Half brick masonry

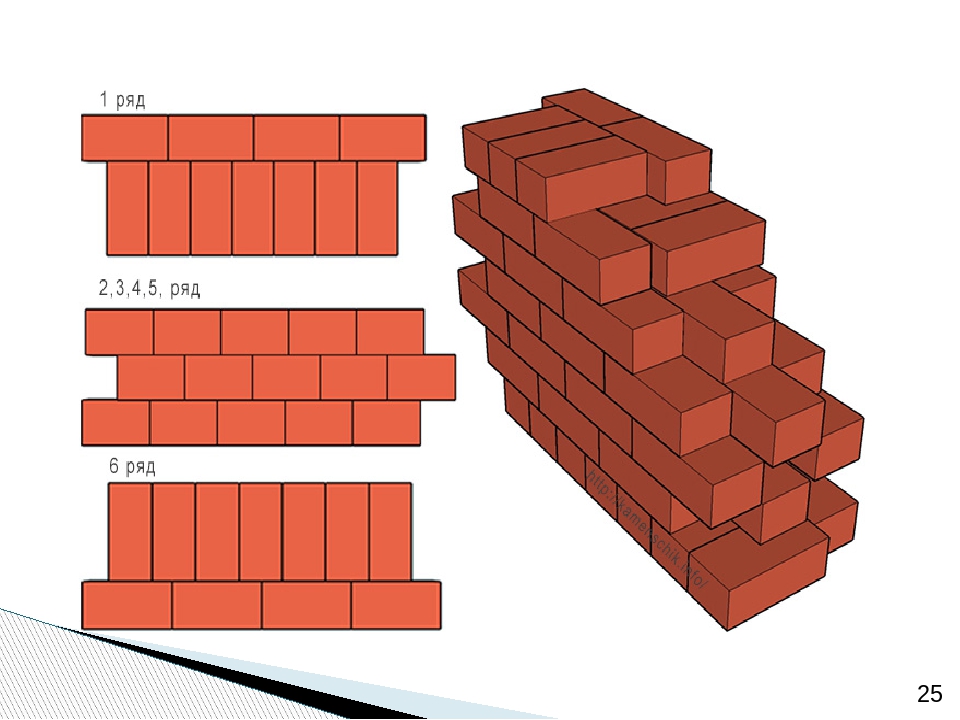

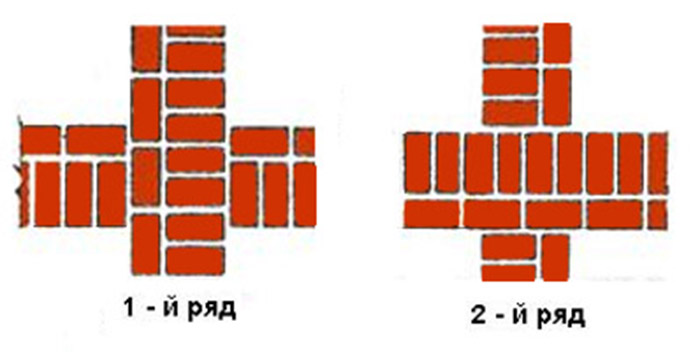

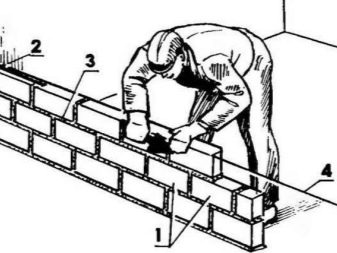

When laying in half a brick, the most important and crucial moment is to lay out the first row correctly.

What is half-brick masonry

Half-brick masonry is considered the easiest to build. It is used for cladding buildings, erecting internal walls, in the construction of sheds, gazebos, fences, and so on.

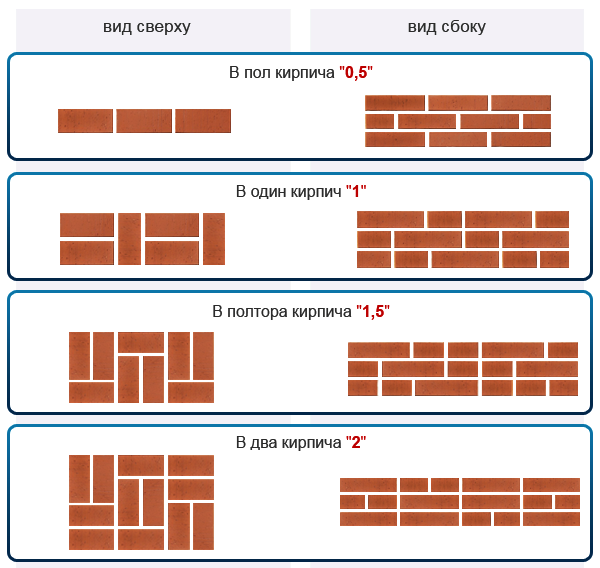

With this method, the bricks are laid with a tape in a row, on the mortar, in contact with the butt side. The front side of the walls consists of a spoon only. Therefore, the thickness of the walls is equal to the width of the brick itself, namely one hundred and twenty millimeters.

Each subsequent row is laid out with a shift of half a brick. As a result, the middle of the top brick coincides with the connection of the bricks of the previous row. Thus, a strong bunch of brick rows occurs.

Bricklayer tools

Naturally, in order to beautifully lay out the wall in half a brick, you need to prepare. First of all, check the availability of the necessary tools for the job.

You will need:

- Concrete mixer;

- Mortar bucket;

- Mortar shovel;

- Master OK;

- Rubber hammer;

- Pickaxe hammer;

- Mason's corner;

- Mooring cord;

- Pencil or felt-tip pen for marks;

- Plumb line;

- Level and others.

And other materials mean that each bricklayer can have his own set of tools that are convenient for him.

These can be various devices for laying mortar, for fixing seams, and so on. Of course, you can do without them, although their presence will speed up the work several times.

Preparatory work

As mentioned above, the most important point is the layout of the first row. In order for the wall to be even, neat and beautiful, an even, almost perfect foundation is required.

If it is far from ideal, has large horizontal discrepancies, wavy surface, then it will be very difficult to achieve good results.

Therefore, the preliminary work is to level the surface for the masonry. When the foundation is properly prepared, pulled together, reinforced, you can proceed with waterproofing.

Calculation of the first row of masonry in 1/2 brick

So, let's imagine that the masonry surface is completely ready. In order to correctly lay out the first row, you do not need to rush.

You don't want to redo everything afterwards. The first row of bricks is laid out without mortar, with the measurement of vertical seams.

For example, you took a steel rod with a diameter of 8 millimeters. We laid the entire row of bricks, from the starting point to the end point, fixing the distance between the bricks.

The first time it will never be possible to lay out the row perfectly, necessarily at the end it turns out not a docking. And then you need to look at the circumstances.

If there is a gap of two or three centimeters, then you can move the bricks a little. For example, instead of 8 millimeters of the vertical seam, make 9 millimeters.

And vice versa, if the last brick does not fit a little, then make all the seams narrower by half a millimeter.

That is, your task is to lay out the first row of bricks as evenly as possible, with the same indents between them. When the desired result is achieved, do foundation marks.

First row masonry

Start laying the first row from the corners. Or rather, from the highest corner of the foundation.

A corner brick is laid on the mortar, leveled strictly according to the level. Further, its height is fixed using a water level.

After that, in the same way, the brick is fixed in its previously marked place on the other corner of the building. The brick is fixed at the same height according to the water level.

And so all 4 corners go.Then, between the corner bricks, a mooring cord is pulled with a corner.

Only after that you can start laying the first row on the mortar. At the same time, be sure to look at the marks made so that the brick lies in its place.

Second row

The second row is laid out, as mentioned above, in a checkerboard pattern. Also, at first the corners are fixed, a mooring cord is installed.

