How to make imitation brick with your own hands using plaster

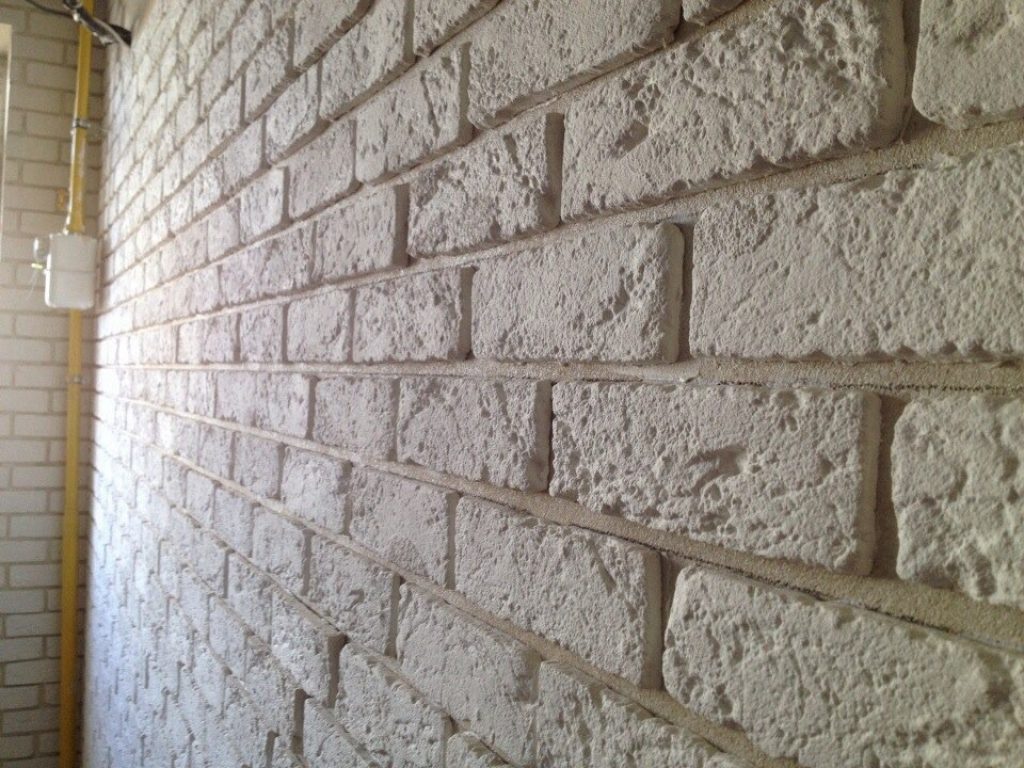

The most common imitation method is to apply a building mixture to the surface and create a relief on it. As an example, consider a plaster-based coating. Ordinary cementitious compounds will do.

Surface preparation

The wall is cleaned of old finishes and leveled. The bottom layer is retained if it adheres well and has few defects. The substrate is primed to improve adhesion to the top layer. It is better to take a primer for concrete with antiseptic additives.

Markup

Then markup is done. The contours of the masonry are drawn on the wall. The dimensions of the front side are taken arbitrarily, focusing on the area to be treated. The tiers must fit perfectly. Their number is calculated by dividing the height of the room by the height of the front side of the brick. The resulting residue is evenly distributed among all rows. You can also increase the height of the seams. In the same way, the length of imaginary products is calculated.

Masking tape is cut into strips corresponding to the distance between the bricks and attached to the wall. It forms a line of seams. First, long horizontal stripes are applied along the markings, then short vertical stripes to make a dressing. Scotch tape is not cut strictly along the corner of the wall, but small gaps are made that go beyond it.

Varieties

Brick finish or brickwork is different. Let's take a closer look at the most common and top-end options for such cladding.

From plaster

Plaster bricks are inexpensive and very popular. Decor made from such materials can have almost any texture, shape and size. In addition, many consumers turn to these products, because they are not afraid of temperature changes - under their influence, gypsum stone does not lose its shape and does not undergo deformation. But it must be borne in mind that gypsum cannot boast of special water resistance. A special protective compound will have to be applied to such a finish, which will protect it from excessive moisture absorption. Usually, specialized varnishes and paints are used for this.

If you focus on the texture of the gypsum brick, then the following varieties can be distinguished:

- matte - these bricks have no shine and shine, but are also treated with protective compounds;

- glossy - these are shiny products that are necessarily covered with a special varnish that provides the material with a glossy shine;

- torn - there are no flat planes on such a finish, but there are chaotically scattered roughness and corners;

- embossed - the surface of such decorative bricks is complemented by a variety of embossed overlays;

- concave and convex - such bricks have an interesting volumetric effect, which is achieved due to their non-standard shape.

