Applications

Galvanized brushed nails, as already mentioned, are in demand by carpenters, builders and repairmen. They are much better suited for rigid structures such as:

- prefabricated pallets;

- scaffolding and flooring on construction sites;

- rough and front floors;

- assemblies from a wooden base and a perforated metal part;

- roof lathing.

They are also required when performing the following tasks:

- preparation of packaging;

- decoration of walls and ceilings;

- installation of slopes at windows and boxes at doors.

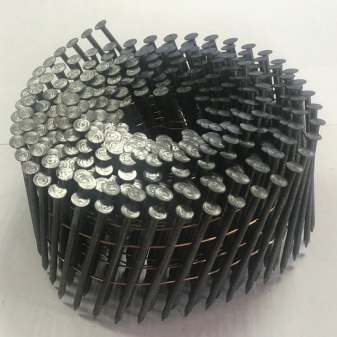

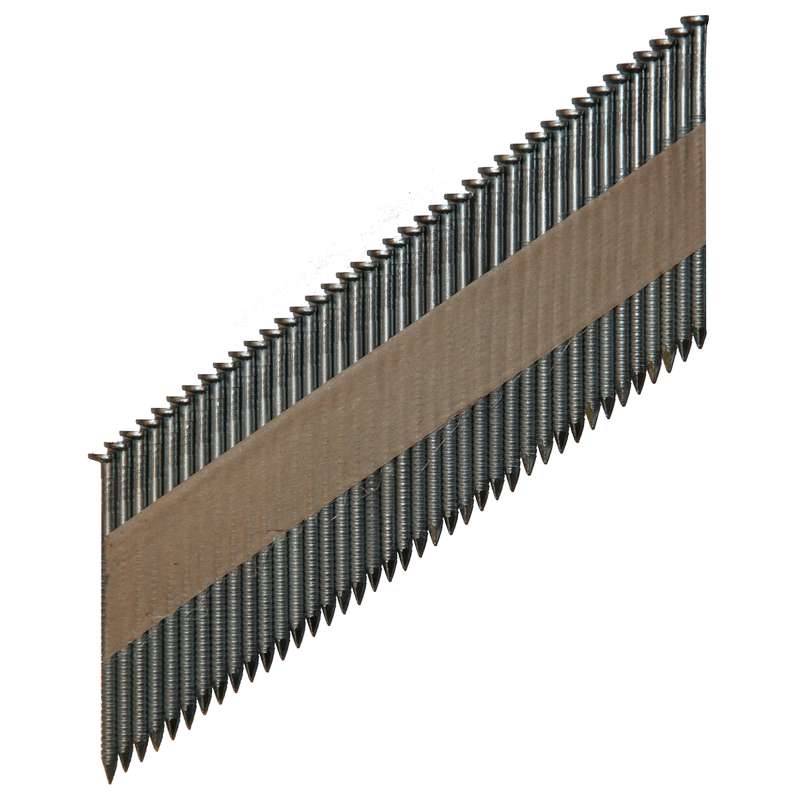

Nails for a nailer differ in the area of application - and this is expressed primarily in different lengths. Frame hardware can be up to 9 cm in length. For cladding hardware, this figure is up to 6 cm. And fasteners with large caps go to the roof. For a pneumatic pistol of a drum type, drum nails are intended; these hardware are held together by wire or plastic sheath.

The need to use brushed nails when assembling wooden containers is understandable. It will inevitably at some stage be thrown, pushed by loaders - if only because they have to do the job quickly. And only reliable fasteners help out in such a situation. Where a sharp nail is driven in, the total strength of the joint will be 5 times higher than with standard fasteners.

In the next video, we will look at one of the options for using a roughened nail for attaching perforated fasteners.