When laying bricks, you need to ensure that the vertical seam of the previous row is strictly in the middle of the brick.

Brick wall construction

The construction of buildings requires specialized equipment. The lack of the necessary tools will slow down the work, so they need to be purchased at the same time as the material. Wall masonry begins after clearing the area from unnecessary objects and debris. First of all, a foundation is laid, which is checked for horizontal and vertical deviations. Accessories that will be needed during construction:

- Fork Traverse - A lifting device equipped with a pallet. Used for loading and unloading materials.

- Iron containers (barrels, buckets) - Used to supply cement slurry.

- Templates from slats - With their help, markings of door and window openings are carried out.

- Flex Cord - Helps to check the level of the walls horizontally.

- Clamp (latch) or ordering (rail 2 m long) - The clamp is used to fasten the rail, ordering is necessary to mark the row.

- Shovels (bayonet, shovel) - Used for mixing cement and transferring the solution to iron containers.

- Pick, hammer - They can be used to split the material and, if necessary, give it the desired shape.

- Plumb - Used for vertical alignment of walls, walls and masonry.

- Level - It checks the vertical and horizontal level.

- Roulette (from 10 m) - Allows you to control and mark partitions and walls.

- Scored Metal Square - Helps to check the angle.

- Trowels, spatulas, trowels - With their help, the solution is cut and leveled.

- Construction racks, scaffolding - Necessary if you plan to lay the wall taller than human height.

There are the following types of bricks (dimensions):

- With horizontally located voids - KG.

- Large-format porous ceramic - KK.

- Double - K.

- With horizontal voids, thickened - UG.

- One and a half - W.

- Building modular single - M.

- Eurobrick - E.

- Single - O.

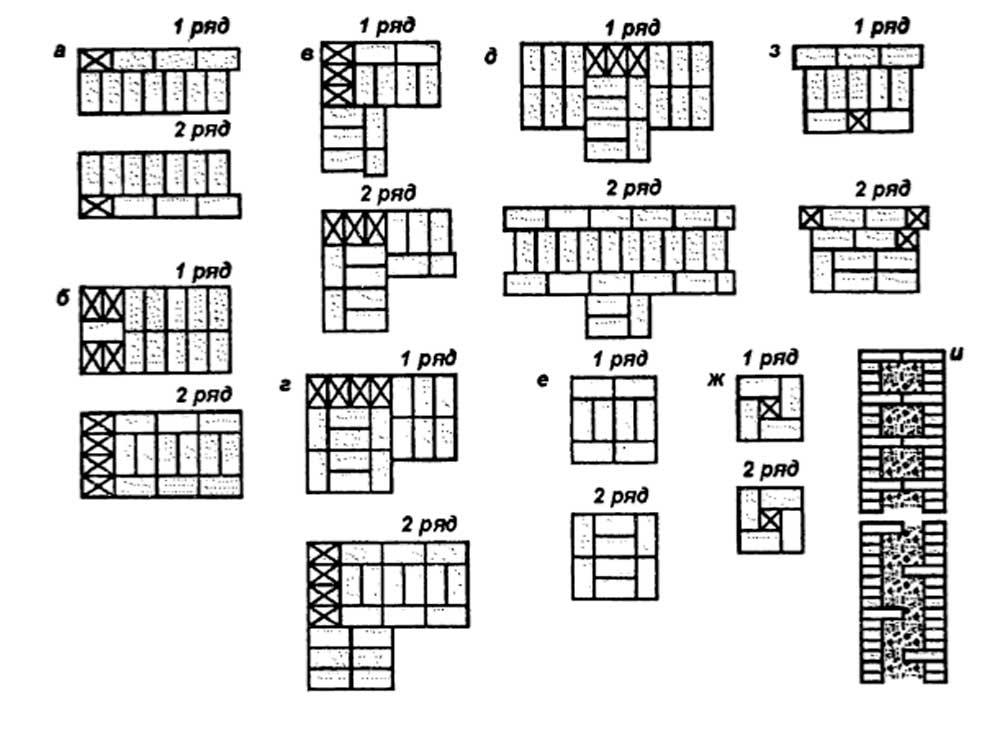

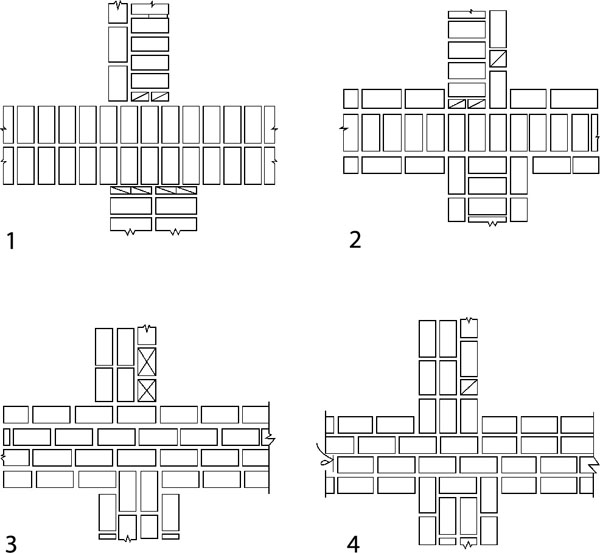

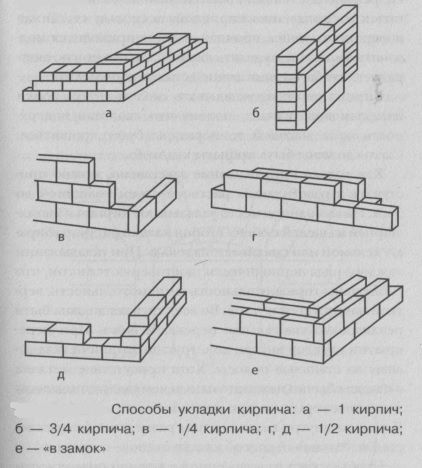

Masonry is carried out in several ways, each of which involves the use of schemes specially developed by builders.

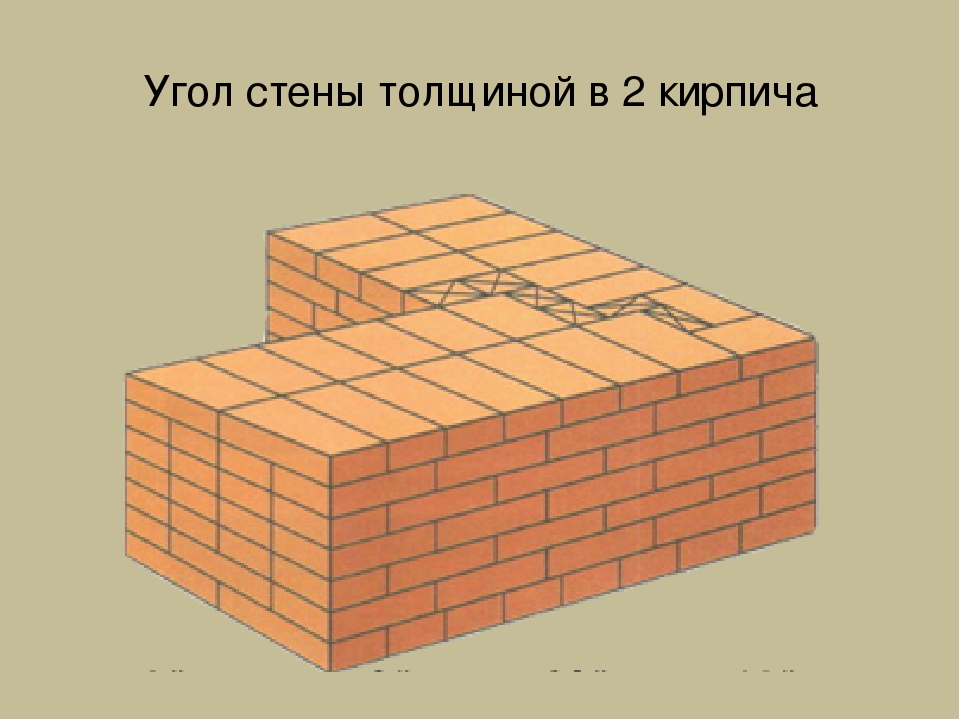

Laying in 2 bricks scheme

For laying in 2 bricks, the mortar is kneaded according to the standard scheme: 1 part of cement to 3 parts of sifted sand. When erecting structures made of ceramic bricks, you will need additional equipment:

- cutter;

- trowel;

- building level;

- hammers;

- plumb lines;

- construction mixer;

- shovels;

- spatulas.