From ceramics

The first decorative bricks were made from these raw materials. Ceramic bricks are among the most aesthetic and sought-after bricks. With them, you can radically change the interior, making it more comfortable and welcoming.

Ceramic bricks are quite practical, durable and reliable. In many of their characteristics, they are similar to the wear-resistant ceramic tiles that are so popular among modern consumers. The main advantages of such products are:

- high strength;

- unsurpassed reliability;

- long service life;

- incomparable practicality;

- destructive moisture does not penetrate into ceramics, which can eventually destroy this material (which is why the same ceramic tiles are an ideal solution for a bathroom);

- such a brick will not undergo deformation, even if serious loads are placed on it;

- ceramic brickwork is not afraid of temperature changes.

From porcelain stoneware

Such decorative bricks are rightfully recognized as the most reliable, durable and durable. Damaging them is not as easy as it might seem. Porcelain stoneware is made using a special technology, which can only be adhered to in large-scale production. At home, high-quality porcelain stoneware finishing materials simply cannot be made.

Decorative brick made of porcelain stoneware boasts the following positive qualities:

- it is frost-resistant;

- he is not afraid of temperature jumps and moisture penetration;

- such a brick does not absorb dirt, since it has a special top layer;

- in stores you can find a huge number of multi-colored decorative stones from porcelain stoneware;

- similar products are available in a wide variety of sizes.

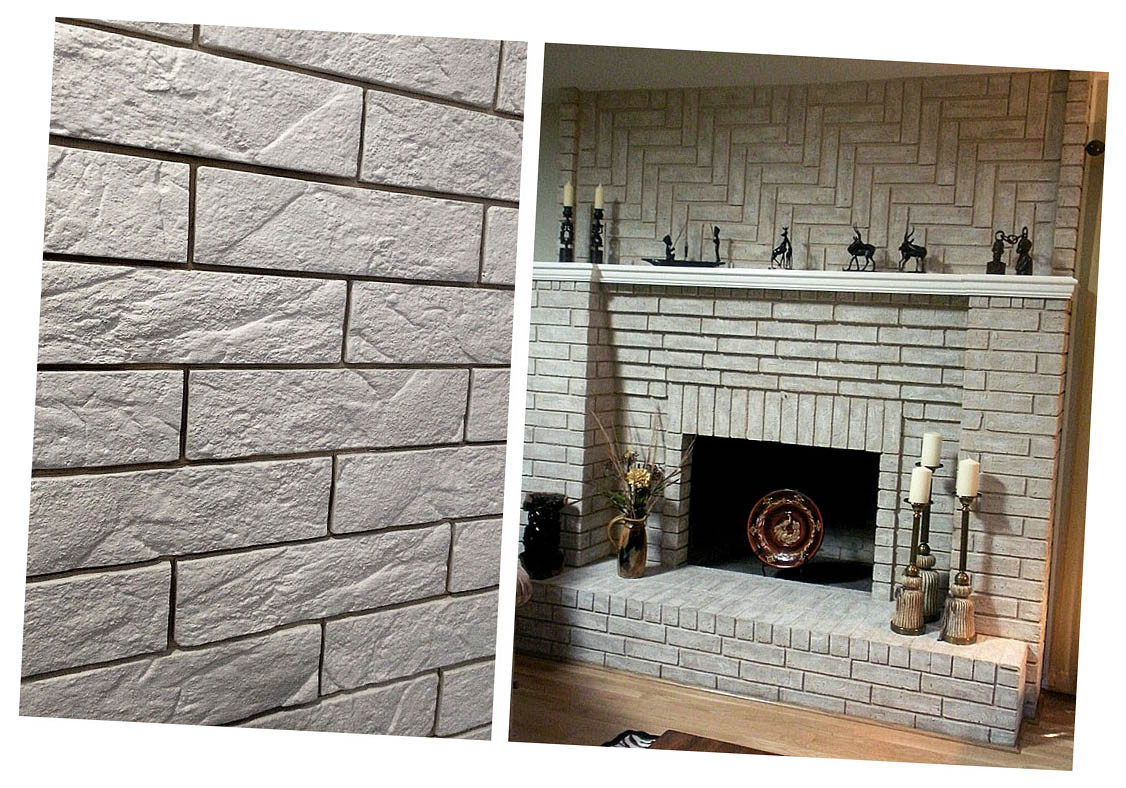

Clinker

This wall decoration has a special charm. Clinker snow-white elements are very similar to real bricks. This material has a high density, so it can be safely used in the decoration of premises where there are frequent temperature changes.

