Method of fixing panels in a small kitchen

If the installation of panels on the frame does not suit you, you can glue the products directly to the walls. True, this method will require ideal smoothness and evenness of the walls, but it will be optimal for a small kitchen. In order to glue the products, you do not need wooden slats, a drill and self-tapping screws. All you need is panels and glue.

- Such an installation will require constant checking of the horizontal level and maximum accuracy.

- You need to glue the panels with a roller or spatula, and after completing the process, you should check the accuracy of the seams, and then wipe the wall covering with a damp sponge.

- All unsightly parts of the panels should be hidden behind the headset cabinets. Calculate their location so that the last and upper segments are "hidden" behind the elements of the kitchen set.

If you are doing a temporary repair and plan to change the situation in the future, the glue fixing option will work. In the photo below you can see how the process of such installation on glue looks like.

Experts recommend installing panels on a frame - this method is more reliable and does not require the ideality of the walls. But the glue mount is suitable for those who need to install panels as quickly and easily as possible.

Experts recommend installing panels on a frame - this method is more reliable and does not require the ideality of the walls. But the glue mount is suitable for those who need to install panels as quickly and easily as possible.

As a rule, installation on glue is carried out in new houses, where the finishing preparation of the walls has already been completed, but the tenant has not yet stepped foot.

Cladding

Arrangement of the attic requires a special approach to the choice of finishing materials and original design solutions. In the photo, decorators offer various design options for the attic space.

On the top floor of the house, you can create a wonderful guest room, billiard room, mini gym, private office and even a bedroom with a small bathroom. To implement the design idea, you can use various finishing materials, but the most popular are drywall, wood and OSB board decoration.

Decorating with wooden clapboard will create a wonderful environmentally friendly interior in a rustic style. It is not necessary to sheathe the entire room with wood; it is enough to decorate only the walls or ceiling.

Decoration with OSB plates or drywall is used less often, this building material is more suitable for creating interior partitions. In any case, after installation, the OSB surface must be painted or pasted over with wallpaper. Each of the types of finishing with one or another material has a number of features.

Working with plywood begins with the preparation of the frame, on which the elements will subsequently be attached using nails or self-tapping screws. Fasteners are attached at a distance of 30 cm from each other.

The first to be sheathed are inclined planes, pediments, after which it is the turn of the ceiling.

All sheets are stacked with a thermal gap of 3-5 mm. Laying should be done in a checkerboard pattern. If the room is distinguished by high humidity, then it is better to refuse to use plywood, so that deformation of the joint seams does not occur in the future.

Drywall

For the installation of drywall, you will need a wooden or metal crate. To fix the material itself, you need to purchase dowels and screws, which should be placed in increments of 25 cm. If the lathing is wooden, then it should first be treated with an antiseptic.

Given the configuration of the room, you should choose a vertical or horizontal method of installing drywall. The screw-in depth of the screw must be 1 cm for single-layer sheathing and 3.5 cm for double-skin. A gap of 5 mm should be left between the sheets of material, which subsequently must be putty and sealed with reinforcing tape.

The most original options for finishing the attic are presented in our photo selection. In order to get a stylish and comfortable living space as a result of finishing work, you need to show all your imagination and make some effort.

Well, now it's time to finish the article. All the material that I wanted to share is reviewed. I hope it will be useful to you, and you will use it if you need to decorate the walls with mdf panels. Improve your own practical skills and gain all the new knowledge, as they say: "It's never too late to learn!" That's all, thanks for your attention, successful and easy repair!