In the construction of high-rise buildings, cement-lime mortar is not used. It can be used to form decorative elements inside or outside the building. The mass has low thermal conductivity, average plasticity. To increase the degree of refractoriness of the building, fireclay clay is added to the cement. It is more convenient to mix the solution in a concrete mixer.

Parameters of a typical brick size (according to GOST):

- the width of the masonry will be 500-510 mm;

- height (including blocks and seams) - about 155 mm.

Before starting construction, experts recommend calculating the width and height of the future building in order to draw up a cost estimate for the material.

Masonry type

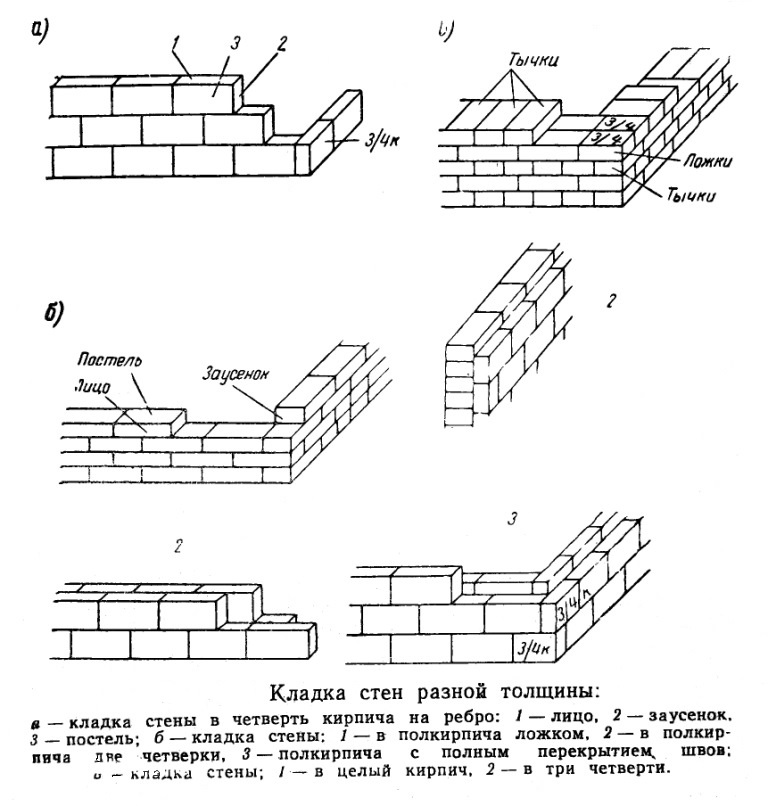

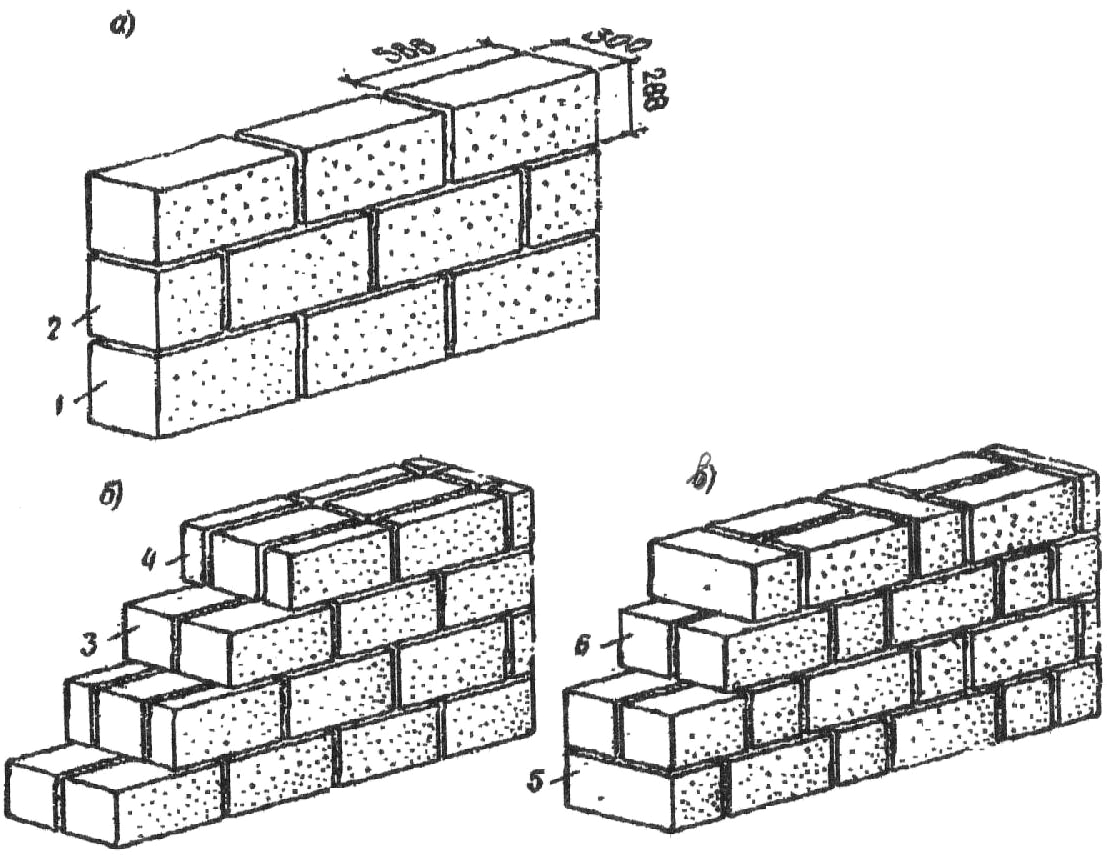

Each of the 2-stone masonry methods is distinguished by the edges of the blocks. There are 3 main surfaces:

- poke;

- spoons;

- pastel.

Pastel is the largest face of the block, its other name is working. The surface is either top or bottom, much depends on how it is placed inside the masonry. The spoon is understood as the second largest perpendicular side.The jab is positioned perpendicular to the other two faces in the brick block. This surface is the smallest in size.

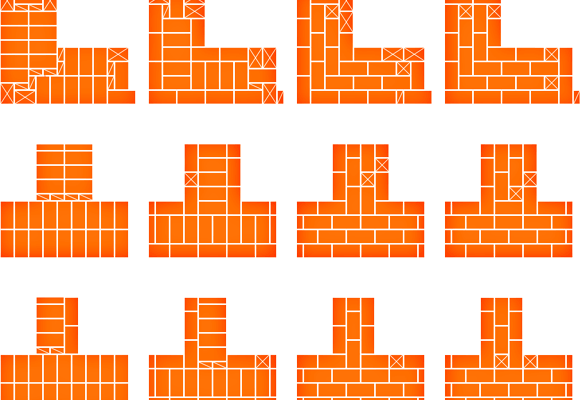

There are several main types of masonry in 2 stones:

- Cross. Lay out 3 poke and 3 spoon rows. The scheme is repeated the required number of times.

- Double row (chain). The easiest way to construct buildings. First, lay out 2 rows parallel to each other and strengthen them with cement mortar. In the process of laying, a ladder is formed with a shift of 3-4 cm.

