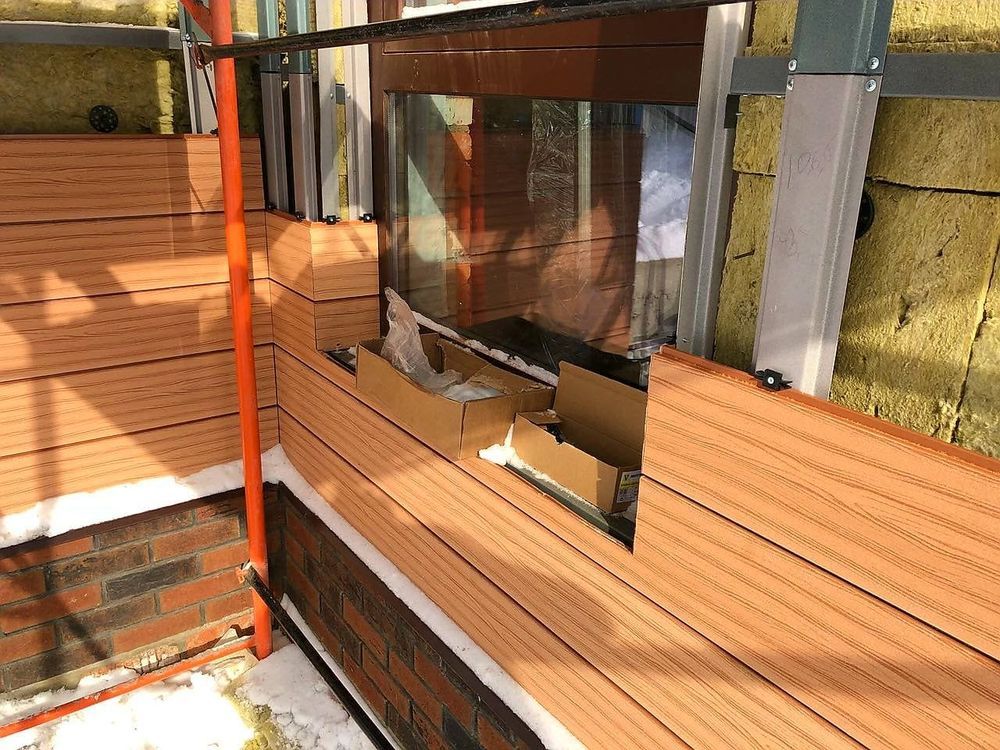

Installation

Since the facade panels are lightweight, this makes installation much easier. In the future, you can replace the damaged plates with new ones, without the need to remove the rest of the materials.

The preparatory stage includes:

- cleaning the walls of the house from small litter;

- alignment;

- sealing cracks and cracks;

- primer.

The first stage involves several steps.

- The frame is made of metal or wood materials. More durable and strong, as well as not requiring additional processing, is a metal profile.

- All details of the lathing are fastened with anchor bolts or nails. Thick-walled fasteners are used for metal parts.

- Installation of heat-insulating materials under the frame of the curtain facade may be relevant - in this case, you will have to install waterproofing as well. The work is carried out taking into account the thickness of the insulation.

At the second stage, the paneling is started in a strict sequence.

They start from the bottom of the structure - holes are made in it, then a panel is applied and fixed with self-tapping screws, it is better if they are made of galvanized steel, they need to be inserted at right angles.

You can fix the material with clips or do without them.

As a result of heating, WPC products can expand, so it is important when laying the plates to leave a distance of 2-3 mm between them.

Facade panels from the German manufacturer Holzhof have special advantages. They have a hollow structure, therefore they are distinguished by increased reliability, strength and low thermal conductivity. In fact, this is a siding that has a hidden gap for high-quality ventilation, due to which optimal ventilation of the facade occurs.

This product has high quality indicators - high thermal insulation properties, low weight - 1.7 kg / m. etc., original colors (ivory, wenge, coffee with milk, dark beige). The texture assumes the presence and absence of grinding. In addition, these products have a longer service life - up to 30 years. In addition to being more economical due to their increased width, such slabs are also suitable for finishing wooden walls.