Buy or do it yourself?

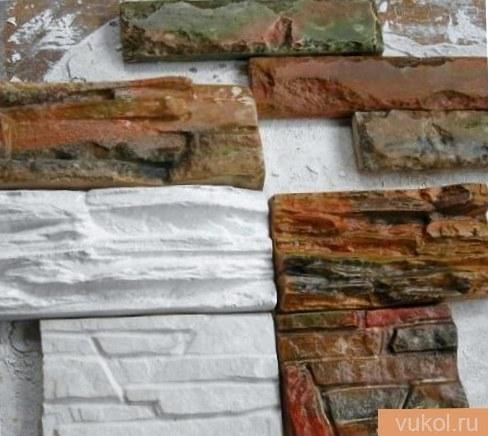

Manufacturers have developed many types of finishing materials. Gypsum brick for interior decoration in catalogs is presented in various modifications:

- The glossy varnished version is fashionable.

- An interesting matte muted look, which is treated with a protective compound.

- Equally in demand are models with a flat surface, embossed or curved.

Gypsum blocks are commercially available that mimic hewn stone segments or irregular shapes of minerals, but imitation brickwork is the easiest to handle.

The whole spectrum of beige color scheme, shades of gray, brown, sand is in demand. Many consumers prefer natural brick color or plain white. The colorless surface can be painted with selected paint. The decorative gypsum material can be smooth, textured or rough to the touch.

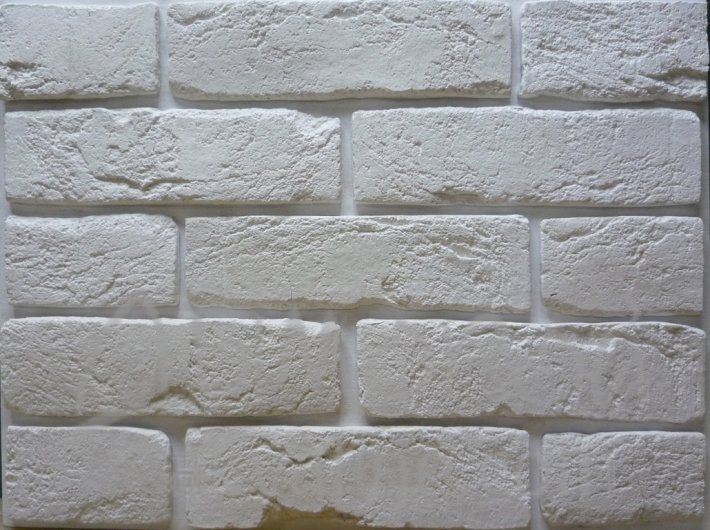

If desired, the DIYer can make a light and stable stylized brick on his own. This process is quite laborious and requires strict adherence to the recipe, the availability of suitable containers for pouring the composition. Experts advise using commercially available silicone molds.

The main ingredients for creating such a finishing material will be: actually gypsum and PVA building glue. If desired, a decorative color scheme or pigment is used, the formation of a white version is possible. To prepare a solution of the desired consistency, water is added when mixing the components.

For 1 kg of dry powder, you will need about 0.5 liters of liquid and about 50 g of PVA. You can add polypropylene fiber for reinforcement: it will need 1-2 g per kilogram of gypsum base.

The required amount of dry matter is gradually poured into the container, water and glue are also added gradually. The resulting "dough" is stirred until smooth, resulting in a composition that resembles 25% sour cream.

To stimulate the setting process, some craftsmen add citric acid to the solution: about 0.5 g per standard bucket. The coloring pigment is first diluted in water, and added to the total mass at the end of the preparation process.

Molds can be greased with vaseline oil or treated with soapy water. The mixture is poured in one layer and in half an hour the decorative "masterpiece" becomes solid. Finished products are recommended to be coated with an acrylic primer.

Varieties

The construction market is represented by a wide range of facing bricks, each model range of which differs not only in price, external design, but also in the material of manufacture. Given the latter indicator, the following types of products are most often found on sale.

Gypsum (cement)

It is produced by the molding method, in which a gypsum or cement mixture is poured into special molds. After that, painting is carried out (if the color was not previously introduced into the solution) and processing. This production technology is in many ways similar to the production of decorative stone, only the relief outline of the slabs differs in it. At the same time, the material obtained from cement is characterized by greater strength and moisture resistance than those made on the basis of gypsum. With such a brick, they can be used to decorate rooms with high humidity.

