How to choose?

A correctly selected primer ensures good adhesion between the base and finishing materials.

It is better to immediately purchase a high-quality solution and avoid all these troubles.

Criteria for choosing a primer from Knauf:

- The primer and the material for further finishing must have the same base.

- An important criterion is the type of foundation. Deep action solutions contain the smallest particles. Fortifying solutions interact only with the surface. This must be taken into account when purchasing.

- The fortifying composition can be applied on substrates that do not require any treatment. It will be more economical.

- It is necessary to determine the type of solution, while evaluating its transparency.

- For processing in rooms with high humidity, it is worth using antifungal primers. They will protect the room from mold.

For an overview of the Knauf primer, see the following video.

Universal primer Knauf Mittelgrund F 10kg

- Brand: KNAUF

- Application: Indoor, Outdoor

1 in stock (or on order)

Attention! The cost of goods and the amount of goods on the balance are for informational purposes only and require clarification from the manager

Description

Universal primer for absorbent substrates.

The primer (concentrate) is quick-drying, vapor-permeable, based on a polymer dispersion with a yellow pigment.

Primer KNAUF-Mittelgrund is intended for the treatment of surfaces made of gas and foam concrete, ceramic and silicate bricks, expanded clay and slag blocks, gypsum and cement plasters, concrete, cement and gypsum screeds. Effectively reduces and regulates the absorbency of the base, promotes uniform setting of the solution of gypsum and cement mixtures.

It is used for processing the base:

- before applying gypsum and cement plasters;

- before laying tiles using tile adhesives;

- when installing the Knauf-Tribon screed, other gypsum and cement screeds;

- before installing Knauf sheets using Knauf-Perlfix gypsum glue.

For interior and exterior use.

Specifications

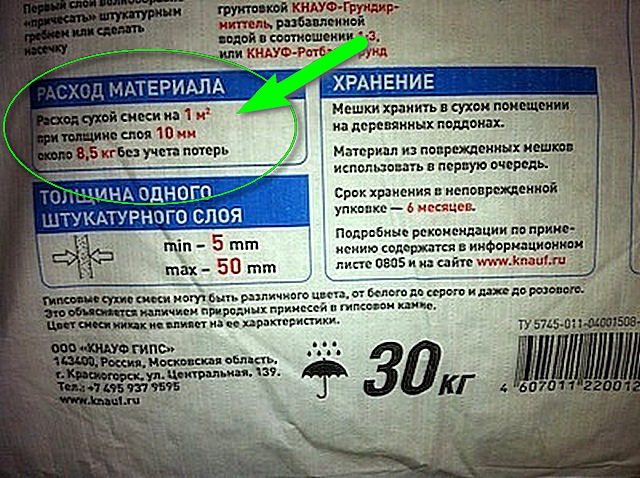

- Consumption: 0.05 kg / m2 (undiluted water);

- drying time: 6 hours;

- yellow color;

- frost resistance (optional): 5 cycles;

- packing: bucket with a sealed lid (without sealing with a film) 10 kg;

- shelf life: 12 months in undamaged packaging.

Dilution Knauf-Mittelgrund

Base - foam-aerated concrete: -concentrate consumption - 0.05 kg / m 2; - dilution of the concentrate: water - 1: 5; - consumption of the primer solution - 0.3 kg / m 2;

Base - silicate brick: -concentrate consumption - 0.05 kg / m 2; - dilution of the concentrate: water - 1: 4; - consumption of the primer solution - 0.25 kg / m 2;

Base - ceramic brick, cement plaster, gypsum plaster, gypsum plasterboard (GKL), gypsum fiber sheet (GVL), cement screed, gypsum screed: - Concentrate consumption - 0.05 kg / m 2; - dilution of the concentrate: water - 1: 3; - consumption of the primer solution - 0.2 kg / m 2;

- building and finishing materials at affordable prices - a huge assortment of goods in stock and to order - delivery at a convenient time - additional services and opportunities - discounts and bonuses for regular customers

1993-1997

Meanwhile, in 1993, the management of the Knauf company made a decision to start production activities in Russia. The first enterprise to produce dry gypsum plaster in Soviet times was a plant in Krasnogorsk.