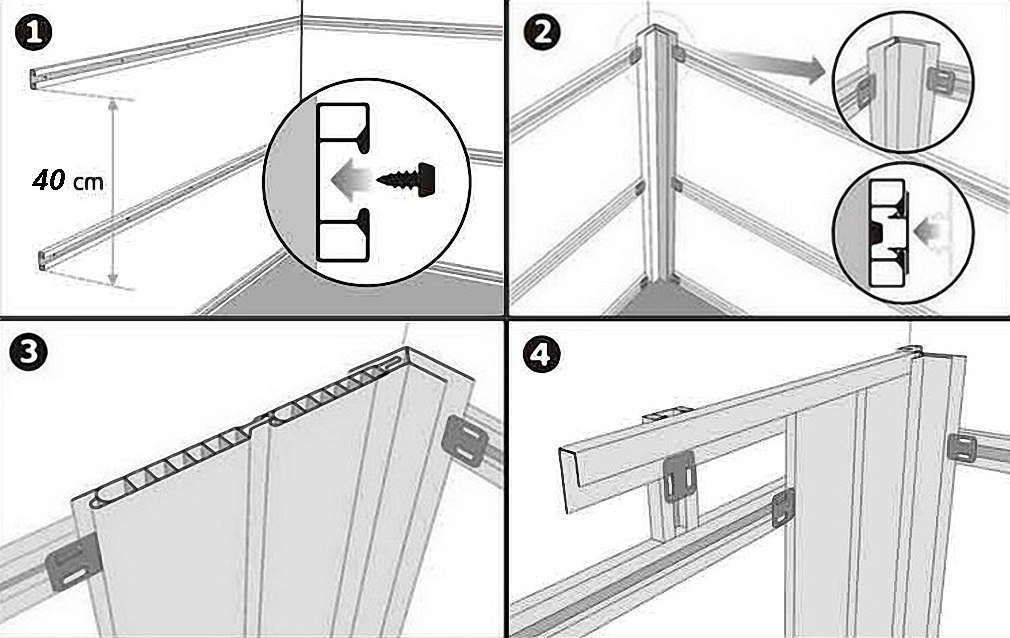

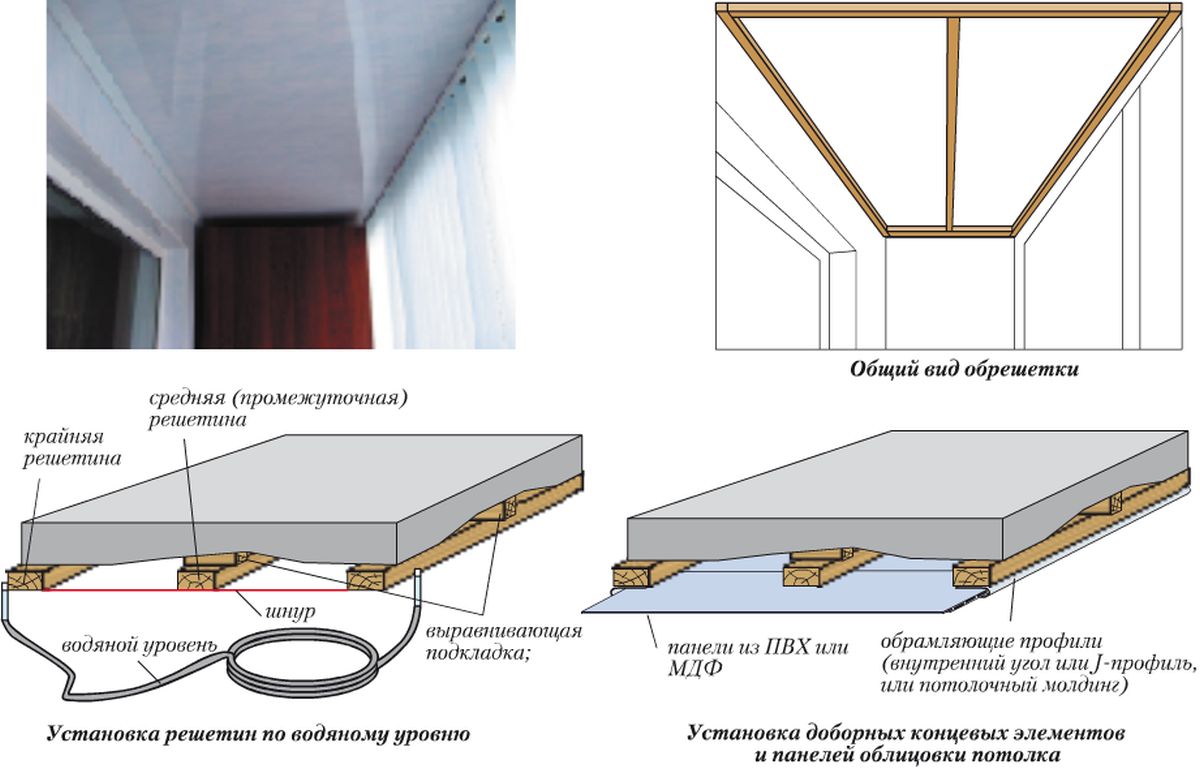

Sheathing device

The cladding of the walls of the insulated balcony with MDF panels is performed according to a specially constructed frame, otherwise called a crate. The frame can be attached directly to the walls and the fence, placing insulation between its elements, but the latter in this case will act as "cold bridges". In addition, the sheathing may turn out to be uneven due to the fact that the frame attached to the wall will repeat all its irregularities. A better option is an independent frame. It turns out to be even for any quality of the wall, and all its elements are located on top of the insulation. The independent frame can be mounted in two versions - metal and wood.

Metal carcass

The material for this type of frame is the profile used for mounting drywall. It can be guiding and supporting, but we are only interested in the first type, which has dimensions of 50x50 mm. In addition to the metal profile, we need:

- drill with perforator;

- building level;

- screwdriver;

- building corner;

- cutter;

- scissors for metal;

- plumb line;

- nylon thread;

- dowels.

A cutter is a device designed to connect two elements of a profile by cutting and bending the antennae formed in this case.

We carry out the construction of a metal frame in the following order:

- First, the crate is installed along the wall between the apartment and the balcony. With the help of dowels, the profiles are fixed on the floor, floor slab and side walls of the balcony so that they form a flat plane parallel to the wall. To do this, their installation is controlled by a suspension (for vertical elements) and a building angle (for horizontal elements).

- At the edges of the door and window openings, frame racks are installed, controlling their verticality using a plumb line. The upper and lower ends of the rack are inserted into the ceiling and floor profiles, respectively, after which the rack is attached to them using a cutter.

- Between two vertical posts framing the window opening, a horizontal section of the profile is fixed by means of a cutter, the level of which coincides with the line of the window sill.