- Art. This type of masonry allows you to form a facade pattern by means of a scheme, painting the joints and laying brick blocks. The facade is not a perfectly flat surface, but an angular architectural relief with slopes, columns, protrusions or niches. Another name for masonry is patterned relief.

- Single row. It is based on the stepped alternation of spoon and butt rows. This method is suitable for building a fence.

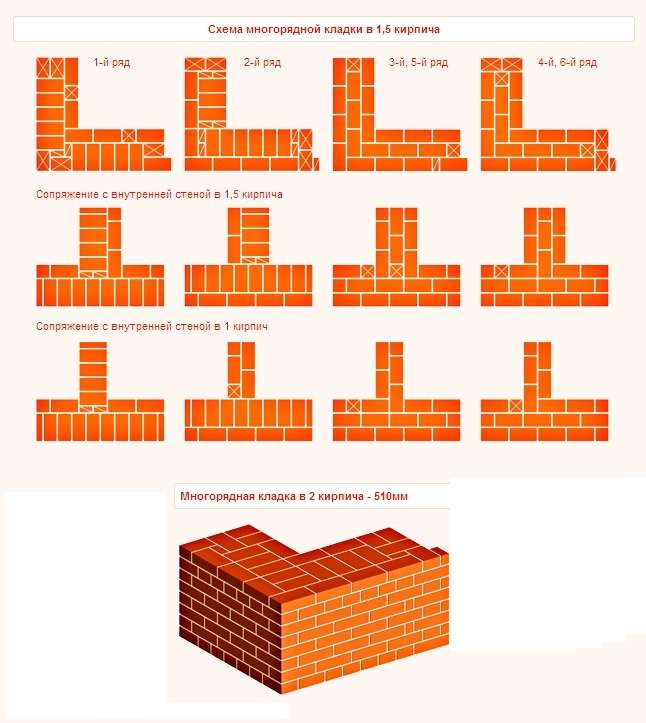

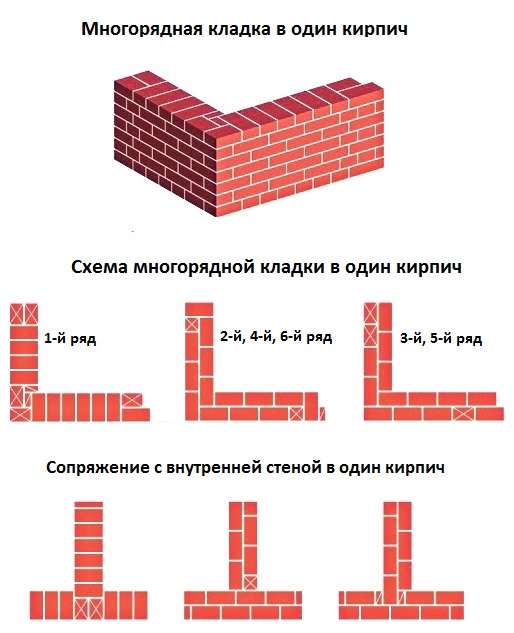

- Multi-row. The wall is laid out in even layers of 6 lines. Each 6th row is bonded, all the rest are spoon. Vertical seams are tied longitudinally across 6 rows.

Laying is carried out horizontally. In the process of construction, the purpose of the structure, the possible load on it and the geometric characteristics are taken into account.

During the stone laying period, attention is paid to the thermophysical properties of the material. Dimensional parameters of bricks and cement make up the total thickness of the walls

The strength of the building directly depends on the chosen ligation scheme: it is carried out transversely or longitudinally. Masonry is often associated with great pressure on the foundation of a building, therefore experts recommend pouring a reinforced base.

