A LITTLE NOTE BEFORE YOU START

This is only the fourth article in the series, and the work that I am proposing today may seem rather complicated to you. If so, just read this material first. First, after reading it to the end, you can see that there is nothing particularly difficult in this work, you only need accuracy and patience. And secondly, it gives us the opportunity to master several essential skills at once, which will be useful in any other marquetry work, namely:

- preparation of veneer for work,

- preparation of drawing for marquetry,

- correct cutting of sharp corners,

- meaningful cutting sequence that greatly simplifies the work.

And even if you do not dare to make something like that, your knowledge base will be enriched with useful tips and techniques that are applicable for pictures of any complexity and any kind.

EVERYTHING YOU NEED FOR THIS ARTICLE IS HERE >>>

I already have some work with these polygons. See how advantageous they look when they are self-styled:

So let's get started.

Pros and cons of stone veneer

Before purchasing stone veneer wall panels, you should familiarize yourself with all the advantages and disadvantages of this finishing material. The pluses include:

- Flexibility and ductility of the material, so it can be attached to objects of various shapes and sizes.

- Water resistance, due to which stone veneer is used in rooms with high humidity.

- Air permeability to prevent the formation of mildew and mildew.

- Durability. Subject to the technology of production and installation, the service life of one panel is at least 35 years.

- Light weight and easy installation.

- A rich palette of shades and compatibility with other materials.

Veneer has few disadvantages:

- The material cannot be called completely environmentally friendly, because it contains synthetic components that can cause allergic reactions in rare cases.

- The price of a standard slab is much lower than porcelain stoneware, but it is also not a budget material.

Installation features

To prevent stone veneer sheets from losing their appearance, they must be properly stored, even for temporary storage. The site must be chosen completely flat, and the panels must be laid face up, back down.

Stone veneer looks organic in any interior. The main thing is to do the work correctly:

- The beginning of the process is traditional for finishing - surface preparation. Any basis is suitable: plaster, drywall, chipboard, fiberboard, MDF, wood. The surface should be even, smooth, since the finishing material is very thin and any flaws in the base will certainly affect the quality.

- What are the sheets of stone veneer glued to? The most suitable are varnish-based dispersion adhesive mixtures (for example, Henkel P685, Soudal Fix Sika Bond T8, D3), as well as waterproof polyurethane glue. You can use adhesives based on ethylene-vinyl acetate copolymers.

- For cutting the panels, it is best to use diamond saws, and the edges are sanded for a better fit and fit.

- The adhesive is applied to the back of the sheet and allowed to dry a little. the base is also covered with a continuous layer of glue. You can use a roller or a wide brush.

- Then the sheet is pressed tightly against the base. If the surface is horizontal, use a press.

If it is necessary to arrange curvilinear sections of the surface or arches, then the workpiece is heated with a construction hairdryer, or in another way and bent under the required radius.

Often, finishing is performed with pre-prepared panels, consisting of a substrate with a sheet of stone veneer glued to it. In this case, for better adhesion of such a panel to the wall, the back side is decorated with compensation material. One of the best solutions is the use of impregnated paper with a density of more than 150 g / m².If significant temperature differences are possible in the exploited premises with stone veneer finishing, then denser materials should be used for the compensation layer.

Stone veneer - what is it?

At all times, decorating a room with natural materials was considered a sign of wealth and luxury. Few could afford stone slabs in the interior. In addition to its high cost, such material has a large specific weight and installation features, in which fastening is possible only on a flat, smooth surface. All the shortcomings that the natural stone finish has were leveled by the discovery of the German Gernot Ehrlich.

While renovating one of the stone countertops, he stripped off a thin surface layer of slate that looked just like stone. At the same time, the layer was light, moderately elastic and strong. The specialist continued to work in this direction and soon the whole world learned that this is a stone veneer. Ehrlich's company began to produce building material from a thin plate of natural stone, bonded with polyester resin and fiberglass.

Stone veneer - composition

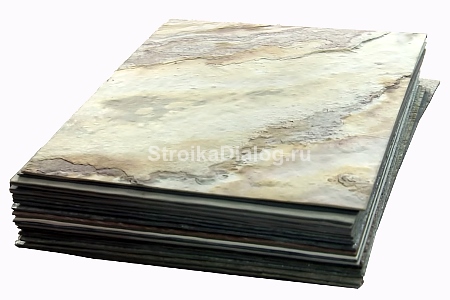

By its composition, composite stone veneer is a hybrid material that combines the gifts of nature and modern scientific developments:

- The top layer is a thin slate or marble slice (0.3 to 2.5 mm thick).

