessera adhesives. In addition to white, they must have high adhesion (from 1 MPa) in order to securely fix an absolutely non-porous material on the base. For cladding vertical surfaces, high thixotropy is important - resistance to slipping of the adhesive mass, especially when mounting from top to bottom. This quality will not allow individual elements and mosaic modules to change their position. When mosaic flooring, which is exposed to the most intense loads or is equipped with heating systems, not only high adhesion, but also the elasticity of the adhesive is required. Then the probability of falling out of individual tesserae will be minimal.By the way, another common reason for the loss of elements is an insufficiently aligned base. A layer of miniature tesserae fairly accurately reproduces the unevenness of the floor, and when walking on it, shoes can cling to the protrusions.

What to consider when choosing?

It is quite difficult to unequivocally determine the best glue for mosaic, because there are many types of adhesives with different consumer and operational qualities. In addition, different types of mosaic coverings have their own requirements for the working adhesive solution. The color of the tile adhesive does not always matter, it does not have to be white.

It is important to remember that the main parameters to look for when choosing a mosaic masonry mix are elasticity and wettability. These important characteristics determine how reliably the composition adheres to the surfaces to be glued. During repairs, sometimes it becomes necessary to do the work urgently, and there is no way to wait until the adhesive dries, so the drying time must also be taken into account

During repairs, sometimes it becomes necessary to perform work urgently, and there is no way to wait for the adhesive to dry, so the drying time must also be taken into account.

In order to correctly choose a special glue for working with mosaics, you should also take into account the following factors:

- type of base;

- type of mosaic;

- terms of Use.

Mosaic type

Any cement-based adhesive mix is suitable for ceramic mosaic tiles, and its color does not matter. The decisive factor in the choice will be the type of surface on which the mosaic will be glued. A smooth, porous substrate with a high absorbency will adhere well to simple standard cementitious adhesives. On overly smooth non-absorbent coatings, the facing material will be more reliably fixed with an elastic deformative compound with increased adhesion.

The glue for glass mosaics must certainly be white, because the base shines through the transparent elements. The gray color can greatly spoil the impression, since the color of the mosaic coating is distorted. The white adhesive mixture can be selected from polyurethane and cement compounds. For opaque glass ceramics, you can use any shade of glue, because you will not see it anyway.

Stone mosaics can be extremely capricious, because some of its types are sensitive to water and change their color over time. In this case, fast drying reactive and polyurethane water-free substances are used. The choice is determined by the type of natural stone.

Mirror mosaic adhesive is selected especially carefully and depends on the composition of the mirror coating (dusting, amalgam). It is necessary to use a specialized adhesive for mirrors that does not shrink and does not contain chemicals that can damage the mirror layer. Epoxies and water-free sealants also perform well. It is recommended to experiment in advance and check the effect of the glue on a small piece.

On grid or paper

To ensure maximum convenience of work, the mosaic is produced in large blocks based on paper or mesh. The fixing adhesive for such mosaic materials, bonded with different bases, does not differ significantly. The only thing is that for laying the mosaic on the mesh, you will need to apply a sufficient layer of glue to the wall so that the fiberglass mesh base, located on the wrong side, is completely and evenly immersed in the adhesive composition.

Mosaic sticker paper connects the mosaic fragments from the front to the front side, therefore, after laying the facing, the paper base is softened with water and carefully removed, trying not to accidentally move the small details of the tile

Surface character

The choice of the fixing component depends on the nature of the surface to which the mosaic covering will be glued. To glue the mosaic on the mesh onto a relatively flat solid base (drywall, cement screed, plaster, etc.) with good absorbency, you can use an inexpensive cement glue mortar that will firmly adhere to it.

The nature of the room

If a mosaic coating is pasted over surfaces in a room with high humidity, then additional requirements are imposed on the adhesive mixture. The mosaic should be laid only on the waterproofing layer so that water absorption is minimal. To fix the cladding, waterproof elastic adhesive solutions are used, which contain plasticizers. It is allowed to use cement powder with polymer additives that turn into latex when mixed with water. Good adhesion is shown by polyurethane and epoxy types of adhesives.

In places with inconsistent interaction with water and low loads, you can use any adhesive mixture.

Cladding of swimming pools, saunas and baths

Mosaics have become a functional covering for swimming pools, saunas or baths. Such cladding is distinguished by its durability, it can withstand constant moisture and the influence of water.

But the influence of water must also withstand the mosaic adhesive.

But the influence of water must also withstand the mosaic adhesive.

The adhesion of the adhesive must be at least 2.5 megapascals for laying glass tiles. Ceramic mosaic needs 1 megapascal adhesion. Adhesion can be improved by adding liquid latex to the solution.

High elasticity and resistance to tile slipping. In order for the mosaic to be firmly fixed, the glue should not dry out quickly.

The pool can be filled with water two weeks after tiling. The cladding should fix and the glue should gradually dry and set. .

Work cannot be carried out at temperatures below +5 C.

It is necessary to apply the solution to the waterproofing with the smooth side of the spatula so that the solution is distributed over the entire area. The excess is removed with the spatula teeth.