Clinker

This is the most expensive type of brick that has improved physical properties. Facing material is produced from clay using a special technology, by exposure to high temperatures. Therefore, the product is durable and resistant to external influences. It can be used for both interior and exterior decoration. Thanks to their solid structure and variety of colors, the slabs are ideal for decorating fireplace areas, kitchens and corridors. The width of such slabs ranges from 160 to 190 mm, the height is 60 mm, and the thickness is 20 mm.

Acrylic (polyurethane)

This type of product has good performance properties, since the boards are strong and very lightweight. Cladding bricks are produced in rich colors of polyurethane and acrylic components. To decorate the interior with such plates in an original way does not require a lot of time and money. In addition, recently on sale you can find products that imitate the 3D effect in finishing. Polyurethane boards are ideal for cladding surfaces in the bathroom, kitchen, balcony and veranda, as they are characterized by high noise and heat insulation, and are also not afraid of moisture.

Ceramic

This decorative brick is considered classic, as it has been used in the decoration of premises for more than a dozen years. In terms of its physical and chemical characteristics, it is in many ways similar to a ceramic tile. Most often it is installed in bathrooms and kitchens. A facing product is made from low-melting types of clay, with the addition of dyes, carbonates and quartz sand. Thanks to this composition, the material is durable and can acquire different shades, ranging from snow-white to black.

Porcelain stoneware

Unlike the above types, this brick has the highest strength indicators. This is due to its special production technologies, in which the material is not produced from clay batch, but a special solution is prepared, consisting of natural stone chips. In addition, the slabs undergo double heat treatment, which increases their wear resistance. The disadvantage of porcelain stoneware bricks is its high price.

Varieties

There are 4 types of decorative brick varnishes for outdoor use: polymer, acrylic, solvent, fireplace / stove and sealing impregnations.

Features of the varieties:

Polymeric. The composition includes alkyd resins, acrylic copolymers, as well as organic solvents and various additives. After processing with such compounds, the brick acquires a beautiful appearance "a la wet stone", while its wear resistance increases. It is possible to work with polymer varnishes even at negative temperatures (down to -10 ° С).

Acrylic. They are used to protect brickwork during both external and internal work. One-component, based on organic solvents, the compositions are well absorbed into the brick, protecting it from microcracks, mechanical damage, and prevent the formation of efflorescence.

Solvent. These are varnishes based on solvents of the same name with the addition of silicone resins. They penetrate deeply into the brick, creating a durable coating that does not crack, peel or fade

Solvent varnishes are fire hazardous, so you need to work with them with extreme caution.

Fireplace / stove. KO-85 or KO-815 - special refractory varnishes

They are used both for external work and for internal (strengthening of internal surfaces of furnaces and protection against condensation). The application of such varnishes gives the brick walls heat resistance, water-repellent properties, prevents the washing out of the oven seams, and strengthens the masonry of the stove or fireplace.

Sealing impregnations. Produced on the basis of silicone and acrylic resins, they give the brick maximum resistance to wear. Impregnation is fluid due to a complex mixture of aromatic and aliphatic solvents, which ensures its high penetrating power. Such a coating does not turn yellow for many years. The resulting protective layer is resistant to water, chemicals, UV rays, oils, reagents. After application and drying, it gives the brick an unobtrusive shine with a "wet stone" effect.

Development of the production of decorative gypsum tiles for brick

Gypsum stones are distinguished by good performance characteristics and are intensively used for interior decoration of premises. This is explained by the following advantages of this material:

- Environmental safety and harmlessness;

- Additional humidifier in the room;

- The highest practicality of the material;

- Excellent performance properties;

- Possibility of staining;

- Affordable cost.

There are many methods for producing gypsum decorative stone. Some masters add additional components to the composition in the form of lime, lemon, glue. But, traditional recipes for making gypsum tiles involve the introduction of gypsum and water.

Using gypsum tiles, you can decorate the room in various styles. It suits almost all current trends. Plaster tiles give the room elegance and sophistication. In addition, with its help, it is possible to hide small imperfections in the walls, such as uneven corners or the ceiling.

Some designers use gypsum tiles to decorate arched gaps, plasterboard partitions, fireplaces, stairs. The tile has a pleasant texture that decorates the room, making it more attractive.

But, gypsum tiles also have a certain drawback. First, it consists in the low strength of this material. Comparing cement and plaster tiles, the 2nd option is the least strong. To improve this indicator, special substances are added to the solution for making tiles; they often have a polymer base.