- A special adhesive is applied to the stone, connecting it to the substrate.

- By producing flexible stone veneer, manufacturing companies have learned to use a variety of materials as a base, the characteristics of which also determine the further use of the product. Fiberglass, cotton, fleece, polyester, translucent fiber can be used as a substrate.

Where is stone veneer used?

Many professional designers claim that stone veneer is the finishing material of the future that fits perfectly into interiors of a wide variety of styles. It is used when:

- Production and decoration of furniture for home and office.

- Transparent stone veneer looks great in various illuminated art objects, creating an amazing play of light.

- Exterior decoration of fireplace portals, as the material tolerates high heating temperatures well.

- Planning the decor of walls, floors and ceilings in any room.

- Particularly durable panels are used to decorate the facades of offices, shops, cafes and country houses.

Stone Veneer Furniture

An innovative area of application of stone veneer can be considered the creation of furniture facades:

Kitchens made of stone veneer based on MDF panels are very popular.

Such material is easy to maintain and can withstand severe mechanical and thermal stress, which is very important for kitchen furniture. In addition, the stone is perfectly combined with a variety of styles for decorating a room for cooking and eating.

We will use the material in the production of furniture for the living room and hall.

It is possible to decorate with stone panels both bar counters or receptionists, and other furniture for business. In addition, illuminated stone veneer looks very original and advantageous, which is also important for the author's interior design.

Stone veneer on the facade of the house

Lovers of natural materials prefer stone veneer facades instead of the usual plaster and painted layer. The material is mounted on top of the insulation using special glue, which gives the following advantages:

- The stage of the so-called "wet operations" is skipped, which reduce the durability of the facade.

- The technological stage of work is simplified, the installation time is reduced to 1-2 days.

- The service life of the facade is increased. Stone panels are guaranteed to be used for about 50 years, withstanding temperature extremes and various atmospheric phenomena.

- Facade maintenance is simplified, which consists only in rare cleaning with plain water.

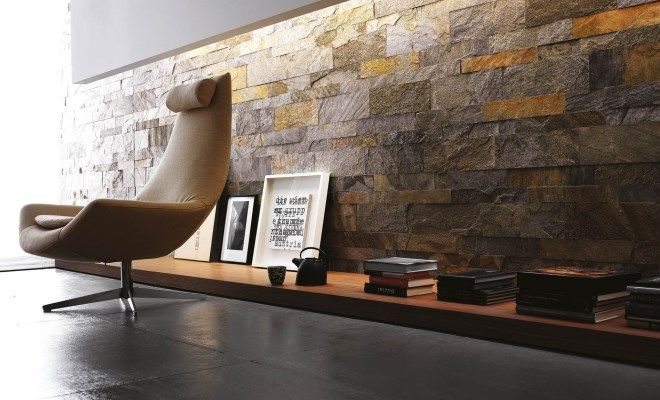

Stone veneer in the interior

In the last decade, flexible stone in the interior has become one of the most popular finishing materials in the mid-price category. Such panels are used for decoration:

- Walls in houses and apartments. The use of the material in the bathroom is especially important, in which such panels are a more stylish alternative to the usual tiles.

Offices and commercial spaces, especially walls and floors.

Unusual ceilings.

Openings, niches and columns.

Window sills and doors.

Portals for electric fireplaces or cladding a classic fireplace with a closed hearth.

Scope of application of stone veneer

- Furniture manufacture: kitchen and not only. In particular, stone veneer is used to create rounded surfaces.

- Cladding of walls, columns, furniture, floors... A stone veneer with a reinforced surface is suitable for flooring.

- Creating mosaics: wall, floor, etc. The seams are rubbed with special waterproof compounds.

- Manufacturing of commercial equipment: both individual products and completely interior for a cafe, office, store, etc.

- Manufacturing of stained glass and other products: transparent stone veneer transmits light, and therefore can be used to veneer backlit products.

- Finishing of facades of houses - another direction of using flexible slate. Such cladding will not crack and fade.

Operation and installation

In order for natural veneer not to prematurely lose its qualities, it must be properly folded and stored. The site for this should be selected as flat as possible, while the panels should be laid with the front side up. Whatever the interior, stone veneer will look as attractive as possible in it. The main condition for a successful result is correct installation.