- Horizontal profiles are installed every 600 mm between the vertical profiles fixed on the side walls and near the openings.

- Lathing along the side walls and balcony railing is arranged in a similar way. The profile should be cut into pieces of the required length with metal scissors.

- When the frame is mounted, all of its elements, except for those that are screwed in with dowels, must be securely fixed with corners. You can make them yourself by cutting the same profile lengthwise and bending it at right angles. One corner shelf is screwed to the frame element with self-tapping screws, the other - with dowels to the wall or to the fence.

Wooden frame

The wooden lathing is constructed from bars with a cross section of 50x50 mm. All its elements are located in the same way as in a metal profile frame, the only difference is in the method of connection: wooden bars are attached to each other by means of furniture corners and self-tapping screws.

If thin thermal insulation (up to 30 mm) was used to insulate the balcony, and its walls and fencing are fairly even, the crate can be formed from slats with a section of 20x20 mm, which are screwed to the wall and parapet. In places where there are irregularities, wooden spacers must be placed under the slats.

Execution of works

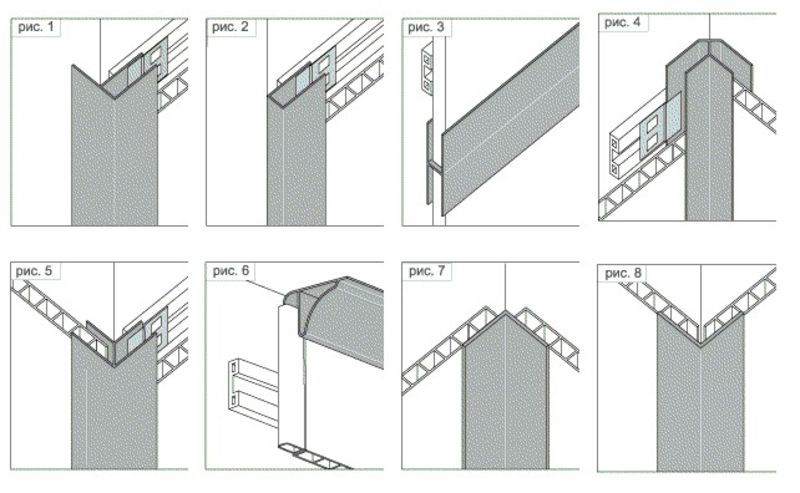

Due to their performance characteristics and aesthetic appearance, MDF panels are widely used in finishing works. Wall panels can not only decorate the ceilings of a corridor, a passer-by, but also original sheathe a doorway or window slopes. Furniture fittings and wall corners are also easily made from the material at home. Since the product is easy to install, it is quite possible to do all the work with your own hands. Before fixing MDF, you should prepare the surface for finishing, cleaning it from the old coating and eliminating all defects.

For additional thermal insulation of window slopes, walls and a doorway, it is recommended to lay insulating material, it will not only serve as a good insulation, but also cope with the task of steam and waterproofing.

To install panels on slopes, they can be fixed along or across, it all depends on the size of the slope. This finish looks original, made from a combination of light and dark pieces of slabs. Installation of panels on walls and ceilings is carried out both on glue and on a pre-assembled frame. To do this, first, the starting profile is attached, and then the guides, along the length of which you need to correctly join the decorative parts. To make a beautiful corner, before installation, you should trim the material, rounding its edges.

It is recommended to saw or cut panels using special tools for working with wood. A jigsaw is considered the best option for this, but if it is not at hand, then a saw with fine teeth will do. Having decided on the direction of the MDF sheathing, the panels are measured and cut to the required length. In this case, at the first plate it is necessary to cut a spike along the entire length, if this is not done, then difficulties will arise when installing the corners.

Lathing

Choosing the method of attaching MDF to the crate, you will first have to make a strong frame from a metal profile or wooden beams

It is not recommended to use a wooden frame for cladding brick walls and rooms with high humidity.

So that wooden beams do not deform during installation, it is worth choosing a well-dried wood. The structure is fixed perpendicular to the direction of installation of the panels, leaving a small margin of 5 cm from the floor and 3 cm from the ceiling.First of all, the vertical elements are fixed, which are placed along the edges of the recesses, in the corners and next to the openings. The planks should be 700 mm apart from each other. For fastening the structure, self-tapping screws or nails with a diameter of 4 to 6 mm are usually used.

The CD profile is inserted into the rack and everything is fixed to the wall with self-tapping screws. Metal profiles can be cut with a special circular saw. If the ceiling is finished with panels, then the frame must be assembled only from horizontal elements, using additional fasteners.