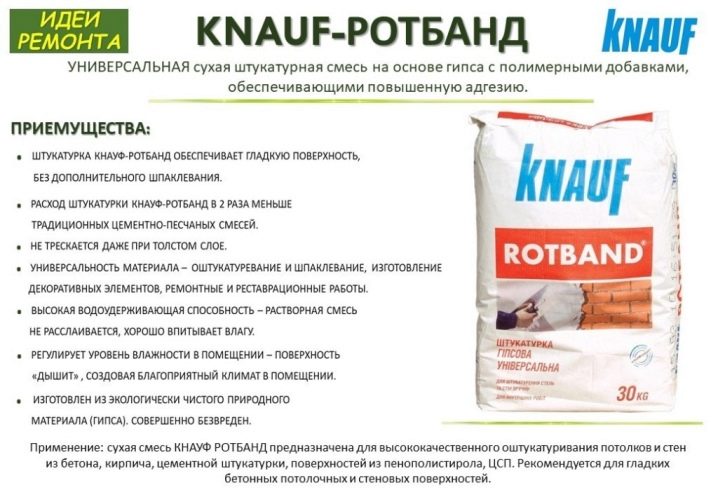

In 1997, a plant for the production of dry building mixtures was built on the territory of the enterprise, which began the production of modified gypsum mixtures, the first of which was KNAUF-Rotband. This year can be called revolutionary for all plasterers in Russia. Together with Rotband, Knauf offered a new and more efficient technology.It took some time for Russian builders to appreciate all the advantages of the new product, because for many years they got used to working using a ratchet to level the walls. However, the efforts of KNAUF specialists, who conducted training in the technologies for the use of dry mix, have borne fruit. The builders, having tried European technology with their own hands, irrevocably abandoned traditional unmodified mixtures.

Finishing putties from renowned manufacturers

Volma finish. A mixture based on gypsum and mineral fillers, which, when dry, becomes strong and resistant to cracking. It is used for surface preparation for painting and wallpapering.

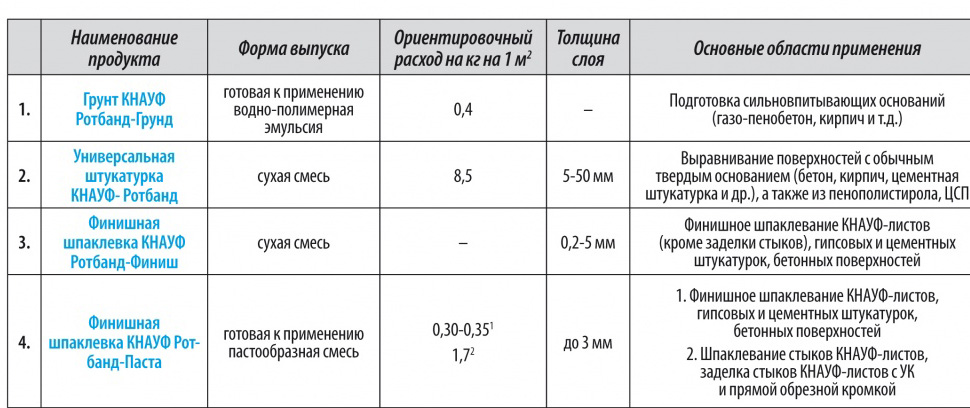

Knauf-Hp Finish. It is used for surface finishing in rooms with normal humidity. Layer thickness - up to 3 mm. Does not crack or shrink.

Knauf Rotband Finish. Finishing plaster mix. Layer thickness - up to 5 mm. It is used for filling concrete surfaces, gypsum board, gypsum plasterboard.

Vetonit. Vetonit LR + is intended for use in dry rooms. It is considered a medium fraction putty. It is applied in a layer of 1 - 5 mm. Easy to sand. Vetonit VH - is used both in dry and in damp rooms. Applied to concrete, brick.

Vetonit KR is well suited for finishing puttying on prepared surfaces. Creates a thin, durable layer.

Sanding of surfaces should be started no later than 2 days after drying.

Then the process is very easy. Suitable for subsequent painting and wallpapering.

Tiefengrund

If you are looking for a versatile acrylic primer then choose Tiefengrund from Knauf. It is a quick drying solution that is colorless. It penetrates deep enough, and this is one of its main advantages. Its composition is based on an aqueous dispersion. It does not undergo saponification. Tiefengrund does not contain any plasticizers and is suitable for drywall applications.

This type of primer perfectly strengthens any surface. With its help, you can regulate the ability of the material to absorb excess moisture.

Main technical characteristics:

- penetrates deep enough;

- has the ability to bind dust settling on the surface;

- does not retain moisture on the surface, but allows it to pass;

- fireproof;

- the consumption of the primer is minimal.

It is suitable for both indoor and outdoor use. Application area:

- When creating a screed. Basically, ready-made parts are used for this. Suitable for slabs made of various materials, including plasterboard.

- Provides moisture protection on gypsum parts.

- Before laying all types of slabs, they must be pre-treated with Tiefengrund primer. This will help protect them from moisture.

