Materials for waterproofing plastic windows

After identifying the cause of condensation, it is necessary to prepare consumables. The list depends on the task to be carried out:

- initial installation of the window;

- repair of contact points;

- frame repair.

In the first case, you need polyurethane foam and waterproofing tape. In the second, only the tape is enough. In the third, silicone sealants should be used. Let's consider these materials in more detail.

Waterproofing tape for windows

There are 4 main types of waterproofing tapes:

- moisture and steam resistant on a self-adhesive base;

- insulated;

- pre-compressed;

- for external use.

The first 3 types of tapes are used only for interior work. The peculiarity of a conventional waterproofing tape is that it does not let through not only water, but also air. If the house is built of foam or aerated concrete use is not recommended... If the joint seam has voids, a fungus will inevitably form in it, which will begin to destroy the stone. The price starts at 60 rubles per roll of 5 m.

The insulated tape differs from the first option only in that it is covered with a special reflective material, which prevents the penetration of cold from the street and heat leakage from the room. It is topical to use in cold regions. The price varies from 80 to 400 rubles. per roll 5 m.

The pre-compressed tape is mainly suitable for aerated concrete structures, since it allows air to pass through, but prevents moisture penetration. In cold regions, it makes sense to use it only in combination with an external diffuse tape. Price 60-300 rubles. per roll 5 m.

Tapes for external use differ in that they are resistant to natural phenomena: rain, snow, sun. However, they only protect against moisture from the street and impede ventilation of the seams. They are best suited if the interior has already been renovated. Price 80-500 rubles.

To correctly identify the tape, it is enough to study the GOST standards:

- GOST R 53338-2009 "Self-expanding vapor-permeable self-adhesive tapes for construction purposes";

- GOST 30971-2012 “Seams of assembly units for joining window blocks to wall openings. General technical conditions ";

- GOST R 52749-2007 "Window assembly seams with vapor-permeable self-expanding tapes".

Rice. 2. Waterproofing tape for the window

Polyurethane foam

Polyurethane foam is used exclusively at the stage of installing windows. According to the principle of operation, liquid foam is blown into the cracks between the frame and the wall and begins to dry out and expand, filling all the voids. Re-blowing the seams with foam will no longer give the expected result. First, it is necessary to remove all old foam and re-blow. Only in this case, the waterproofing will be performed with high quality.

Another indisputable advantage of foam is that insects, bacteria, fungus and other parasites do not start in it. On the other hand, there is a significant disadvantage - the foam burns out very quickly in the sun and begins to crumble, so the seams must be sealed with a waterproofing film.

The choice of the manufacturer does not really matter, the pricing policy ranges from 40 to 200 rubles per can.

Window sealant

This is a collective name for a whole group of finishing materials. Window sealants are sold in different forms:

- paste;

- tube;

- ready mix in a bucket;

- dry mix.

The first two options are suitable for sealing small seams, since they are sold in small quantities and cost up to 200 rubles. Ready mixes are used if the work on installing the sealant is done in one go.After opening the can, the sealant dries out and becomes unusable. On sale there are different displacement from 1 to 20 liters. Cost from 150 rubles. per liter.

Dry mix is cheaper, on average 300-400 rubles. per kilogram. When diluted, 3-5 liters of sealant are obtained. In terms of physical and operational properties, it does not differ from the finished mixture.

Liquid sealant for windows

Liquid assembly sealant is also a complex group of insulations, which is used both for filling assembly seams and for repairing the frame itself, in the event that the rubber band on the glass unit has worn out or received mechanical damage.

In general terms, one can highlight the high reliability of these insulations, ease of use and durability. However, their cost is the highest, from 300 rubles. for the can. There are clear and white sealants on sale.

Rice. 3. Liquid sealant for windows

Waterproofing with sealing tape for windows

The window slope at the point of contact with the frame always has a through slot. Even if polyurethane foam was used, there are still micro voids through which moisture seeps.

You can find tips:

- plaster the gap;

- cement the joint;

- cover with acrylic.

All these options are ineffective in practice. The plaster will get wet and crumble from moisture, cement passes moisture well, acrylic can poorly adhere to the surface of the slope and micro cracks form.