- To begin with, it is worthwhile to properly prepare the surface. In this case, drywall, plaster, chipboard, fiberboard and MDF can act as the basis. The main thing is that the surface is flat and smooth.

- Natural veneer sheets should be glued using a dispersion adhesive mixture with a varnish base. Alternatively, you can use a waterproof polyurethane or ethylene-venyl acetate adhesive.

- It is better to use a diamond saw to cut the product. The edges should be sanded to ensure a good fit and fit.

- The adhesive must be rolled onto the back of the veneer and left to dry. An adhesive is also smeared on the base.

- The veneer sheet must be pressed tightly to the main surface. In some cases, installation is impossible without a press.

If it is necessary to design a curved section or an arch, the workpiece is heated in advance. Unfortunately, one veneer sheet is not always enough for wall cladding, so the master has a new task, namely, sealing the seams. To solve the problem, experts recommend using a moisture-resistant epoxy grout. Since this substance is sold in different colors, the consumer can easily choose the option that best suits the stone veneer.

Stone veneer Classic

Stone veneer Classic from the Slate Lite trademark is a strong and reliable four-layer material. Its structure includes directly slate, polyester resin, fiberglass and a substrate of any material (based on the scope of application).

Classic opaque stone veneer is used for cladding buildings, floors, walls, ceilings, fireplaces, columns; manufacturing of furniture, facades, countertops and design elements.

We do not produce stone veneer ourselves, but we cooperate with its manufacturer - the company "Leaf Stone". If you would like to have a stone veneer in your interior, our experts will not only help you with the choice, but will also make any product for you from flexible slate.

Slate Lite stone veneer is a reliable innovative material characterized by naturalness, safety and durability.

VENEER MARKETRY - PRODUCTION TECHNOLOGY: VIDEO

Craft 45: Marquetry Technique

Wood mosaic master class Marquetry

- Device for folding clothes with your own hands CONVENIENT DEVICE FOR FOLDING CLOTHES To ...

- Do-it-yourself bent tree How to bend a tree with your own hands ...

- Do-it-yourself bouquet in a pumpkin - master class and photo Do-it-yourself pumpkin bouquet Often ...

- Wet facade with your own hands "Wet facade" technology as an example ...

- Do-it-yourself tiled table - decor Old table decor Many have somewhere ...

- Stable do-it-yourself folding goats for a workshop - photo and drawing Folding goats for a workshop with your own ...

-

Box with a secret with your own hands - photo master class CASKET PUZZLE WITH YOUR HANDS STEP BY STEP Today ...

With your own hands ›Joiner› Do-it-yourself veneer mosaic (marquetry) - a beautiful master class

Varieties and sizes

There are currently several varieties of stone veneer on the market.

- Slate Lite. This material, which is made of stone, has high strength and a large thickness of the inner layer. It contains slate, fiberglass and backing. This type of veneer is used for facade cladding, interior and exterior finishes. The seamless texture of the sheet allows it to be laid on metal, concrete, brick and wood surfaces.

- Eco Stone is a natural stone veneer with a natural cotton backing. Walls, furniture and objects in the interior are clad with flexible and thin material.

- Translucent is a transparent stone veneer used for illuminated interiors. It is characterized by brightness and showiness, which is why it is often chosen by consumers.

With the help of composite marble veneer, you can make your life more original. Material imitating marble, white, onyx, granite, black, light gray and others are simply irreplaceable for decorating columns, walls, partitions.

Benefits of using stone veneer in the interior

1. Sheets are suitable for interior and exterior decoration of premises.

2. The flexibility of the material allows it to be used on curved surfaces.

3. For the protective treatment of veneers, standard varnishes can be used. Over time, they will make the surface color deeper and more saturated.

4. Installation of sheets is simple and quick, as their standard dimensions are large enough (610x12200 or 1220x2440 mm).

5. A thin fiberglass backing creates a waterproof barrier in the veneer. It also gives the material additional strength.

6. The light weight of the sheets facilitates their transportation and installation.

7. Cutting of stone veneer sheets can be done with any carbide joinery tool or metal scissors.

8. For fixing veneer to the surface, you can use a wide variety of compounds: PVA, contact, construction, epoxy and other adhesives.

9. Sheets adhere perfectly to concrete, brick, plywood, chipboard, MDF and other surfaces.

10. Stone veneer combines a rich array of colors and textures.

How to glue stone veneer?