Peculiarities

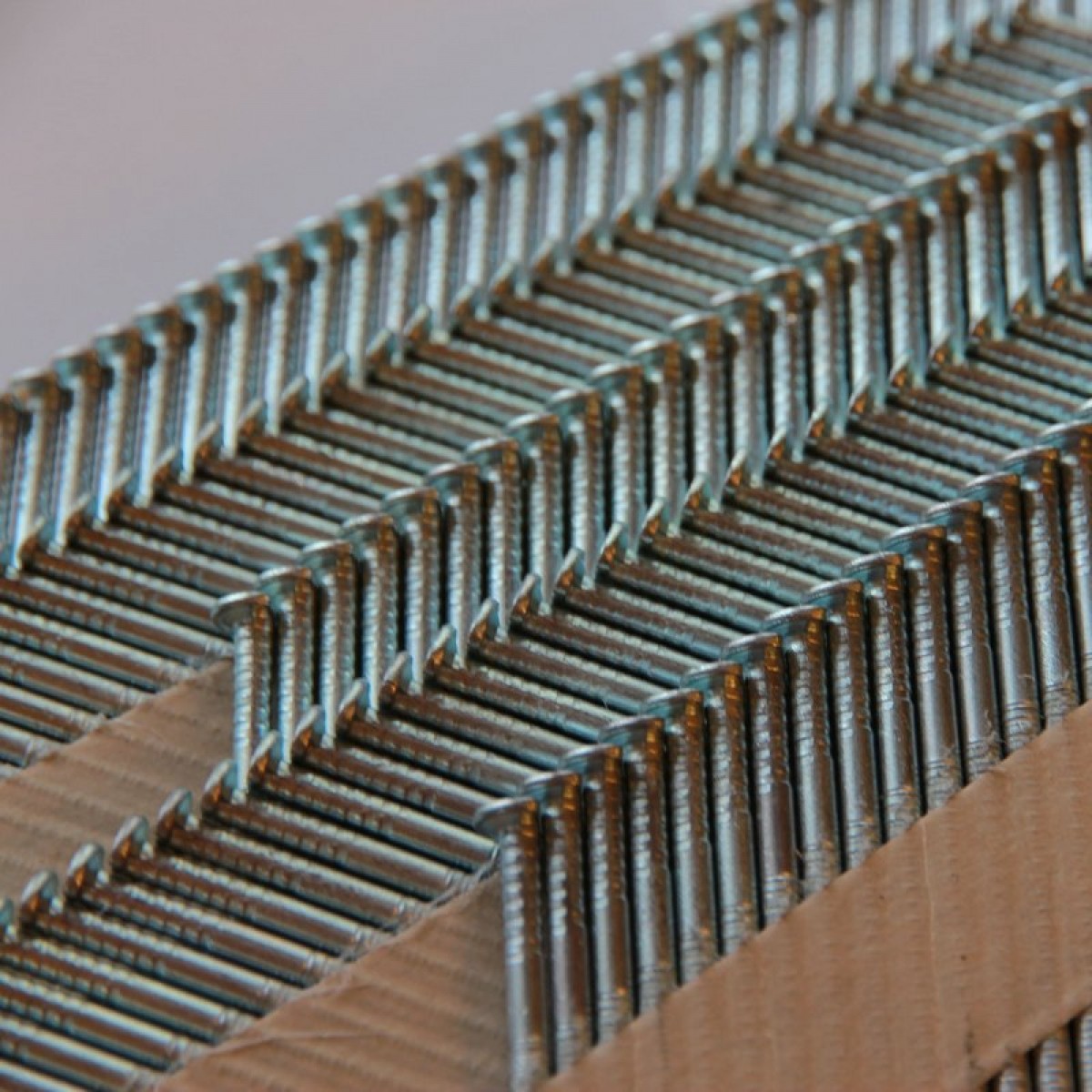

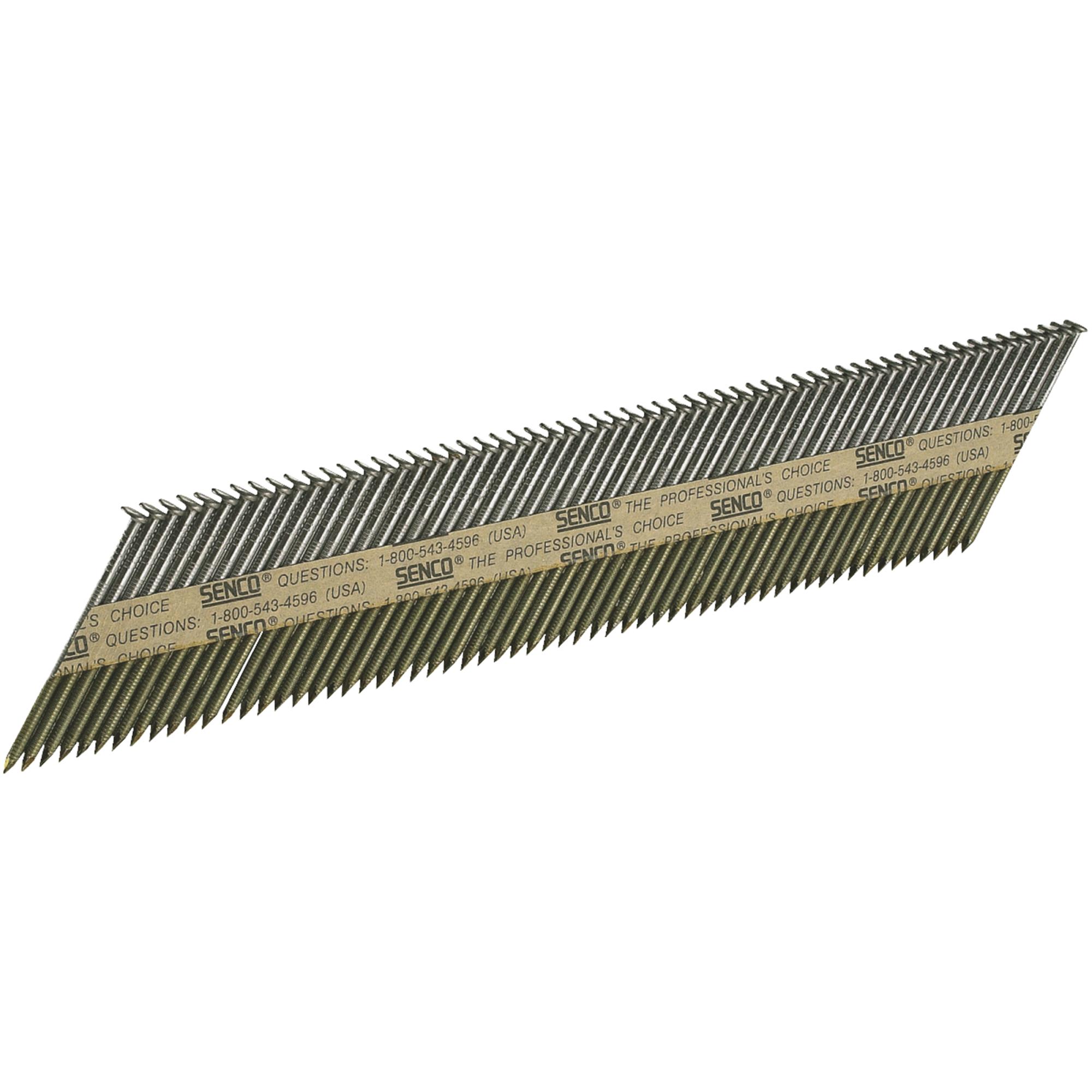

Ruffled nails are usually called a special category of hardware. Along their core is a specially made transverse notch. This component of the nail helps it provide a fairly reliable bond even in loose and unstable materials. Since hardware is coated with a zinc layer in production, it turns out to be quite reliable. The low cone-shaped head helps to further improve the efficiency of the connection.

Even the combined effects of shock, vibration and shrinkage are perfectly tolerated by a ruffled nail. Ordinary hardware, for comparison, even under the influence of one of these factors, can lose its supporting qualities. Ring-shaped "ruffs", entering the tree, repel the fibers. The force of inertia makes them tend to return to their original position.

The aforementioned cone-shaped head sinks into the wood without any problems. After that, pulling out the nail becomes much more difficult. Attempts to pull it out will result in a breakage of the cap or the hardware itself. Summing up, it is worth noting that such products:

- stable and reliable;

- operated for a long time;

- resistant to corrosive effects.

Dimensions (edit)

The sufficient variety of areas of use of such fasteners forces manufacturers to offer a variety of sizes. The marking must indicate the length of a particular nail and the cross-section of the rod. It should be borne in mind that the latter indicator is 10-16% inferior to the thread diameter. The best way to present the main parameters will help this table:

|

Overall dimensions |

Pieces per 100 g |

Weight 100 pcs, kg |

|

3.4x40 |

41,7 |

0,2341 |

|

3.4x50 |

33,9 |

0,2739 |

|

3.4x60 |

28,5 |

0,3662 |

|

3.4x70 |

24,6 |

0.4278 |

|

3.4x80 |

21,7 |

0,4893 |

|

3.4x90 |

19,3 |

0,5508 |

|

3.8x100 |

12,9 |

1,1203 |

With a size of 3.9 by 90 mm, 100 grams will weigh 14.3 such nails, 100 of them will "pull" 1.007 kg

Important: galvanized products will be heavier just due to the insulating anticorrosive layer. Basic technical parameters are controlled according to GOST 283-75

It provides information about the required precision for parameters and custom properties. Although the standard was adopted back in 1975, it remains relevant.

The regulation prescribes the use of wires made from low carbon steel. Additional heat treatment is not recommended. The finished wire is square.

