Applying enamel to the surface

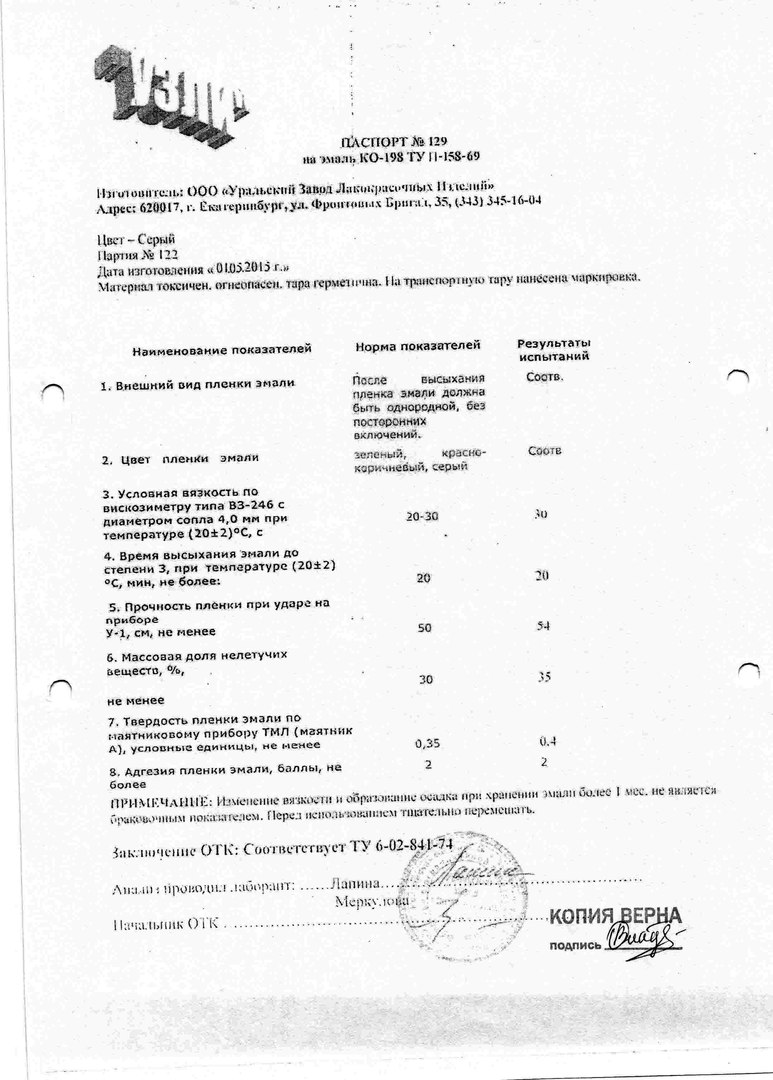

When you buy paint, you need to ask the seller for a certificate of conformity and a quality passport. This will ensure that you have purchased good material that will last a long time. Painting any surface requires preparation and is carried out in several stages.

Stage 1: surface preparation

Before you start painting, you should take care of the cleanliness of the surface. It should be free of dust, moisture and other liquids. If necessary, degrease the material with a common solvent. To do this, apply a small amount to a rag and wipe the surface thoroughly.

Stage 2: applying the enamel

Shake the enamel thoroughly until smooth, then open the lid and check the viscosity of the material. It can be thinned with solvent if necessary. The enamel should be applied to the surface in two layers, taking a break between applications for about two hours. If concrete, brick or plaster acts as a surface, then the number of layers should be at least three.

Stage 3: heat treatment

Heat treatment of paint occurs within 15-20 minutes at a temperature of over 200 degrees. This is necessary to protect the surface from the influence of substances such as gasoline, kerosene, oil. These aggressive solutions can significantly shorten the life of the film.

You will learn more about the enamel application process in the following video.

Dyeing process

Work should take place at a humidity of less than 80%, in a temperature range of -30 to +40 degrees. The spray gun will provide high-quality spraying, the minimum number of layers is two.

It is necessary to take into account some of the subtleties when painting:

- On areas with low accessibility, joints and edges, it is better to apply the compound with a brush by hand.

- When using pneumatics, the distance from the tool nozzle to the surface should be 200-300 mm, depending on the device.