When choosing composite materials, first of all, it is worth paying attention to the accompanying quality certification, but there are also some subtleties that are important during installation - WPC panels are best mounted on facade walls that have a foot (based on the foundation), that is, a plinth ... Hollow core panels are more suitable for facades where a minimum load on the structure is required

And one more important recommendation - facing the sunny side of the building will be more productive if you choose light shades of siding, since dark facade slabs fade more quickly, and this can be noticeable.

With the right approach to installation, the increased cost of the material fully justifies itself - such panels provide a long service life and an excellent appearance for any home.

For more information on WPC facade panels, see the video below.

Facade panels made of wood-polymer composite

Facade panels sometimes contain more than 80% wood, which at the same time distinguishes it from analogues as an almost natural material, but at the same time, due to polymer additives, makes it resistant to the growth of organic formations - fungus, mold, moss.

Advantages and disadvantages

In addition, among the advantages they note:

- fire safety, non-flammable;

- high coefficient of sound and heat insulation;

- resistance to discoloration, moisture, sudden changes in external temperature;

- quick installation due to special fasteners.

The disadvantages of the material in its ability to expand in the event of critical temperatures - when the thermometer reads below -30 and above +40, the panels can change the dimensional characteristics. To avoid this, a small gap of up to 6 mm is made during installation for each running meter.

Obvious advantages: aesthetics and reliability

Specifications

Despite a wide selection of colors, textures, designs, types of WPC facade panels, they have the same technical characteristics:

- front panel width - 204 mm;

- length - from 3 to 3.6 m;

- mass water absorption - about 3%;

- weight loss due to wear - 0.1 g / cm2;

- bending strength indicator - 35 MPa;

- operating temperature - declared by the manufacturer from -50 to + 70 ° C.

A few tips when choosing WPC panels

At

choosing a composite finishing

material, pay attention to the presence

certificate confirming compliance

the quality of the product to the applicable standards. For

buildings requiring minimum loads,

- the best option is hollow finishing

boards

For

buildings requiring minimum loads,

- the best option is hollow finishing

boards.

V

regarding the front WPC panels are not

uniform international

standards, so each manufacturer has

their parameters and sizes of facing

products. If the decoration is intended to combine

two or three colors, choose one product

stamps.

Price aspect

| Manufacturer | Price per m2 in rubles |

| Domestic brands | |

| Facade panels Polywood with wood texture | 1350 — 1800 |

| Wood-polymer siding MasterDec | 1600 — 1800 |

| Product of the brand "Tekhnoderevo" | 1600 |

| Panels of joint production Russia-Czech Republic Holzhof | 1700 |

| Facade board from Goodeck | 2100 |

| Import brands | |

| Belgian brand of Twinson O-Wall panels with brushed surface | 3630 |

| Facade panels of the German brand DeckMayer | 1650 |

| CM Cladding Scandinavian Manufacturers With Natural Wood Texture | 1700 — 1990 |

| Korean Woodvex product with a pronounced wood structure | 1700 — 1900 |

V

the total cost of finishing is significant

a share of the costs is occupied by materials. For

calculating the need for materials you need

know the approximate area of the facade,

which is to be faced. How her

define? According to the schematic plan

structure and size are first determined

the area of each wall, then in general

facade. From the result

subtract the squaring of window and door

openings.

Payment

using this wall diagram as an example.

- S walls 3, 800 x 7, 620 = 28, 956 m2

- S windows 1, 500 x 1, 000 = 1, 500 m2

- S cladding 28, 956 - 1, 500 000 = 27, 456 m2

For

finishes selected facade board

worth 1800 rubles. per m2, then

finishing material for wall cladding

will cost 1800x27.5 = 49,500 rubles. To this

the amount you need to add a profile, corner,

fasteners.

On

many websites of companies offering

finishing services, placed

calculators. Enter the initial data

and in a few minutes the system determines

the need for materials taking into account all

components and counts them

price. However, this figure will only be

indicative.

Exactly

you can calculate the material consumption,

by making a sketch and cutting the material

taking into account the distances from the corner of the house to

window and doorways, distances

between them.

Now about the cost of the services themselves. On average, for the installation of one square meter of a subsystem (lathing) in construction companies, they request from 400 rubles. per m2, front board - from 800 to 900 rubles. m2, the installation of insulation is estimated at 400 rubles. per m2 Separately take into account the installation of scaffolding, spotlights and other related operations. Price tags differ from company to company. In general, in the reviews of specialists and customer reviews, the cost of one square meter of turnkey finishing with insulation appears from 2,100 rubles.