The most correct option is to use waterproofing tape. The work includes the following items:

- elimination of dust or large particles of construction waste from the slope and frame;

- degreasing the surface;

- gluing tape.

For the first work, we use dry rags. It is enough to wipe the surfaces so that no visible debris remains. Next, we take acetone or alcohol and wipe the surface of the frame and slope. Then carefully unwind the insulating tape, separate the protective film from the adhesive base and glue it. Distribute the width of the tape in half, so that equal parts of the insulation are on the wall and frame.

This type of work refers to finishing work, it is used after the actual installation of the window, if during operation there are problems with the ingress of moisture into the room.

Rice. 5. Waterproofing with sealing tape for windows

It should be noted that the adhesive base must not be wetted, otherwise adhesion to the frame and wall will not occur and the tape will soon fall off. It does not need to be repaired additionally. This will not only not improve the effect, but also vice versa, can lead to the fact that the tape begins to detach under the influence of plaster, acrylic or other material used to decorate the slope seam.

Installation features

The tape is glued both before fixing the window block in the opening and on already installed structures. The first option is more convenient in cases where external insulation is installed.

Let us consider the algorithm for using tape insulation using the example of gluing a pre-compressed sealing tape (PSUL) and an internal GPL-S with an additional strip of double-sided tape:

- We prepare the opening. If there is an old window block, we dismantle it as carefully as possible, without causing unnecessary damage. After dismantling, we align the surfaces adjacent to the future structure, clean them from extraneous contamination.

- We carry out a test installation of the block in the opening, temporarily fixing it. This is necessary to mark the edge of contact between the walls and the window, so that when gluing the tape is hidden behind the outer slopes.

- We measure the window block. In accordance with the dimensions obtained, we cut the PSUL for gluing on top and on the sides of the frame, prepare the diffusion tape to isolate the area of attachment of the casting profile.

- We proceed in the same way with the GPL-S (internal slopes) and butyl rubber tape (for the window sill profile). The material is measured for each side with a 10 cm allowance to form corner joints.

- We glue the tape, gradually removing the protective layer from the PSUL adhesive surface. We glue GPL-S to the inner side of the window profile using a strip of double-sided tape (we do not remove the protective film from the main adhesive surface at this stage).

- We fix the window in the opening. We wedge it and then fasten it with anchors or by means of mounting plates. We fill the seams with polyurethane foam.

- After complete polymerization of the foam and rough preparation of the inner surface of the walls, we fix the GPL-S on them (remove the protective paper and glue it to the slopes).

It should be remembered that the tape must be selected in accordance with the weather conditions. Working in the winter, it is possible to glue only material intended for use in low temperatures.

Features of the use of window sealants

Window sealants on the construction market are a dime a dozen. They are used for sealing frames, glass, etc.:

-

Silicone sealants. The most common material that is made on the basis of silicone rubber. The name "silicone" is apparently given for convenience. Due to their simple production and standardization, they are in great demand. Depending on the substance that provides vulcanization, silicone sealants are divided into two types: neutral and acetate. Neutrals work well on smooth (frames) and porous surfaces (concrete or brick), making them suitable for sealing external seams when installing windows. This material practically does not emit toxic substances during vulcanization. It is characterized by high adhesion (bonding) to glass, wood, ceramics, porcelain, PVC, enamel, aluminum and almost all painted surfaces, and also retains its properties at a temperature difference from -50 ° C to +180 ° C.

Acetate sealants should only be applied to smooth surfaces such as glass. Their strength is higher than that of neutral ones, however, when vulcanized, they release acetic acid, which requires good ventilation of the room. Sometimes acetate sealants are called general purpose sealants.

-

Acrylic sealants. Designed for glass putty. During installation, they are used to protect the polyurethane foam from moisture ingress, since the vapor permeability of these sealants is quite low. They are resistant to low temperatures and adhere well to many building materials, including wet surfaces. However, they are not suitable for resinous and bituminous surfaces or gaps that are frequently exposed to water.

- Polysulfide or thiokol sealants. They are used in a wide range of temperatures, they are highly elastic, so they are suitable for many materials. They are flowable masses with a density of 1270-1300 kg / m3 and a viscosity of 10 to 60 Pa. To improve the quality of the connection with porous materials, thiokol sealants are used together with primers.