- The metal is painted in two or three layers at intervals of up to two hours, if the temperature is below zero, the break time is doubled.

- Initial drying takes two hours, after which polymerization occurs and final drying, which is completed in a day.

Dye consumption can range from 90 up to 110 grams per meter of area, depending on the texture of the base, the degree of its porosity and the experience of the master.

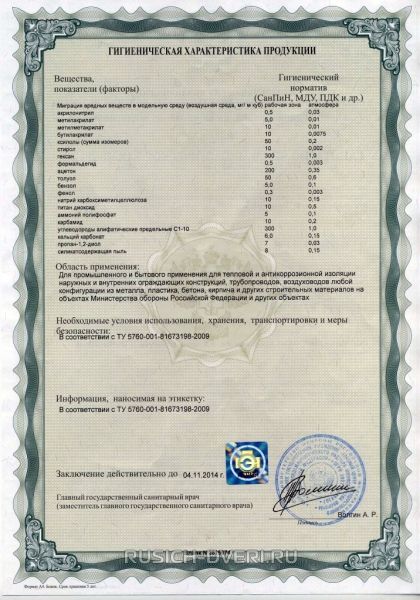

When working, follow the safety regulations. Since the enamels contain solvents, this determines the III class of hazard to human health. Therefore, for quiet operation and harmlessness of the process, you should take care of the maximum ventilation of the room, personal protective equipment, always have on hand materials at hand - sand, asbestos fire blanket, foam or carbon dioxide fire extinguisher.

Appointment of enamels KO-174, KO-198

Facade weather-resistant enamel KO-174 is used for facade decoration of buildings, as well as for application to various structures, structures, concrete products, asbestos cement. This material can also be used for painting machinery and equipment. Resistance to weather conditions makes it possible to apply paint even in the Far North in harsh climates.

KO-174 performs a coating that, thanks to good pigments, looks very beautiful. The properties of the resulting film are as follows:

- Excellent grip on surfaces.

- Moisture resistance, moisture tightness.

- Frost resistant (up to 90 freeze / thaw cycles).

- Thermal stability - the ability to withstand temperatures up to +150 degrees.

- No burnout in sunlight.

The product is available in a variety of colors, depending on the dye added. Acceptable shades - gray, blue, white, black, green. There are corresponding certificates for any batch.

Enamel KO-198 organosilicon is necessary for other purposes. In the description it is noted that it is used to protect the metal from the action of mineral soil waters, as well as from substances based on chemistry:

- saline solution;

- nitric acid;

- of hydrochloric acid;

- sulfuric acid, etc.

These properties make it possible to paint tanks, tanks, containers, equipment in chemical production with this material. The product has anti-corrosion and frost-resistant properties, thanks to which it is applied to foundations, supports made of reinforced concrete structures, railway platforms, bridges. Enamel can be used in hot tropical climates. Paint color - red, brown, blue, yellow, black, white, gray.

Cooking the surface

Before applying any of these paints, the surface must be properly prepared. To do this, it is cleaned of grease, oil, dirt, dust, and rust is removed. The paint that is already outdated is also cleaned off. Preparatory work is done using a sandblasting machine or hand finishing, depending on the size of the product itself. If the surfaces will be used at moderately hot temperatures (up to +100 degrees), only a rust converter can be used. Rusty spots that remain after the completion of all work must be processed again with a converter, then washed perfectly.

Features of the composition

Organosilicon enamel has properties that allow this type of product to be used wherever it is necessary to ensure the best quality and maximum durability of the painted surface. The enamel has a water-repellent effect, and is also immune to temperature extremes, so it can be used in conditions of maximum and minimum temperatures.

The composition is also not afraid of the sun's rays, even with prolonged exposure, the initial shade of the surface and its inherent technical characteristics do not change.

Enamels are produced synthetically on the basis of air oxygen and silicon. This composition gives special strength and reliability to the structure. In the composition of organosilicon materials there are special impurities to prevent corrosion, which improves the quality and resistance of the painted surface to adverse factors.

By adding acrylic resins and cellulose ethyl ester to the composition, manufacturers have achieved rapid drying of the painted surface. Carbide layers in the paint provide sufficient coating hardness, they also prevent mechanical damage to the surface. Thanks to the compounds of enamel with epoxy resins, resistance to the negative effects of chemical agents has appeared.