- For priming facades and other outdoor works.

- Surface treatment before painting.

The primer is applied to the wall covering with a regular brush. It is more convenient to apply it to the ceiling with a roller. Thus, the consumption of building material will be reduced. Priming must be carried out at an air temperature of at least 5 ° C.

Estrichgrund

Estrichgrund is a cementitious primer mainly used for screed floors. It greatly reduces the ability to absorb moisture, and also increases the adhesion of screed floors, especially combined ones. These are the main advantages of this solution.

Estrichgrund has a viscous consistency. It must be diluted with plain water before use. The proportion should be 1: 1. A surface that has a high absorbency should be treated not once, but twice.

Application method:

- Clean thoroughly and dry thoroughly. There should be no household dust or paint from the old coating on the surface to be treated.

- The primer must be carefully applied with a construction brush or roller to the floor covering, without leaving any puddles.

- The surface must be left to dry for a while. This will take about a day. It is imperative to ventilate the room during work. This way you will not only protect yourself, but also speed up the drying time.

You can purchase this solution in special plastic buckets. Their weight is 5 or 10 kilograms. It is necessary to store the solution at room temperature, always in a closed container. After opening, the solution must be used within one month.

What is the difference between start and finish?

To begin with, consider what criteria for dividing the putty exist.

By composition:

- Plaster;

- Polymeric;

- Cement;

- Glue-oil.

According to the degree of readiness:

- Ready-made solutions used for direct application to the wall;

- Dry mixtures to be diluted in water and then used.

By fraction and grain size of the base material:

- Starting;

- finishing;

- universal.

All putties are divided into starting and finishing. This division is somewhat arbitrary, since the starting putty can sometimes be used as a textured base before applying paint. And the final mixture, on the contrary, before gluing complex wallpaper.

The division of the putty into starting and finishing is determined, first of all, by the size of the base filler fraction.

In starting putties, the size of the grains of sand is larger, which allows you to apply a thicker layer and not be afraid of shrinkage and cracking. The relief of the walls after applying such mixtures turns out to be rather coarse and grainy and requires subsequent finishing.

Such surfaces cannot be sanded to a perfectly smooth state.

The main purpose of starting putties is to create a base layer for finishing. Such mixtures can be applied in a layer up to 5 cm. They perfectly cover all depressions and small bumps.

Finishing putties outwardly resemble a pasty mass with small filler particles. There are no large grains of sand in it. Its creamy consistency lays down on the walls in a thin layer and fills in all the smallest flaws and irregularities. Such walls are easy to sand and become perfectly smooth. Paint and decorative plaster fit well on them.

Most often, starting and finishing putties are used in combination. The first layer, depending on the degree of unevenness of the walls, is the starting mixture. Second, after high-quality drying and sanding, a finishing putty is applied.

Betokontakt

If you need to treat a surface that has poor absorbency, then you need to purchase Knauf Betokontakt primer... It is a polymer dispersion that is sufficiently resistant to any alkali. It contains quartz sand. This mortar is suitable for use on concrete.

Specifications:

- suitable for interior work;

- alkalis have no effect on this composition;

- you can apply with a regular construction roller or use special equipment for this;

- the solution has a pink color for more convenient application;

- no need to dilute the primer, it is completely ready to use.

The primer must be applied undiluted to the concrete surface. If you use it on less dense surfaces like enamel, then you can add a little water to it - about one liter of clean water for 20 liters of primer. Use the same solution if you apply it to the surface through a special spray bottle.

Betokontakt dries up within 24 hours. The optimum temperature for quick drying is 20 ° C. Air humidity should be no higher than 60%. By adhering to these recommendations, you can reduce the drying time of Knauf Betokontakt.

1962

Then the company KNAUF developed the composition of the plaster mixture for interior work and released it on the market in 1962 under the name "Rotband". For 55 years, many good gypsum plasters have appeared on the world market.The "Rotband" recipe has improved over time, gradually it has become the most popular material of its kind.

Not so long ago, in the early 90s, there were no ready-made modified mixtures for rough finishing on construction sites in Russia. Workers on the spot prepared plastering compounds, like their German counterparts in the middle of the last century. Despite the fact that each master, as a rule, had his own secrets, it was difficult to get a guaranteed high-quality result with this technology.

Universal primer manufacturers

Today, the universal primer is produced by many well-known manufacturers on the market of finishing materials. The pricing policy for the products is regulated by the manufacturer.

The most popular and high quality universal soils:

Primer Bergauf

Joint domestic-German production allowed us to obtain a uniquely high-quality and professional staff. Products are certified in accordance with European quality and safety standards.

