Subtleties of application

Tools for applying Sheetrock putty:

- spatulas (width - 12.20-25 cm);

- Sheetrock Joint Tape

- sponge;

- sandpaper.

It is necessary to apply the topcoat on the prepared surface, which has been pretreated with a filler for leveling, plastered or sanded. The surface must be free from unevenness and cracks. It is necessary to apply the first layer of putty on completely dried plaster, otherwise, mold will form over time. A small amount of putty is collected on a wide spatula, then stretched in a uniform layer over the entire area of the wall or ceiling.

Next, you need to let the first layer dry. The next layer is applied only to the completely dried previous layer. To obtain an ideal surface condition, experts recommend sanding each layer of putty using an abrasive mesh with a grain size of 180-240 units. The maximum number of layers is 3-4. After all work, the treated area is cleaned of dirt and dust.

If necessary, you can dilute the composition with water, but you need to add it in portions of 50 ml, followed by stirring. A large amount of water will only worsen the adhesion of the solution to the surface, but the result obtained will not give the desired effect. It is forbidden to mix the putty mixture with other materials. Stir the frozen putty mixture to a homogeneous consistency without lumps and air bubbles.

To prevent the applied finishing material on the walls from freezing, it is recommended to cover it with a heat-insulating coating (foam). At the end of the finishing, the putty remaining in the container must be tightly closed with a lid. Store at room temperature.

Sealing with Sheetrock:

- close up the seams (trowel width - 12 cm);

- install the tape in the center, which must be pressed into the wall;

- the excess putty mixture must be removed, applied in a thin layer on the tape;

- screw head putty;

- after one hundred percent solidification of the first layer, you can proceed to the second. For this, a spatula 20 centimeters wide is used;

- give time to dry the second layer of putty;

- Apply a thin layer of finishing filler (trowel 25 cm wide). The same layer is applied to the screws;

- if necessary, smooth the seams with a sponge soaked in water.

Interior corner finishes:

- cover all sides of the tape material with putty;

- the tape is folded along the middle, pressed against the corner;

- get rid of excess mixture and apply a thin layer to the tape;

- give time to harden;

- applying a second layer to one side;

- drying;

- applying 3 layers to the second side;

- give time to dry.

Outside corner finishes:

- fixing a metal corner profile;

- application of three layers of putty with preliminary drying. The width of the second layer should be 10-15 cm larger than the previous one (the width of the spatula is 25 cm), the third layer should slightly go beyond the previous one.

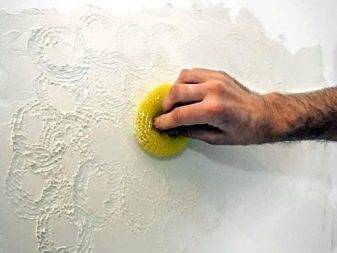

Texturing:

- apply Sheetrck filler to the required area with a paint brush;

- texturing technology using special tools (paint roller, sponge and paper);

- drying time is about 24 hours at air humidity 50% and temperature + 18 degrees.

Grinding putty:

- To carry out sanding work, you will need a sponge and sandpaper.

- A sponge moistened with water is wrapped in paper. This is necessary in order to generate less dust.

- Grinding is carried out with light movements along the resulting irregularities.

Starting putty - consumption per 1 m2.

For the initial leveling of the base, a starting putty is used. It is applied as an intermediate coating between plaster and finishing putty. At the same time, the starting putty contains a rather coarse fraction, since it is most often based on gypsum or lime. Therefore, its consumption will be the greatest. Starter putty is on sale in paper packages of 25 and 30 kg.

It has been proven by practice that one standard bag for 30 kg of any starting putty with minimal irregularities, and even under a paint net, is quite enough for 10-20 square meters. m walls.

But if the walls are in poor condition and not leveled, then the consumption of the putty mixture will increase. For example, if the interlayer of the starting putty is planned to be 5 mm, then its consumption will increase to approximately 4-8 kg per sq. m.

Features for the consumption of starting putty

An important point should be taken into account: it is not recommended to apply a starting putty composition thicker than 5-10 mm in one pass, otherwise it may crumble in the future. The description for any putty usually indicates the minimum and maximum permissible level of interlayer at a time.

For example, for "Polimin SHG-11" putty, the calculated thickness at a time is taken not less than 3 mm, but not more than 10 mm. Composition yield: 1.05 kg per "square" with an interlayer of 1 mm.