For professional craftsmen, wall decoration with stone veneer is an easy type of work that can be done in a relatively short time. With the proper skills and tools, an ordinary man in the street will also cope with such a task. Stone veneer can be glued to flat and curved surfaces made of:

- metal;

- concrete;

- plywood;

- wood;

- Chipboard and MDF;

- ceramic tiles;

- drywall.

Stages of pasting:

- Leveling the surface from significant irregularities.

- Dedusting with a special primer if necessary.

- Laying out and drawing up a plan for laying out sheets.

- Some masters advise to protect the edges of the panel with masking tape from the ingress of adhesive.

- Dilution of glue. It is applied to the panel and surface with a special notched trowel in a zigzag motion.

- The panel is pressed against a section of the wall, smoothed and fixed by hand for about 10 seconds.

Stone veneer adhesive

In order for a stone veneer on a wall or other surface to firmly adhere and serve the number of years declared by the manufacturer, it is important to choose the right adhesive composition. Professionals recommend using two-component adhesives or sealants based on:

- polyurethane formulations such as Tenax Titanium;

- dispersion varnish compositions, for example, Stauf D3;

- epoxy resins such as Litokol Litoelastic;

- silicones that are used in formulations of the Iposkol brand, for example;

- hybrid polymer mixtures (MS-polymers), for example, s-m Soudal.

Areas of use

Stone has long been a priority when decorating walls, as well as a furniture facade for a kitchen. Subject to the correct selection of texture, the master can achieve a unique design solution in his room.

Stone veneer has found its application in the following cases:

- cladding of walls and interior partitions;

- finishing of various niches;

- furniture cladding;

- covering of columns and other structures with a semicircular shape;

- the base for the wall panel.

The thin and lightweight veneer sheet looks great both in a public place and in a cozy home room. In order to decorate the room, it is not necessary to cover all the walls with this material, you can arrange picture frames with it. Such an interior is characterized by sophistication and completeness. Many craftsmen recommend including natural veneer in the design of an interior or front door.

Application in the interior

Natural stone veneer is widely used by designers in the design of premises for various purposes. Its rough surface makes it possible to use the material when decorating furniture, cars and yachts.

Veneer sheets are used for masonry paths, steps, foundation cladding and facade walls. Stone veneer can be used even in damp rooms, for example, when decorating a bathroom. This material, installed on ceilings, walls, floors and fireplaces, creates an aristocratic atmosphere in the living room.

Thin and lightweight sheets look equally good in public places as well as in cozy home rooms. All walls of the room do not have to be made of veneer only. Some owners prefer to make only picture frames out of it. In this case, the interior already looks complete and refined. Another option for partial decoration with veneer is its inclusion in the decoration of entrance and interior doors.

Impregnation for stone veneer

By its nature, oil shale is a porous material that can absorb moisture, fats and other substances. To minimize damage to the surface after installation, special impregnations are necessarily applied to the panels - impregnates. This flexible stone treated finish will not only last longer, but also have a more attractive appearance.

The following formulations can be used:

- Water based impregnation used on panels located in dry rooms and free of heavy mechanical loads, for example Henkel Ceresit CT17. Such compositions protect the material from dust settling.

- Acrylic impregnation , such as IPKOM (IR-01) EcoCristal, have greater strength and protection against moisture, therefore they are applicable for kitchen facades and aprons, bathroom panels, hallways and corridors.

- Polyurethane compounds are considered the most durable and help to protect the canvases from the external effects of an aggressive environment, for example, atmospheric phenomena. One of these is IPKOM (IR-15) front semi-matt varnish.

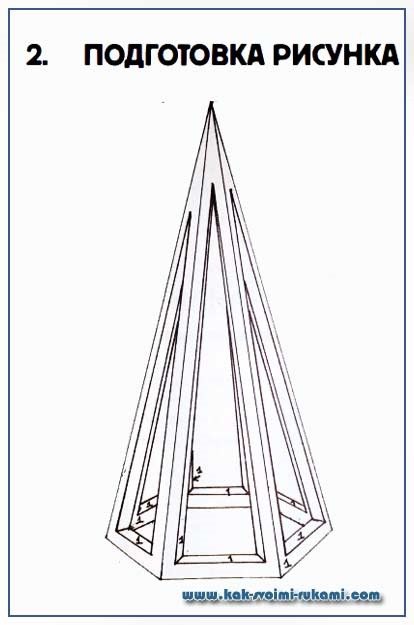

PREPARATION OF THE DRAWING

Let me explain right away why we specially prepare the drawing, and do not take it and immediately begin to cut it. First, the work is educational, and the process is more important here than the result. During the preparation of a picture from scratch, you will begin to develop the skill of developing any drawing: what is geometric, what is a flower, what is a river with a house.Secondly, during preparation, you comprehend the drawing: you understand how, where and why each line goes, then how to cut or saw it and what color it should be. Therefore, if there is no one behind your back who will always tell you, show and give the required veneer, then learn from scratch and thoroughly, performing each work by 110%. This is the only way to see your skill grow.

