Applications

Earlier in the article, we have repeatedly said that garnet sand has excellent properties, the main of which is high strength. Due to this, it is widely used in various fields of activity.

The material is used:

- in mechanical engineering;

- gas and oil industry;

- the process of restoration of bridges, buildings and structures;

- woodworking industry;

- the process of arranging tennis courts;

- shipbuilding;

- design;

- filtration systems for various liquids;

- the process of manufacturing ceramic products;

- automotive industry.

The area of application of pomegranate sand is quite extensive.

Today, garnet sand occupies a leading position among abrasive materials. For a long time, for example, quartz sand has not been used to clean the bottoms of ships or the facades of buildings; it is pomegranate sand that has been used. As for the purification and filtration of water, experts say that the use of this abrasive helps to improve the properties of the liquid.

Another area of activity in which garnet sand has become an indispensable material is waterjet cutting.

The use of pomegranate sand makes it possible to process:

- various metals;

- elements made of heat-resistant and stainless materials;

- natural and artificial stone;

- glass and rubber parts;

- concrete and reinforced concrete structures;

- ceramics and plastic.

There is a water jet cutting technology using garnet sand. The material of a certain size is mixed with water under high pressure to create the ideal cutting machine.

The video below shows an easy way to test the quality of pomegranate sand.

Features and requirements

Garnet sand is of natural metamorphic origin. It belongs to non-metallic minerals, consists of almandine - garnet, the granules of which are a very heavy and hard abrasive.

This material has many features and unique properties:

- has a high degree of resistance to various deformations;

- ecological cleanliness, that is, it is completely safe for humans;

- resistance to destruction;

- resistance to degeneration;

- high hardness.

The physical and technical properties and characteristics of garnet sand are simply unique.