We suggest that you familiarize yourself with the advantages of introducing gypsum stone in the construction of tiles at home:

- The presence of ergonomic forms activates the process;

- The technological process does not require a vibrating table;

- The material is easy to paint;

- Compositions for the production of tiles are affordable.

It will be painfully easy to design a gypsum stone at home if you approach this process with the highest seriousness and seriousness.

For the production of brick tiles from gypsum, you will need special shapes. Better if they are made of silicone. Because the material, at the end of solidification, is simply removed from the mold, without damage. The purchase of silicone molds is expensive, but they can be used many times, not only for the production of tiles.

Polyurethane molds are more expensive and are suitable not only for the production of gypsum tiles, but also for cement tiles, as they are able to resist alkali. The service life of such forms is much longer than that of silicone ones.

In addition, during the production of tiles, it will be necessary to have a special container in which the gypsum solution will be kneaded.We advise you to give preference to plastic products, as they are easy to clean.

The connection between gypsum and water without additional impurities will allow to make tiles with a huge level of fragility. Such material is not suitable for interior decoration. Based on this, additional lime must be added to the gypsum before adding water.

Use a drill and mixer attachment to mix the solution. Pour the purchased solution into the mold and wait until it dries. Please note that the form should be in a room free from drafts and cold.

Long-term mixing of gypsum is unacceptable. Because the material quickly seizes and does not freeze in the future. if you find bubbles on the surface of the solution, then put the mold with it on a vibration table for one hour.

For the production of colored decorative tiles for a brick, dye is added to it in the process of mixing the solution. Special coloring compositions are distinguished by their high price and low service life. Another substitution is dyes, thanks to which it is possible to tint the paint.

On the advice of some professionals, adding cement to the gypsum mix will increase its strength. But, such a tile loses its antiseptic characteristics and is rapidly covered with fungus and mold.

When making decorative plaster brick tiles, you must take into account the following tips for working with this material:

- In the absence of additional plasticizers supplying the strength of the finished material, they are replaced with citric acid in a certain proportion.

- The setting time of the gypsum creates fifteen minutes, later it is removed from the mold. The finished tiles are dried on a flat surface for another couple of hours.

- Please note that gypsum solution is only suitable for one casting of molds, as it rapidly deteriorates.