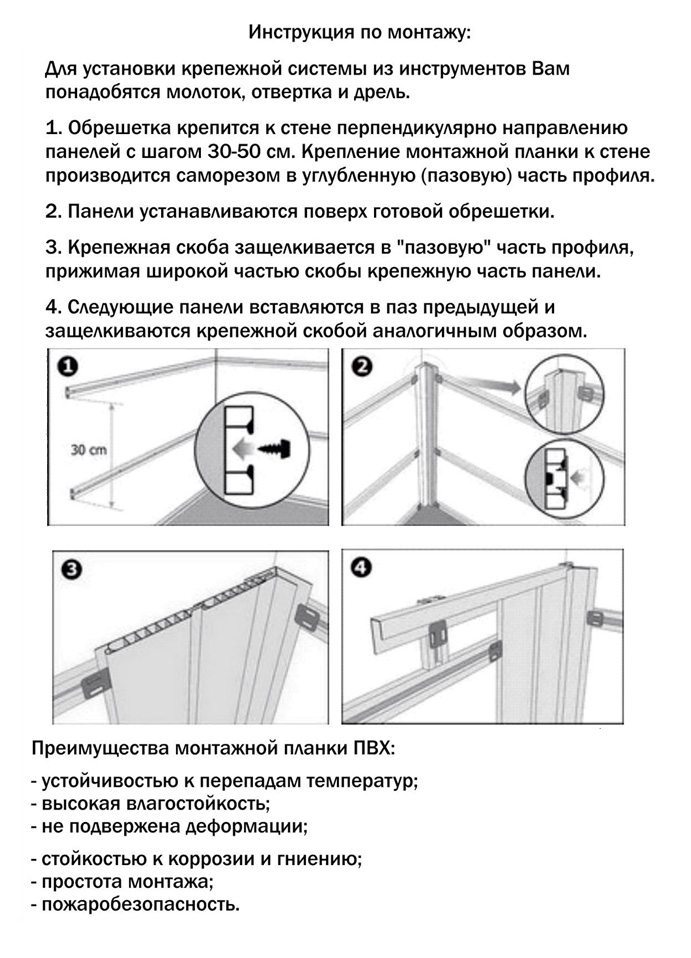

Paneling

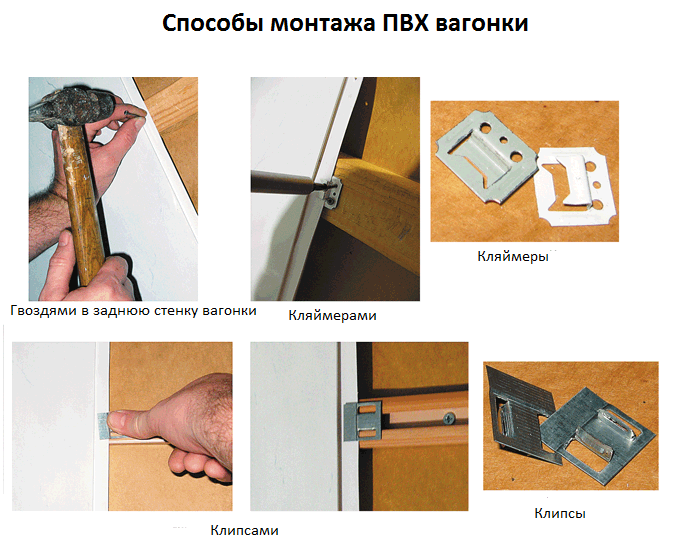

After the frame structure is ready, the paneling is started. MDF boards are fixed to each other using a tongue-and-groove lock, consisting of a recess and a ridge. The parts are fastened to the wooden crate with small nails, they are hammered obliquely with a hammer. To install the material on the metal profile, clamps are used, they are placed in the groove of the plate and fixed with self-tapping screws.

MDF paneling

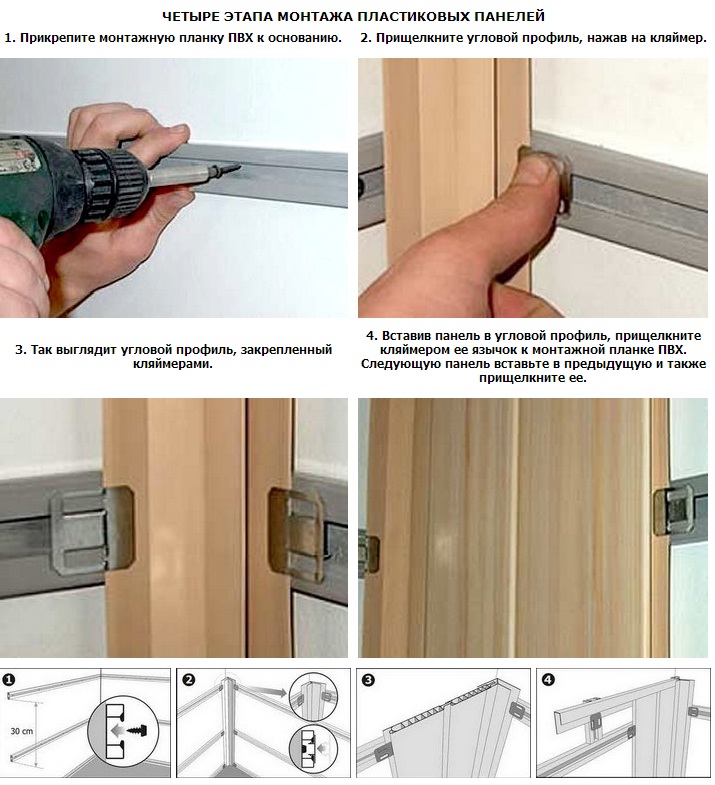

Striker and Claymers

MDF panels are connected by a symmetrical tongue-and-groove lock in the form of a ridge and a corresponding groove. MDF panels can be attached to the wooden crate with small nails, hammering them obliquely into the corner of the groove. To the end, the carnations are finished off with a metal striker and a hammer.It looks like a center punch for metal, only at its narrow end, instead of a point, there is a shallow depression along the head of the nail. A nail head can be made from a center punch by removing the point on an emery wheel and carefully drilling a recess on a drilling machine.