Primer Beckers

Produced on behalf of a Scandinavian company recognized as a leader in its field. The effectiveness of Scandinavian soils has been scientifically and empirically confirmed. They are suitable for processing all types of substrates.

Ceresit primer

The brand belongs to one of the largest German factories Henkel. Almost 150 years of experience of the company makes it possible to obtain extremely high-quality soil, which is consumed very economically.

Unis primer

One of the best compositions of Russian production. Popular not only within the Russian Federation, but also in the CIS countries. It attracts with quality characteristics and long pot life of the solution.

The primer Osnovit and Lakra is of no less interest to the domestic consumer. Having a fairly low cost, the solutions are distinguished by impeccable performance parameters.

The properties and characteristics of the universal primer make it truly unique. A high-quality set of components allowed us to obtain an unusually functional composition that gives the surface optimal strength, moisture resistance and wear resistance.

Characteristics of the universal primer, video

Haftemulsion

Haftemulsion is an alkali resistant dispersion. It is suitable for treating absorbent substrates. Apply Haftemulsion just before filling. You do not have to wait long for the solution to dry.

Specifications:

- the primer is combined with alkaline materials;

- resistant to gasoline, saponification, acid solutions.

Scope of application:

- making floors from cement, such a surface does not attract dust;

- used for leveling compounds, as well as putty mixtures;

- protection of floors;

- element in effective concrete mortar;

- improvement of many grouting;

- used for mixed bases.

Knauf Haftemulsion is available in 5 or 10 liter buckets. You can choose the option that suits you best.

The solution should be stored at positive temperatures. Storage at -5 ° C is rarely allowed. This can be tolerated when transporting goods.

European quality

Knauf is recognized worldwide as a reliable manufacturer of building materials. It offers its customers a wide range of products at affordable prices. The products of this company are produced in one hundred enterprises that are located in China, America, Europe and other countries. That is why the geography of sales of this brand is quite wide.

Knauf is engaged in the production of many building materials, including primers, which have different modifications.

Among the advantages of primers of this brand, the following points can be noted:

- They are fully compatible with most of the finishing materials on the modern construction market.

- The composition is designed in such a way as to minimize its consumption during application.

- The primers of this company can be safely used for finishing the facades of buildings. They are resistant to temperature changes and moisture resistant.

- The composition does not retain air, which provides an excellent microclimate in any room.

- The mixtures are completely safe for the human body, environmentally friendly.

The only drawback of this company's primers is their cost. Many companies in the modern construction market offer identical products at a lower price. For many buyers this fact turns out to be decisive and they purchase mixtures from other companies.

Starting putties for walls - types

In terms of composition and intended purpose, the starting putty is a transitional stage between plaster and finishing mixtures. It, like plaster, is used to treat rough surfaces. However, at the same time, the structure of the starting putty is not as coarse as that of plaster and allows the application of a finishing layer.

In particular, start putty is suitable for:

- finishing around door and window frames;

- filling strobes;

- alignment of slopes.

Starting putties are divided into homemade and ready-made mixtures. They resort to self-preparation of the putty, if necessary, to save financial resources. In this case, all the constituent parts are mixed in the right proportions. It can be gypsum-chalk and oil mixtures.

However, in practice, this happens quite rarely. Basically, ready-made mixtures are used for repairs. In them, all the constituent parts are selected, and the only thing that needs to be added is the right amount of water. Ready mixes are of the following types:

- cement;

- gypsum;

- polymer.

Here is a list of the most common companies that produce starter putties.

Volma. The company specializes in the production of ready-made putty mixtures and produces base and finishing putties. There are several starting mixtures:

- Aquastandard is a cement putty used to level surfaces for decorative coatings - textured paint, plaster.

- Volma-Standard base putty is a gypsum-based mixture used for the main leveling of walls, ceilings for painting, wallpapering, decorative plaster.

- Base cement putty. Designed for basic finishing of walls and ceilings in dry and damp rooms. It is also used for facades.

Prospectors. Russian manufacturer of starting putty.

The white cement-based mixture is used indoors and in the decoration of façades. Does not crack or shrink. When dry, the putty forms a waterproof layer, therefore it is widely used for repairs in bathrooms and toilets. Surfaces can be easily sanded both by hand and using special equipment.

Knauf. Ready mixes Knauf are deservedly considered one of the market leaders.

Combining the high quality of the constituent materials and ease of use, they are loved by many builders and repairmen.

Knauf putties are of 3 types:

- starting;

- finishing;

- universal.

Knauf starting mixtures:

- Start Rotband for indoor use - used for leveling brick, concrete, expanded polystyrene, gas-block bases, easily applied to walls and ceilings.