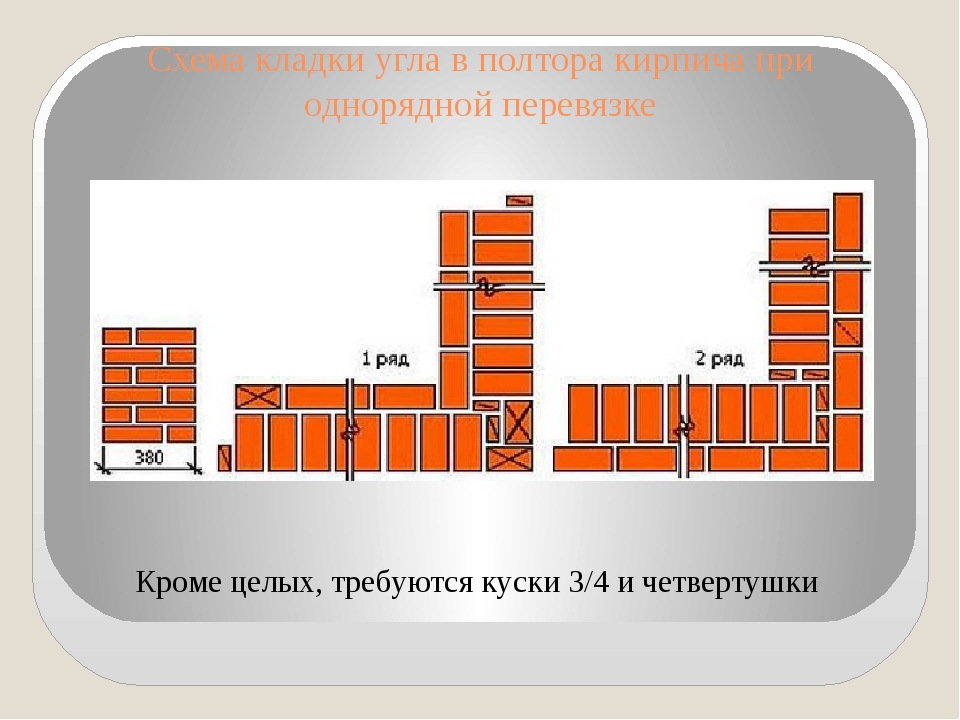

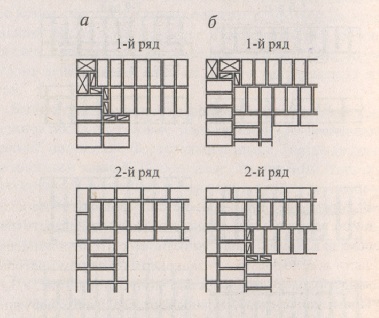

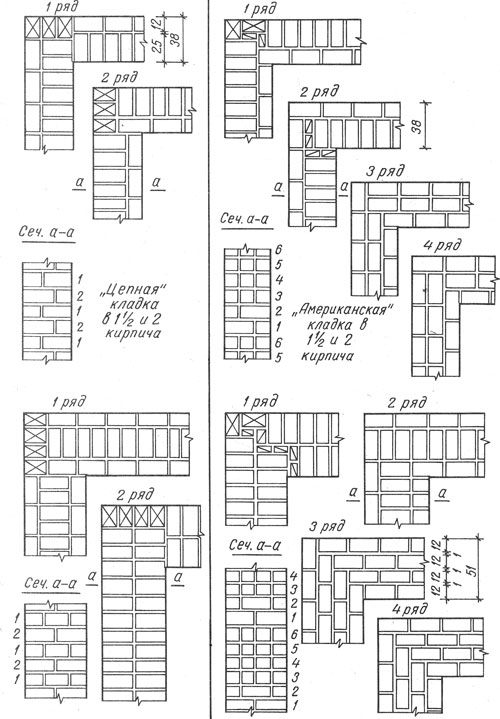

Wall thickness of one and a half bricks and its features

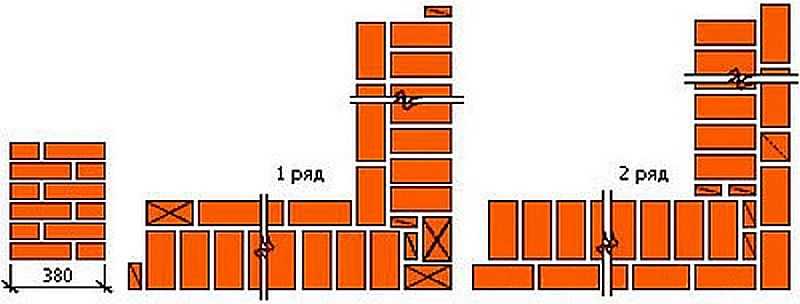

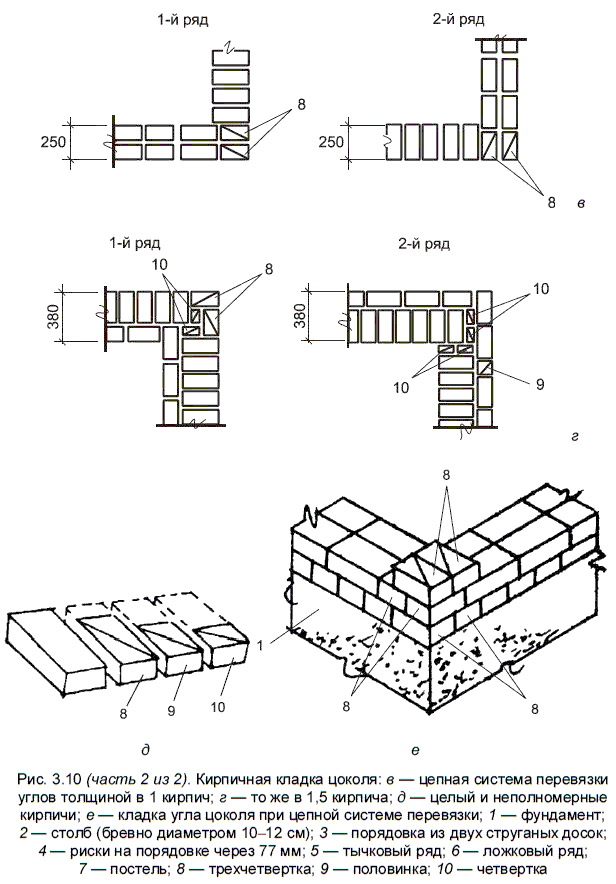

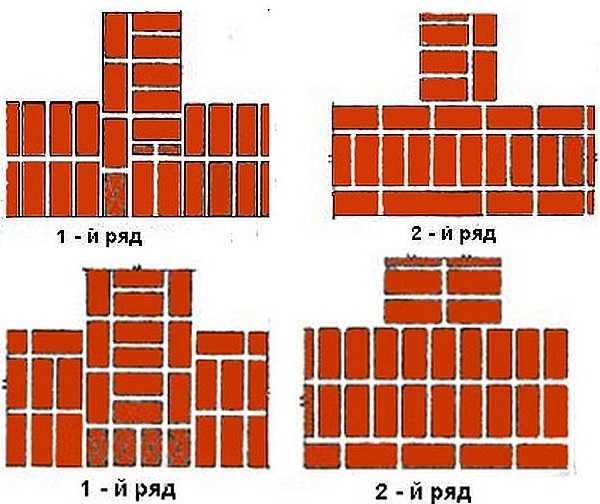

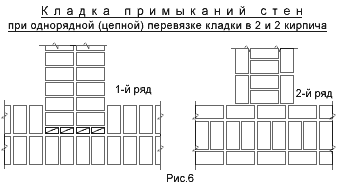

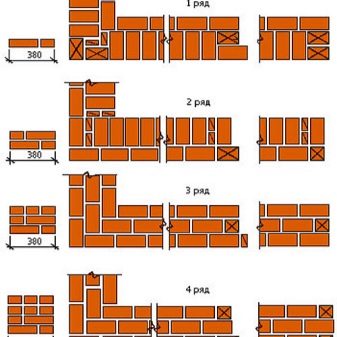

The wall thickness of one and a half bricks is another common masonry in the construction of buildings. The bricks are laid from the corners, the first bricks in the row are necessarily perpendicular to each other. The thickness of a brick wall of one and a half bricks is equal to 38 cm of masonry.

Control over the correct laying of bricks can be carried out using a special building corner.

The laying of the first row in this form is carried out using a cord that is stretched in height between the first and second bricks. The jagged surface of the bricks is located on the outside, and the bricks of the first row of the inner side of the masonry are directed with the spoon part inward.

The bricks in the next row are stacked in the opposite order. This creates a mirror image of the bricks in the first row. As a result, the inner side of the wall is bricked, and the outer side is half-brick.

The use of one and a half brick masonry has become widespread due to the required structural strength. The vertical seams do not match anywhere, and are overlapped by the surface of other bricks.

When performing masonry, the width of the seams is a very important indicator. If the size of the seams increases, it means that there is a deviation from the vertical or from the direction of the entire masonry.

