Increasing moisture resistance

Is it necessary to process plywood to increase its moisture resistance, and, most importantly, how to do it? The easiest and relatively inexpensive way is to use a PVA (polyvinyl acetate) -based putty. In consistency, this putty resembles PVA glue. The impregnation process is as follows - putty is applied to one side until spots appear on the other. After that, the application must be continued, but from the other side.

Drying of the impregnated sheet will take about three days, while ensuring that the sheet is upright. After the specified time has elapsed, the plywood must be treated with an antiseptic solution. To increase the strength characteristics of the top layer, it is necessary to apply a layer of acrylic varnish on its surface. Painting can be done with a brush or roller in two layers.

There are other methods that can be used to turn ordinary plywood into waterproof. In other words, it is necessary to protect the wood from the moisture contained in the atmosphere. How to process plywood before laying it on the floor, you can use to solve this problem:

- paints and varnishes;

- drying oil;

- fiberglass.

Before soaking plywood from water, it is necessary to select only those paints and varnishes that are intended only for wood.

By the way, the use of paints is not very advisable, especially if the plywood will act as an independent floor covering. Over time, it will begin to peel off the plywood and, as a result, moisture will penetrate through such places into the body of the sheet.

In addition, if plywood will be installed in rooms with high humidity, then it should be painted on both sides and in several layers. If plywood is to be used as a floor covering and decorative coating is to be applied to its surface, varnish should be applied last.

Fiberglass, applied in accordance with all the rules on the surface of plywood, can guarantee its full protection from water and significantly extend its service life in the form of a base for linoleum or laminate, or an independent floor covering. Instead of fiberglass, medical gauze is allowed. Before laying it, varnish is applied to the surface of the plywood sheet, but at the same time it must be remembered that the use of epoxy or polyester materials is not desirable.

One of the disadvantages of this waterproofing method is the long drying time. It can take several days. Fiberglass is applied in approximately the same way, it is laid on a fresh layer of varnish. In this case, varnish must be applied to the edge of the sheet. The photo shows the process of applying fiberglass.

Plywood preparation for processing

Before processing plywood for the floor, it is necessary to perform some fairly simple measures. Plywood intended for additional processing must be dried to a certain limit.

In particular, before applying varnish or paint, the surface of the sheet must be treated with a fine-grained abrasive paper. In addition, it is necessary to process the ends of the sheet and remove possible burrs, scuffs, etc. from its surface. If necessary, you can use a putty. With its help, it is possible and necessary to eliminate relatively deep defects.

Surface grinding can be done manually, or using a surface grinder. Its use will speed up the preparation process several times.

The plywood that will be used for installation as a base or floor covering, like any other wood, must be acclimatized at the site of use. The length of this period depends on the temperature and humidity in the room. If in a warehouse or in a store where plywood was purchased there are approximately the same conditions as in an apartment, then one day is enough for acclimatization. If the temperature difference is up to 8 degrees, then before laying the plywood it is necessary to withstand three days, if the temperature difference is even greater, then the plywood holding period can reach one week. During this period, the plywood should be stacked.

Interested in how to make plywood moisture resistant yourself? Meanwhile, an ordinary sheet of plywood for interior work can be made water-repellent (in any case, the quality will be no worse than purchased plywood!). Not sure what materials are needed for this? Then get ready-made recommendations with step-by-step instructions from our specialists!

Plywood dyeing

When the question arises of how to treat plywood from moisture, experts advise covering it with varnish or paint. These materials definitely extend the life of the plywood sheet by an order of magnitude. To carry out high-quality work using paint, you will need:

- sandpaper;

- putty;

- primer for plywood;

- brush, roller or spray bottle;

- putty knife;

- paint for plywood.

Choice of paint

To maximize the life of a coating made of this material, consider the following recommendations when choosing a treatment solution:

- The paint does an excellent job of water-repellent function and ennobles the appearance of plywood.

- If you intend to install plywood sheets in a residential area, choose a water-based paint for them. It does not have a pronounced unpleasant odor, dries quickly and is easy to apply.

- If you will be working in an open space, enamel wood paints are better suited for this purpose. You can purchase any of them both ready-made and in concentrated form, which are intended for self-tinting.

Staining technology - method 1

A full-fledged painting technology consists of several stages:

- Sand the plywood to a smooth finish using sandpaper.

