Description of sealing products

TechnoNICOL sealants have the following advantages and features:

- the company "TechnoNICOL" has long been specializing in the production of sealing and waterproofing compounds, therefore, the sealants are of high quality, which is not worse than the quality of European products;

- silicone and polyurethane sealants are made using modern technologies, after application, the compositions very quickly become a reliable waterproofing material that is resistant to atmospheric factors and other adverse conditions;

- TechnoNICOL sealants have excellent elasticity and a high rate of adhesion (adhesion) to many building materials and different types of surfaces;

- the funds set and dry quickly enough;

- have good resistance to ultraviolet rays;

- after years, cracks and any other defects do not form on the sealed seams;

- after hardening, waterproofing materials-sealants from the TechnoNIKOL company do not deform and do not collapse under the influence of unfavorable factors;

- products are resistant to the influence of organic substances and chemical compounds;

- fungi and mold do not settle on the surface of TechnoNICOL sealants, the applied material can be operated without problems in conditions of high humidity;

- sealed seams and joints can be operated for a long period of time, which reaches 20 years;

- after application to metal surfaces, TechnoNICOL products protect against corrosion and rust;

- chemical solvents and petroleum products such as oil and gasoline do not harm the sealed products;

- almost all types of butyl rubber, silicone and polyurethane sealants do not shrink over time;

- have excellent resistance to temperature extremes, can withstand frost and heat without problems.

The TechnoNICOL company manufactures many types of sealants, each of which is used for specific purposes.

When choosing one or another product, it is important to consider the purpose of the composition. Next, the main types of sealing substances will be considered.

Advice

The manufacturer "TechnoNICOL" produces various sealants, so the scope of their use is very wide.

These formulations are suitable for:

- repair work;

- used instead of a waterproofing layer;

- are used to eliminate empty gaps around communications;

- to align the seams when installing plastic structures;

- these types of sealants are used for many in the industry.

Experts recommend using the material in this order:

you need to mix the material well;

it is also necessary to clean the treated surface from dust and dirt, since such factors negatively affect the quality of adhesion of the composition to the surface;

it is important not to forget to degrease the material;

in the event that work must be carried out at subzero temperatures, the sealant must first be left in a warm room for a day;

- the composition is applied with a rubber or iron spatula, but it is necessary to wear protective equipment for hands and possible places where the composition can get;

- it is not recommended to add a solvent to the composition, although this will facilitate the process of work, but will negatively affect its quality;

- when performing processing, you need to monitor the gaps (if there are gaps on the seam, this will affect the quality of the sealing);

- it is recommended to follow the instructions for use, which is on the packaging with the sealant.

For information on how to properly seal the seams and abutments on the facade, see the video.