The range of colors was expanded by pigments, which are also part of the enamel. They can withstand ultra-high temperatures up to 150 degrees without losing their original shade. Organosilicon enamels, in addition to their inherent unique properties, have advantages and disadvantages in comparison with other types of paints and varnishes.

The main advantages include:

- thermal and frost resistance;

- resistance to high humidity;

- moisture resistance;

- fire safety;

- resistance to ultraviolet radiation;

- resistance to chemical reactions;

- wide color palette;

- low consumption in the painting process;

- the ability to work at subzero temperatures;

- corrosion protection.

Disadvantages of the material:

Differences between enamels of the KO series

Several enamels are produced in the KO series, which have much in common, but also have a number of differences in description and characteristics.

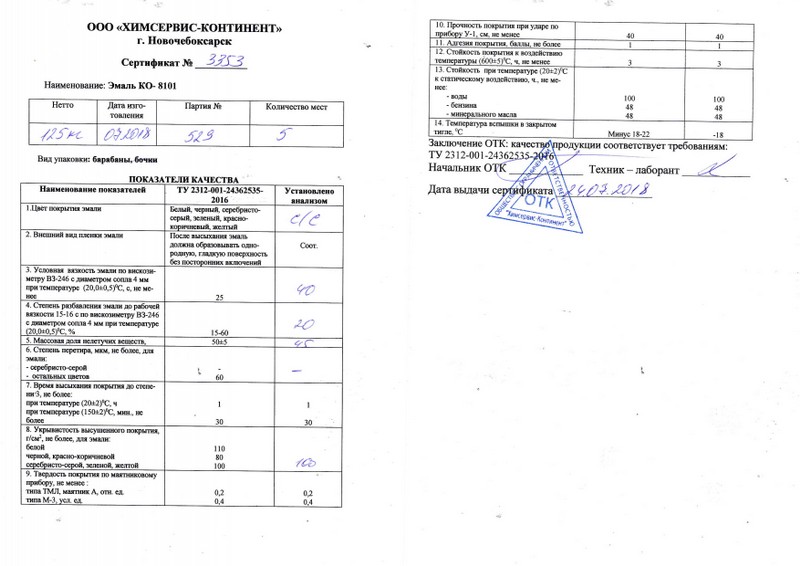

KO-8101

Anticorrosive enamel KO-8101 is used at temperatures of -60 ... + 600 degrees, mainly for painting exhaust systems of cars, for application to pipelines, furnaces, heating systems. The aim is to protect against rust and to give the products an attractive appearance.

Enamel colors:

- black;

- Gray;

- blue;

- green;

- White;

- Red;

- beige, etc.

The product is one-component, does not require special preparation before application. Priming before using the enamel is also optional.

KO-8104

The scope of application of this tool is similar - it is used to protect metal products from corrosion, it can withstand temperatures up to +600 degrees, but for a shorter time. Therefore, paint is most often used in mechanical engineering, for application to pipelines. Also, the product can be used to process products made of concrete, stone, brick, and other mineral materials. Product colors - green, gray, blue, red-brown, blue, yellow and others.

KO-8111

This product can be used to protect steam, gas turbines, generators, heat pipelines. KO-8111 stands out favorably from other organosilicon enamels by its ability to not react for a long time to the action of various chemicals, not to lose its properties in an aggressive environment. Also, this material can be applied to surfaces at subzero temperatures.

KO-870

In terms of properties, this enamel practically does not differ from the previous ones, but it has higher indicators of resistance to the action of water. Therefore, it can be used where there is contact of products with moisture, there is an increased humidity of the air. The tool has proven itself perfectly in outdoor use, where surfaces are exposed to the direct action of precipitation. Scope of application - concrete and brick fences and other products, appliances, gas and steam turbines, generators. Like its counterparts, the material is available in a variety of colors.

KO-868

It is used where the surface is affected not only by high temperature, but also by high humidity. It is permissible to apply the agent on concrete, artificial stone, brick, but the main material for protection is metal. Most often, enamel is used for application to:

- pipelines;

- construction equipment;

- reservoirs;

- tanks;

- hydraulic structures;

- agricultural machinery.

Also, the material can be applied to asbestos-cement surfaces. It fits well even at negative temperatures, withstands up to +600 degrees.