- Apply acrylic primer with a roller or brush.

- Let dry for a few hours.

- Scrap the surface, eliminating all microcracks.

- Leave the sheet until the putty is completely dry.

- Sand, removing any unevenness caused by the putty, to a level surface.

- Carry out the priming work again.

- Make a technical pause until the solution is completely dry.

- Prepare the paint if you are tinting it yourself.

- Paint the plywood sheet.

Staining technology - method 2

Another way to protect plywood from moisture is to use nitro paint along with the fabric. Coarse calico or plain fabric is usually used. Plywood processing with these materials is carried out as follows:

- Apply a layer of drying oil to the plywood sheet.

- Dry for a few hours.

- Treat with liquid paint that will function as a primer.

- Dry again.

- Cover the plywood generously with a layer of thick paint or nitro putty, first diluting it with a solvent.

- Prepare the fabric and spread it over the entire surface of the stove. Press lightly.

- Saturate with nitro paint thinner. It is convenient to do this with a brush.

- Wait for it to dry and cover the entire surface with liquid nitro paint.

A few more features to consider when painting plywood:

- Plywood sheets that have been in a damp, damp room must be thoroughly dried before processing.

- If you plan to install plywood in an open space or in places with increased dampness, then paint the sheet on both sides and in several layers.Work the edges especially carefully.

- Painting is not suitable for floor-mounted plywood. From constant walking on the painted surface of such a coating, the paint will peel off and fall off. In order to decide how to process plywood on the floor, consult with specialists in hardware stores.

- If you spray paint with a spray gun, you will achieve a more even color distribution. Use a brush in hard-to-reach places.

- If you decide to paint the plywood in different colors, limit the work area with masking tape.

We make plywood moisture resistant

There are three proven ways to improve the moisture resistance of plywood at home:

- Paints and varnishes (varnish and paint should be exclusively for woodwork);

- Drying oil;

- Fiberglass.

paints and varnishes

The first way to make plywood moisture resistant and extend its life is varnishing and painting.

Regular enamel paint for wood will perfectly cope with such work, it is easily applied to the surface and dries quickly enough at room temperature.

Before starting work with paint, you need to prepare the surface of the plywood sheet, the surface must be even and smooth. This work needs to be broken down into several stages, which include:

Before doing it, you need to level the surface and make it smooth. For this, coarse sandpaper is suitable. To get perfect smoothness, you need to go through the second layer, but this time with fine-grained sandpaper. This will give the smoothest plywood sheet surface needed for further work.

Then we treat the smooth plywood with a primer. The best solution would be an acrylic primer. This will preserve the structure of the plywood and get rid of small cracks.

The next step will be the painting itself.

If plywood will be used in places with high humidity, then special attention should be paid to painting. Painting on both sides is the right solution.

The edges of the plywood must be carefully processed with 2-3 layers of paint (these are the most problematic areas). If you are going to use plywood in a room where the air humidity is within normal limits, then you can paint the plywood on one side, but do not forget about the edges.

You can paint with a roller or brush. If you have a spray, it is of course best to use it.  With the help of a sprayer, you can get a better result and in this case the paint will be applied evenly.

With the help of a sprayer, you can get a better result and in this case the paint will be applied evenly.

And the last step is varnishing. The varnish is applied to the painted surface, previously slightly sanded with fine-grained sandpaper.

We thoroughly clean the surface from the dust obtained as a result of grinding and apply diluted varnish.

Drying oil for moisture resistance of plywood

Drying oil is the simplest and most common way to increase the moisture resistance of plywood. Drying oil can be purchased at any specialty store. When buying, you should think carefully about how much you need for high-quality plywood processing. The drying oil should saturate the plywood well.

The drying oil treatment will take place in several stages:

We heat the drying oil in a water bath to a temperature of 50-60 ° C.