The nails are checked on random samples from each batch. A party is recognized as fit, in the sample of which violations are found no more than 0.5%. Most often they try to focus on the following properties:

- misalignment with respect to the bar - by diameter;

- the range of cross-section and length values - according to the standards of GOST 3282-74;

- violation of the roundness of the cap - in accordance with the diameter (for example, if the cross-section of the nail is 3 mm, the deviation from the perfectly round shape of the cap can be no more than 0.4 mm);

- obligatory smoothness of the head part;

- taper angles (on the edges of the tip) - maximum 40 degrees;

- deflection corresponding to the length of the nail rod.

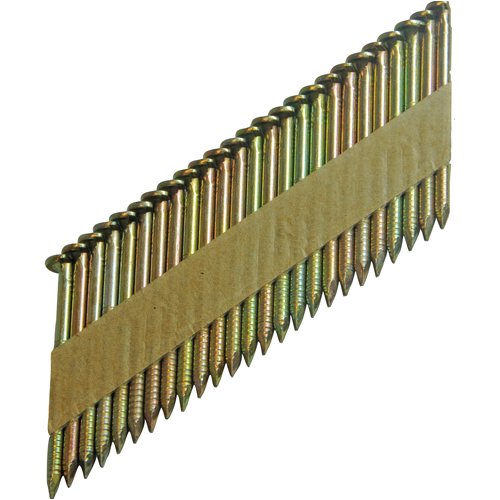

Views

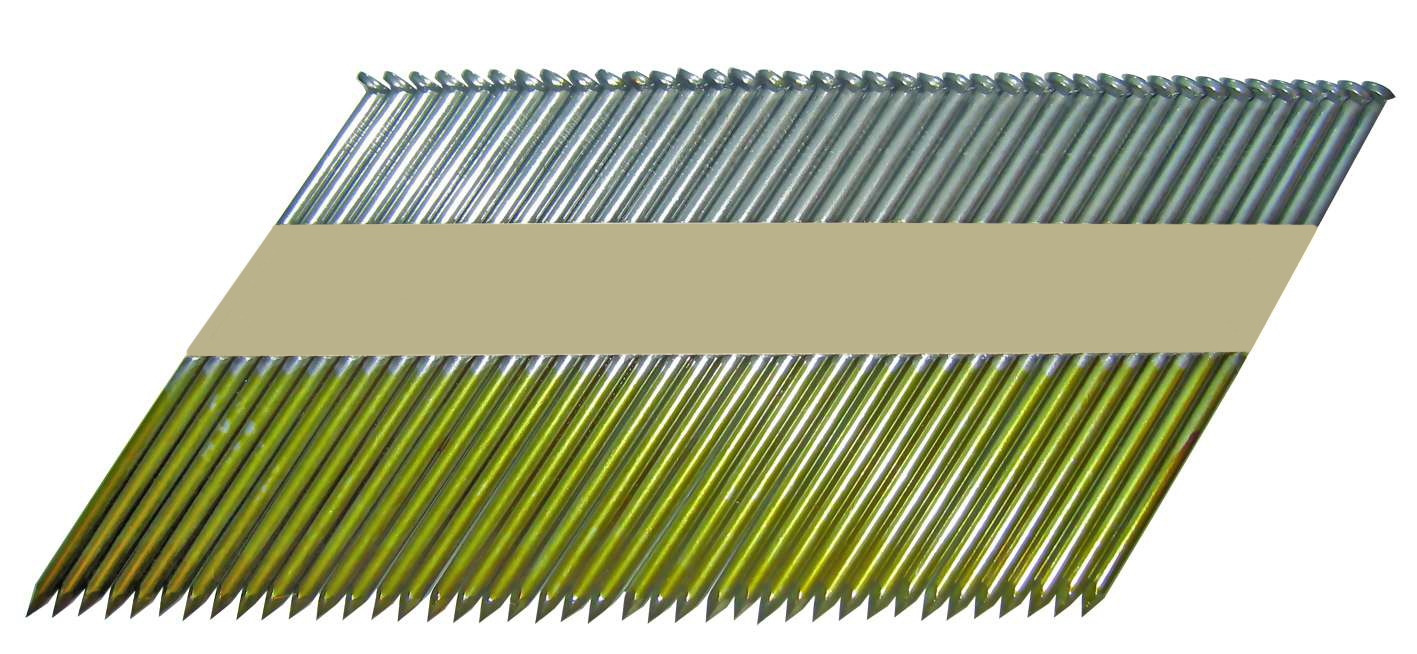

Serrated nails can be made using steel wire. It is of the light-drawn type or is applied with a zinc layer by diffusion. The second option allows you to increase the protection against destruction and extend the service life. The length of brushed galvanized nails can be 2-10 cm. Their cross-section varies from 0.2 to 0.45 cm.