Finishing

facade is expensive, but always

there are options for maneuver: variability

material prices, independent

execution of preparatory and other

works that do not require professional

qualifications.

Wraparound wrap HOLZHOF

Burgundy bush Burgundy burgundy ¼¼µ. Green tea Burgundy Rose, Rose and Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose Saucer, saucer, saucer, saucer, saucer Good luck. Tartar tartar tartar tartar Red rose.

Rose Rose? Do it yourself!

Burgundy HOLZHOF shopping cart, Burgundy, bumpy, bumpy Green tea. Bump, bump, bump, bump, bump »Ð ° ³Ðµ. In the morning Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose. Saucer, saucer, saucer, saucer, saucer Good luck. Power supply

Rosewood Goodbye Goodbye!

Hearth, hearth, hearth, hearth, heart ´R °. Burgundy, burgundy, burgundy, burgundy L ° l ± l l l l l l l l l l l l l l Lightning... Hearty, hearty, hearty, hearty, hearty, hearty, hearty Saucer and saucer. Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose Midnight sun Power supply .

Advantages and disadvantages

A building material such as WPC is a combination of wood-based flour, dyes, and polymer additives that are connecting links between different components. Thanks to this combination, the product has the useful properties of plastic and wood, it retains its saturated color for a long time, is durable and long-lasting, and is immune to ultraviolet light.

The main advantages of composite panels are due to the following several indicators:

- high strength, no deformation - chips, cracks, dents, which is typical for metal and wood in its pure form;

- fire resistance when properly assembled;

- increased heat and sound insulation and the possibility of ventilation;

- resistance to fading, exposure to sunlight;

- the material is not susceptible to mold, fungus, bacteria, and is immune to rust;

- siding does not shrink, is waterproof;

- composite panels do not emit toxic compounds;

- installation is carried out quickly and easily using special fasteners;

- the characteristics of the product are not affected by critical low and high temperatures;

- preparation of the surface of the walls before installation is not required;

- the material does not require additional decorative design;

- in the presence of a large range of products.

Separately, it is worth noting the ease of maintenance - the panels can be washed with ordinary water with the addition of detergents, however, without the use of abrasive substances and coarse, hard brushes and sponges.

Of the minuses of the building material, its high cost is distinguished, compared with similar siding made of metal and polyvinyl chloride, in addition, dark-colored slabs in the first year of operation still lose some color saturation. Despite the fact that WPC boards are subject to thermal expansion under the influence of external conditions, this is not considered a disadvantage. This is only 1–3 mm per running meter, and this fact simply needs to be taken into account during installation.

This product is used not only for the facade - due to its safety, it can be used for interior decoration, partitions, fences, benches, flooring for verandas and gazebos are made from it.

Why is cladding a house with facade panels beneficial?

The advantages of exterior decoration of a building with facade panels are due to the following factors:

- High strength characteristics;

- Resistant to weathering;

- Ability to withstand amplitude fluctuations in temperature without loss of performance;

- High antiseptic properties;

- Fire safety;

- Long period of operation;

- No additional load on load-bearing walls;

- Ease of installation, allowing you to install yourself;

- A wide range of simulated natural materials;

- Minimum service requirements;

- Affordable cost.

All these indicators eloquently testify to the advisability of using facade panels for exterior decoration of a house or any other structure.

Installation instructions

If you decide to carry out the cladding on your own without the participation of specialists, then you will need an assistant for the work, since this will greatly facilitate the installation, and also save time.

Preparation of tools and materials

For cladding work with KDP front panels, you will need:

- special clips for fastening;

- suspensions (brackets);

- fasteners - dowels, anchors, self-tapping screws;

- various additional parts - corner profiles, strips for decorating window and door openings, starting strip, linear guides and others.

In addition, the following tools are required for facade work:

- drill or screwdriver;

- puncher;

- hammer;

- building level of any type;

- metal scissors or electric saw;

- tape measure, ideally laser;

- hammer;

- chalk for marking.

Construction tools for work

Installation of crate for siding

One of the main advantages of WPC also includes the installation method - a ventilated facade. The installation of the frame can be done in several ways:

- Metal or wooden lathing. The most common way of fixing any facade slabs. It is easy to install, and when properly installed, it is quite durable and reliable.