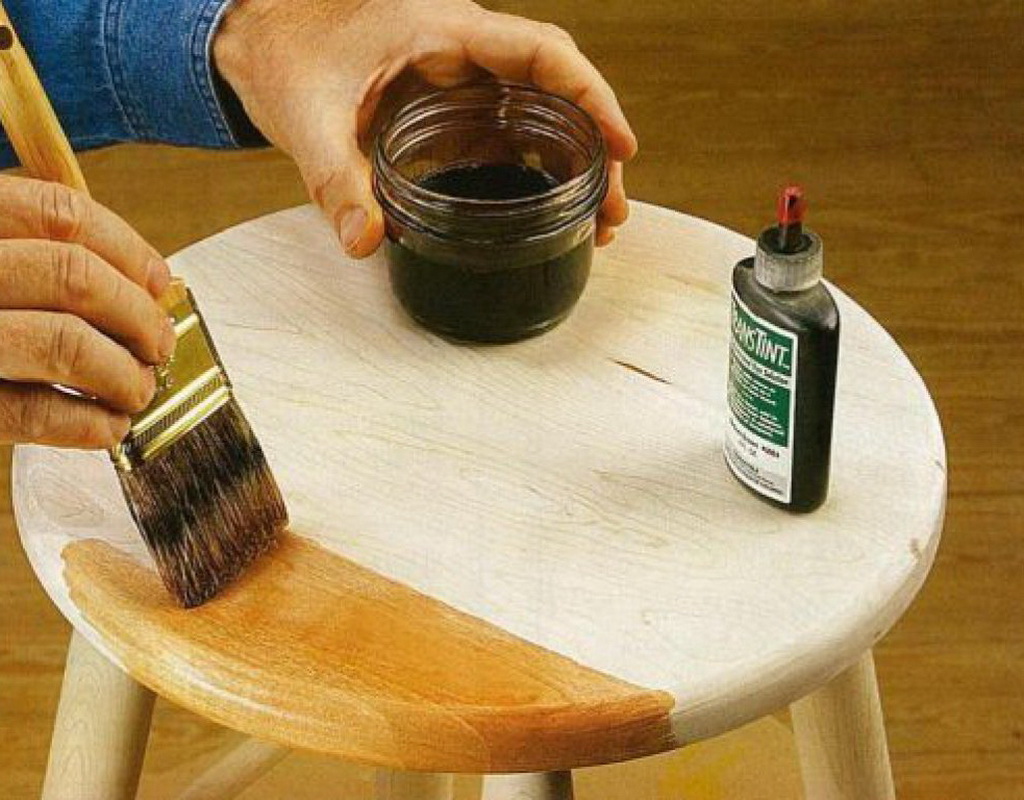

Apply drying oil to a sheet of plywood. This can be done with a brush.

Pay special attention to the edges and ends.

Then you need to dry the sheet. An iron or a hair dryer heated to 200 ° C is suitable for this.

After drying, apply another layer of drying oil and dry again.

We carry out this process until the plywood stops absorbing the drying oil and starts to push it away.

Plywood should be kept horizontal. This will give the maximum impregnation effect.

Fiberglass

This material will significantly increase the moisture resistance of plywood. The installation of fiberglass is quite simple. We treat the surface of the plywood with varnish and after a couple of hours we lay a layer of fiberglass.We process the ends of the sheet well with varnish and leave it to dry naturally for 2 - 3 days. This is the whole work.

If all the work is done carefully and observing all the rules, then there is no doubt about the moisture resistance properties of plywood.

Moisture-resistant plywood in accordance with GOST is designated by the FSF marking. This type of laminated board has many technical advantages and is used in many industrial applications.

But let's talk about everything in more detail.

Photo of waterproof wood-laminated board

How to increase the working life of wooden floors?

- The organization of the roof protrusion above the plywood sheet, fixed on the outside of the house, will make it possible to increase its service life.

- In order to protect the glued veneer placed on the street from the manifestation of moisture, it must be covered with another material, for example, plastic.

- The fasteners are susceptible to moisture first. Due to this, they should be covered with a reinforced impregnation layer.

- As very small cracks began to appear on the surface of the plywood exclusively, they must be immediately sanded and primed.

Likewise, by following a number of common tips, you can maximize the life of your plywood flooring.

Additional Information: How to protect plywood from moisture when laying on a wooden floor

All types of material are made on the basis of deciduous and coniferous veneer. To connect the layers together, special adhesive solutions are used, which are applied in accordance with a specific technology. This is what makes the product water-repellent.

- instability before ignition and spread of fire, since plywood is a wooden material, the level of its fire safety remains rather low;

- the cost of the material is slightly higher than that of similar materials in the form of chipboard or fiberboard;

- leveling with plywood by a few centimeters increases the height of the flooring, if the room has a rather low ceiling, this option is not suitable for it.