-

Polyurethane sealants. They are the most inexpensive, but they are characterized by increased heat resistance, which is excellent for cold coatings: concrete and brickwork. Resistant to acids, oils and weather.

As for liquid plastic, it is a one-component adhesive based on white dissolved PVC. It does not change its color over time, is distinguished by its durability (up to 15 years) and excellent adhesion to polyvinyl chloride. UV and temperature resistant.

Usage

Sealing can be done independently. When working, you will need a syringe, water and mounting tape. To prevent the slopes from getting dirty, you need to stick construction tape on them. Work areas should be thoroughly cleaned and degreased, but for PVC windows you cannot use products containing acetone, otherwise ugly stains will appear on the surface. Slowly squeeze the sealant into the seam with a syringe.The tool should be held at such an angle so that its nose straightens the applied putty. Then everything is smoothed with a finger soaked in water. Seams should be thoroughly filled with a product so that no voids remain. Even before the material hardens, surplus is carefully removed from the surfaces without violating the integrity of the sealant applied to the seams. Putty should not be applied to all seams at once, but work in stages.

For interior and exterior work

According to their physical and chemical properties, all sealants are divided into two categories - used for outdoor work and used indoors.

Certain requirements are imposed on sealants used for outdoor work, which contribute to their effective resistance to an aggressive, external environment.

Sealing the outer seam with sealant

Requirements for outdoor sealants:

- Chemical resistance. Expressed in successful resistance to mold, water and chemicals.

- Successful resistance to mechanical stress. That is, such a sealant must be durable and not destroyed by the action of external forces.

- Elasticity.

- Good thermal insulation properties.

- Have a dye in its composition or have an easily dyed structure.

- When applied, to have such a state in which all hard-to-reach places are easily filled (to have fluidity).

- Easy to stick to surfaces (high adhesion).

- Wide range of temperatures for application and use.

Requirements for internal sealants:

- Lack of toxins. This is a basic requirement for sealants used in residential premises, preventing poisoning of people, animals and the development of allergic reactions.

- Counteracts biological agents, mold and bacteria.

- Moisture resistance.

How effective is polyurethane foam against water

Window waterproofing is a strip of material that is used to bond between the opening and the plastic window before foam is applied. Its main function is to protect the window from moisture and leakage. Polyurethane foam suffers the most from water. When wet, its structure is destroyed, and properties are lost. Since many for some reason are sure that polyurethane foam is a reliable waterproofing material, let's take a closer look at its properties.

Experts recommend calling it "polyurethane foam", that is, according to the main material that is part of it. Its main purpose is not installation, but filling the joints that have appeared between already installed structures, overlapping voids, cracks, etc. It would be more logical to call it “overlapping foam”.

For protection against moisture and ultraviolet radiation it is necessary to provide several layers during installation: heat, vapor barrier and vapor permeable

For protection against moisture and ultraviolet radiation it is necessary to provide several layers during installation: heat, vapor barrier and vapor permeable

Under the influence of moisture, the foam increases in volume from 50 to 200-250%, hardens within 24 hours in the temperature range from + 5-35 ° C and air humidity not less than 60%. It also absorbs moisture well, so it itself needs waterproofing, in addition, it collapses under the influence of UV rays. But the polyurethane foam has sound and heat insulating properties.

Therefore, when waterproofing windows, consider other materials rather than relying on polyurethane foam. Correctly installed plastic windows protect the room from dust and noise, retain heat and serve for a long time

If any mistakes were made in the installation, then after a while a gap forms at the junction of the window and the wall, in which moisture collects and mold forms. Poor vapor barrier plays a role

Correctly installed plastic windows protect the room from dust and noise, retain heat and serve for a long time. If any mistakes were made in the installation, then after a while a gap forms at the junction of the window and the wall, in which moisture collects and mold forms. Poor-quality vapor barrier plays its role.