TECHNONICOL 2K two-component polyurethane sealant

| retail 1 920 ₽ | small wholesale 1 740 ₽ | wholesale |

1 560 ₽

- Product description

- Advantages

- Application area

- Specifications

- Mode of application

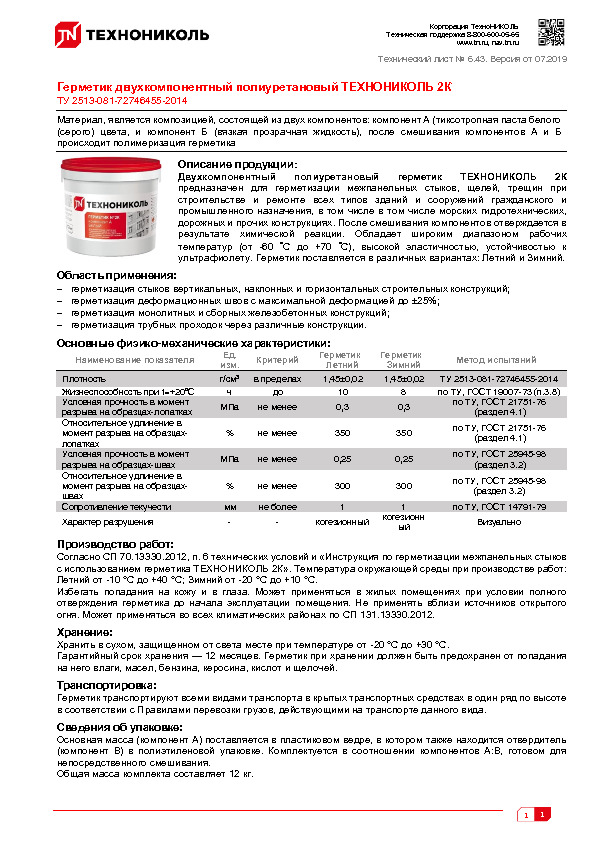

TECHNONICOL 2K is a high-quality two-component polyurethane sealant designed for sealing interpanel joints, cracks, cracks during construction and repair of all types of buildings and structures for civil and industrial purposes. The material is a composition consisting of two components: component A (thixotropic paste of white or gray color without foreign inclusions, and component B (viscous transparent liquid), after mixing components A and B as a result of a chemical reaction, the sealant polymerizes. The curing rate increases with temperature rise The bulk (component A) is supplied in a plastic bucket, which also contains the hardener (component B) in a polyethylene package. It is completed in the ratio of components A: B, ready for direct mixing. After curing, the sealant has excellent adhesion to basic building materials . Has a wide range of operating temperatures (from -60 ° C to + 70 ° C), high elasticity, UV resistance. acrylic facade paints.

- For joints with a maximum deformation of up to 25%.

- It has good adhesion to concrete, brick, wood and PVC.

- High resistance to weathering.

- Wide operating temperature range.

- Excellent thixotropy, does not flow in vertical seams.

- Can be applied at sub-zero temperatures.

- The components of the sealant mix easily.

- Paintable.

- It is used for reliable sealing of interpanel joints, cracks, cracks in the construction and repair of all types of buildings and structures for civil and industrial purposes.

- Sealing joints of vertical and inclined building structures.

- Sealing expansion joints with a maximum deformation of ± 25%.

- Sealing of monolithic and prefabricated reinforced concrete structures.

- Sealing joints and cracks in horizontal structures (floors) in the absence of mechanical stress.

- It can be used in residential premises, provided that the sealant is completely cured before the premises are used.

- It can be used in all climatic regions according to SNiP 23-01.

To carry out the installation of the sealant, you must:

- Low-speed drill with paddle attachment

- Molar tape

- Rubber or metal spatula

Before applying, it is necessary to clean the surface from: dust, adhered solution, previously used sealants, snow, ice. The sealant can be applied to both dry and damp surfaces, but the presence of dripping moisture is not allowed. To make the seam look aesthetically pleasing, mounting tape is glued to the edges of the abutting surfaces.

For thermal insulation, we use a Vilatherm harness.

It serves as a base for applying the sealant. In width, it should be compressed 20-50% of its original diameter. Bundles should be built up at a distance of at least 0.5 m from the intersection of horizontal and vertical joints.

Polyurethane foam harnesses perform several functions:

The sealant does not stick to the harness. Thanks to this, three-sided adhesion of the sealant in the joint is excluded and deformations occur on the entire layer, in contrast to the joints made of polyurethane foam.

It is necessary to mix the components, observing the following conditions: With a larger amount of hardener, the sealant will harden faster, but will be less durable when deformed. With less quantity, it does not harden and remains sticky.In winter, before mixing, the sealant must be kept indoors for at least a day at t + 23 ° C.

Stir both components with a low speed paddle drill for about 10 minutes (no more than 300 rpm), until smooth.

It is recommended to apply the sealant to the expansion joint with a rubber trowel. The layer thickness must be at least 3 mm.

With a joint width of more than 40 mm, it is recommended to seal it in 2 steps: first, the sealant is applied along the edges of the joint. Then the application is done in the middle of the joint.

The pot life of the sealant at t + 23 ° С is not less than 6 hours (it increases with decreasing t). Winter formulation is not less than 3 hours. The time of complete curing at t + 23 ° С is up to 48 hours (with decreasing t, the curing time increases).

After the sealant has cured, you can remove the molar tape.

Silicone

Sealing silicone products from the TechnoNIKOL company are universal products that are used for any work on sealing and sealing joints. These compositions freeze at a speed of about two millimeters per day at room temperature. Sealants are universal, therefore they are suitable for both outdoor and indoor work. Sanitary species contain fungicidal additives, so fungi and mold do not appear on them, in addition, the products are resistant to atmospheric influences.

The main area of application of these compounds is the sealing of joints and seams between plumbing fixtures and walls, means are used during the installation of shower cabins, sinks, toilets, bathrooms and shower trays. Also, the products are used during construction, decoration and glass installation. These sealants have excellent adhesion to porcelain, glass, ceramic, enamel surfaces, as well as to tiles, concrete, brick, PVC, and other materials.

Scope of application

Due to the variety of types, TechnoNIKOL sealants have a huge scope of application. They are used by masters when repairing premises, using them as waterproofing and to fill voids around pipes in bathrooms, to fill cracks and align seams and joints of panels in rooms, when installing door blocks and PVC windows.

Sealants are used in many industries: shipbuilding, automotive, electrical and electronic. It is difficult to overestimate the importance of sealants in construction.