An important point! When processing plywood, special attention should be paid to the edges. However, before starting to cover the edge of the sheets with a coloring composition or impregnation, it must be putty, pasted over with a metal edging and primed

After all the above work, a coat of paint / varnish can be applied.

When performing protective plywood processing very carefully it is necessary to dwell on its edges. How to protect plywood from moisture and decay on the loggia? Impregnation for plywood on the floor is applied to the edges only after they have been putty, closed with an iron tip and primed.

Having done all these procedures, we proceed specifically to applying varnish or paint (in more detail: “How to paint plywood on the floor in order to improve water resistance”).

Among the variety of products, the most popular are glass fabrics, paint, varnish and drying oil. All these materials are able to protect plywood from moisture and temperature extremes. With such a coating, plywood will not absorb moisture, swell and crack, and mold and mildew will not grow on it.

The plywood ends of the structure require additional protection with a moisture-resistant sealant or paintwork. It will be more reliable to cover the ends with an additional plastic or metal plate. For this, ordinary corners made of thin metal - aluminum or duralumin - will do.

Thus, it is possible to significantly limit the contact of plywood with moisture and prevent swelling and delamination of the plywood sheet.

There are several methods for doing this. One of them is leveling the floor base with plywood. In order to properly carry out all the work, you need to know how and with what you can fix plywood to a wooden floor.

In addition, you need to know what kind of surface preparation work you need to do.

If you decide to lay linoleum indoors, then the device of a high-quality and solid foundation should be given primary attention. If the base is prepared poorly, then the life of the coating will be much shorter, so understand this issue as best you can in order to avoid mistakes.

We will tell you which plywood to choose and deal with the main features of the workflow.

Paint coating specifics and selection of suitable paint

The main thing is to keep the coating in good condition for a long time. Various colorants are good substitutes for the materials described above. Before impregnating plywood for the floor, it is necessary to decide on the paint, it is necessary to take into account what the operating conditions of the plywood coating will be. Water-based pigments and paints, especially latex and acrylic, are ideal for interior work other than flooring. It is best to cover a floor made of plywood sheets with linseed oil, and then some kind of varnish.

The situation is completely different if linoleum laying is supposed to be on plywood. In this case, acrylic-based dyes are suitable for processing glued veneers in the best way, because they perfectly protect against moisture and mold. Impregnation of wall and ceiling panels can be done with various quick-drying enamels.

For plywood processing, located on the outside of the building, very often choose either acrylic-based paints or varnish.

How to apply paint correctly:

- preparatory sanding of plywood will provide better protection against moisture;

- the hitch is provided by processing the glued veneer with a primer layer;

- in order to fill in all the microcracks and imperfections on the surface of the plywood, it is worth making a putty;

- excess putty is removed by re-grinding the surface;

- then another soil layer is applied;

- as soon as the soil dries up, we proceed specifically to painting the plywood.

All these steps are highly recommended by experienced professionals, as they provide a reliable and high-quality coating, as well as a beautiful appearance.

Plywood lamination

Another very effective method of protecting plywood sheets from an aggressive environment is lamination. In this case, you can immediately purchase the appropriate material with a protective film, or apply it yourself. What is lamination for:

- significant decrease in hygroscopic properties (plywood absorbs water and moisture less);

- increased durability and reliability;

- increased resistance to abrasion of external surfaces;

- mold protection;

- decrease in the degree of slip;

- giving the surface the desired shade and additional aesthetic appeal through the use of lamination with decorative patterns.

Performing lamination at home requires compliance with a number of safety requirements. The fact is that many lamination films contain formaldehydes, which become harmful to human health when heated. The lamination procedure involves heating, which ensures high-quality adhesion of the film to the plywood. That is why, for a safe procedure, it is necessary to use a respirator, and also to stick it in a room with good ventilation (or providing ventilation).

Film selection

For processing plywood and other sawn timber, the following types of films are used:

- melamine. They improve the resistance of wood sheets to moisture and wear. The composition contains formaldehyde resins.

- PVC films. Artificial polymer with excellent water repellency. Not harmful to health, ideal for residential use;

- phenolic. They provide a gain in wear resistance, but against the background of PVC analogues, they are worse in terms of moisture protection.