For fastening to a metal crate (and to a wooden crate when working according to a standard scheme), glue is used. Claymer - a small metal bracket to the hole for the fastener and the teeth that press the flange of the tongue groove. The glue is inserted into the groove of the MDF panel until it stops, and fixed with a self-tapping screw. Fastening with staples is more expensive and requires a lot of labor, but it is more reliable, and the cladding, if necessary, can be disassembled without damaging the MDF.

Installation of panels

Installation of MDF panels on the crate is much easier than preparatory work:

- We start from the corner. We cut the required number of MDF panels to size for sheathing the mounting plane to the nearest rack. We go through the corners of the cuts once ("shirk") with sandpaper.

- On the first panel, we cut off the tongue groove, and fix it in the corner with nails (on a wooden crate) or small self-tapping screws (on a metal one). From the side of the groove of the lock, we fix it with nails or stamps.

- Put on the next panel, slide the comb into the groove, fix it along the groove, etc., until the last two panels remain.

- The last panel is cut to length in size, with a grip of 2-5 mm, depending on which corner or plinth the final finishing will go.

- Cut the ridge of the last panel in half and round it off.

- We insert the last two panels into place with a “house”, press until they “snap into place”.

- Push the last panel all the way onto the penultimate one; fix with self-tapping screws at the free edge.

What you need to know about MDF

Almost all of us have heard about this material, but not everyone knows what MDF is made of and why these panels are better than their competitors. By the way, the main competitors of this cladding are chipboard (particle board) and fiberboard (fiberboard).

Several common building materials, fiberboard, chipboard, OSB and MDF, are now made from waste from the woodworking industry. But from this list, only MDF is considered an absolutely environmentally friendly product, and the reason lies in the original production technology.

Assortment and colors of MDF cladding.

For the production of such boards, finely dispersed wood dust is used. Notice, not sawdust or chips, but dust. I will not bore you with an in-depth story about the intricacies of technology, after all, this is not why you came to this site.

In short, the general principle looks something like this: initially, paraffin is added to well-dried wood dust for binding and the desired configuration of plates is formed from this mass. After molding, the products are put under a powerful press with simultaneous heating, and the finished sheet comes out from there.

The secret of high strength and environmental friendliness of the material lies in the fact that under high pressure and at high temperatures, a natural adhesive substance lignin is released from wood dust. Thanks to this lignin itself, the wood pulp turns into a solid monolithic board.

Ceiling with built-in lighting.

If you believe the manufacturers, then, unlike competitors, in the production of MDF, modern adhesives are not used at all, everything is natural. Accordingly, the plates will not glow with the same formaldehyde as, for example, chipboard. This means that you can mount them even in the nursery.

From my own experience, I can say, of course, this cladding looks decent, is relatively easy to install, it is durable and will last a long time. But keep in mind, MDF burns well, so there can be problems with the fire inspector in the office.

Plus, I do not recommend using MDF panels for the ceiling in the bathroom.Although many models are declared by manufacturers as moisture resistant, they cannot withstand really high humidity and stratify over time.

Continuous finishing of the ceiling with MDF panels.