The installation seam needs careful isolation from the ingress of water from the outside

The installation seam needs careful isolation from the ingress of water from the outside

How to make a high-quality gap between the wall and the window, and not only plastic? It is important to prepare the opening as well as the window structure. For this, dirt, dust and other unnecessary elements are removed, oily areas are degreased.

The cleaned surfaces should be sanded, if necessary, the cracks should be repaired. During freezing temperatures, the surface must be cleaned of snow and / or ice. As a result, it should be clean and even.

Often, the installation seam of windows is made of foam, and it can fail for the following reasons:

- exposure to sunlight: foam does not "like" them.

- erosion of polyurethane foam due to water ingress.

- erosion can also occur due to the expansion / contraction of windows, negatively affecting the window.

It is possible to determine whether the tightness is broken by the following signs: when the vents are closed, drafts appear, mold and fungus form on the walls and joints, and leaks form during rain. They indicate that the window should be well taken care of.

These unpleasant consequences can be eliminated by waterproofing window openings and joints. For such purposes, the most popular materials are:

- window sealant;

- liquid sealant (or liquid "plastic");

- sealing tape, which is applied to the polyurethane foam.

Polyurethane foam is an excellent sound and heat insulator

Polyurethane foam is an excellent sound and heat insulator

How to use?

Sealing may well be done on your own. Turning to workers is an unnecessary and unreasonable waste. With the instructions, this work can be done in no time. We will assume that the slopes have already been made earlier, therefore we will not dwell on this issue.

The algorithm for sealing work will be as follows:

- The first point will be the preparation of tools and consumables. In the process, you will need a syringe for applying sealant, a container of water and construction tape.

- The slopes need to be prepared for further work. The essence of the preparation is to stick construction tape, which will protect the window structure from dirt and will save us time.

- The working area must be carefully cleaned. There should be no dirt or even dust. It is also necessary to remove the protective film down to the slightest fragment. For degreasing plastic structures, it is forbidden to use solvents containing acetone. With this treatment, cloudy, matte stains, stains that differ in color and other troubles may appear on the surface.

- Using a construction syringe, slowly squeeze the sealant into the seam area. The tool should be angled so that the tip flattens the material to be applied.

- The remaining irregularities and other defects are smoothed out with a finger previously moistened with water. This trick will prevent material from sticking and provide a smooth finish. Seams need to be well filled with putty so that there are no voids.

- It is necessary to remove the remnants of the material from the surfaces even before it hardens. In this case, it is convenient to use a damp sponge. You need to act very carefully so as not to violate the integrity of the sealant applied to the seams.

- You don't need to put putty on all seams at once. Better to work in stages. In this case, it will be possible to avoid hardening of the material until it is flattened and the residues are removed.