Features of the facade enamel of the organosilicon type

The main advantages of paint include the following indicators:

Facade organosilicon paint KO-174.

- gives the surface additional thermal, moisture and light resistance;

- facade paint perfectly fights against atmospheric influences;

- high rates of air tightness;

- excellent hydrophobic parameters;

- low indicators of the level of fire.

The silicone-type facade paint has excellent adhesion to the concrete surface. The coating of such enamel will be durable. This painting material is produced in various colors at specialized chemical plants. The paint is delivered to the construction site in finished form. The price of paint varies depending on the properties. A thinner is specially added to the thick mass of paint to the desired viscosity of the painting material.

In the photo, silicone paint.

Before applying paint to the facade of a building, it is thoroughly prepared. The surface of the facade is cleaned from rust, dirt, dust. In this case, the moisture content of the concrete should be 8%. Organosilicon enamel is applied to the facade surface in 2-3 layers with brushes, a roller or a special paint sprayer. There should be no spots, wrinkles or streaks on the painted surface.

Security

When working with any paint, safety precautions should be followed. Materials are toxic as they contain solvents. The latter belong to the 3rd hazard class, in the working area the maximum permissible concentration for them is 150/50 mg / m3. m.It is better to paint products in open areas and make sure that they are well ventilated. Hands should be protected with special pastes or gloves, a respirator should be put on the face.

You can not work in pits, wells, closed rooms, if there is no ventilation and no personal protective equipment. In such conditions, a gas mask should be used. Solvents also cause a high fire hazard of enamels, so there should be no sources of heat and fire in the working area. In case of fire, extinguishing is carried out using foam, sand, water mist.

Surface preparation for painting

The surface to be painted must first be cleaned of mechanical impurities, water-soluble salts, fats, oils. Degreasing is carried out with a cloth moistened with solvent, xylene, acetone or other aromatic solvents. The surface must be dry and clean before painting.

Cleaning from rust, scale, old paint residues is carried out manually or mechanically up to St 3 or by shot blasting (sandblasting) to the degree SA2 - SA2.5 according to the international standard ISO 8501-1: 1988. This cleaning gives the required heat resistance and adhesion.

If the previously applied coating is strong, without corrosion damage and the percentage of its destruction is less than 20, it is necessary to use partial treatment (in places where there is no coating, capturing the adjacent areas by 15-20 cm around the perimeter).

If the old (previously applied) coating has a thickness of more than 0.5 microns or it has deteriorated by more than 20%, such a coating must be completely removed before painting.

Benefits and general parameters

Feature of enamel KO 8101 is that this material is very resistant to heat. Enamel is actively used to paint a room from the inside, and when it dries, it absolutely does not emit any harmful substances.

If we carefully consider the technical characteristics of the enamel, then we can highlight the following advantages:

- The enamel does not corrode and is heat-resistant, which makes it possible to use it for stoves and fireplaces.

- The material can be used as a waterproofing material to reduce water absorption.

- Enamel KO 8101 is used for decoration, it has excellent adhesion to stone and metal, while maintaining vapor permeability.

- Elcon enamel can be applied at any time of the year, even in winter, at a temperature of -30 ° C, it will help create a high-quality anti-corrosion coating.

- Before applying this material, it is not required to treat the surface with an additional primer.

- Due to the fact that the enamel is created in accordance with all GOST standards, the manufacturer boldly gives a 15-year guarantee.

- When working with enamel, its consumption is minimal.

- The material does not lose its appearance even under the influence of sunlight.

The main advantage is not only a passport of quality, but also the fact that the enamel has a huge selection in colors

It is important to remember that it is necessary to apply enamel taking into account all the recommendations and according to the rules, otherwise there is a possibility that the expected results will not be achieved. If you want to store enamel KO 8101, then this will require special conditions

Storage periods can be up to 12 months. Store the material in a dark and cool place.

Preparation before staining

Before applying silicone enamel to a metal surface, the base must be properly prepared. The first step is to clean old paint and varnish material, dirt, dust, grease, salt, scale, rust and traces of corrosion. To remove oily and greasy stains, you can use a cloth soaked in a solvent such as xylene, solvent or acetone. To remove rust and scale, you can use sandblasting or power tool cleaning with a power tool or sandpaper.