We print the desired drawing and outline the contours of future veneer inserts. Everything is simple here.

Who has seen coloring by numbers, where each number is a specific color? Our task is to do the same with the layout.

FIRST STEP.

We define the light source. My light will fall on the right, in front (I draw an arrow). Now we strain our spatial imagination and look at which facets the light will fall directly, illuminating them as much as possible. We mark all these edges with the number "1" (the lightest veneer). You can peep into the source, but still, each facet needs to be independently imagined and comprehended. Leonardo da Vinci will not paint other drawings for you, learn to work on your own.

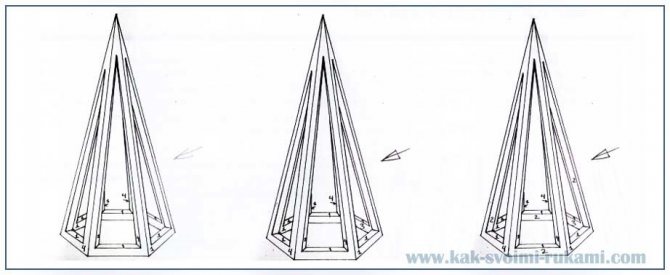

THIRD STEP.

The sides that are very slightly turned away from the light are the number "2", and those that are slightly turned away from the full shadow are the number "3". Ready.

With a palette of six gradations, the same steps: first the extreme values, then gradually move away from them. If some line is not clear, leave it, fill in everything that is understandable. Then go back to the blank and take a look. Most likely, it will be parallel to some already marked side, so little by little everything will be filled.

And remember that the layout for the marquetry is done in a mirror projection, because the side that will be the front for us during work, then goes under gluing onto the base, that is, the drawing is turned over. Our pyramid, of course, is symmetrical, but still, hanging it on the side of a window or other light source, the picture will look more natural if the light on it is located in the same way as it falls in life.

Properties and characteristics

In the case of the correct technology for finishing with stone veneer, it will be quite difficult for the consumer to distinguish it from natural slate. However, it should be noted that veneer is characterized by greater mobility, pliability and is lighter than stone. The presence of a fiberglass base and resins in the composition of the material makes it pliable and easy to bend. For this reason, it is practically indispensable for finishing surfaces with a complex or curved texture.

Stone veneer can be used to decorate the interior of the bathroom and dining room. Thanks to a wide range of panels, everyone can choose the perfect option for their interior.

Material advantages:

- environmental Safety;

- wear resistance and water resistance;

- the ability to use in hard-to-reach places;

- light weight and small layer thickness, equal to no more than 2 mm;

- incombustibility;

- ease of installation.

There are practically no disadvantages of stone veneer.

Using stone veneer for interior decoration in a private house

When developing a project for a private house, a lot of factors and values are taken into account. Compulsory calculation requires the load created by the building on the foundation. The lighter the material at home, the cheaper the foundation will cost. Cladding with natural stone looks very impressive, in addition to the high price, this method of finishing is very difficult. Each 2500x1500 mm slab weighs about 300 kg.

There is always a way out of this situation. Home decoration can be done with stone veneer. The relatively light sheets are easy to transport and install. Thus, the load on the foundation is reduced, and the appearance of the building is almost not affected. This is confirmed by numerous positive customer reviews.

Where is slate veneer used?

The possibilities for using stone veneer are unlimited. This material is used to finish almost any indoor surface, as well as decor items.The blades are lightweight (no more than 1.6 kg), so it is easy to work with them. Slate veneer is used for:

- cladding of walls, partitions, columns, ceilings in rooms for almost any purpose;

- manufacture of countertops, shelves, niches, bar counters;

- design of facades of kitchen furniture, interior doors, cabinets with hinged and sliding doors.

The thinnest stone veneer Slate Lite deserves special attention. Its thickness does not exceed 2 mm. Light weight and high flexibility make it unique. And such qualities as natural origin, durability and ability to transmit light are used in the production of plafonds for ceiling, floor, wall and street lamps. The same properties are widely used in the creation of individual decorative items and souvenirs.