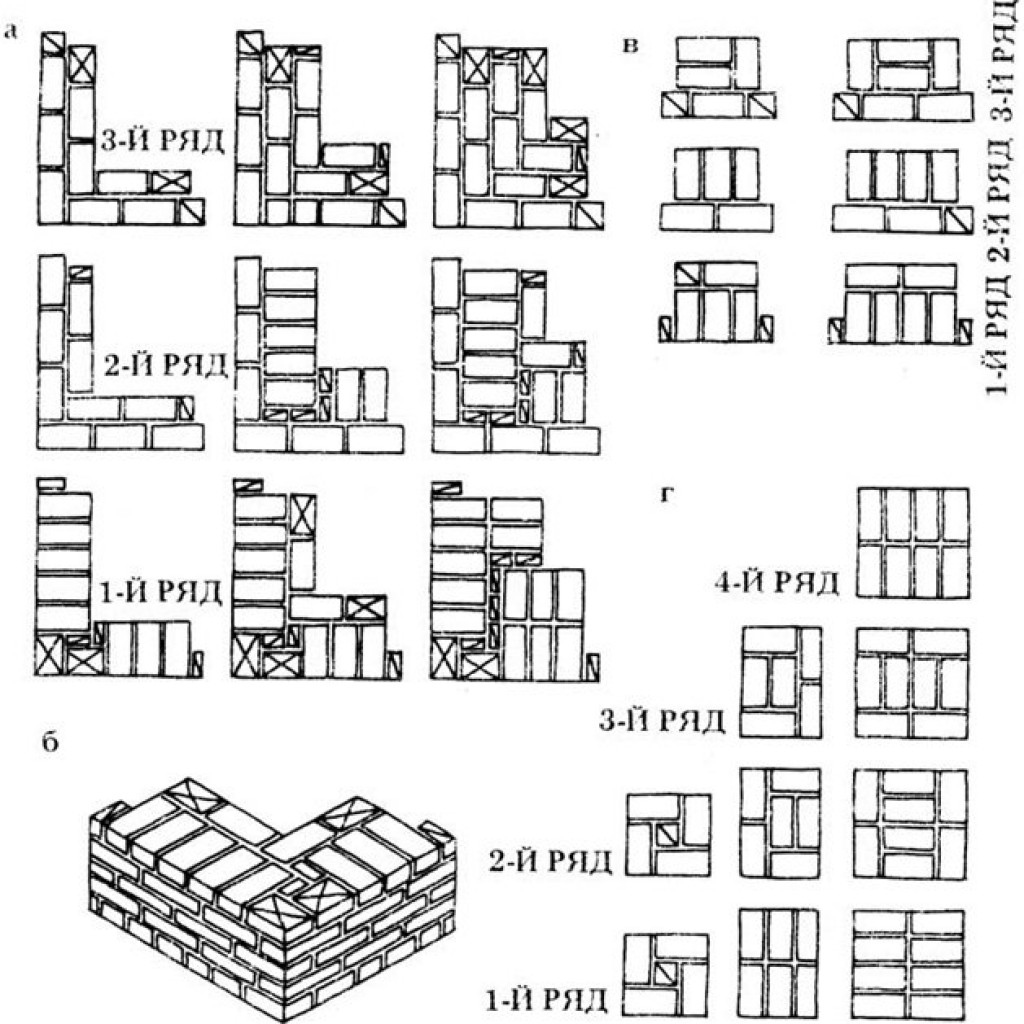

Fence masonry: technology

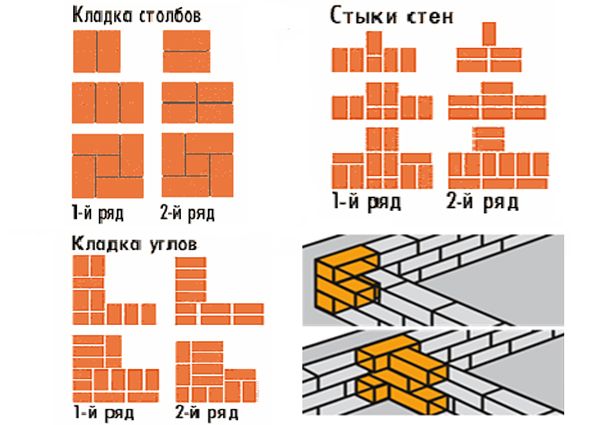

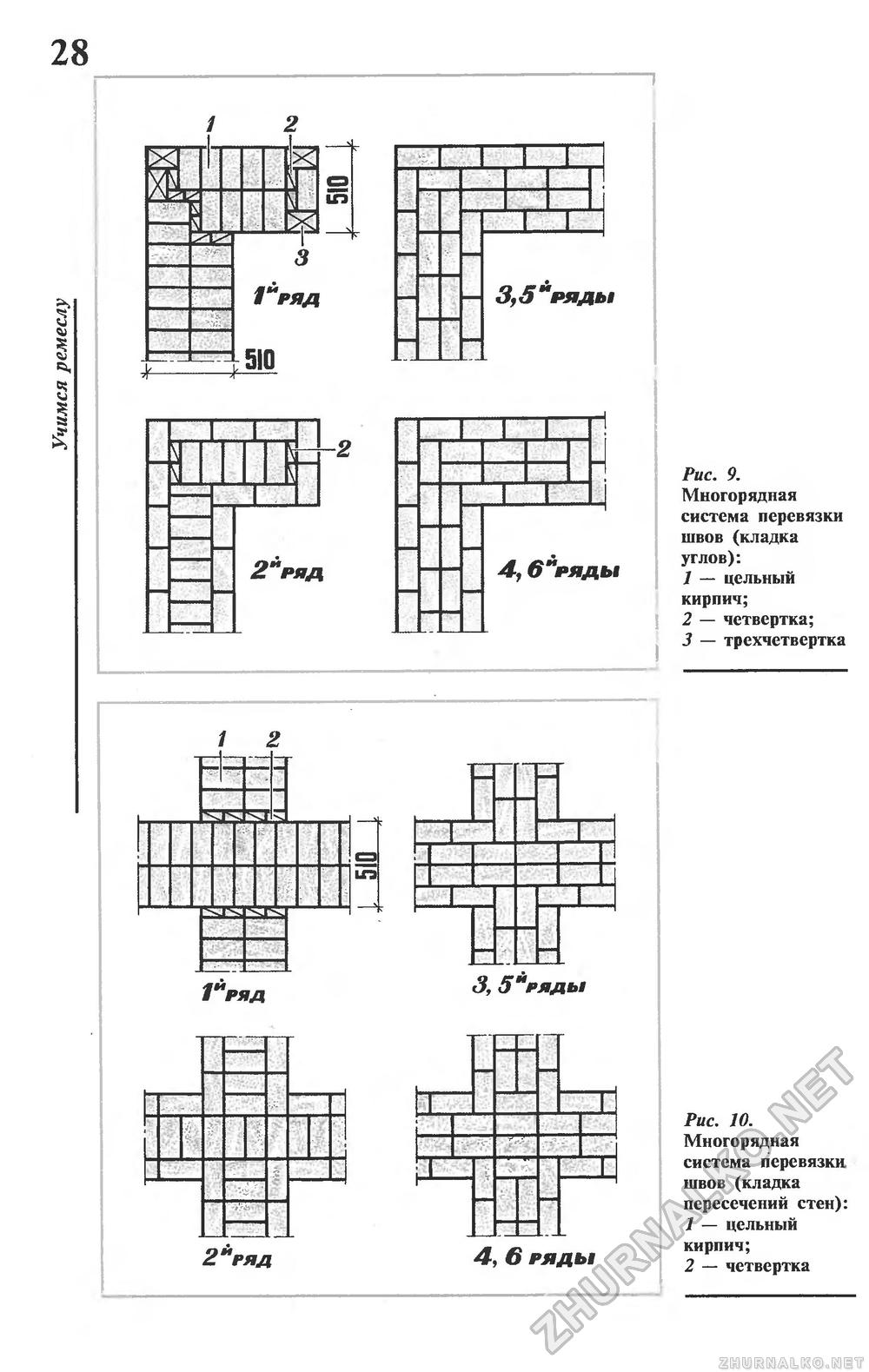

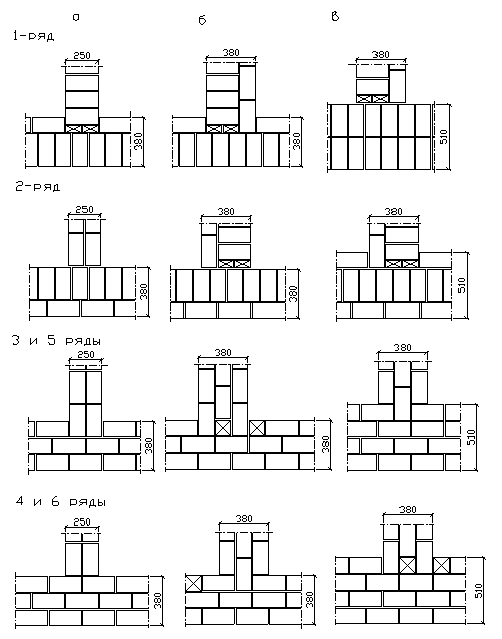

In most cases, the fence posts are made in 1.5 or 2 bricks, the section is 380 * 380 mm and 510 * 510 mm, respectively, the height is up to 3 meters.