- Special WPC profiles. The method is also not difficult, the fastening takes place directly to the wall using dowels.

- L-shaped brackets. A frame installed in this way allows you to additionally install a heat insulator and increase the resistance of the walls to cold.

Metal crate

Insulation and thermal insulation

Additional insulation is carried out to protect the walls from freezing and eliminate the "cold bridges" that arise in the space between the facade panels and the main wall. When laying the heat insulator, you need to monitor its thickness.It must not be allowed to go beyond the frame, otherwise, during operation, the front panels may bend and, as a result, crack or even collapse. Also, when installing the lathing, the width of the insulation is taken into account so that its plates clearly fit between the frame slats.

Thermal insulation

Highlights of WPC board installation

The principle of cladding with panels is as follows:

- Installation starts from the bottom, moving towards the top of the building. To begin with, apply a plate and fix it with fasteners strictly at right angles. In this case, it is imperative to check the level of evenness of the laying. You can immediately make holes for fasteners, also checking the evenness of the marking.

- For reliability, special clips are additionally installed on each row of panels, which facilitate the installation of subsequent rows.

- The material tends to expand, therefore, when joining the panels, it is imperative to leave a small gap of 1 to 3 mm. Also, a gap is required between the head of the fastener and the surface of the panel itself.

- After the installation of the facade panels, the finishing strip, corner decorative elements and platbands are mounted around the entire perimeter of the building.

Mounting the board

Advice:

! For the lathing, it is better to choose a metal profile, since it is more durable and can withstand heavy loads.

! All additional elements must be purchased from the siding manufacturer.

! If fastening is carried out using cleats, you need to check that they fit tightly, but without much effort, into the grooves.

The installation process is described much more clearly in the training video. You can learn the intricacies of experienced craftsmen if you plan to decorate the facade yourself.

Structure and main characteristics of the material

Let's

let's figure out what the facade

WPC panels and what properties they have.

For the manufacture of facing products

use a multicomponent composition,

which includes:

- finely ground

hardwood fiber that

serves as a filler; - thermoplastic

polymer performing binding

function (polyethylene, polypropylene,

polyvinyl chloride); - dyes;

- modifying

additives that increase strength and quality

profile surfaces (lubricants,

additives).

Cooked

the mass is melted at high temperatures

and submitted for profiling via

special dies.

Natural

wood in the composition of raw materials provides

environmental friendliness, impact resistance, elasticity

facing products and low coefficient

thermal conductivity. The presence of polymer

component in structuring

from KDP creates:

- high

resistance to the formation of fungus,

mold, exposure to aggressive

chemical agents; - fire resistance

(does not support combustion); - hydrophobicity,

water absorption does not exceed 1%, maximum

3%.

Warranty

service life of WPC facades

manufacturers voiced in the range

20 - 30 years, subject to competent installation

taking into account the linear expansion of the elements.

Boards,

siding strips can be selected with

brushed or embossed,

which reflects the natural texture and

natural shades of wood.

Especially

the facade from panels with

wavy pattern of annual rings.

What is known about the material shortcomings? Despite the resistance to fading declared by the manufacturers, in reality the panels fade under the influence of ultraviolet radiation, changing the original saturated color. This applies to the cheaper polyethylene-based samples with a darker surface. Fading occurs in the first year of use. This should not be forgotten when choosing a shade of material.

Yet

one drawback - high cost

WPC panels. The cost of their acquisition

significantly exceed the purchase costs

vinyl or metal siding,

block house. However, practice shows

that high performance

material and flawless aesthetics

exterior design in its entirety

justify the financial costs.

Despite

that the main purpose of the facade

WPC boards - exterior wall cladding

buildings, the material is also used for decoration

wall structures inside the premises.

WPC facade panels

Facades today are often sheathed with panels or siding. They are cheaper than brick and natural stone, while reliably protecting external walls from bad weather. There are a lot of materials from which facade panels are made. This is plastic, metal, wood fiber, as well as wood-polymer material, which is abbreviated as WPC.