One of the innovations in waterproofing technology is polymer membranes. They are a completely new approach to roofing. They have a long service life - up to 60 years, they have many advantages:

- fire resistance;

- resistance to ultraviolet rays and temperature fluctuations;

- aesthetic appearance;

- waterproof;

- not subject to mechanical damage and punctures;

- suitable for use on roofs of any inclination and any size.

By watching the following video, you can learn about the characteristics of TechnoNICOL # 45 butyl rubber sealant.

Sealant "TechnoNICOL": polyurethane two-component roofing version, product characteristics PU, 70 and 42 in a 600 ml package

- Type: Polyurethane

- Density: 1.3 kg / m³

- Seam mobility, no more: 25%

- Elongation to break: 250%

- Packing type: Tubes, 0.6 l.

Sealant TechnoNICOL PU (600 ml) is a one-component mixture of a viscous consistency based on polyurethane and is used for work outside the building.

Sealant TechnoNICOL PU 600 ml is a one-component mixture of a viscous consistency based on polyurethane and is used for work outside the building.

Sealant TechnoNICOL PU 600 ml is a one-component mixture of a viscous consistency based on polyurethane and is used for work outside the building.

To obtain the most up-to-date certificates, quality passports and other documents, send a request by filling out the document order form.

Our specialists will send you the necessary documents as soon as possible.

To process an order, you must select at least one of the required documents and fill in the required fields marked with *.

Our company strives to make the order of the required materials the most comfortable for its customers. All you need to do is send an application to our specialists by filling out the order form.

Our specialists will prepare for you a calculation of the quantity and cost of the material, and send it to the email address specified in the order form.

To process an order, you must fill in the required fields marked with *.

Our company "TK CentroStroy" has been on the market of building insulating materials for more than 15 years as an official partner and dealer of production companies "TechnoNIKOL", "PENOPLEKS", "BASF", etc. During this period we have developed close cooperation and relationship with professional teams of builders performing installation of both simple structures and the most modern building insulation systems.

To order a calculation of the cost of construction and installation work, you only need to send an application to our specialists by filling out the order form.

Our experts will calculate the amount of required materials and assess the implementation of construction and installation work.

To process an order, you must select at least one of the required documents and fill in the required fields marked with *.

Recommendations for use

In order for the sealed seams to be of the highest quality and durable, it is important to adhere to the following recommendations of specialists:

if the sealant is two-component, it is important to thoroughly stir both components;

before proceeding with the application of the composition, the surface must be carefully processed, dust, dirt, debris, greasy spots, crumbling finishing materials, and so on, must be removed from it. Thanks to this preparation, the adhesion (adhesion) of the sealant to the surface will be the best;

after cleaning, contact materials are degreased;

if the product will be applied in the cold, it must first be kept for 24 hours at room temperature;

It is most convenient to apply sealing substances with a special gun or a conventional metal or rubber spatula, while it is important to take care of personal protective equipment, such as gloves, goggles and a respirator;

it is not recommended to mix the sealant with a solvent, because of this, the sealing performance will deteriorate .. Before proceeding with the application of the sealing agent, first of all, carefully read the instructions on the package

Thanks to the strict observance of all the manufacturer's recommendations and the correct selection of the type of product, it is possible to qualitatively and reliably seal any seams, joints and cracks

Before proceeding with the application of the sealant, the first step is to carefully read the instructions on the package. Thanks to the strict observance of all the manufacturer's recommendations and the correct selection of the type of product, it is possible to qualitatively and reliably seal any seams, joints and cracks.

Peculiarities

TechnoNICOL sealants have a number of features and advantages.

- TechnoNICOL is one of the best manufacturers of waterproofing materials. The fact is that the company develops products together with practical builders. As a result, the products will not only be inferior in anything to their European counterparts, but even surpass some indicators.

- TechnoNICOL sealants have a unique composition that forms a waterproofing coating with high elasticity and resistance to environmental influences.

- They guarantee excellent adhesion to all kinds of materials and surface types, and have a sufficiently high setting speed.

- After drying, it is resistant to ultraviolet radiation, it does not crack.

- The waterproofing layer not only reliably protects against moisture and does not deteriorate under its influence, some types even become stronger.

- The product is also biologically stable: if the environment has high humidity, the sealant will not undergo organic destruction, and fungal mold will not start on it.

- The resulting elastic coating is very durable, will last 18-20 years, which significantly increases the life of various structures and structures without repairs.

- Sealants do not allow corrosion to develop in metal structures and fasteners, are neutral to solvents, and are resistant to the effects of oils and gasoline.

- Many species do not shrink, are resistant to temperature extremes.