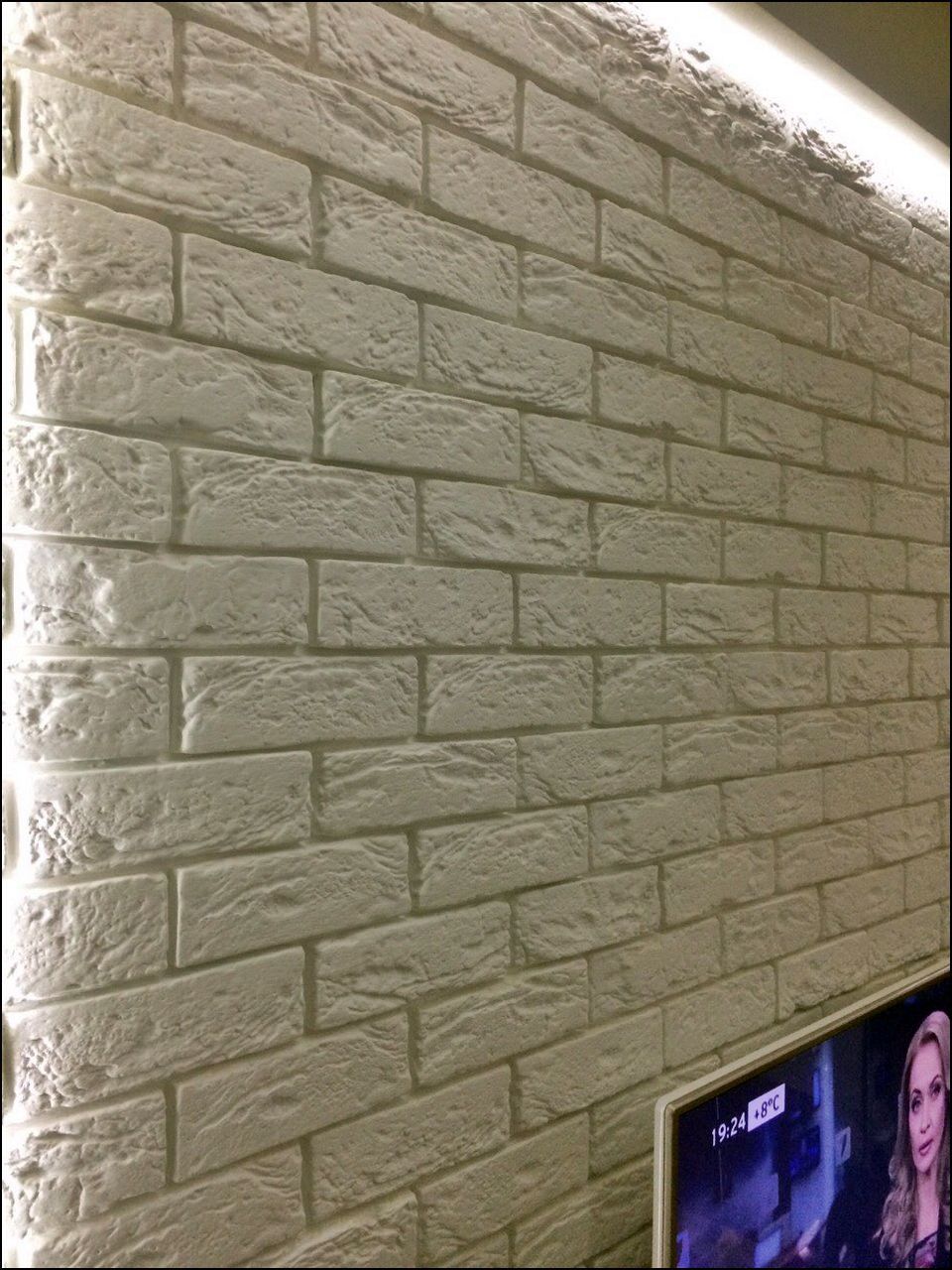

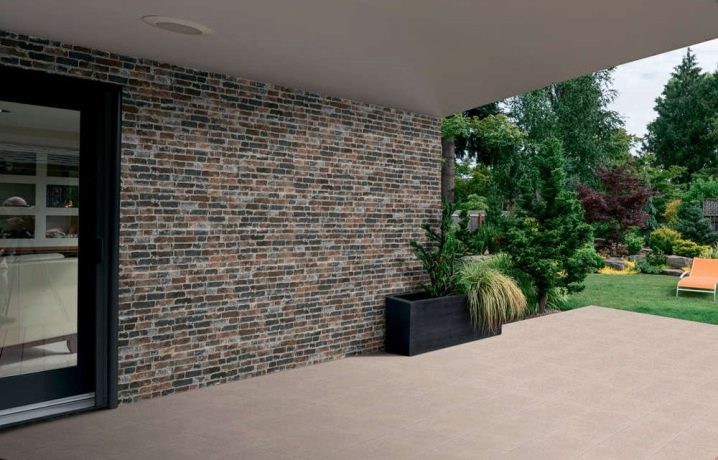

Loft

The brutal texture of the brick has literally become the hallmark of the modern Loft style. In such an interior, it will look appropriate in any room - in the living room, in the bedroom, in the kitchen and in the hallway. As a rule, in a loft, one wall is made out with brickwork - an accent one. The color of the masonry can correspond to the taste preferences of the owners - light, white, light gray masonry will contribute to the visual expansion of the space, while saturated colors - brick, brown and even black are permissible only in spacious apartments.

The loft goes well with modern furnishings and vibrant colors. Its main companions are metal, wood and glass. To create a stylish interior, you can paint the remaining 3 walls white. As a representative of the minimalist movement, the loft does not accept small cluttered decor. Windows in this style do not need to be curtained, and blinds will look good on the first floors. Wooden floors will add coziness to the room.

In the kitchen, a loft-style zest will be added by a kitchen apron made using the brickwork technique. However, you can also brick the work wall all the way to the ceiling.

The advantages and disadvantages of such a finish

The main advantages of using artificial material in the decoration of fireplaces and stoves are:

- When facing surfaces with the help of such elements, special skills and abilities are not required. It is easier to work with such material than with tiles.

- You do not need a large set of tools, the most difficult of which will be a grinder or angle grinder

- The weight of the masonry will be minimal, since the artificial stone for lining the stove is lightweight

- Due to the huge assortment of types and palettes of such material, it will not be difficult to choose the drawing or texture you need in style.

- Prices for such decorative elements are much lower than for natural rocks.

- With the help of such a stone from a stove or fireplace, it is easy to create a real work of art that will become a worthy decoration of the room.

There are practically no downsides to such a finishing stone, with the exception of some features of certain materials. Decorative stone for finishing a gypsum stove is afraid of high temperatures, at which it loses its properties, darkens and collapses. Therefore, it should only be used in fireplace cladding. The same applies to wooden cladding elements.