- Knauf Goldband. Possessing the above properties, Goldband is used only for wall decoration. It contains no adhesive components. This mixture works well when processing concrete and brick walls with deep depressions. It is applied in a layer up to 5 cm.

- Knauf Fugenfüller. Starter type gypsum putty for sealing drywall joints. It is characterized by special strength and crack resistance.

Vetonit. The Vetonit company is represented by a wide selection of starting and finishing putties. Vetonit TT is a starter filler for dry rooms and rooms with high humidity levels. It is applied in a layer up to 6 mm., Does not crack, is not afraid of frost.

Acrylic fillers.The main substance that determines almost all the characteristics of such a mixture is synthetically made acrylic. It has a unique ability to change its properties depending on the conditions acting on it. The advantages of such a putty in:

- high plasticity of the created surface;

- creating a water-repellent layer;

- fast drying;

- easy application and sanding;

- environmental friendliness;

- fire safety;

- no shrinkage;

- long service life.

Acrylic starter fillers are designed to correct the most serious defects and surface imperfections. Acrylic putty mixture is produced ready-made - in plastic buckets. Among the firms producing acrylic putty, one can distinguish Ural quartz, Lacra, VGT, Parade.

How to make the right choice for drywall?

So that the quality of the repair leaves no doubt, when choosing ready-made solutions, one should be guided by some circumstances:

- the material from which the surfaces are made;

- estimated operational humidity of the premises;

- location of premises inside the building, or on the street;

- the main material of the starting putty in the case of applying a finishing layer on it.

To choose a plasterboard putty, it is important to take into account the specifics of the upcoming work. GKL and GVL finishing works include the following procedures:

GKL and GVL finishing works include the following procedures:

- sealing of seams;

- applying a finishing layer.

Due to the fact that the surface of drywall sheets is already intended for applying the finishing layer, the starting layer must be used when sealing the most vulnerable parts that are most susceptible to deformation. These are the seams.

For the treatment of seams, starting gypsum mixtures of a coarse fraction with high resistance to shrinkage and mechanical stress are used. The starter layer is applied in two stages using a paint net.

Builders and specialists in repair and finishing work when finishing drywall partitions advise using gypsum putty mixtures. And there are a number of explanations for this:

- this mixture does not shrink;

- gypsum adheres perfectly to drywall;

- easy to apply and level;

- dries quickly.

Attention! When decorating walls in rooms with high humidity, moisture-resistant gypsum board and putty with water-repellent fillers should be used

Features and properties of the universal primer

It is intended to prepare the bases for finishing. The composition of the universal primer helps to increase the operational parameters of the surface.

Composition

The mixture for priming surfaces contains:

- film-forming agents;

- plasticizers;

- modifying additives;

- antiseptic components;

- substances that accelerate the absorption and polymerization of the primer;

- coloring pigments.

Appointment

The universal primer is designed to simultaneously perform many functions:

- Strengthen the surface, preventing it from crumbling, crumbling or chalking;

- Strengthen the base, making it monolithic and reliable;

- Promote an increase in the water-repellent characteristics of the surface;

- Improve the adhesion of the base with subsequent finishing;

- Ensure uniformity and ease of application of putty, plaster or paintwork;

- Protect walls from mold formation;

- Equalize absorbency;

- Save materials used for decorative or finishing;

- Accelerates the hardening of the putty layers;

- Extend the service life of the decorative finish.

Views

The composition can be produced in two varieties:

- Universal acrylic primer containing acrylic polymers;

- Universal deep primer used for the deepest possible impregnation of the base.

Also today you can find both a latex universal composition and an anti-corrosion one.

Application

The scope of application of the soil is quite extensive, which makes it universal:

- concrete bases;

- metal;

- wooden;

- foam block;

- aerated concrete;

- wood fiber;

- chipboard;

- brick;

- plastered;

- stone;

- plasterboard;

- gypsum fiber.

No exceptions are surfaces made of limestone or gypsum, gas silicate and cement-sand materials.

Technical characteristics of the universal primer

| Specifications | unit of measurement | Indicator value |

| Temperature regime | ° C | +5…+30 |

| Approximate area of application of 1 layer (10 l.) | m² | 65 |

| Polymerization time of 1 layer | min. | 30-90 |

| Packing options | l | 0.9; 2.5; 5; 10, etc. |

| Shelf life | month | 6 |

| Storage temperature | ° C | from +5 to +50 |

Consumption of a universal primer is on average 0.15 kg / m2. First of all, it depends on the type of base and its porosity, as well as the number of layers.

The average price ranges from 280 to 700 rubles. for 10 liters.