But not all such hardware is equally in demand. Many people buy diffusion-galvanized products with dimensions of 6.5x0.335 cm. They are needed to attach 22 mm wind braces to roof trusses and to perform other carpentry work. Nails based on light-drawn metal (5x0.265 cm in size) are also widely used. Such products are used to fasten sheet finishing materials to the floor.

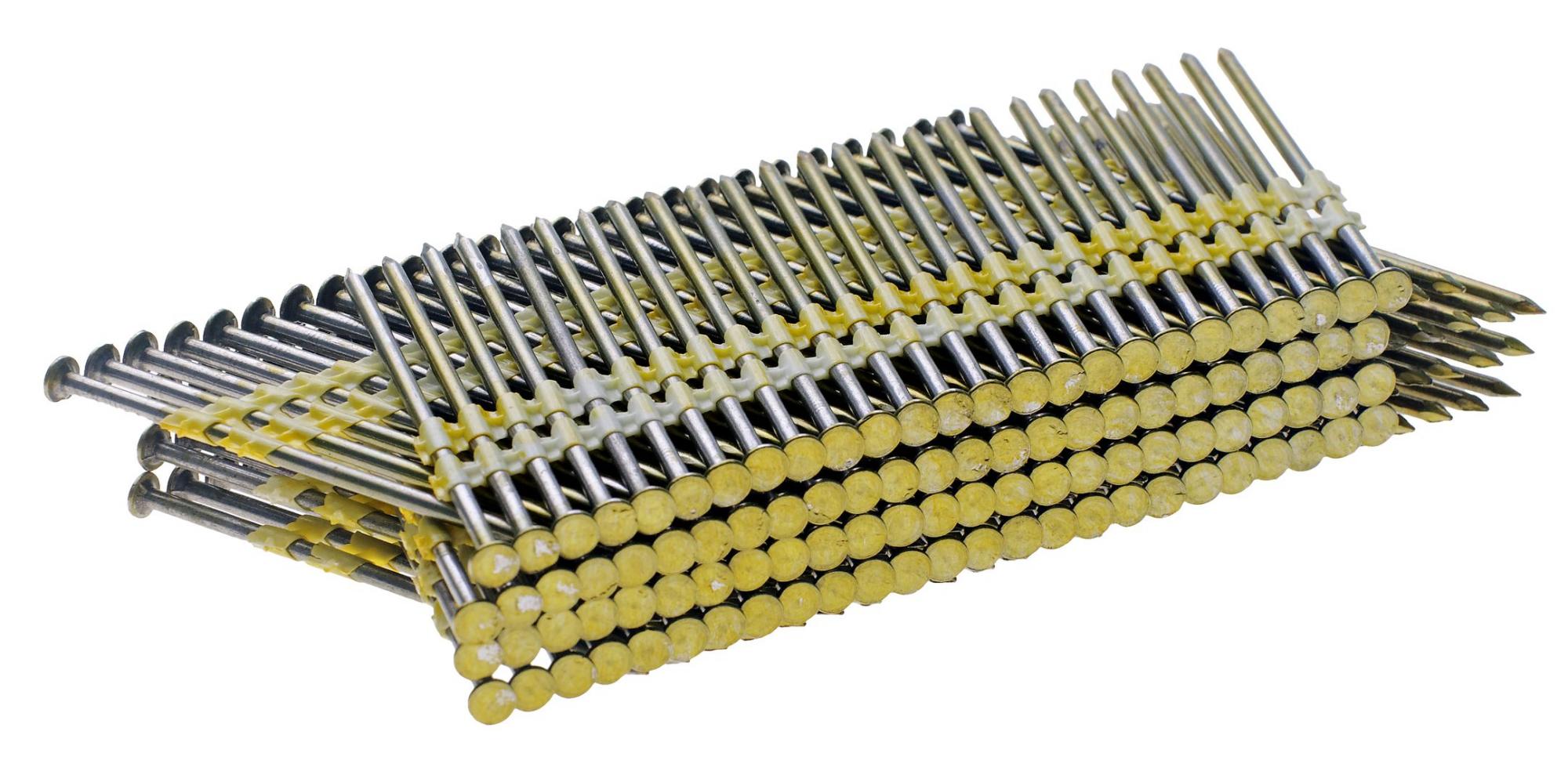

Also worth mentioning is the division into:

- marked;

- having a cone-shaped head;

- pallet variety (nail with a flattened head);

- cassette type of nails.

The latter type is located in the compartments of the plastic tape. It is not used by hand and is only intended to be operated with an air gun. As for roofing brushed nails, they allow you to fasten not only sheet metal and roofing material.