If it is not possible to use sandblasting, and if the application of enamel will be carried out at a temperature of less than 100 degrees, then a rust converter can be used. As a result, a dry and clean surface should be obtained, without crumbling particles.

After preparing the surface, you need to prepare the enamel. Toluene or xylene can be used to dilute it to working viscosity. If KO-811 paint is used, then you can add 30-40 percent of the solvent, and when using KO-811K white paint, you can add up to 80% of the solvent, for any other color - a maximum of 50%. After thoroughly mixing the enamel with the solvent, the mixture should stand for 10-15 minutes so that all air bubbles come out of the solution.

Scope of application and technical characteristics

Designed for painting metal structures exposed to short-term exposure to sulfuric acid, vapors of nitric and hydrochloric acids, saline ground water, sea water, atmospheric conditions. It is also used to protect products supplied to countries with a tropical climate. Recommended for painting foundations and the foundation part of reinforced concrete overhead supports.

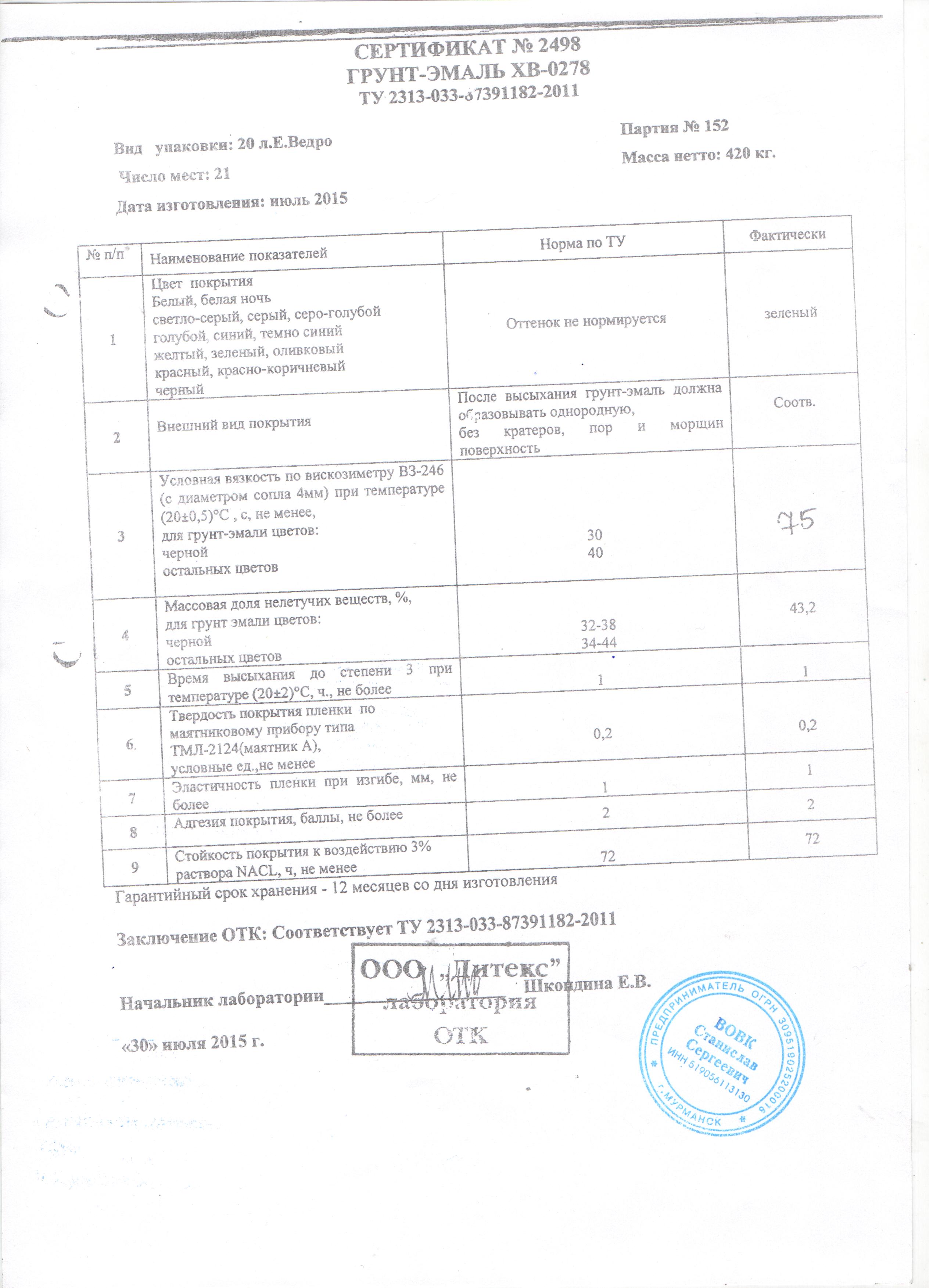

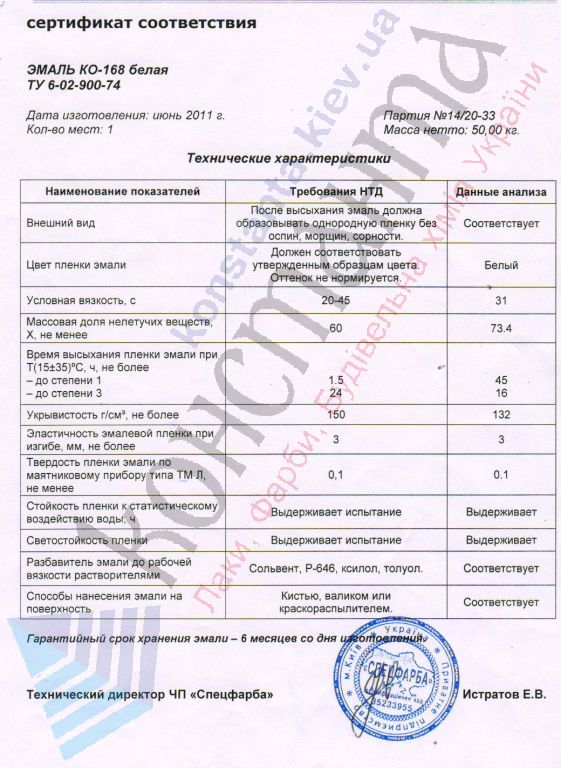

Shelf life is 12 months. Each new batch has its own quality certificate. Paints and varnishes are produced in accordance with the requirements of GOST and TU.

Metal surfaces are painted in 2-3 cross layers with intermediate drying of 0.5-2.0 hours, depending on the ambient temperature. Concrete, asbestos-cement, plastered, cement-sand surfaces are painted in three layers. Drying time - 20 minutes at a temperature of 20C.