Characteristics of the material and the most effective ways to install it

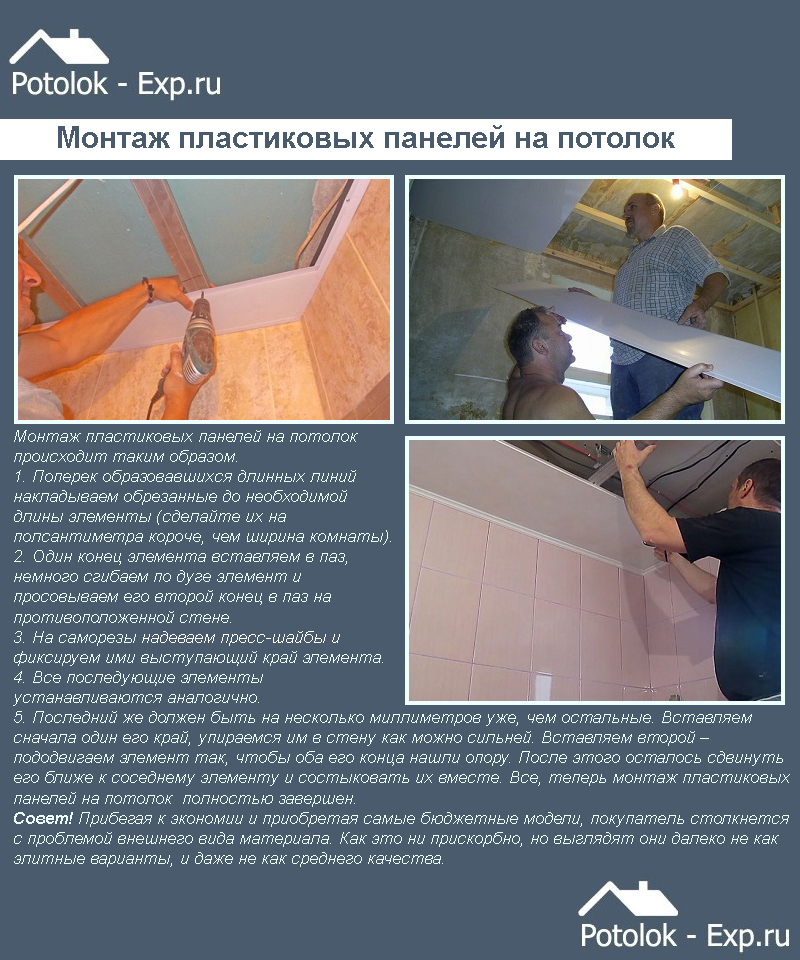

Plastic panels are versatile material. They are impervious to moisture, have good frost resistance and are distinguished by a huge range of models. The material has a simple structure and consists of two sheets of plastic, between which are located a kind of partitions, which are also stiffeners. The finished product bends well and is extremely plastic, and the variety of textures and shades allows you to diversify any interior.

An example of the internal structure of a plastic panel

Plastic panels are rarely used for cladding plasterboard structures and walls, which are characterized by evenness and solidity. As a rule, they use fundamentally different finishing materials to work with drywall. PVC panels are rather intended for masking defects on walls or leveling them. However, a combination of these two materials is possible.

The main criterion for installing plastic panels on drywall is considered to be the protection of the material from moisture. It can be considered a budget or temporary alternative to ceramic tiles that provides full surface protection and a more sophisticated appearance. Most often, PVC panels can be found in the bathroom or kitchen. They are practically not used to decorate living rooms.

Plastic panels are used for wall decoration in the bathroom Finished walls and plasterboard ceiling with plastic panels

The highest quality options for mounting PVC on a plasterboard base are:

- the use of glue;

- the use of fasteners.

These options have the highest efficiency and solve the problem of installing plastic panels. However, the first of them is less practical, since it provides an unnecessarily strong fixation of the material, which complicates its dismantling.

An example of fastening plastic panels to a wooden frame PVC panels on the ceiling plastic panel on wood frame

Tool for work

In addition to the usual household tools, you will need a plumb line (it is easy to make it yourself from a nut, not a fishing line or thread), a tape measure, a building level and a drill attachment for screwing in self-tapping screws. It is quite possible to do without a special screwdriver. You also need a locksmith's square (metal, with legs of different thickness). It will be convenient to cut pieces for slopes along it: a thick leg is used as an emphasis, and based on a thin one, a cut is made.

To cut MDF, you need a jigsaw or a hand-held circular saw. The saw is good for its compactness, convenience - it is similar in size and shape to a hair clipper - and versatility. By changing complete circles, you can cut wood, metal, stone. But a saw with a cutting depth of more than 12 mm or more is more expensive than a jigsaw; the thickness of MDF is 16 mm.

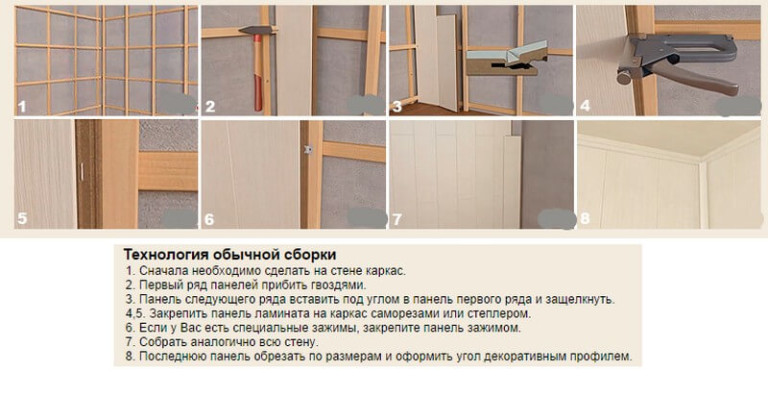

The main stages of work

Having prepared everything you need, you can start marking under the crate. All other elements will subsequently be attached to it, so you need to approach the layout and installation with all responsibility.

First, a line is marked along which the ceiling plane will pass. It is necessary to place it at such a level that the built-in ceiling lamps and all communications, such as air ducts and wiring, fit in the space that remains above its plane.

Then it is necessary to apply the marking lines to the ceiling plate, so as to get a kind of grid of squares, with a side of about 1 meter. In the places where the lines intersect, suspensions for the transverse parts of the structure will be attached.

There can be many transverse parts when covering a large area, or only one part can be sufficient when working in a narrow or small space.

If the installation of MDF wall panels is carried out, then first the place is marked where the first horizontal or vertical batten will be fixed. It must necessarily be perpendicular to the length of the cover strips to be attached.