Installation of hydro and vapor barrier of windows

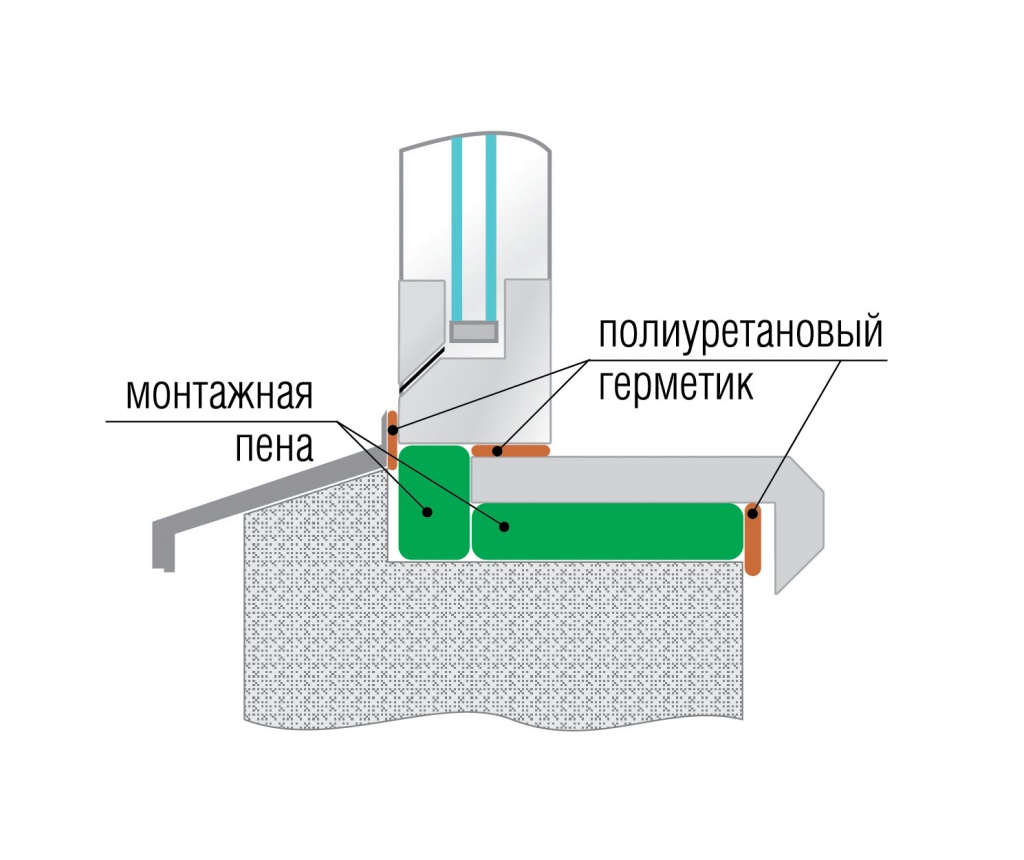

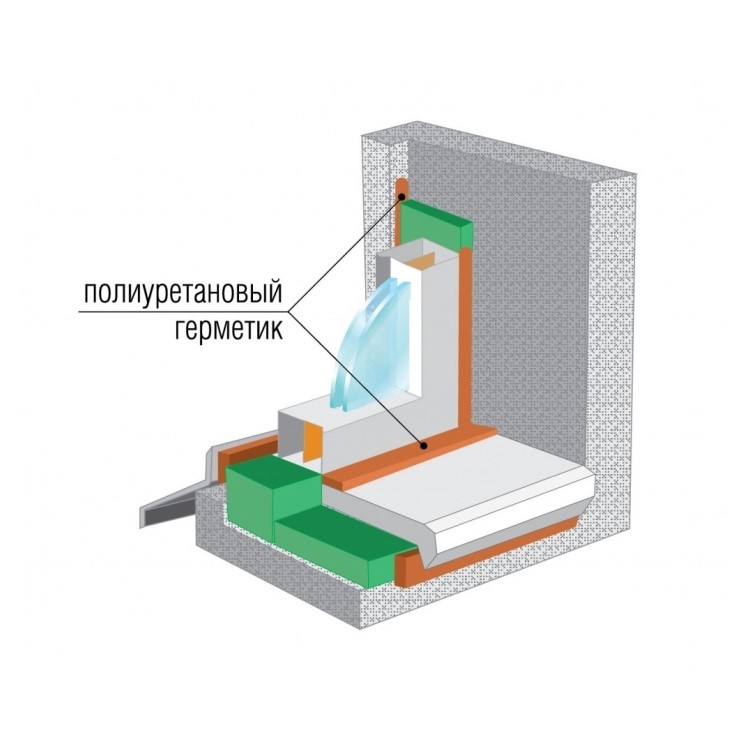

Sealing the space between the window block and the opening includes three main layers: central, external and internal.

The central layer is, in the overwhelming majority of cases, polyurethane foam.

It, in conjunction with the fasteners, fixes the structure in the opening, protects the room from drafts and heat loss, and also prevents moisture from entering.The polyurethane from which the foam is made degrades quickly under the influence of solar ultraviolet radiation and other external influences, which is why it cannot be left open. Therefore, a full finish implies the use of additional protection.

The outer layer is waterproofing. Basically, it is necessary to exclude moisture from entering the street, in addition, it insulates the opening and protects it from the negative effects of atmospheric factors, including UV radiation. One of the important features of external waterproofing is its one-sided vapor permeability, which ensures proper ventilation of the joint and prevents the accumulation of any liquid in it.

The most common materials are specialized tape products such as PSUL and sealing liquid mastics.