KO-198

KO-198 paint provides protection not only for metal, but also for coatings from other materials. The protective film has the following properties:

- Protects against saline solutions;

- Protects against acids: nitric, hydrochloric, sulfuric.

Used for painting equipment in chemical plants. The enamel has anti-corrosion and frost-resistant properties. Rails, foundations, metal supports are actively painted. Suitable for tropical climates. Available in seven colors: red, black, blue, yellow, brown, white, gray.

The main property is the protection of metal structures from corrosion, as well as aggressive chemical attack.

KO-174

The main difference between KO-174 is used only in cold climatic zones. Only the facades of structures are painted. The enamel has excellent adhesion. They are moisture resistant. The resulting film is heat-resistant. Withstands temperatures up to +150 C. It does not lose color saturation when exposed to sunlight. Withstands 90 freeze and thaw cycles. The surface must be prepared in advance (cleaned from dirt, degreased). The paint is applied with a brush, spray gun, roller.

Enamel KO-174 is intended for obtaining a protective and aesthetic coating of materials and parts, structures. It can be concrete, brick, wood, asbestos cement. Painting can be done on panels made of heavy concrete with a moisture content of up to 9%, expanded clay concrete - up to 14%. The enamel has excellent hydrophobicity, resistance to UV radiation, frost and moisture resistance while maintaining good vapor and air permeability.