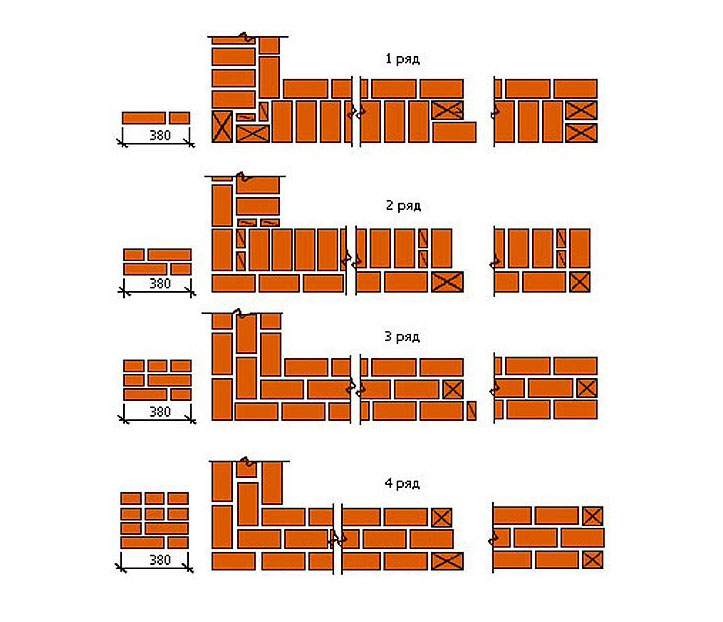

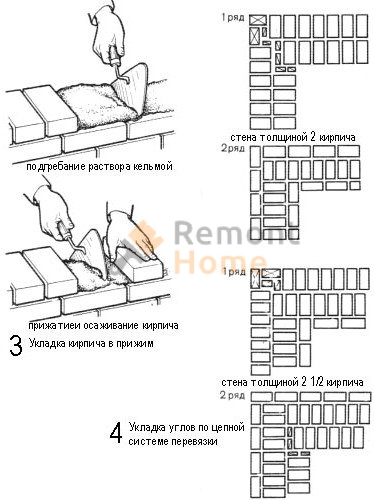

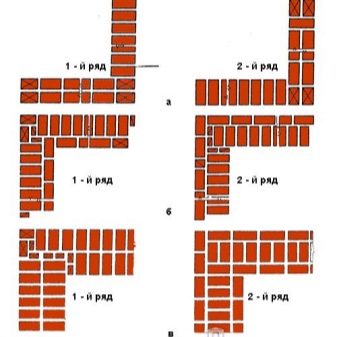

The laying is carried out with a bandaging (offset) - the seam of the lower row is overlapped by the "body" of the brick lying on top. The seam is standard - 8-10 mm. The scheme of laying posts in one and a half and two bricks in the photo below.

Brick pillars in 1.5 and 2 bricks

Laying pillars: order of work

Cut-off waterproofing is spread on the finished foundation. It can be roofing material in two layers, but waterproofing on bituminous mastic is better. This layer is necessary so that the brick does not "pull" moisture from the soil. If wet brick freezes, it quickly begins to crack and crumble. Therefore, waterproofing is necessary.Rolled waterproofing can be replaced - twice smear the foundation with bitumen mastic, and in areas with high humidity it is better to make a double waterproofing - smear with mastic, and then also lay "Gidroizol".

According to the dimensions of the pillar, a solution is applied to the waterproofing with a layer of a little more than 1 cm.According to the diagram, bricks are laid on it. They are leveled vertically and horizontally by tapping with a special rubber mallet. Craftsmen can use the handle of the trowel, but, in this case, the remnants of the mortar can fly off the plane of the trowel, staining the hands and brick, and it is not wiped off the cement well.

Ceramic brick absorbs moisture very quickly, so if you hesitate a little, it will be difficult for you to "put" it in place. In order for the mortar to retain its plasticity longer, the brick is dipped in water for a few seconds before laying. The same maneuver makes it easier to wipe off the solution from the surface (it is removed immediately, with a dry cloth).

Hammer down

The second row is also placed: a mortar is spread on the bricks, bricks are placed on it, but with a dressing - unfolding so that the seam is blocked. Level again. Then they take a tape measure and check the dimensions of the stacked rows. Even a small offset of 1-2 mm is eliminated. They tap on the end of the brick (called a "poke"), moving the bricks closer. Then, if the side edges were not coated, the vertical seams are filled. All subsequent rows are laid in the same way.

If there is a void between the inner reinforcement pipe and the brickwork, it is filled. If the distance is small, you can use a masonry mortar, if the void is significant, to save space, you can fill it up with rubble, tamp it, then spill it with a liquid cement-sand mortar.

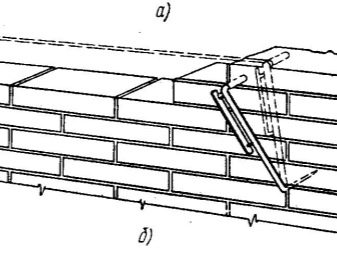

Bar masonry

The laying of the pillars described above has long been tested, but for beginners, when making their own, it is difficult to maintain an even seam. Another problem - the solution crawls out of the seam, staining the surface. It turns out not very nice. To facilitate the work, they came up with a masonry for a bar. Take a square metal bar with a side of 8-10 mm, cut it into pieces, 10-15 cm longer than the size of the post.

Bar layout

Having laid the first row, a bar is laid on it along the edge of the brick. The site is filled with a solution with a small margin, and closer to the pipe, the layer is made larger. Then, leading with a trowel along the bar, remove the excess, cleaning the bar from the solution. But at the same time, the slope of the solution remains. They put a brick, level it. At the same time, the bar does not allow it to settle strongly, and the position of the other end is controlled by the level.

Apply the solution to the side face under the bar.

Then they take a short piece of a bar of about 10 cm (for a vertical seam), put it along the butt, apply the mortar with a trowel to the side of the laid brick, also removing the excess along the bar. The second brick is placed and leveled. After the level is set, the seam is pressed from above with a trowel, and the vertical bar is removed.

We take out the bar, holding the seam with a trowel

This is how all the bricks in a row are laid out. Then the rods are taken out, proceed to the next row. This technology of laying brick posts allows you to control the seams and make them neat. Even a novice amateur bricklayer can fold a pillar with his own hands.

It is only important in the process to control the parameters of each row (so that the column in the section is of the same size)

Video lessons

A more complex version of a brick pillar - twisted with a screw

Features of working with ceramic bricks

How to do it yourself?

A wall, a basement and any other structure can be made using 1.5 brick masonry without the involvement of professionals. Of course, the result will largely depend on the quality of the work performed. It is necessary to rely on step-by-step instructions to achieve the desired result. Let's get acquainted with all the stages of such work on the example of making a wall of 1.5 bricks.

Preparatory stage

As with any other construction work, the manufacture of a brick structure according to the above scheme involves a number of preparatory steps. You will need to buy high-quality building materials and prepare a suitable binder solution for it. In addition, you will definitely need to purchase a number of tools and accessories:

- trowel (otherwise it is called a trowel);

- hammer;

- jointing;

- mop;

- plumb line;

- level;

- square;

- cord;

- ordering;

- roulette;

- rule;

- pendulum.

Before proceeding to installation, you will need to familiarize yourself with a number of nuances (consider them using the example of building walls):

the thickness of the specified masonry usually reaches 380 mm (this parameter is the sum of the parameter of the width of one part, the width of the element joining it and the thickness of the seam);

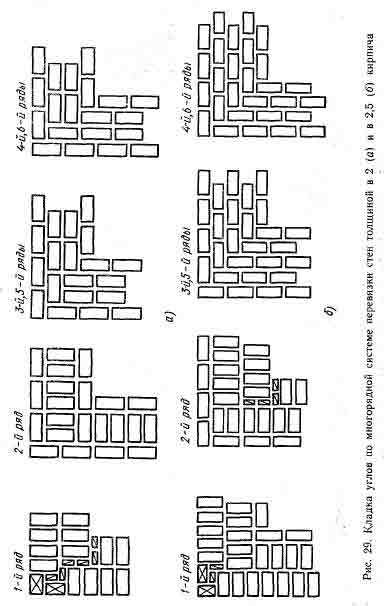

you will need to pay special attention to the correct layout of each corner and bandaging of the rows;

for a sufficiently good dressing of 1.5 bricks, it is required to use full-length, half-length, and three-quarter products;

you will first need to mark the placement of 1 row (of course, after choosing the laying technology).

Bandaging options

Usually, masters turn to these types of dressings:

- single row (or chain);

- multi-row.

Single-row dressing is recognized as simple. With it, the butt and spoon rows are alternated on the outside of the planned base (if it is a wall). In this case, large quantities of non-full-sized bricks will be needed.

Multi-row dressing is done like this:

- the starting row is laid out with a "spoon-poke";

- the second is the opposite;

- 3,4,5,6 rows are laid out with spoons with a bunch of seams in a half-brick.

