FAQ

1. Do I need to prepare the surface and clean for paint application if the product is rusty and has some defects? How do rust compounds work?

The composition of paints "against rust" contains fatty acids, which neutralize the process of rust spreading, and the protective layer preserves the product. But, since the surface of the metal with traces of rust is porous, it is better to carry out a little preparation of the metal. To do this, go over the surface with sandpaper or other abrasive material, wipe the product dry with a cloth and degrease with acetone or alcohol.

2.How does ink density affect consumption? What other indicators of paints should be considered when calculating the consumption?

The higher the density of the paint, the more firmly and completely the initial surface of the metal will overlap. The hiding power is indicated by the manufacturer for ideal conditions, therefore it is better to take a correction factor of 1.3 (multiplying the calculated amount of the composition). In this case, we can accurately calculate the flow rate. But, even the best paint will not cover the initial surface in one layer, only if this is a new product without flaws.

3. It is necessary to paint a surface that heats up to significant temperatures (metal oven). What kind of high temperature paint can be used, and how do they differ from ordinary enamels?

When choosing a heat-resistant paint, we focus on the operating temperature indicator at which the coating will not deteriorate and retain its original characteristics. On average, the compositions can withstand 400-600 ° C, which is enough for painting a metal oven. Silicone resin paint is suitable for your application.

4. How to remove old paint from metal surfaces?

There are three main ways to remove old paint from metal surfaces. First, the mechanical method. The layer is removed with an abrasive, but the effect can be obtained only on relatively flat surfaces.

Good results are obtained when using cord brushes on a drill or flap emery wheels on a grinder. Look carefully at the maximum speed markings on the brushes, use thick canvas gloves, goggles and a respirator or face shield.

Secondly, the chemical method. We purchase a gel or liquid composition that is intended for these purposes and apply to the surface with a brush. The composition is very active, you should work with plastic gloves and a protective apron. Glasses are required. The tool eats up rubber products in 2-3 minutes.

The compositions are a complex composition of chemically active substances. As a rule, manufacturers include in the solution: complexing agents, corrosion inhibitors, alkalis (or acids), surfactants.

And, the third way is fire. Using a blowtorch (not a cutter), heat the surface before burning the paint. The main thing here is not to overheat the metal, otherwise it will deform. After processing with fire, we clean the remnants of the paint layer with an abrasive or a metal brush.

5. I heard that there are so-called “grounds”. How do they differ from paintwork for metal? Are they a complete replacement for metal coatings? In what cases is it necessary to use a primer and is it necessary to “put” a layer of high-grade paint on top of the primer?

The primer is intended for the primary coating of metal and the formation of a protective layer before applying the decorative composition. "Primer" provides protection against corrosion, evens out defects, creates a solid base for enamels.The primer blocks dirt that cannot be cleaned from the surface.

The primer differs from paint and varnish coatings by the presence of special complexes in the composition, which prevent rust from developing and protect the metal from moisture penetration. Nevertheless, paints are now produced that "work" no worse than primers (3 in 1).

As a rule, the primer is produced in one color, often “brick” or other not very attractive matte color. You can use only a primer when painting if the aesthetic component of the product's appearance is not important to you. The selected paint is applied in two coats for a shine and an even coating on the ground.

The best hammer paints for rust

Hammer paints form a specific rough coating, creating the effect of hammering. At the same time, the enamel perfectly protects against moisture and temperature extremes. After evaluating the technical characteristics and feedback from specialists, 2 winners were selected that met the necessary requirements.

Hammerite

... I used enamel to paint a metal door to appreciate the strength of the hammer effect. Hammerite well masks irregularities that have arisen during the operation of the canvas, and creates a visually effective coating ...

Expert opinion

Another best paint for rust protection for both exterior and interior work. It adheres well to surfaces with signs of rust due to its high adhesion rate. The enamel creates a smooth coating with excellent water repellency even on rusty, unprepared surfaces and fully cures within 2 hours after application. The product has excellent thermal stability, maintaining its integrity even when heated (up to 80 ° C).

Hammerite is designed to protect ferrous metal only. It contains corrosion inhibiting components - alkyd varnish, sunlight-resistant pigments and functional additives. It is allowed to start painting when the air is warmed up to 5 ° C with a roller, brush or spray, which allows you to choose the most convenient tool in each case. After applying the base coat, wait at least 5 hours. The manufacturer offers 11 shades.