Plywood lamination procedure

In addition to the film and plywood sheet, you will need a respirator, rags and a hair dryer for work. Lamination sequence:

Heating the protective film with a hairdryer (it is important to observe the measure, otherwise bubbles may form on the surface).

Applying a heated film to the plywood and smoothing the already treated areas with a rag in order to get rid of the air between the tree and the polymer layer.

Getting rid of bubbles (if they have arisen, then a regular needle will help get rid of them). After that, you need to reheat the film with a hairdryer and level the layer .. As practice shows, from the point of view of saving time and effort, it is better to buy laminated plywood right away, since the procedure for self-lamination is quite troublesome and requires some skill and skill

As practice shows, from the point of view of saving time and effort, it is better to immediately buy laminated plywood, since the procedure for self-lamination is quite troublesome and requires a certain skill and skill.

Step-by-step instruction

We bring to your attention an algorithm on how to make plywood waterproof at home using a simple tool - drying oil:

- Apply drying oil heated to 50 ° C with a special brush on the prepared plywood sheet. Dry the oil coating from moisture with an ordinary household iron or a building hair dryer (at a temperature of at least 150-200 ° C). Further, you can alternate the layer of varnish impregnation and drying as many times as the plywood surface can absorb.

- Apply varnish to the surfaces treated with linseed oil, especially carefully processing the ends of the sheets of material.

- To enhance the waterproof characteristics, you can apply a reinforcing fiberglass cloth, having previously moistened its fibers with turpentine (cotton gauze is also suitable in "home-grown" construction). To check the adhesion of the fabric, you need to tap it with a miter brush.

- Apply a second coat of varnish (not earlier than a few days after the previous one). It should be checked that the glass cloth material is completely dry.

- Before applying the finishing coat of varnish (or a suitable paint), it is necessary to treat the surfaces with a fine-grained emery cloth to remove any seizure marks and bubbles. You can speed up the sanding process by using the power of a surface grinder.

In order for the moisture-resistant impregnation for plywood to be of better quality, plywood treated with linseed oil and varnished with varnish must be additionally protected with metal or plastic linings in the end faces of the sheet, which are most vulnerable to moisture.

If the points of our step-by-step instructions were followed carefully and in full, there is no reason to doubt such plywood. If the protective coating of plywood begins to "age" over time, becoming covered with a network of small microcracks, use coarse-grained sandpaper! It is already known how to treat plywood for moisture resistance, so remove the damaged top layer of the plywood coating immediately, and then open it with varnish (or paint of a suitable composition).

Important!

The plywood should not delaminate (even when trying to pry the edges of the sheet with a spatula or chisel). This, to a large extent, will increase the water-repellent characteristics of future self-made moisture-resistant plywood! Do not buy plywood with defects in the form of scratches, cracks or chipped edges !. Today, plywood of the FC brand remains the most demanded building material

The range of its use is very wide. But, over time, FC begins to darken, exfoliate and rot. The moisture resistance of plywood sheets can be increased by processing with special impregnations. The article reveals ways to protect plywood from moisture and mold and answers the question of how to impregnate plywood for moisture resistance

Today, plywood of the FC brand remains the most demanded building material. The range of its use is very wide. But, over time, FC begins to darken, exfoliate and rot.The moisture resistance of plywood sheets can be increased by processing with special impregnations. The article reveals ways to protect plywood from moisture and mold and answers the question of how to impregnate plywood for moisture resistance.

Plywood sheet treated with water-repellent impregnation

Before talking about how to protect a product, you need to understand what we are dealing with. The building material in question, consisting of several interconnected veneer layers, is plywood.

Most often it is used in the construction industry. It resists the negative effects of moisture due to the use of bakelite varnish and / or an adhesive that binds it in the production.

Boats and other floats / means are made of this material without special and additional processing. Although, such material is very expensive.

Fiberglass

For moisture resistance of plywood, glass fabrics are also used. It performs very well the function of wood protection, with long-term operation. Gauze can be used as fiberglass to give plywood moisture resistance.

She is fixed on a sheet water-based varnish.

The process consists of several steps:

- a layer of varnish is applied to the plywood sheet;

- after a couple of hours, a layer of gauze is applied;

- the end sides are additionally varnished;

- dry for several days.