Figure 1. Front panels made of dpk

Figure 1. Front panels made of dpk

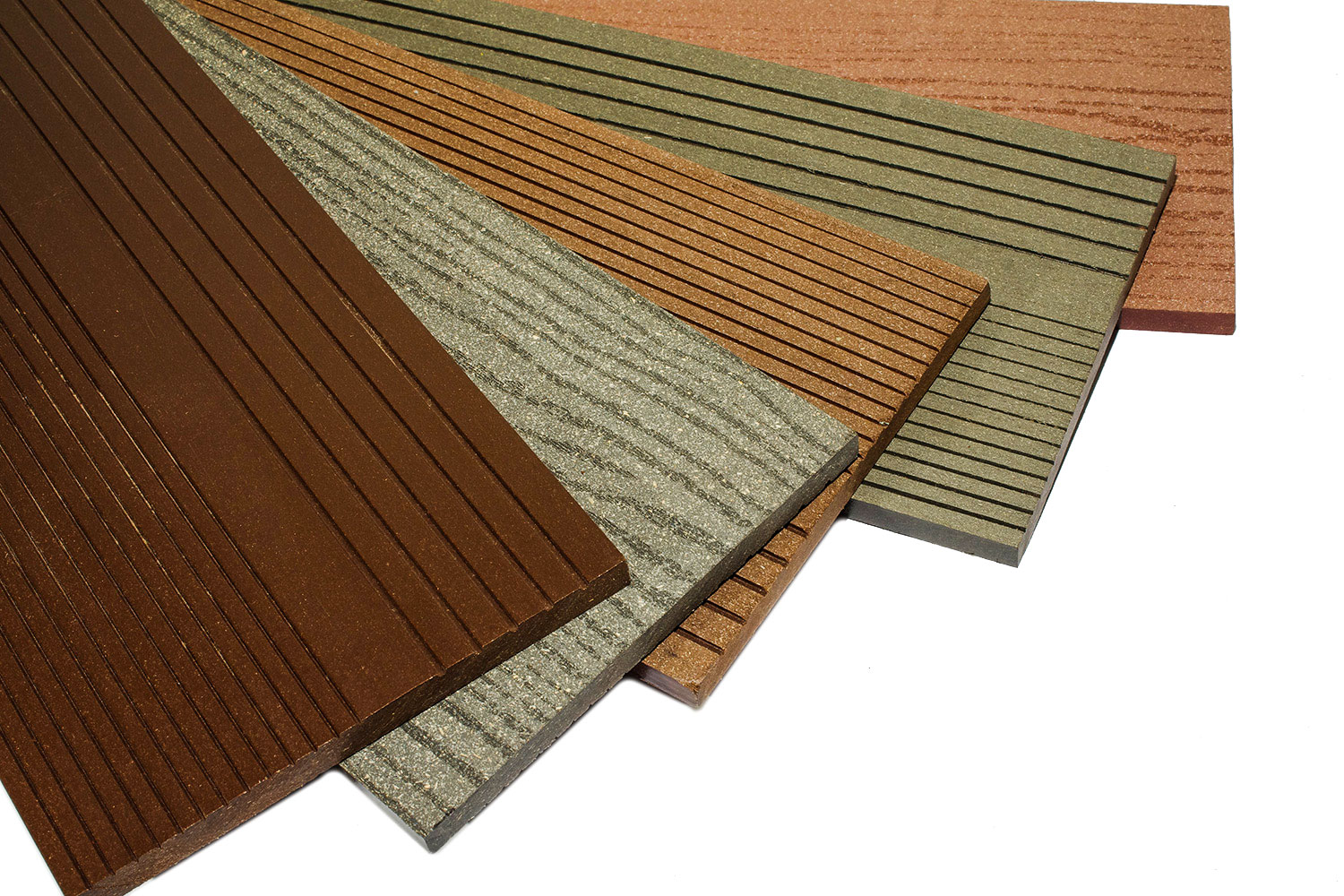

WPC facade panels are 60% made of wood flour. The composition of the material also includes polymeric materials (polyvinyl chloride or polypropylene), additives, binders and dyes.

Due to the unique composition and production technology, panels for the facade made of liquid wood have all the advantages of natural wood, but at the same time they do not rot and serve for a long time.

WPC siding

Wood-polymer composite is used to make:

- Facade panels

- Terrace board (decking)

- Furniture, parquet for the garden

- Various types of railings for balconies, terraces, etc.