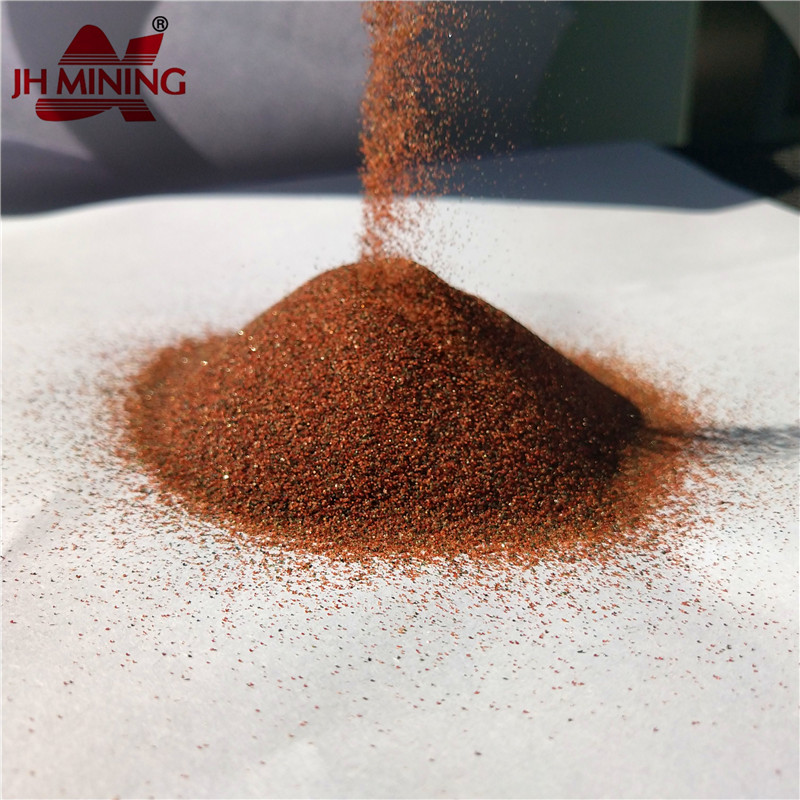

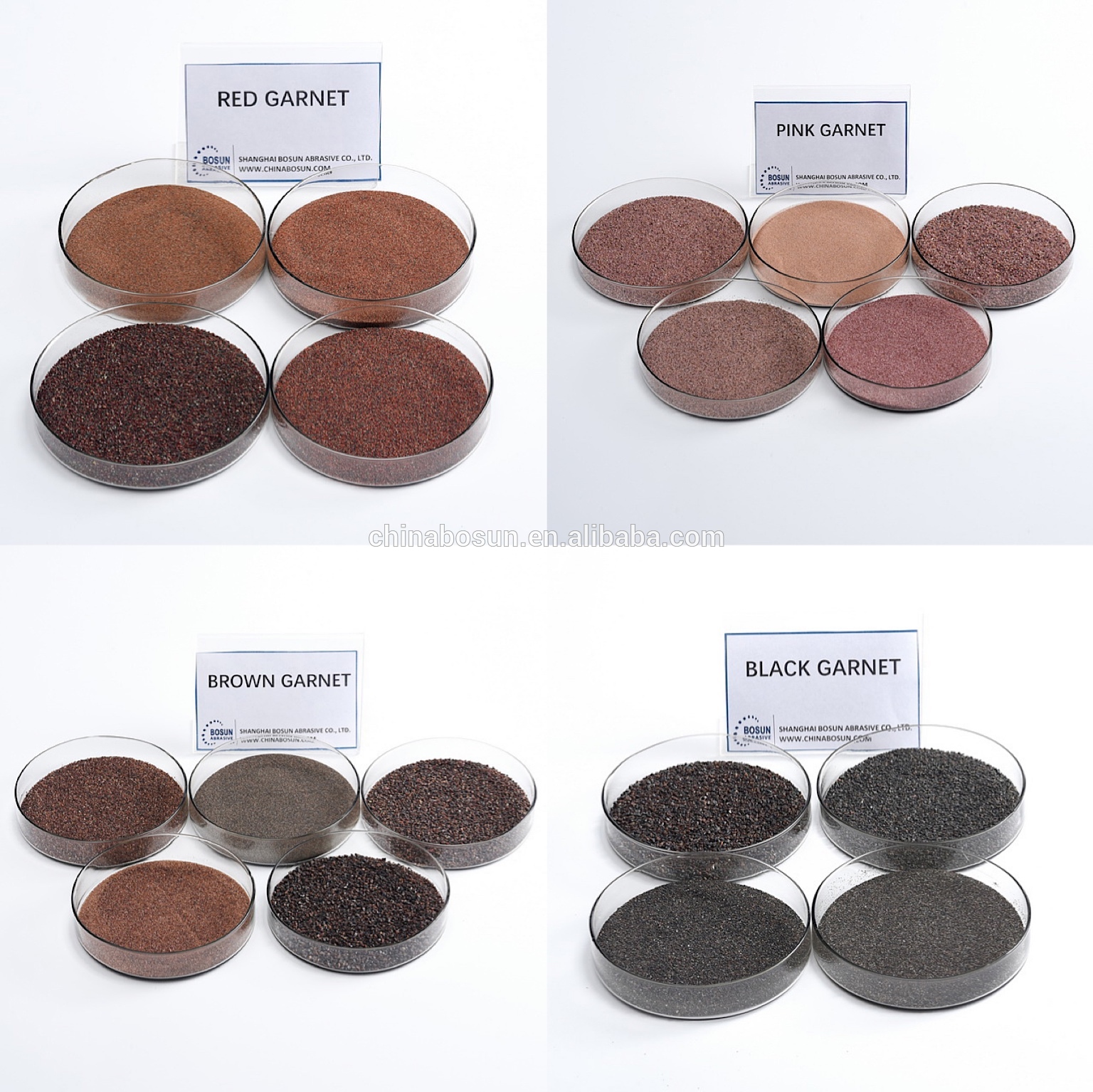

Garnet sand is not only composed of almandine. It also includes other impurities: quartz, zirconium. But according to the requirements, the amount of impurities in it should not exceed 3%. It is characterized by a red-purple or dark burgundy color.

Today there are two types of such sand.

- Oceanic (also called natural or beach). No equipment is used to obtain this type of material. All that is needed is the time during which the rock, under the influence of weather conditions and the erosion process, will turn into the necessary substance.

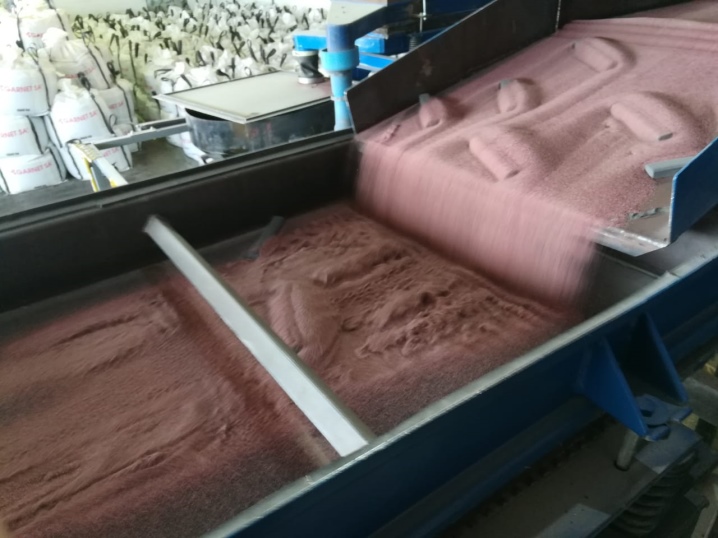

- Mountain. It is obtained using the method of crushing rocks. It is this type that is considered the most durable, and it is preferred to use it in enterprises. In addition to strength, the material is also characterized by a variety of fractions, from the smallest to the largest. Sand of the required size is obtained by crushing.

Each of these types of sand is unique in its properties and parameters and is used in various fields of activity.

Production

India and Australia are considered the birthplace of garnet abrasive sand. It is from the rocks of these countries that the highest quality material is mined and produced, the name of which is Mesh 80 (the most popular and demanded).

Thanks to the availability of modern equipment, the extraction of garnet sand in Russia by crushing has also become possible. On the territory of the country there are several places of occurrence of abrasive rocks, the quality and technical parameters of which are in no way inferior to the garnet sand brought from India or Australia. Its largest reserves are located in Karelia - there are 13 deposits there.

The domestic product is characterized by:

- high cutting ability;

- high quality and cutting speed;

- high density;

- environmental safety;

- the absence of carcinogens and chemical elements in the composition.

It is also worth noting that even despite the large labor costs required to obtain a domestic product, it is economically unprofitable to bring material from other countries. The cost of raw materials mined in the Russian Federation is much lower.