If the installation of MDF wall panels is carried out, then first the place is marked where the first horizontal or vertical batten will be fixed. It must necessarily be perpendicular to the length of the cover strips to be attached.

If the planks are mounted horizontally, then the parts of the resulting lattice should be vertical, and vice versa - if the planks are mounted vertically, then the lattice is made horizontally.

After marking, the first parts are attached. When working with ceilings, a special profile will become such a part, one of those used when working with plasterboard sheets.

For work with wall panels, the first part of the lattice is fixed. And behind her - all the others, with a step of about 40 centimeters.

You need to fasten the profile with a distance between the dowels in the region of 50 centimeters. You can increase the distance slightly, but not more than 60 centimeters. Drilling is done through pre-drilled holes in the profile. After the hole is ready, a dowel is inserted into it and the screw is tightened.

Sometimes, for the construction of the frame, only wooden bars are used, dispensing with a metal profile.

You can limit yourself to wood if the installation room is not too humid. In damp places, such as a bathroom, the wood can begin to deform from the moisture.

In this version, the bars are attached to the walls in the same way as the guide profiles, and the subsequent elements are attached to them.

You can combine two types of materials, making the base around the perimeter of metal, and making the transverse parts of wood.

The attached guide profile will serve as the basis for the rest of the frame. Transverse parts are inserted into it. This is necessary if panel ceilings are installed. On the walls, everything is limited to the fastening of the lathing.

The distance between the transverse parts should be within 40 - 60 centimeters.

There is no need to do them more often, and if you install them with a large step, then the structure will not turn out to be the most reliable, and the panels may sag over time.

When the entire frame or lathing on the wall is assembled, you can proceed to work with parts of the covering.

Previously, all the planks need to be sawed off to the desired size. The only exception is the last detail. In both cases, whether on the ceiling or on the wall, it is cut off last, when the rest of the parts are already fixed in place. This will allow you to cut it exactly to size.

Holes for fixtures should already be cut out and all wiring in place. After installing the coating, it will be difficult to work with it. Naturally, the voltage must be disconnected, or all parts of the wiring must be carefully insulated.

Holes for fixtures should already be cut out and all wiring in place. After installing the coating, it will be difficult to work with it. Naturally, the voltage must be disconnected, or all parts of the wiring must be carefully insulated.

The strips are attached in a simple order - the first one is fixed first. The next is inserted into it, and so on, until the very last.

Each of the strips is fixed with self-tapping screws or clamps. If you use only self-tapping screws, then it is better, in the place where it will be screwed into the panel, drill a hole slightly smaller than the diameter of the self-tapping screw, this will allow you not to split the part.

Using the clamps, you need to firmly press the panel, fix the clamp on it, and fix it with a self-tapping screw or with a stapler. You can use a stapler or air hammer, with a set of staples or nails. Both speeds up the assembly process, but requires skill in handling such a tool.

The whole process is simple, rather monotonous. The last part must be fixed with self-tapping screws or brackets in such a way that the decorative plinth hides the attachment point.

The last stage of work will be the installation of a decorative plinth or other finishing panels that hide the junction of two planes.

Installation of MDF panels on walls: step by step instructions

In order to qualitatively mount the panels, it is important to strictly follow the technological process, which is generally not particularly difficult.

Surface preparation

Special preparation for working with MDF sheets is not required. When it comes to walls, it is enough to tear off the wallpaper and carefully prime the surface to prevent the formation of fungus.

If you wish, you can paste over the wall with insulation (for example, foil foamed foam).

Measurements

Any finish requires accurate measurements. And the first thing that needs to be done is to determine the indicators of the height and width of the walls. The easiest way to calculate the amount of material is to draw up an accurate layout of the elements on the wall.

Frame selection and its subsequent installation

The lathing for MDF panels can be of two types:

- from a metal profile for drywall;

- from wooden planks.

The latter option is somewhat cheaper. But for installation in a humid room, it is unlikely to be suitable, since wood is a material that does not differ in an increased indicator of moisture resistance. The metal profile is stronger and more durable.

Fastening panels

You can attach MDF to the frame using glue, clamps (these are special brackets made of metal) or self-tapping screws. If glue is used, it is strongly recommended to use moisture resistant materials.

When working with self-tapping screws, the latter should be installed at a distance of 10 to 15 millimeters from the edge. This will be enough to then successfully hide the caps of the screws under the baseboards or under the corners.

MDF panel mounting technology

Before starting finishing work, you must: prepare a working tool, purchase the required number of panels and additional elements (see Ceiling plinth Format: information about the manufacturer, types of plinths, related products).

MDF ceiling panels

Required tool

We will need a tool that a home craftsman will probably find:

- Pencil.

- Building level.

- Roulette.

- Perforator.

- Scissors for metal.

- Screwdriver.

Of the materials, we need:

- MDF panels.

- Ceiling skirting boards.

- Galvanized metal profile.

- Suspensions.

- Connectors.