Consider the time of working with the solution: after half an hour, the glue will begin to set. Sun, direct rays and wind will reduce the working time, so make sure that the grout does not set. The solution can be refreshed by stirring without adding water.

Ceresit CM 115 or Litokol K55 will cope with laying tiles in pools and wet areas. Adhesives from the manufacturer Litokol are distinguished by high adhesion and elasticity, as well as fast setting.

Litokol is suitable for laying mosaic ceramics, glass cladding on various surfaces.

Two-component adhesive

The components are epoxy base and hardener, which are mixed before use.

It does not contain water, so it is suitable for foundations that do not tolerate water well or do not absorb it at all. Two-component glue will fix the mosaic on difficult surfaces: glass, wood, metal.

The high cost of the material and the specific purpose forces it to be used only as a last resort.

Consider the following when working:

- the solution dries quickly, so you need to work quickly;

- do not apply the solution to a large area of the base;

- you must immediately remove the glue from the front of the mosaic, because then it will be difficult to wash off or peel off.

Selection Tips

Thanks to the wide range of Litokol adhesive mixtures, you can choose the right composition for any task. When choosing, consider the following factors:

- place of finishing work: inside or outside the premises;

- base type: horizontal or vertical surface;

- the materials from which the tiling and base are made.

Interior decoration

For indoor work, it can be used as a universal adhesive mixtures Litokoland special-purpose formulations. As a rule, special modifications of glue for interior work are made from the most environmentally friendly raw materials.If cement-based compositions are used, then it is desirable that when preparing the solution, the amount of dust emitted is minimal. The dust-free materials category includes the mixtures Litogres K44 ECO and Litoflex K80 eco.

For outdoor work

For finishing the facades of buildings, sidewalks and porches, it is necessary to choose compositions that have good resistance to weathering and temperature extremes.

It is also worth paying attention to the mode of operational parameters of the mixture. Outdoor formulations must withstand high temperatures and be frost resistant

For example, these are mixtures such as Litokol K17, Litoelastic, Litoplus K55 and Litofloor K66.

Difficult foundations

Complex substrates include surfaces that will be subjected to significant mechanical stress during operation, as well as some materials: wood, iron, plastic, asphalt, old finishing layer, warm floor. The two-component composition Litokol Litoelastic is well suited for this purpose, due to its versatility.

This mixture has high adhesion to any substrates, has no shrinkage and is highly resistant to the negative influence of external factors. The glue is not afraid of water, and it is also resistant to vibrations, therefore it can be used in elevators or on staircases. Litoflex K81 adhesive can be used to finish the underfloor heating system.

Litoacril Plus dispersion is also well suited for some difficult substrates. With this composition, you can lay tiles on surfaces that are subject to deformation, wood panels, as well as on old finishing materials (for example, on tiles or paintwork).

Wet rooms

In rooms with a high level of humidity, it is necessary to use only those compounds that are water-repellent. Among the various Litokol adhesives, you can find many suitable options for decorating bathrooms and swimming pools. For example, mixtures of Superflex K77, Litostone K98, Litoflex K81, Litoplus K55, as well as dispersion compositions.

Various materials

Litokol adhesive mixtures are widely used for tiling surfaces. However, some modifications of the glue allow you to work with other materials. Litokol acrylic-based compounds are widely used for fixing various sound and heat insulation materials.

Betonkol K7 is used for the formation of walls and partitions from bricks, aerated concrete, foam blocks and other materials. Also, this composition can be used to level surfaces. Some Litokol adhesive mixtures can be used for laying marble and other natural stone, including large format.

Glue preparation and application features

Craftsmen prefer to purchase large Litokol packs containing 25 kg of dry mass. To dilute the entire package, you need to take 6-6.5 liters of water. The temperature of the liquid should not exceed -20 degrees, but also not less than +15 degrees. The glue is prepared only by pouring dry powder into water. Changing the mixing order will result in lumps.

It is better to stir the glue not by hand, but with a construction mixer, a drill with a nozzle. Beat the glue until it acquires an even structure without lumps. For ripening, the mass is kept for 10 minutes, covering it from above. After that, Litokol is mixed well again. Further, it is considered ready for use.

To work with tiles and glue, you need to buy two spatulas (flat and comb) or one tool with two different sides. The size of the prong is selected according to the tile - the larger it is, the larger the prong size.

Recommendations for work are as follows:

- distribute the glue over the base with a smooth spatula;

- apply glue to the tile with a notched trowel;

- immediately cover the tile, which is planned to be glued within 15 minutes;

- in some cases (the need to increase adhesion, improve the quality of work), it is necessary to apply the agent both to the base and to the back of the elements, otherwise it is enough to apply only to the tile;

- within an hour, you can change the position of individual elements, this will not affect the quality of the masonry;

- we must not forget to make the seams between the elements, their dimensions are determined by the dimensions of the main material;

- between the tiles you need to insert the appropriate crosses, then the seams will be even.

With a material size of less than 10 cm, 2-3 mm seams are sufficient, for 20 cm elements - up to 4 mm. Tiles up to 30 cm in size will require seams of 4-5 mm, more than 30 cm - up to 5-10 mm.