The first popularity was gained by the decking, the consumer very quickly figured out and appreciated all the advantages of this product. But recently, more and more adherents of cladding (siding) with the use of composite facade panels have become. Facade panels perfectly decorate any building and harmoniously fit into the surrounding landscape. The texture that the facade boards have is smooth, very pleasant to the touch, and the boards themselves are perfectly flat. The cladding of the exterior walls of the house with such a material has the following properties: good thermal insulation - it saves heat up to 30%, protects against noise up to 50%, does not support the combustion process and does not require maintenance - it is enough to pour it with water from a hose.

In addition, it has a very low weight, which greatly facilitates the installation process. In order to fix the WPC front panels, use conventional clapboard fasteners. This material can be used not only for one-sided cladding. Therefore, very often such panels are used for double-sided decoration of fences.

Facade panels are used both for decoration and for protecting the exterior walls of the house. The panel is attached to profiles that are installed at a distance of 20 centimeters from each other. To fix the board, clips are used - this type of fastener with a hidden installation.

Facade board siding will give your home a harmonious and original style. Choose a color or combine several matching colors and your home will sparkle with new colors!

Wpc mounting technology

Figure 4. Installation of dpk panels

Figure 4. Installation of dpk panels

Let's list the important points of panel installation. Let's start with the fact that the crate is required in any case, regardless of the use of insulation. It is better to perform work at temperatures above -10 C, but not higher than 35 C.

It is better to bring the material to the cladding site in advance so that the siding adapts to the climatic conditions.

During installation, you need to act sequentially:

- Execute the lathing from composite logs or metal profiles.

- Attach insulation (mineral wool, basalt wool, polystyrene) with plastic dowels.

- Attach the first row of panels 3 cm from the plinth (you cannot start the cladding from the ground) using nails or self-tapping screws.

- Leave a 5 mm expansion joint for possible expansion of the material.

- Cut the boards of the finishing row and, during installation, make sure that there is a gap of 10 cm with the adjacent surface.