Dignity

- Resistance to aggressive factors;

- Ease of application to areas of corrosion;

- Doesn't require preparatory work;

- Suitable for outdoor and indoor work;

- Lead free.

disadvantages

- Not low cost;

- Dilution requires Hammerite Thinner.

Zip guard

It is a urethane rust paint designed for metal surfaces, but it is also suitable for concrete and wood. The enamel may be used directly in areas with signs of corrosion. At the same time, it is not required to carry out any actions to clean up the affected areas, except for those only cases when there is a swelling of the old coating - they must be removed.

In the production of Zip Guard, the Ziprust technology is used, which allows you to apply a layer without prior use of primers. Enamel can be used to perform interior and exterior works... It is a one-component formulation and creates a corrosion-resistant coating due to a combination of soil properties, anti-corrosion ingredients and finishing compound.

Dignity

- Protection of all types of surfaces, not just metal;

- No surface preparation required;

- Suitability for outdoor and indoor use;

- Creation of a resistant coating with anti-corrosion properties.

disadvantages

- Before painting, you need to grind glossy surfaces;

- Dries for a long time.

Varieties

Odorless paints for painting metal surfaces are available in a huge range. The compositions differ among themselves in composition, technical characteristics and operating conditions.By the type of binder, emulsions are of several types.

Latex

These are elastic water-based enamels (better known as "water emulsion"). The particles of synthetic latex, when dried, combine and form a thin homogeneous film. This allows you to form an even layer on the painted surface.

In their texture, latex paints are matte, semi-matte, glossy and super glossy. Matte formulations well mask base defects, and glossy ones require the preparation of a perfectly flat surface. Latex paints are non-toxic, odorless, dry quickly, have high wear and moisture resistance. The emulsion is available only in white. It is used both with the use of colors and in its pure form.

Acrylic

These are quick-drying paints that are highly resistant to aggressive environmental influences. Due to this, emulsions can be used for interior work both in heated and cold rooms.

For painting heating radiators, there is a special acrylic thermo enamel that can withstand high temperatures well, while maintaining its color (without cracking).

Work can be performed with hot batteries. In this case, the paint will dry completely within an hour. When painting metal structures in unheated rooms, you must carefully read the product labeling, and then purchase a frost-resistant version.

Oil

This type of enamel is made on the basis of oils, drying oil and color pigments. The material is widely used for painting metal surfaces in warm and cold rooms.

The paint has high elasticity and coverage, forms a flat and smooth surface and has a low cost. The disadvantage of oil enamels is a long drying time.

Alkyd

Alkyd paints have high wear resistance, brightness and color saturation, as well as a complete lack of odor and a long service life. The enamel is suitable for painting radiators and heated towel rails in the bathroom.

The alkyd surface is not afraid of high humidity and is resistant to chemicals. This allows you to paint tanks for fuels and lubricants and other liquids of chemical origin with such paint.

Such a mixture is frost-resistant and has an anti-corrosion effect, thanks to which it can be painted not only metal structures of internal premises, but also gates, fences and other objects located on the street. The presence of fire retardants in the composition significantly reduces the combustibility of the enamel, and the presence of antiseptics resists the appearance of mold and mildew.

Acrylic paints

Acrylic paints are generally odorless. Acrylic-based compounds can be used not only for painting the floor, but also for other types of substrates. This paint is often produced only in white, so it can be tinted to give it the desired color.

Such a material can withstand moisture, but here we are not talking about constant exposure to water. Such a coating can sometimes be wiped with wet cleaning, but it will not withstand streams of water (especially hot).

Odorless acrylic-based coloring products are used when painting even an already painted floor surface made of wood or concrete. Very often, such paints are used for decoration in kindergartens, hospital buildings, residential apartments.

Before applying the paint, the base of the surface must be primed. The characteristics of the primer will depend on the accompanying properties of the surface substrate. For example, wood absorbs the primer quite strongly, therefore, for high-quality adhesion, it is imperative to reapply the primer.

Specialized components are added to such products, allowing the paints to retain their basic properties for a long time.

Which company is better to choose a paint for rust

When choosing enamels with protective properties, it is necessary to give preference to proven companies. We carried out an in-depth analysis of the manufacturers on the market and selected the most demanded ones.