But the putty "SATYN PW-01" has a maximum allowable layer thickness of 8 mm, consumption per sq. M. m is 1.3 kg.

The instructions for the starting polymer-cement putty "Ceresit CT 29" indicate that the thickness of the application of one layer varies from 2 to 20 mm, and in fact, the consumption of this mixture per sq. M. meter goes by 1.8 kg at a millimeter layer

By the way, in the form of an initial leveling compound, you can also choose the popular Knauf HP Start starting mixture based on lime and gypsum. It is very convenient and is suitable both as a plaster and as a starting putty. The declared borders of the coating are 1-3 cm. With a mortar thickness of 10 mm, a 30-kg package of mixture is enough for 3.8-4.0 sq.m.

- Applying a layer of material to the wall

- Leveling the walls with putty

What is the finishing putty Shitrok APJC

Almost all types of finishing putties are made on a polymer basis with the addition of fine fillers, gypsum, resins and stabilizers, which makes most types of thin-layer finishing materials somewhat similar in characteristics and capabilities. But even in such conditions, the use of Shitrok putty makes it possible to bypass the closest competitors, for example, Vetonit and Multifinish, in terms of the quality of the surface obtained.

The main difference from competitors is that Shitrok, like a putty, is a highly specialized material that is good only in specific conditions of use:

- The thickness of the layer to be laid does not exceed 0.1-0.5 mm, although the manufacturer allows a maximum thickness of the working layer up to 2 mm;

- After applying the putty, the surface is not sanded or sanded;

- The finishing putty is not used to level the walls, the surface is covered with the thinnest possible layer, filling in the marks remaining from the preliminary finishing, micro-caverns and point defects.

Important! It is not recommended to prime the Shitrok putty laid on gypsum bases, this deteriorates the quality of the finish and, as the masters say, can erode the surface finish.

Finishing mass Shitrok in 99 cases out of 100 is used for finishing for painting walls. After drying, the finishing putty gives the effect of frosted glass - an even and uniform layer, translucent in thickness. After painting, it is almost impossible to understand how many layers have been laid on drywall or concrete surface. It is possible to apply two or three coats with polishing, but the total thickness of the finishing putty should not exceed 2 mm.

The secret of the composition of the Shitrok branded finishing material

Most craftsmen who professionally prepare walls with putties recognize the high plasticity of the Shitrok finishing mass, excellent adhesion and relatively small shrinkage of the material. The manufacturer's specialists give the following approximate composition of Shitrock APJC:

- Finely ground limestone or dolomite of fraction 20-40 microns, most often these are magnesium-calcium carbonates of natural origin;

- Ethylene vinyl or vinyl acetate copolymers;

- Atapulgite and pyrophyllite, providing a dry sliding effect, when the finishing putty, even with too much pressure of the spatula on the surface, easily glides on a dry substrate.

For your information! APJC Sheetrock putty is positioned as a completely ready-to-use product - open the package and you can finish the walls.

But this does not explain all the nuances of high ductility and strength. In fact, the composition of the putty should be much more complex and voluminous than American technologists tell us. As a minimum, the Shitrok finishing mass should include mixture stratification stabilizers, preservatives and thickeners.

Cellulose microfiber, which is quite expensive and difficult to manufacture, is used as an additive that can make the finishing putty more airy and viscous, like whipped butter cream. The fiber provides excellent ductility and strength to the Sheetrock layer even on glass surfaces. So that microcellulose does not cause the development of mold or mildew, liquid preservatives based on polyhydric alcohols are always added to the Shitrok putty production formulation.

The huge popularity of Shitrok putty and its high cost have caused numerous fakes, but handicraftsmen, as a rule, limit themselves to replacing microcellulose with ordinary carboxymethyl cellulose, so such finishing masses are stored much worse.

Advantages and disadvantages

Which is better, Shitrok putty or other mixtures? This tool has a huge number of advantages that distinguish it favorably from analogues:

- It is not necessary to mix the product, it is sold ready-made. After opening, you can immediately start working, which will save time and effort.

- The material is universal, it is suitable for leveling walls and finishing. You don't have to buy another finishing product.

- The product has a unique texture. Oily, smoothness, plasticity of the putty allows it to adhere perfectly to the spatula and the wall. This makes things a lot easier for a beginner. Ease of use is due to the ease of rubbing and filling the layer.

- Quite low consumption per 1m2 of putty makes it attractive for those who value calculation and are trying to save money without sacrificing quality. The savings are also due to a layer that is insignificant in thickness; there is no need for a thick coating.