Popular manufacturers of gypsum tiles for interiors

There are many interesting proposals on the construction market from domestic and foreign manufacturers. Most firms offer 2 types of collections:

- under a wild stone;

- under brickwork.

The products of Italians are highly trusted by buyers. Firms such as Sergio Pietra, for example, supply White Hills imitation stone collections.

Modern tile manufacturers make their product with high quality.

Modern tile manufacturers make their product with high quality.

The Loft-Brick enterprise is constantly renewing its assortment. The latest novelty is variations under the broken and old brick. Dorset Land imitates rocky stone with an inimitable texture. Fashionable novelties fit perfectly into the modern design of kitchens and dining rooms, hallways and corridors, hallways and living rooms.

A lot of interesting textures have been developed and proposed that can be reflected in the form of gypsum finishing tiles. This is an imitation for almost any natural stone, brick or even leather. The Casavaga stone is an excellent indoor plaster cladding. They are used to decorate partitions, accent walls and niches. For fans of Kasavag cladding:

- homemade bricks with a format of 250/65 mm;

- "Adobe" - 200/65 mm;

- clinker brick - 210/50 mm;

- color mix 200/65 mm.

Having carefully studied the proposals and the technology for laying decorative tiles on a gypsum basis, it is easy to create an exclusive interior. To make homemade finishing plates, you will need to purchase ready-made molds. Designs with brick or wild stone finishes look modern and stylish.

Application technology

Working with varnish is not much different from applying regular paint. The temperature regime at which the composition lays down as evenly as possible is -10 + 30 ° С. There are only 3 methods of application: brush, roller, spray. For the latter, it is necessary to slightly dilute the varnish with a suitable solvent. The number of layers is at least 2, each must be allowed to dry thoroughly (at least 1 hour).

Tools and materials

Before painting, it is necessary to examine the surface quality. After that, analyze what materials and tools you need. A standard set, providing the ability to completely clean the wall from the old finish, as well as grout small and large cracks, in addition to varnish, includes:

- a loofah or brush made of stiff steel wire;

- soapy detergent for washing walls;

- brushes with hard nylon bristles or a roller;

- manual (auto) spray gun or spray (spray gun);

- a sponge with a hard surface;

- scraper knife or spatula;

- sandpaper for grinding rubbed cracks;

- putty or grout;

- cement M-400;

- primer;

- rubber gloves and goggles;

- flat synthetic brushes;

- rollers of various sizes.

Surface preparation

Before applying varnish, you need to tidy up the brick wall. If it has an old finish (paint), it must be removed with a hair dryer or thinner. Slices from cement mortar are knocked down with a chisel and a hammer. If there are small cracks, they must be repaired with latex brick paint, and dried paint off the surface with sandpaper.

If there are large cracks or ugly seams, they need to be "embroidered", cleaned, dust removed and repaired. Then sand with sandpaper.

Further actions:

- Rinse the brick to remove dust, dirt, and efflorescence. This can be done with dish soap and a large, soft sponge.

- Dry the surface.It is good if the weather is sunny and warm at this time.

- If after drying, efflorescence appears again, rinse the surface again using a sponge with a hard surface.

- Wait until the brick is completely dry.

- Treat the walls with a deep penetration primer. Pick it up correctly. It is better to buy a composition from the same manufacturer as the varnish.

The subtleties of working with varnish

After the surface is completely prepared and dry, it can be varnished. This is done with a long-pile roller (bristle length up to 2 cm) or with a thick stiff brush. Adjacent strokes should overlap each other by at least a few millimeters (overlap). The best result will be obtained by using a spray gun. Work starts from any upper corner of the wall. Each subsequent one is applied after the previous one has completely dried, so that the coating turns out to be even.

It is better to cover brick walls with varnish in summer, in dry weather, otherwise there is a high probability that the composition will lie unevenly or the coating will "go" with stains.

This kind of finishing is much easier in terms of labor costs and cheaper in finance than plaster or other cladding. Caring for the varnished surface is simple - wash it a couple of times a year with warm soapy water and then rinse it with clean water.

From time to time we want to change the furnishings and interior of the apartment in order to freshen it up and make it more modern. For this, the industry is ready to offer a wide range of finishing materials.

Today the article will be devoted to how painting an artificial stone from plaster with your own hands can make an original look out of the usual interior of a room.

Gypsum tile finishing technology

The decor layers are easy to cut; a conventional hacksaw (small teeth) is used. Use a power tool with suitable attachments at medium speed to avoid cracking.