High-quality products are offered by the following companies:

- Kudo is a Russian brand specializing in the production of paints and varnishes for various types of coatings, including for rust. The products fully meet the requirements of the standards in the areas used.

- Rogneda is a Russian company that has existed on the building materials market for over two decades. The manufacturer's leading specialization is the production of paints, primers, mastics and other types of coatings. The Dali series of paintwork materials is in high demand.

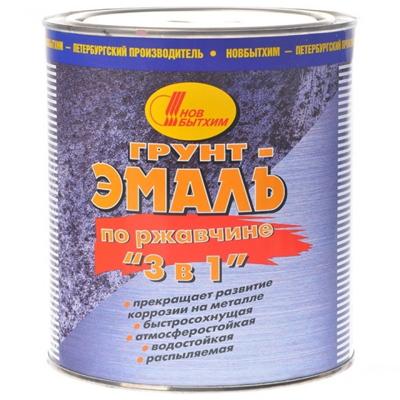

- Novbytkhim is a manufacturing company from St. Petersburg. The company's catalog includes more than 60 names of paints and varnishes and household chemicals. The enterprise has its own research laboratory.

- TikkurilaUnica is a Finnish manufacturer that has been producing high quality paints and varnishes for 155 years. The brand occupies a leading position not only in the Russian markets, but also in Sweden. The assortment of the company is represented by goods for household and industrial use.

- Finnigans is an English metal paint manufacturer established in 1962. The company offers truly high-quality products, using modern developments in the production process. Its manufacturing plants are located in different countries, and the company itself is known all over the world.

- Absolute Coatings, Inc. is a US company founded in 1923. Its sphere of activity is the production of modern urethane-based paints and varnishes. The range of the manufacturer includes construction varnishes, enamels, paints and solvents.

- Yaroslavskie Kraski is a Russian company that has existed since 2013. The manufacturer is engaged in the development and production of high-quality paintwork materials that meet modern quality and environmental standards.

Best rust converters

Types and characteristics

Enamels and other paints and varnishes for metal are represented by three main types:

- oil;

- alkyd;

- acrylic.

Two-component blends, polyurethane-based dye combinations and other similar improvements are more likely to fall under the industrial category. They are resistant to corrosive processes and aggressive environments. It is impractical to use such mixtures, despite their high anti-corrosion characteristics, in domestic conditions: the work is costly and insufficiently effective. The oil type is cheaper and can be bought at almost any paint and varnish store.

The problem is that such enamels cannot be called quick-drying. Under the influence of sunlight, they quickly fade, losing their visual appeal. The effectiveness of metal protection against rust also leaves much to be desired. Oily paint products are not resistant to high temperatures. They cannot be used for boilers, radiators, it is dangerous.

In terms of anticorrosive activity, alkyd enamels are better. It is not difficult to buy them now. Increased resistance to negative atmospheric influences and temperature changes allows the use of such mixtures when carrying out outdoor work. Acrylic paints and varnishes, which are based on pure water, are recognized as the best choice by the vast majority of practitioners. They are completely safe for the health of painters, do not have an unpleasant odor.

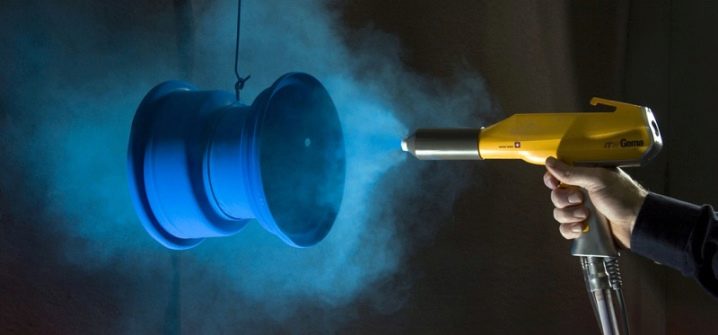

In terms of resistance to strong heat and the negative effects of the external environment, combinations based on acrylic are no worse than alkyd counterparts. This allows you to increase the period during which metal objects retain their external attractiveness. Fast drying will appeal to professionals and ordinary customers.Powder coating of metal, with all its advantages, cannot be done at home. The need for a special chamber devalues the high technical qualities of such a coating and its durability.