The inner layer is vapor barrier. Located on the side of the room, prevents moisture from entering the assembly seam

This is especially important when glazing rooms where there are relatively many steam accumulations - kitchens or bathrooms. Steam insulators are characterized by practically zero moisture permeability, have a hygroscopic outer surface, so that water does not stay on it and dries quickly

There are also foil types of vapor barriers used for dry finishing of slopes (lining, panels). Most often, tape butyl rubber materials are used for installation, less often acrylic or silicone sealants.

The choice of insulation products depends on the finish and the specific climatic conditions prevailing in the region.

However, regardless of these factors, it is important to have all three layers and adhere to the technology of their laying. Only then can the freezing of the seam, the destruction of the insulation and the appearance of accumulations of moisture on the inner slopes be completely excluded.

Views

Today the construction market is represented by a huge selection of glass sealants. Each of them is characterized by individual characteristics and scope.

Depending on the basis on which the material is made, two product groups are distinguished:

- Acetate.

- Neutral.

Sealants belonging to the first group are most often used for structural sealing of insulating glass units or for glazing windows. As for the second type, it has high adhesion, so it can be used not only for sealing glass, but also for sealing the external seams of facades, supporting structures made of metal.

The sealant can differ in the components that make up its composition and can be varied.

- Acrylic. This material is considered ideal for sealing windows. It can be used to cover both new glass units and to use it to seal old ones. The sealant creates a strong layer between the glass and the frame and prevents air from entering. The result is a tight connection that is resistant to moisture and low temperatures. Most builders consider this sealant to be a versatile glass sealant.

- Butyl. It is a construction product that is intended for finishing double-glazed windows. It is mainly used when several glasses need to be joined together. Such a sealant is characterized by excellent protection and well resists the penetration of wet steam and air into the space between the panes. It should be applied to the work surface at temperatures above 100C.

- Polyurethane. The material has an excellent seal structure and is therefore often chosen for sealing plastic and glass. In addition, it can additionally play the role of thermal insulation. The surface after sealing with such a sealant acquires strength, and its service life increases. Craftsmen most often use this material for edge joining. Glass reinforced with sealant is not “afraid” of temperature extremes, acids and oils.

- Silicone.It is the most common and demanded type of sealant. It is used at almost all stages of construction work. The material is also well suited for sealing facade glass, as it has high performance indicators. The popularity of this product is due to the fact that it is inexpensive and characterized by excellent quality.

Thanks to its unique characteristics and special composition, silicone glass sealant allows you to reliably seal joints and adhere materials. In addition, the product has found its application in auto repair, as it can act as gaskets. Often one has to deal with the problem of sealing joints between glass and coatings such as metal, ceramics or brick. Many adhesives cannot cope with this, but silicone glass sealant will ideally glue all objects, including elastic polymers, plastics, aquariums, and automotive parts.

In addition, the building product is used to seal joints between various glass objects. In a car, it can be used to strengthen headlights, fixed windows and sunroofs. However, when using this sealant, you must remember that it is not suitable for work in which glass must be combined with polymers. When interacting with fluoroplastic, polycarbonate and polyethylene, a chemical reaction occurs and the material loses its properties. In addition, this sealant can degrade when exposed to gasoline, synthetic oil and ethylene glycol.

Recently, a new product such as polysulfide sealant can be found on the construction market. It does not contain solvents in its composition, it is produced not in tubes, but in large cans and is used, as a rule, in the manufacture of insulating glass units. This sealant is obtained by mixing polymers with pigments and a structuring agent, resulting in a sealing material that has high resistance to gas, steam and water penetration. Typically, this product is used as a secondary sealant.

When will the sealing tape help?

To use the sealing tape, it is necessary that the surface of the window opening is perfectly clean and smooth. Between the window itself and the opening, the distance should be the same everywhere, only then the waterproofing will be reliable. Thanks to the sealing tape, moisture will not enter the seam and window opening, and steam will escape outside.

Depending on the degree of compression of the tape, there may be one or another resistance to rainfall and wind load. This parameter is usually 20%.

The sealing tape is not attached to the window by fasteners, but simply pressed tightly into a special groove in the profile

The sealing tape is not attached to the window by fasteners, but simply pressed tightly into a special groove in the profile