The low weight of plaster decor has the advantage of being easy to install. You can take a cement mortar or construction glue for gypsum board, any composition for tiles is allowed. With different grout, a “solid” wall will look different.

Use modern plaster tile laying techniques.

Use modern plaster tile laying techniques.

At the end of each row, it is recommended to clean up the blemishes of the styling. For colored tiles, you will have to tint the glue with pigment in order to do without grouting. High-quality grouting to match the tiles will make the cladding more aesthetically pleasing. The fewer the voids filled between the layers, the more convenient it will subsequently be to take care of the torn stone masonry, especially in the kitchen and in the bathroom.

Always strive for perfect tiling.

Always strive for perfect tiling.

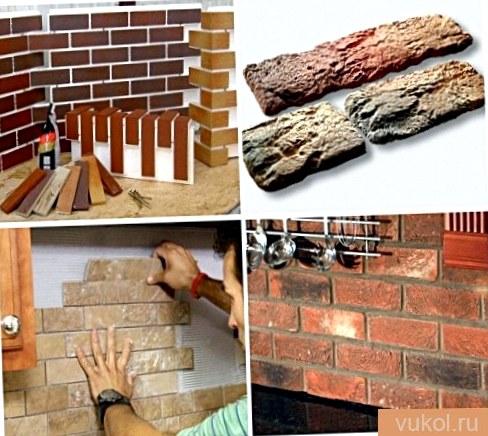

DIY imitation of brickwork

Pretty plaster masonry

Homemade options are among the most budgetary. If you try hard, you can imitate a brick wall, indistinguishable from the real one. Let's analyze the three most affordable and easy ways to imitate a brick with our own hands.

We make polystyrene tiles ourselves

Expanded polystyrene is cut into tiles of the desired size 1 cm thick. For greater similarity, the edges are melted with fire. Instead of reflowing, you can rub each tile in different places with sandpaper to achieve roughness, dents and bumps.

Production of tiles from expanded polystyrene

Work with fire is carried out in the open air, protecting the nose with a respirator. When burning, the material releases toxic substances.

- The wall is leveled and primed

- Mark with a level and ruler

- Cut polystyrene foam into bricks, and decorate them for better imitation

- Pasted on liquid nails

- Treat the seams with standard grout

- Paint the surface with color using a brush

We apply a ready-made stencil

Purchase dry plastering cement. It is flexible and convenient for finishing procedures. Prepare a stencil (cage) with a brick pattern.

The stencil can be plastic, wood, rubber.

This is what a standard plastic stencil looks like.

1The wall must be perfectly flat. Apply a primer to it and wait until it dries.

2Next, cover the surface with 1-1.5 cm thick mortar

3Apply the stencil to the fresh layer of cement and press firmly

4After a couple of minutes, it is transferred to the next area next to the pressed pattern

Apply the device so that the masonry is even, its symmetry is not broken, and distortions do not occur. This is the hardest part of the process

5When you finish pushing the picture, wait until the solution is completely dry. Run the primer over the surface again. Paint the wall with acrylic paint of the desired color

We use narrow masking tape

Scotch tape helps reproduce a brick pattern on a wall with a thick layer of regular plaster. The role of the latter is performed by the above-mentioned cement or gypsum. Watch the video, which clearly demonstrates the process of creating a "brick" pattern on gypsum plaster using strips of narrow tape:

VIDEO: Construction tape allows you to achieve perfect similarity

All methods of imitation of brickwork for interior decoration: expensive and budgetary, simple and virtuoso. Installation Instruction (80+ Photos & Videos)

Construction tape allows you to achieve perfect similarity

A cozy and homely brick wall is conducive to peace and peace of mind. It gives a sense of solidity, protection and security. One wants to return to such a house, there is no desire to leave from here.

The rough texture of rough stone is interestingly combined with fragile and airy textiles, allowing you to create amazing ensembles. It also looks good with wood, other rocks, glass and plastic. Effectively "plays" in daylight and artificial lighting.

The correct color scheme helps to visually expand the space

Even a beginner in finishing work can easily decorate a wall under a brick. If you carefully understand the issue, you can create a spectacular design without spending a single extra penny. Feel free to experiment and try new things - make your home interior enjoyable.

VIDEO: 5 ways to apply brick decor. Imitation brick

All methods of imitation of brickwork for interior decoration: expensive and budgetary, simple and virtuoso. Installation Instruction (80+ Photos & Videos)

8.2

Total Score

Imitation brick for interior decoration

Ease of implementation

7

Appearance

9

Originality

8.5