Chemical-resistant paint is distinguished by its resistance to caustic substances, it should be technological and practical, without creating problems during application. Heat-resistant and fire-resistant enamels have nothing in common, they are mutually exclusive concepts. In the first case, the surface must remain unchanged under the action of strong heating, and in the second, on the contrary, it must swell and cover the base from the effects of the flame. The two-component mixture, in addition to the base pigment, contains epoxy resin, anti-corrosion agents and polyurethane. Typical polyester enamel in most cases creates a glossy finish on pre-primed surfaces.

In addition to these varieties, it is customary to distinguish the following types:

- dielectric;

- polymeric;

- oil and petrol resistant;

- weatherproof.

KM varieties for iron

CM classification is carried out in three directions:

- by composition;

- on the performance of a particular function;

- according to technical characteristics.

According to the composition, the types of paints are distinguished:

- KM epoxy: has an unpleasant odor, which does not allow its use for interior work. Low drying speed. The manufacturing process is based on silicone resins with hardeners. High-temperature coating (withstands + 60 ° C).

- CM of oil composition: there is a toxic odor, but below the level. It is based on natural oils and drying oil. The coating does not tolerate temperature fluctuations, therefore it is used for interior work. On the street, the coating will not last long. The material is not able to protect the metal base from corrosive phenomena. Therefore, the metal is pre-treated with a primer. The paint is produced in an assortment of colors and has a low price. A large number of coating imperfections forces the oil composition to be changed to another. It dries for a long time, quickly loses color brightness, exfoliates. You can repaint the surface only with the same dye or, after removing it with a special remover, another paint is applied.

- Alkyd: low toxicity, which allows it to be used for interior work. Good adhesion to metal without pre-treatment with a primer. The covering layer is smooth, shiny, protects against corrosion. Drying speed is fast. Poorly tolerates high temperatures. The material is flammable. Paints on galvanized surfaces, but the choice of colors is limited.

- Acrylic: no toxic smell. The composition is based on polymers. The diluent is water. The paint is universal. Used for both indoor and outdoor use. But acrylic enamel for metal used outdoors is expensive and does not tolerate sub-zero temperatures. You can cover products that heat up during use. Maximum threshold for temperature rise: up to + 110 ° C. The coating protects against corrosion, is durable and can be used for up to 8 years. Adverse weather conditions, mechanical damage are transferred.

- KM rubber: considered the best for painting the roof. The unpleasant smell does not allow to use it for interior work, only outdoors. The rubber cover is easily removed with a remover and protects against leaks. In the composition - bituminous resin. The color of the material is most often black. The coating is resistant to weathering, with a long service life. Without experience, it is not always possible to apply the dye evenly. The paint is not available to the average buyer due to the high price.

Specialized composite materials for metal are classified according to their properties:

- Anticorrosive compounds: the coating protects the metal from moisture and oxygen. The base is not pre-treated with a primer.

- KM is applied to rusty areas: it is coated immediately, without processing oxidized iron.In the process, the cost of surface treatment is reduced and the operating time is shortened. The composition is based on synthetic epoxy resins with anti-corrosion pigment. The coating dries quickly.

- Hammer compositions: after drying, potholes form on the surface, which imitate the marks of hammer blows. It contains a mixture of acrylic, epoxy, alkyd with fine fractions of glass and aluminum powder. The surface becomes rough with a metallic sheen. Good resistance to mechanical damage. If the material is applied in 2 layers, then the metal base is not primed and does not need additional final coating.

- Primer-enamels: a compound in the composition of the properties of a primer, a coating with anti-corrosion qualities and an enamel.

- Aerosol nitro paints: a can is a container often used for them. They have a toxic odor, therefore they are used for staining on the street. The coating is even, without streaks.

- KM forging: the basis of the material is polymers. High wear resistance, excellent tenacity with a metal base are their main advantages.

Experts advise not to choose cheap CM, so that you do not have to repaint products every year. For example, an oil coating bursts after a couple of years, a nitro paint coating loses its color brightness in one year. A composition from a well-known brand will last longer. Its price is higher, but the name of the manufacturer is a guarantee of the quality of the paint. The longest service life of the hammer compound (10 years). Throughout the entire period, the coating does not lose its original appearance. But replacing it with something else is difficult.