- The material is sold in containers of different sizes, you can choose the one you need in each individual case.

- After drying, the surface will be very beautiful, even, pleasant to the touch, primer can be easily applied to it. The material does not shrink, the manufacturer guarantees at least 5 years with the absence of even small cracks.

- Shitrok will completely replace the primer. To do this, you just need to dilute it with water to a liquid consistency, then apply it as a standard primer. Shitrok is also compatible with any brands of other building and finishing materials.

- The shelf life of the package after opening is several months. If you close the lid tightly and put the material away from heat sources, it can be stored for a year. By the way, it can be frozen, for further use it is necessary to defrost it at room temperature.

Shitrok doesn't have many cons. After being applied to the wall, the shade of the material becomes not white, but light beige. This can adversely affect the color of the walls that are planned to be painted white.Also, the disadvantages include the need for careful preparation of the surface - it must be cleaned, degreased, leveled in the presence of rough irregularities and defects. If this is not done, the adhesion of the Sheetrock to the base will decrease.

Product range

There are three products in the Ready-Mixed category. Among them, users can find one that is useful in a given situation, depending on the purpose of use.

Danogips SuperFinish

Superfinish is a finishing material for finishing walls. Super Finish is a ready-made polymer mass with high adhesion quality, which is suitable for such surfaces:

- fiberglass;

- drywall;

- painted walls.

The product is not suitable for sealing large cracks and seams. Superfinish gives a perfectly even surface smoothness.

Danogips Fill & Finish Light

Fill Light putty is also used as a top coat. It is suitable for lamination of the base, for leveling out small defects. The composition contains latex, which gives the material special strength, scratch resistance, moisture resistance.

Danogips ProSpray

Danohypsum Pro spray is a multifunctional (universal) product that is suitable for any surface and any type of finish. They can make decorative surfaces, use them to seal seams and cracks, level the joints of brickwork.

Danogips SuperFinish SHEETROCK universal, ready-to-use putty 28kg

Preparation for work

To open the package, cut the security seal or remove the security ring. Open the lid and stir the filler to a homogeneous consistency before use. If necessary, the putty can be diluted with water: pour in water in small portions (no more than 50 ml / l), mix. Avoid thinning the filler too much, as this can lead to increased shrinkage and reduced adhesion.

Aligning surfaces

The air temperature in the room and the base must be above 13⁰C. The surface to be putty must be dry, free from dust, dirt and delamination. Significant differences (2-6mm) are recommended to be pre-leveled with Dano JET fillers. To equalize the absorbency of mineral substrates, it is recommended to treat it with DANO primer. When used on gypsum plasterboard, preliminary priming is not required.

Continuous filling of the surface

- Apply a layer of putty to the substrate and smooth with a trowel.

- Each subsequent layer of putty is applied after the previous layer has completely dried.

- It is recommended to sand the filler by hand using sandpaper no larger than P240.

- It is recommended to treat the resulting surface with DANO primer.

- After the primer layer has completely dried, you can proceed to the subsequent stages of finishing, such as painting, wallpapering, etc.

GKL seam finishing

Treatment of seams of gypsum boards with UK * and application of paper tapes (manual method):

- Put putty on the joint with a narrow spatula.

- We apply the tape and lightly, without pressure, fix the tape with a spatula. For best results, we recommend using SHEETROCK paper strips.

- We accelerate the putty under the tape from the middle to the edges. Thus, we glue the tape, remove the excess adhesive layer from under it and level the surface.

- We are waiting for the complete drying of the putty.

- Next, take a wider spatula and apply a layer over the tapes. This layer should be 5-10 cm wider than the previous one on each side.

- After the layer has completely dried, we can proceed to the continuous leveling of the surface into a plane.

* UK - thinned edge

External and internal corners processing:

- Prepare in advance a piece of a corner or tape of the required size. For a perfect result, we recommend using SHEETROCK professional corners.

- Apply an adhesive layer of putty to the base on both sides of the corner with a narrow spatula.

- We fix the corner or tape on the surface.

- We accelerate the putty under the tape from the middle to the edges.Thus, we glue the tape, remove the excess adhesive layer from under it and level the surface.

- We are waiting for the complete drying of the putty.

- Apply a layer over the corner or tape using a 25-30 cm wide spatula.

- After the layer has dried, we proceed to the continuous filling of the surface.

Storage

Store putty in tightly closed buckets in a dry place at room temperature. Protect the putty bucket from excessive heat and storage in direct sunlight.