Veneered MDF panels for ceiling

Frame installation

- Let's go directly to the installation. First of all, we start assembling the frame from metal profiles. Using the building level, we mark the perimeter of the room. In this case, the indent from the ceiling should be at least 5 cm. After marking, using a special device, we check the location of the hidden wiring.

- We fix the starting profile around the entire perimeter of the room, using dowels or self-tapping screws. It depends on the material of the walls. The fastener pitch is 400 millimeters.

- The next step is to install the ceiling profile. It is inserted into the starting profile parallel to one of the walls. Profile step 400-600 millimeters.

- Next, we attach the ceiling profile to the straight ceiling hangers. The profile is attached to the suspension on both sides with self-tapping screws.

For each subsequent profile, we take the horizontal level from the previous one, set all the remaining profiles identically, shortening them if necessary using metal scissors (see Styrofoam ceiling tiles - choose the appropriate option).

If the length of the profile is not enough, you can use special connectors in order to lengthen it.

- Installation of wooden blocks. It is with their help that the MDF panels will be fixed to the ceiling. We fasten it with a screwdriver and self-tapping screws. When installing the extreme bars, a prerequisite is a gap from the wall of approximately 5 centimeters. We carry out the calculations individually for your existing ceiling plinth.

- Calculate the length from one bar to another, relying on the geometry of your particular MDF panels, as a rule, the distance between the bars is about 40 centimeters.

Thus, we have prepared the ceiling directly for the installation of MDF panels.

Installation of MDF panels

Fastening MDF panels to the ceiling is very simple. To do this, it is enough to acquire special metal holders.

The editing algorithm is as follows:

- The panels are fastened using the tongue-and-groove technology. Therefore, finishing the ceiling with MDF panels begins with fixing the very first screws or nails. Then these fasteners can be easily hidden using a ceiling plinth.

The step of fixing the panel is not more than 200 millimeters (see Installation of the ceiling plinth: expert advice).

Panel mounting

- The next panel is inserted into the groove of the previous panel. We fix it, from the side of the groove, with a kleimer.

Kleimer is a special fastening element that allows you to fix the forcing, MDF panels on the walls and ceilings of the room.

It is a rectangular metal plate that has special cuts and a tongue with which the panels are actually attached (and screws are screwed into the cuts of the plate or nails are hammered). Considering that the panels can be used in rooms with high humidity, the stamp is specially made in such a way that its anti-corrosion properties are maximum - it is made of carbon steel and additionally galvanized.

Kleimer fastening

- If the panel is too long, then it must be shortened. We do this using a jigsaw with a cutting blade designed for a clean cut.

Jigsaw

When installing the panels, holes should be made in advance for spotlights using a "crown".

This can be done on an already installed panel, or before installing it. In the resulting holes, we install the sources of point lighting. When installing halogen bulbs, remember that they are very sensitive, do not touch them with your hands. All subsequent panels are installed in the same way.

- A decorative skirting board is installed last. It will give our design a complete look. It also helps to hide the starter hardware.

Ceiling plinth option

This completes the finishing of the ceiling with MDF panels. We examined in detail all stages of installation work. We talked about all the subtleties and nuances. Now you shouldn't have any questions.

Helpful installation tips

The main recommendations of the masters

- For children's rooms, the best solution is a canvas with a varnish-and-paint or enamel coating, since it has a wide range of colors, absolute safety.

- In corridors, hallways or kitchens, an interior is well created from slabs with a wood texture.

- Matte tiles of light shades with veneering or a paint layer best create an atmosphere of coziness and comfort in bedrooms and living rooms.

- For cladding corridors, bathrooms, it is best to take materials with a glossy PVC layer.

- For rooms with an unstable microclimate, temperature changes or fluctuations in humidity, MDF materials with moisture resistant properties will be required. The cladding looks equally good on the ceiling and walls of the room.

Advice

To acclimatize wood, it is recommended to keep the materials in the room where they are planned to be installed for at least 3-4 days. Then the structure will not deform as a result of changes in microclimate parameters.

How to accept the work of a master for finishing with MDF panels

Unlike plastering, painting or tiling, wall paneling is difficult to ruin. However, there are several of the most problematic areas that must be carefully examined when accepting work:

- Cuts of boards at the junction with the floor or ceiling. The cutting line must be straight and very neat

You need to give it a little space to resize.

- Execution of skirting boards and corners. MDF panels do not bend, therefore, they are cut off at the outer and inner corners, and the joint is covered with special corner pieces. To keep the corner neat and of high quality, the panel is cut very close to it, leaving a little space for possible swelling. The corner is fixed in such a way that its edges overlap the cuts of the boards, including their possible displacement during drying. The same applies to skirting boards along the floor and ceiling: they must be installed taking into account changes in the dimensions of the panels.

- Lack of sagging and "waves". This applies mainly to panels that are fastened in a frame way. Where the panel is fixed to the profile, it fits snugly against it, but in the intervals between the profiles it can protrude slightly forward. To avoid this effect, the lathing is done quite often. The maximum distance between the profiles should not exceed 40 cm.

- Visual perpendicularity of the panels to the floor and ceiling. In houses with crooked corners, this can create problems, since usually MDF panels are installed from the corner.

It is important that the master initially aligns the panels to the level