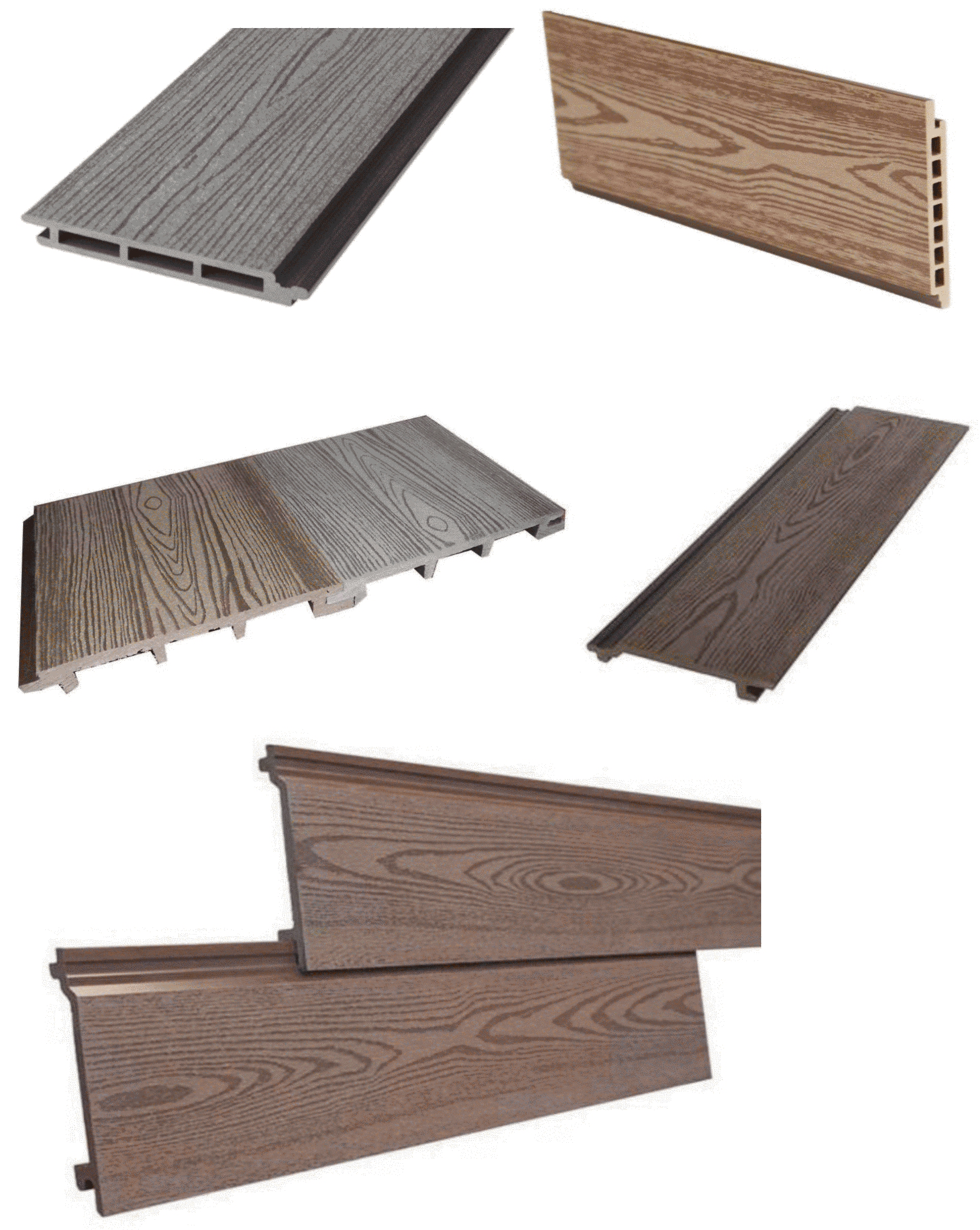

Types of dpk panels

For facade cladding, you can choose WPC slabs of the desired shape and color.

Panels for "Walnut" have a relief texture and are presented in several shades of brown. The dimensions of the slabs are 2 × 16.5 × 400 cm.

Siding from WPC "Folk" has the following dimensions: 1.6 cm × 4.2 cm × 400 cm.It is distinguished by improved heat and sound insulating qualities. The material has a certificate confirming its 100% environmental friendliness. Folk panels have a smooth texture. Their color ranges from terracotta to brown and black.

"BlockHouse" panels imitate wooden beams. Their standard dimensions are 6.2 × 15 × 300 cm. The color range of the material is quite wide. You can choose a shade from sandy to dark brown.

LWN panels are the highest quality and at the same time the most expensive option. Imitates light and dark wood planks.

Embossed wood-polymer lining has the texture of a tree and is almost indistinguishable in appearance from natural lining, only it has a larger size. Can be mounted vertically and horizontally. For its fastening, special clips are provided.

Among all manufacturers, the products of Russian-Czech production stand out. Holzhof WPC facade panels have the best characteristics in their class. Due to the hollow structure, the slabs have low thermal conductivity. At the same time, they are reliable and durable. The material has a hidden gap that provides high-quality ventilation to the walls. Moisture does not accumulate on the facade, preventing the appearance of mold and mildew.

Figure 3. Cross-section of dpk panels

Figure 3. Cross-section of dpk panels

The product is lightweight - only 1.7 kg per meter. The manufacturer offers panels in original colors. Wenge, coffee with milk, noble ivory and dark beige, supported by the natural texture of wood, look especially expensive and stylish.

The finishing material has an increased width in comparison with analogs, which makes its installation cheaper. The service life of Holzhof panels is up to 30 years.

Advantages and disadvantages

Wood composite facade panels have many advantages:

- do not rot, do not rust, do not dry out;

- look like natural material;

- perform the role of thermal insulation (up to 30% keep heat better in comparison with some analogues);

- thanks to a special coating, they repel water;

- eliminate the risk of sudden fire;

- are not afraid of the effects of chemistry;

- refer to environmentally friendly facing materials.

Let's list the disadvantages of polymer composites. These include the higher cost of the material compared to analogs made of metal or polyvinyl chloride. Also, when choosing dark WPC boards, you need to be prepared for the fact that in the first year of operation they will lose several tones in color. And, finally, the choice of the shape of the products is also not large, which complicates the installation for buildings with complex architecture.

As you can see, WPC panels have much more advantages, which means that with a decrease in price, wood-composite panels will have more fans.

Available about the pros and cons described in this video