The putty has a shelf life of 12 months from the production date (the production date is indicated on the bucket).

Range

Sheetrock putty, as we have already noted, is used for various purposes. Such as:

Sheetrock putty, as we have already noted, is used for various purposes. Such as:

- Leveling surfaces;

- Seam processing;

- Sealing cracks, deep scratches;

- Grouting of the formed joints;

- Finishing on walls, ceilings, plasterboard partitions, etc.

Today sheetrock is available in three different finishes. Each of the presented putties has its own unique properties, functions, consumption per 1m2 and purpose.

- Taping Joint Compound. Great for cracking, clings to any kind of gypsum board. With the thinness of the layer being created, it has excellent strength indicators.

- Toping Joint Compound. The shrinkage of these putties is minimal, it is used for re-treatment of surfaces. The only caveat is that it is not used for processing seams.

- All Purpose Compound. It is a versatile solution that additionally allows you to do manual texturing. Not recommended for use on surfaces that are regularly exposed to humid environments. In all other cases, it is an ideal putty for all kinds of purposes.

Work with all types of sheetrock putty is carried out in compliance with the general recommendations. Namely, the temperature inside the premises should not be lower than 13 degrees Celsius, and any of the applied layers of the mixture should be placed exclusively on dry surfaces.

Features and prices

It is worth visually studying the technical characteristics of the putty, its consumption per 1m2, and other criteria that play an important role in the choice of finishing material.

- The basis for creating sheetrock mixes is vinyl.

- The method of applying the putty is manual or mechanized.

- Consumption per 1m2 is 0.68 kilograms with a layer thickness of 1 millimeter. Accordingly, if the applied layer of putty is larger, then the consumption increases.

- The shelf life of the composition is 1 year with the condition of possible reuse without loss of initial properties.

- The density of the composition is 1.65 kg per 1 liter of the mixture.

- The price is about 500 rubles for a container of 5.6 kilograms. But it is more profitable to buy a sheet for 28 kilograms, since the price of such a capacity is about 900-1000 rubles. The cost depends on the city and the store where you buy the material. It will not be difficult to find the putty of this manufacturer, since the brand is in great demand, therefore it is available in almost all stores where finishing and building materials are served.

The experience of the finishing masters shows how important the quality of the finishing materials used is. An attempt to save on putty can sadly affect the result of the repair, its service life.

Therefore, we recommend immediately choosing Sheetrock level putties, which have proven their high quality and reliability.

Specifications

Sheetrock putty is arguably the best option for interior decoration. This building material has a lot of advantages that guarantee the quality of the final result. The technical characteristics of the putty make it a leading product in the construction market:

- finishing material dries from 3 to 5 hours;

- the mixture can be applied mechanically or manually;

- ready-made Shitrok putty has a special consistency that is suitable for processing any type of surface;

- the mixture perfectly removes defects, which makes it suitable even for painting;

- the product can be used at temperatures from 13 ° С;

- the goods are packed in containers of various sizes - from 3.5 to 17 liters.

Such characteristics are currently considered advanced, because each of them is thought out to the smallest detail in order to simplify the technology of using mixtures and their further operation.

Views

Facade

The facade must be flat. The putty is always applied to vertical enclosing structures that separate the room from the surrounding space.

Facade

This material is not susceptible to moisture, thanks to this, it can be used to process the future facade. The material should not collapse under strong influence of moisture

Therefore, it is important to purchase it in a package that says “for processing the facade”

Indoors

In this case, the consumption should not exceed a kilogram per m2. This building mixture is used for sealing seams, creating the most even surface on which wallpaper will be glued or a layer of paint will be applied in the future.

Vetonite

For the treatment of walls, Vetonit putty is widely used.

For more information about the finishing putty Vetonit, see the video:

With adhesive components

She processes wooden structures. Its consumption is about four hundred grams per 1m2 of the wall and half a kilogram per 1m2 of the ceiling.

Oil and glue

From calcium sulfate

It is very often used in European countries.

Calcium sulphate hydrate putty is used to create maximum even load-bearing structures. You need to purchase 1kg to handle a square meter.

Finish

It is used to create the most even surface. The consumption of the finishing putty will be 1.5 kg per 1 m2. It is allocated by fine-grained particles that perfectly evenly cover the surface, while it becomes as smooth as possible.

Finish

More than a thousand grams of material must be spent per m2 of the wall to be treated.