Dyeing

For enamels KO-8104, KO-8111, KO-868, KO-870, the staining process is carried out as follows. Application is carried out in 2 layers by roller, brush, pneumatic spray, airless spraying. You can apply products in an electrostatic field. Conditions for work:

humidity - up to 80%;

temperature - from -30 to +40 degrees;

when working in the cold, it is important to ensure that the surface temperature is at least 3 degrees above the dew point (this is required to prevent the appearance of ice crusts and frost);

distance from the nozzle of the sprayer and the base with pneumatic spraying - 20-30 cm, pressure - 1.5-2.5 kgf / sq. cm, nozzle diameter - 1.8-2.5 mm .. On hard-to-reach places, seams, edges, enamel is applied with a brush

Metal surfaces are painted for 2-3 layers (crosswise), drying each layer for 30-120 minutes (the exact time depends on the temperature, the base is checked "to touch"). If the temperatures are below zero, the time may increase by 2-3 times. Products made of concrete, cement, surfaces with plaster are painted 3 layers

On hard-to-reach places, seams, edges, enamel is applied with a brush. Metal surfaces are painted for 2-3 layers (crosswise), drying each layer for 30-120 minutes (the exact time depends on the temperature, the base is checked "to touch"). If the temperatures are below zero, the time may increase by 2-3 times. Products made of concrete, cement, surfaces with plaster are painted in 3 layers.

Drying of the final coating is done for at least a day at a temperature of +20 degrees, the final hardening is observed when using the products. It is possible to do hot drying - first, keep the surfaces at room temperature for half an hour, then increase the temperature by 3.5 degrees / minute, and so on for an hour. If it is supposed to use products under the influence of oils, gasoline, saline solutions, other substances, it is necessary to hot dry for 15-20 minutes at 250-400 degrees. The thickness of the finished coating is usually 40-50 microns. The number of layers is determined by the application method and the total coating thickness. It is possible to start up and transport products after painting in 3 days.

Enamel KO-8101 has some differences in the drying process. At a temperature of +20 degrees, the coatings should be dried for only 2 hours, and not 24 hours, as is the case with other products. Full hardening occurs during the operation of products when heated. The baking technique is similar.

Similar:

| Guidelines for the use of heat-resistant anticorrosive enamels "Certa"This manual is compiled on the basis of TU 2312-001-49248846-2000 with rev. 1, 2 on enamel "Certa" silver, black, white, ... | Guidelines for the use of heat-resistant anticorrosive enamels "Certa"This manual is compiled on the basis of TU 2312-001-49248846-2000 with rev. 1, 2 on enamel "Certa" silver, black, white, ... | ||

| Instructions for the use of the organosilicon composition "elkon-sauna" ...The composition of "elkon" -sauna is a composition of organosilicon varnishes, resins in organic solvents with the addition of additives ... | Terms of Reference No.Insulated men's suit made of heat-resistant materials with permanent protective properties | ||

| Guidelines for the use and operation of electrode boilers Galan-hearth….Efficiency, ease of installation, repair, cost of heating 1 m2 of premises, material consumption per 1 kW of boiler power, etc., application ... | Guidelines for the use of micro-tunnel boring systems and technologies ...Guidelines for the use of microtunnel boring systems and microtunnelling technologies in construction | ||

| The instruction is advisory"Manual to SNiP 09. 01-85 on the use of chemical additives in the production of prefabricated reinforced concrete structures and products", "Guide ... | User's Guide Annotation This document presents ...This document is a user guide for using the Cyberplat Mobile Dealer mobile application, developed by ... | ||

| Instructions for use F3 | ergo contents 1 scope of deliveryRead the instructions for use of the device before putting it into operation and using it. In any case, follow the instructions ... | Guidelines for applying the principlesThe committee submits its findings to the Secretary of Agriculture and the Minister of Health and Welfare. One of… | ||

| The instruction is advisoryInstructions! This instruction is a recommendation document, in the development of which the following were used: “Manual to SNiP 09. 01-85 ... | A practical guide to the use of hypnotic psychotechnics ...A practical guide to the use of hypnotic psychotechnics in business and medicine, advertising and propaganda, trade and everyday ... | ||

| Directions for use Appliance descriptionContinuous Passive Movement (CPM) designed for the development of the ankle | Instructions for use of the tool and product data sheetThe tool is intended for professional use in commercial production purposes | ||

| Instructions for use of the tool and product data sheetManufacturing of any structures using nails with a rod diameter of 2.3 to 2.5 mm and a length of 30 to 65 mm | Operating instructions ContentsSMT Unit 60A (P) Ersanet Rework Station Application Guide, 2003 |