Metal paint is selected taking into account the indicators:

- purpose: indoors or outdoors;

- toxicity level;

- the degree of economical spending;

- price;

- life time;

- requirements for preparation of the base;

- condition of the metal base.

The best paint for rust 3 in 1

The presence of the "3 in 1" prefix indicates that the product works in several directions - priming, converting rust and decorating. Products of this type are resistant to any impact. After analyzing the reviews of consumers and experts, among a variety of products, two nominees with the best recommendations were selected.

Novbytkhim primer-enamel

The paint "Novbytkhim primer-enamel" is intended for painting all types of surfaces. It is applicable both for new and already partially or completely corroded products. The composition of the product is represented by resins of synthetic origin, additives, solvents (organic) and anti-corrosion components. The product combines the qualities of an anti-corrosion primer, rust remover and topcoat. Its consumption is quite low - up to 120 ml per m² with a single layer.

Work can be started at an air temperature of -10 ° C. The coating is preliminarily cleaned from the existing detachments. If it was painted with oil or alkyd compounds, then cleaning to a matt state is necessary. A brush and roller are suitable for applying the composition. The paint also adheres well to pneumatic application. For best results, you need to put 2 layers. Intermediate drying should take at least 60 minutes. It takes only 2 hours to dry completely.

Dignity

- Fast drying;

- Resistance to different types of exposure and temperature extremes;

- High adhesion rates;

- Excellent decorative properties;

- Good hiding power.

disadvantages

Not suitable for heating surfaces due to odor.

Metallista

The paint on rusty metal in question from the brand with the myrrh name Tikkurila provides a 3-in-1 effect. Thanks to the wax included in it, it creates an increased protection of the metal against the negative effects of moisture, giving it excellent water-repellent properties. The structures covered with the composition will last at least a decade without renewal. Metallista is immune to the effects of fats, lubricants, industrial alcohols and turpentine, therefore, its field of application is unusually wide.

The manufacturer offers several basic shades for tinting, all in all, they can be created up to 32 thousand. The hardened layer can easily withstand heating up to 80 ° C while maintaining the original color. Drying of the applied composition until it comes off takes up to 2 hours. Thinner must be added to Metallista prior to use. It fits well on uncleaned surfaces without first applying a primer.

Dignity

- Creation of an insoluble base;

- Delaying the formation of corrosion;

- Eliminates the need for preliminary preparation of the base;

- Double chemical formula;

- Convenience of working with any tool.

disadvantages

- Implementation in small volumes;

- The need for tinting;

- Not a very large number of ready-made colors (four).

Enamel is sold in small containers - from 400 ml to 2.5 liters.

Metal rusting - what is the problem for painting

Iron, oxidizing, turns into a loose brown oxide, prone to crumbling, stratification. The strength of the metal deteriorates, fistulas are formed. Depressurization of pipelines and tanks occurs. The destruction of iron-containing alloys occurs under the influence of moisture present in the atmosphere. According to experts, losses from corrosion reach 12%. The pressure rate increases with an increase in the concentration of exhaust gases, sulfur and nitrogen compounds.

Iron is an active reducing agent and exhibits different valences. There are several types of oxides; rust has a variable chemical composition. Hard-to-reach places are the most vulnerable; it is difficult to visually determine the degree of destruction. When painting with conventional metal paints, the moisture contained in the loosened layer accumulates under the coating, and the corrosion rate increases. Special paints and varnishes contain substances that stop the process of rust formation.

Special paints and varnishes contain substances that stop the process of rust formation.

Special paints and varnishes contain substances that stop the process of rust formation.

Under what conditions can metals be painted without stripping

Anti-corrosion compounds are allowed to be applied to the surface without preliminary cleaning in places that are not directly accessible with abrasive tools. The strength of the metal is pre-checked by non-destructive testing. If thick-walled metal is used, an inhibitor treatment of the metal is preliminarily carried out, and then a layer of paints is applied.

In other cases, rust must be removed for several reasons:

- In a loose layer, moisture vapors, harmful gases accumulate, destruction will continue under the paint layer;

- If the operating conditions are extreme, any defect can lead to depressurization of the protective coating, moisture will get inside;

- The component composition of coatings for rust is different, the protection efficiency is difficult to determine accurately, it is possible that the concentration of additives is insufficient, and the corrosion process will continue.

In a loose layer, moisture vapor, harmful gases accumulate, destruction will continue under the paint layer.