Prospectors

It is often used to finish seams and is also suitable for surface lamination or as a finishing layer.

Prospectors

The material in question is available in the form of a dry powder or a ready-made mixture. The consumption will be approximately one thousand grams per m2.

Sheetrock

Construction crews use it as a final layer, and it also creates the effect of a laminated surface. You need to spend a thousand grams per 1m2.

Sheetrock

Sheetrock is formulated with vinyl adhesives. Therefore, it is ideal for filling cracks.

Oil

Among all the varieties, oil putty is also distinguished, which is considered a universal tool for all types of work.

Oil

Its consumption is slightly higher: three kilograms per square meter

Sheetrock putty - features, pros and cons

Shitrok is a versatile tool, for example, it can prepare a wall well before painting, gluing wallpaper, suitable for working with concrete, brick, plasterboard. The coating of Sheetrock putty is distinguished by its plasticity. This product has received all its positive aspects thanks to its constituent components.

The unique composition allows you to easily apply the universal Sheetrock putty on a dry surface. There are also a number of additives that help to obtain additional properties. They even contrast Shitrok Knauf.

Shitrok finishing putty can also be used to eliminate irregularities on a brick wall with a plaster layer and on concrete. Suitable for filling joints between gypsum boards. They work with it in the corners, it is possible to work with metal products, decorative options for wall decoration are created, the implementation of the embossed technique.

The unique formulation makes Sheetrock easy to apply to dry surfaces.

The unique formulation makes Sheetrock easy to apply to dry surfaces.

The following advantages stand out:

- Ready-made Shitrok putty goes on sale, no need to waste time mixing the components;

- Versatility of application;

- The texture of the product makes it easy to apply to the surface, it is smooth and oily, which simplifies the process, and is convenient for beginners;

- Low consumption;

- Shitrok is released in buckets of different sizes, it will be easy to find the necessary one without purchasing an excess amount;

- The dried surface looks beautiful, and the application of the primer occurs evenly, while the material does not shrink;

- Can be used as a primer. Then dilution with water to a liquid state is required;

- Long service life even after opening the container, if the container is tightly closed. You can freeze the product, after defrosting is carried out at room temperature.

Of the shortcomings, it can be noted that the color is not white, the wall becomes light beige. Requires thorough preparation of the substrate before application.

The texture of the product makes it easy to apply to the surface.

The texture of the product makes it easy to apply to the surface.

Specifications

The description of the property of the tool will help you understand why it is so in demand. Finishing putty Sheetrock has the following technical characteristics:

- The drying process takes 3-5 hours;

- Possibility of manual and mechanical application;

- The ability to carry out work at temperatures from +13 degrees;

- The density index is 1.65 kg / l.

The drying process takes 3-5 hours.

The drying process takes 3-5 hours.

What connects Shitrok and Danogips

The Danogips brand is a German company that is known to everyone in its country, it produces high-quality building materials. It is not so well-known on the domestic market, there are more products under the name Shitrok.

Shitrok putty differs from Danogips products only in its external design. This is a modern version of the packaging of the company's products.

Shitrok putty differs from Danogips products only in its external design.

Shitrok putty differs from Danogips products only in its external design.

Finishing stage of finishing

After applying the finishing layer, you must wait until all the applied putty layers are dry. Then you need to smooth out the "bumps" with a spatula so that the surface becomes even. The rest of the mortar is applied to the seams and fasteners. At this stage, a small addition of water to the mixture is allowed. The applied layers must be well leveled. This will shorten the surface treatment time with a sanding float. It is also worth "walking" with putty on all noticeable defects.

Ready putty mixtures are an ideal option for preparing gypsum plasterboards for further painting. When applying glossy paints, all irregularities and depressions can be visible on the wall. The use of Sheetrock finishing putty eliminates the possibility of such situations.

Precautionary measures

It is necessary to remember about the safety rules that must be observed during construction work with Sheetrock material:

- If the putty solution gets into your eyes, you must immediately rinse them with clean water;

- when performing dry sanding of the material, it is recommended to use protective equipment for the respiratory tract and eyes. Finish with gloves;

- it is strictly forbidden to take the putty mixture inside;

- keep away from small children.

If the use of putty occurs for the first time, then it is better to give preference to branded manufacturers with positive reviews. Sheetrock putty has only proven itself on the good side. According to the description of the technical characteristics and the technique of applying the material, it can be seen that the finishing work is not particularly difficult.

For an overview of Sheetrock Finishing Putty, see below.