- The types intended for the installation of building blocks in residential premises are non-toxic, do not emit harmful substances into the surrounding space and therefore do not harm health, are fire and explosion proof, and dry quickly.

- There is a fairly wide color variation of sealants, some types can be painted after hardening.

- TechnoNICOL sealants are economically consumed and have a reasonable price.

When working with them, the technology, material consumption rates should be observed. When choosing a material, you need to familiarize yourself with possible disadvantages, for example, intolerance to low temperatures or heating above 120 degrees. Therefore, before carrying out work, it is better to seek professional advice.

Bituminous-polymer

TechnoNICOL manufactures several bitumen-polymer sealants, which are used to seal joints and cracks in concrete surfaces and asphalt roads, and are also used to repair airfield pavements. Sealant "TechnoNICOL" 42 is a bitumen-polymer composition that has excellent elasticity, a minimum hardening period, it absolutely does not shrink. The company produces three types of sealants based on bitumen polymers, each designed for specific climatic conditions. TechnoNICOL produces the following formulations:

- BP G25;

- BP G35;

- BP G50.

The number in the name of each of these sealants indicates the lowest possible application temperature.

Colors

If we talk about the colors of the sealants produced by TechnoNICOL, they can be gray, white and black. So, a black composition is often used to seal cracks, gaps and joints between structures. Also, with the help of such a sealant, thermal insulation panels and air conditioning systems are glued together. The shelf life of the composition is about 15 years. The main disadvantage of this material is its dark color, due to which it cannot be used in all cases.

Gray and white sealants are popular today. Such formulations are the best option for use on any type of material. They do not shrink during solidification, have a high level of elasticity, are resistant to oil, and can also withstand aggressive environmental influences. Such sealants are made on the basis of thiokol, which is why they can be used in all weather conditions.

The main feature of the white sealant is the fact that after hardening it can be repainted in any desired shade, but the paint must be water-based.

Views

The manufacturer "TechnoNICOL" manufactures a wide range of sealing compounds, which have their own characteristics and various technical characteristics. Let's consider the main types of sealants.

Polyurethane-based composition

One-component polyurethane material is the most demanded. This is justified by the fact that it has excellent adhesion to any type of surface. For example, such a sealant adheres perfectly to wood, metal, concrete, brick, ceramics, plastic and other types of materials.Such a connection is of high quality, reliable, and also does not react to moisture and vibration. When exposed to moisture, this material acquires additional strength. It can be used at an air temperature of +5, but not higher than +30. No less effective and practical is a two-component composition based on polyurethane (2K).

When the composition hardens, it is able to withstand temperatures from -30 to +70 degrees. As for the use of such a sealant, it is necessary to clean and then dry the surface before starting work. It begins to harden after 2 hours, and complete hardening takes place with the calculation of a day per 3 mm of material layer.

Based on bituminous polymer

Such a tool is marked with number 4. This material is based on bitumen mixed with artificial rubber and mineral components. This two-component sealant is used to seal the seams of asphalt, concrete and airfield surfaces. It cures quickly. When dry, this sealant does not shrink, but remains elastic.

Bitumen-polymer composition of 3 types is produced:

- BP G25;

- BP G35;

- BP G50.

The first type is used in an environment where the air temperature cannot drop below -25 degrees. BP G35 is used in places where the temperature does not fall below -35, and BP G50 is used where the temperature indicator can drop below -42 degrees.

Based on mastic

Such a sealant is produced with the marking number 71. Typically, sealing mastic is used as a roofing material that can hold about 20 kg. They can repair the roof or glue the elements of the roof. It also has excellent adhesion to concrete and metal surfaces. Such a sealant does not allow water to pass through and is resistant to high temperatures, which allows it to be used as a membrane.

Silicone based

The silicone type of materials is used during construction work. It is recognized as a universal composition that is suitable for high-quality surface sealing, and therefore is relevant in a variety of areas. After application to the surface, it hardens quickly. When water gets on it or moisture is affected, the composition becomes even stronger and more elastic. It is a popular product that is sometimes used as an analogue of a rubber seal for various types of structures, for example, for PVC.

Consumption

Consumption of materials produced by TechnoNicol is very economical. It should be noted that this parameter depends, first of all, on the size of the seam that needs to be closed. For example, the minimum packing is enough to "close" a joint 6 mm wide and 3 mm deep. These gaps are common in bathrooms. The consumer will need about 25 ml of sealant to carry out all the necessary types of work.

There are also large packages, for example, the composition of PU 600 ml. Such packaging will last for a long time. With its help, you can correct many shortcomings, for example, oblique seams, semicircular gaps between the bathroom and the tiles, as well as any other problem areas.