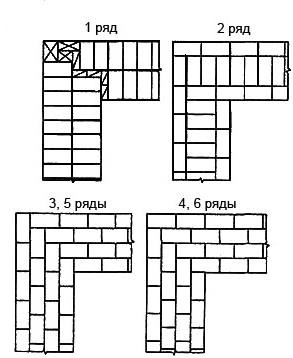

Laying corners

Angles are the basis for building brick structures such as walls. Even small flaws in the layout here can lead to a serious violation of the geometry. Because of this, the bearing capacity of the structure can be significantly reduced.

This is required so that it becomes possible to set orders and it would be possible to stretch a special cord between them. It will help keep track of the evenness of the rows during the laying process. The technology of laying out 1.5 bricks is complicated when compared with the technique of 1 block. This is due to the fact that in the first case, it will be necessary to use building materials of various formats (this means fours, three-quarters and half).

Masonry work

First, you need to waterproof the foundation by laying sheets of roofing material on it. After that, using the building level in the corners of the future construction, masonry is made in several rows. Angular orders will then be attached to them using special brackets. You will need to stretch a special lace along the orders. It is advised to place it every 5 m. If the value of the length between the constructed corners is more significant, then in order to avoid stretching the lace, a beacon made of bricks is placed in the middle. After that, it is possible to move on to arranging brick rows.

Using a trowel, lay out the prepared masonry composition. The distance from the edge of the wall should be about 20 mm. If the seam begins to fill entirely, then no more than 10-15 mm. The thickness of the layer should be kept within the range of 25-30 mm. Based on the consistency of the solution, seams of 10-12 mm will be obtained.

Masonry techniques

There are three types of masonry in 1.5 bricks. Let's get to know them.

- We will press. This method of laying bricks is recommended if you are working with a solid binder. In this case, the seams are completely poured, their joining is carried out. The remains of the mortar are pushed to the vertical of the previously delivered block with a trowel. Then they put the next brick, which must be pressed against the trowel. The trowel must be pulled out sharply. At the same time, the laid out part is upset.

- Inspired. This method is relevant when working with a plastic composition. At the same time, the brick is slightly tilted, the laid mortar is touched with one facet, it is moved to the previously fixed part and upset.

- Insertion with undercut. This technology differs from the above only in that the binder must be laid at a small distance from the edge of the wall. The solution protruding beyond the joints is then removed with a trowel.

A 1.5 block layout can be done with insulation. It is simply attached to a load-bearing wall base with further plastering.

Features of brickwork basement

It is important to be careful about the phased execution of work, to do everything in the prescribed manner. This will make it possible to get a high-quality structure.

Expose the corners of the structure: bricks are placed along the width of the planned structure

It is important to apply a level for the accuracy of the position of the corners. Once the position is established using the level, the bricks do not move.

Then the sides and diagonals of the surface are measured: they must be equal

This makes it possible to establish the correct placement of bricks. The maximum error can be 2 cm. Correct setting of the corners affects the strength of the house.

There are a number of nuances when laying bricks.

Brickwork during the construction of different stages of the building has its own subtleties:

- The brick for the basement is placed on a mortar of cement and sand: in it, one part of cement corresponds to three parts of sand.

- The thickness of the basement structure is determined by the material that will be used for insulation. When using foam, the thickness should not be more than 38 cm.

- Usually the laying is done in 2 bricks, this technique is optimal. Do not forget about the thickness of the planned walls. It is not advised to lay out the basement thicker than the walls. Then, at the junction of the basement and the walls, water can accumulate, which will entail accelerated destruction of the room.

- When laying out, you can use different bricks. The choice depends on the installation. Both solid bricks and halves can be used. When laying, it is recommended not to forget about the ventilation holes, they should be at a distance of 2 meters from each other.

- It is recommended to reinforce the masonry every 2-4 rows; for this purpose, a mesh mesh of 5 * 5 cm is used.

- In relation to the walls, the plinth can be flush or sink. It is better to prefer the second option, this will not allow moisture to get from the walls.

How to properly lay out a brick base?

Device brick plinth differs little regardless of the thickness of the wall and the number of rows.

Step-by-step instructions on how to lay a brick base:

- The foundation is treated with bituminous mastic.

-

The base is waterproofed by laying roofing material and treating the side surfaces with penetrating compounds. The rolled material is laid with an overlap at the level of 10 cm, the waterproofing should protrude 3-4 cm beyond the foundation.

- Final check for correct location of corners and plane.

- A working solution of the M100 brand (M75-M125) is prepared.

- The solution is laid on the foundation to a thickness of up to 2 cm, and a 4 mm wire with a cell size of 4 cm is inserted inside.

- The laying of the first row is carried out, work should be started from the corners.

- After the first layer, check the level of the plane to correct the thickness of the seam.

- During the laying of the subsequent rows, dressing is performed, the scheme is selected individually, more often occurs after 1-3 rows.

- Reinforcement mesh is laid every 4 rows.

- In the last layer of the base / plinth, holes may be required for laying the floor with the installation of rails or channels.

- Thermal insulation of the basement from bricks from the inside or outside with extruded polystyrene foam.

- Facing the plinth with decorative stone, plaster or ceramic tiles.

1 brick

Plinth masonry in 1 brick is used for lightly loaded structures: garages, agricultural buildings, workshops, etc.

If you do everything with your own hands, you can simplify the task a little and lay out the brick in one row.

If you do everything with your own hands, you can simplify the task a little and lay out the brick in one row.

The laying procedure is performed according to a single system, but it is important to adhere to the basic rules:

- in the process of laying, the seams of one row and the other must not be allowed to coincide;

- the wall must be reinforced to prevent cracks;

- it is recommended to cover the brick base with cladding.

2 bricks

The laying of a basement in 2 bricks differs only in the method:

- dressing is performed infrequently, 1 time in 2-3 rows is enough;

- reinforcement is best done every 2-3 rows;

- acceptable brick displacement in each row - 25%, ideal - 50% of the brick width.

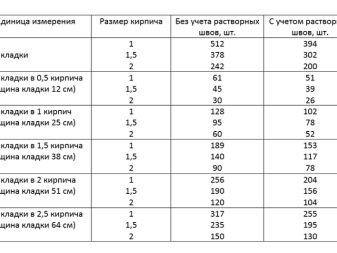

Payment

A standard brick is a product 25 centimeters long, 12 centimeters wide and 6.5 centimeters high. The proportions are quite harmonious. Knowing the size of one brick, it is easy to determine the quantitative need for its application. It is believed that if the mortar joint is 1.5 centimeters, at least 112 bricks will be used for each square meter of masonry. However, the brick that was available after production and transportation may not be ideal (with chips, etc.), plus the stacker may not have very good skills. In this case, it is appropriate to add 10-15% of the required amount of material to the calculated amount.

112 bricks per square meter turn into 123-129 pieces. The more experienced the worker, the fewer additional bricks. Thus, 112 bricks per 1 meter is a theoretical minimum, and 129 pieces is a practical maximum. Let's consider the simplest example of calculation. The wall is 3 meters high and 5 meters long, giving an area of 15 square meters. It is known that 1 square meter of single-row masonry requires 112 standard bricks. Since there are fifteen square meters, the number of 1680 bricks needs to be increased by another 10-15%. As a result, no more than 1932 bricks are required for laying the specified wall.

The optimal thickness of the brick wall of an individual house

Water at low temperatures tends to expand, and this causes deformation of insulation structures or seams at the joints. It penetrates directly into the insulation and lowers its thermal insulation properties; it is also an excellent medium for the reproduction and growth of fungi and other microorganisms. When water vapor critically saturates the air, surfaces that have a colder surface become covered with water, and this is called condensation. If you do not take action, then the insulation will be at risk.

How can you get rid of this? In order for the wall insulation to be protected from moisture, the insulation must be covered with a vapor barrier film (better known brand), while ensuring the sealing of the joints and lines where the film adjoins. The thermal insulation material must have a low vapor permeability, this will allow steam to escape, thereby ensuring more efficient use of the material.