Also, do not forget about the correct construction of an object from plywood. If the material is well ventilated, then it will be less susceptible to moisture and possible delamination will not occur.

This website is for informational purposes only and under no circumstances information materials and prices posted on the website are a public offer determined by the provisions of Article 437 of the Civil Code of the Russian Federation

Additional Information: How to protect plywood from moisture and rotting on a loggia

What should be done for this? First of all, take sandpaper and remove those layers that are already weak, then start applying a new layer of protection. How to apply acrylic varnish on a water basis?

Only in this case will the plywood sheet last a long time and justify the funds put in to protect it.

- The first layer of PVA is applied to a horizontally laid sheet.

- After the formation is impregnated with the composition, this area (layer by layer) is covered with the selected agent until the spots appear on the reverse side.

- Then the board is dried at room temperature without the use of additional agents.

- The treated areas are covered with plastic wrap while drying.

Will increase the service life of the multilayer sheet and the application of glass cloth to its surface. In the absence of this material, you can use ordinary gauze. Both fiberglass and gauze are glued to plywood with any varnish that does not contain epoxy or polyester components.

You need to protect plywood from moisture using these materials in the following order.

After complete solidification, a thin layer of nitro paint is distributed on the surface, which will act as a primer. Before applying with a spray gun, it is advisable to dilute the enamel with a solvent intended for this purpose. It is easier to saturate the plywood with a diluted solution of nitro-paint, and it dries out faster.

In general, this process of increasing moisture resistance will take much less time than using all other methods of plywood processing.

However, it should always be remembered that the most various methods of impregnation or processing can only increase the ability to resist, but it is best to place such structures under structures of a different type, which will protect it from moisture. If the external walls of the building are covered with laminated veneer boards, then the overhangs of the roof can become the best protection for them. In addition, when mounted on vertical surfaces, the fibers of the outer layer must be vertical.

Linseed oil plays not the last place for imparting moisture resistance to plywood. How to protect plywood from moisture and decay on the loggia? With its help, the coefficient of moisture resistance of the material is significantly increased. This oil liquid is inexpensive and can be bought on any construction market. The main thing is to determine the amount, which should be enough for the entire volume of material.

In addition to impregnation, for the process of protecting plywood from moisture, a powerful hair dryer or device is needed, for example, an iron, the heating of which reaches 200 0 C. At this temperature, it is easiest to dry a plywood sheet impregnated with linseed oil with high quality. The impregnation filling of the wood is carried out until it itself begins to repel the oily liquid.

Plywood is a very good material in construction. It is cheap to manufacture, which makes it an even better material. But there is one drawback - plywood swells and exfoliates from moisture.

But if it is specially processed, it will significantly increase the life of the plywood.

The question remains: what is the best way to cover the plywood so that it can be used in the nursery? As environmentally friendly impregnations - in the manufacture of products that people or animals come into contact with during operation, wax, linseed oil, turpentine are used. The coatings provide a high moisture-repellent ability of wood, preserve its texture, and add additional natural warmth to the home atmosphere.

Output

To get it, it is not at all necessary to buy its most expensive brands. As we found out, there are several effective processing methods that allow conventional FC grade sheets to be made resistant to water.

Plywood is a building material made by gluing several layers of veneer together. The strength of this structure ensures that the veneer fibers used in the manufacture of plywood are perpendicular to each other. Plywood is made from several types of trees - birch, oak, etc. Manufacturers have mastered the production of several types of plywood, including waterproof. But its relatively high price leads to the fact that many craftsmen independently enhance the water resistance of plywood and decide the question of how to impregnate the plywood for moisture resistance.

For the production of plywood, wood is used, which is highly hygroscopic. This assumes that when working with plywood, certain conditions will be observed when working with it indoors. So, the maximum (peak) humidity should not exceed 72%, and the constant 68%.

When working with untreated plywood, the ambient humidity can reach up to 60%. It should be noted that the specified humidity parameters must be checked at an air temperature of 18 to 27 degrees Celsius.

In the event that the specified parameters of humidity or temperature are higher or lower than the specified characteristics, then this can lead to delamination of the plywood, especially if it is not properly processed. It is this property that limits the applicability of plywood. It is not advisable to use it as a covering or base for it in places with high humidity, for example, in a kitchen or bathroom.