Some points to know

This type of special fastener has long been used in a variety of works, where fastening becomes a necessary process, according to technology. Below are some important points to consider:

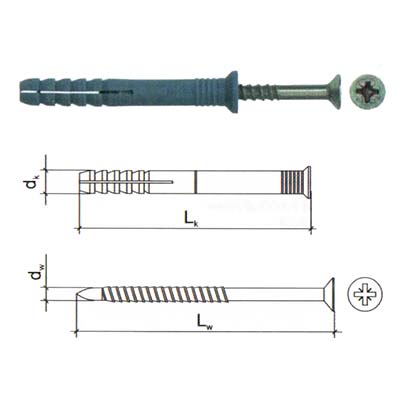

The two main parts that make up the element are the nail and the dowel itself. Such a connection allows without destruction to carry out the fastening of objects to such materials as concrete, brick, stone.

Other materials, which are classified as corpulent, with a high density, lend themselves to fastening. It is possible, among other things, to give the types of appropriate fasteners suitable for installation processes, where fiberboard, chipboard, drywall are used as the main materials for connecting to the bases.

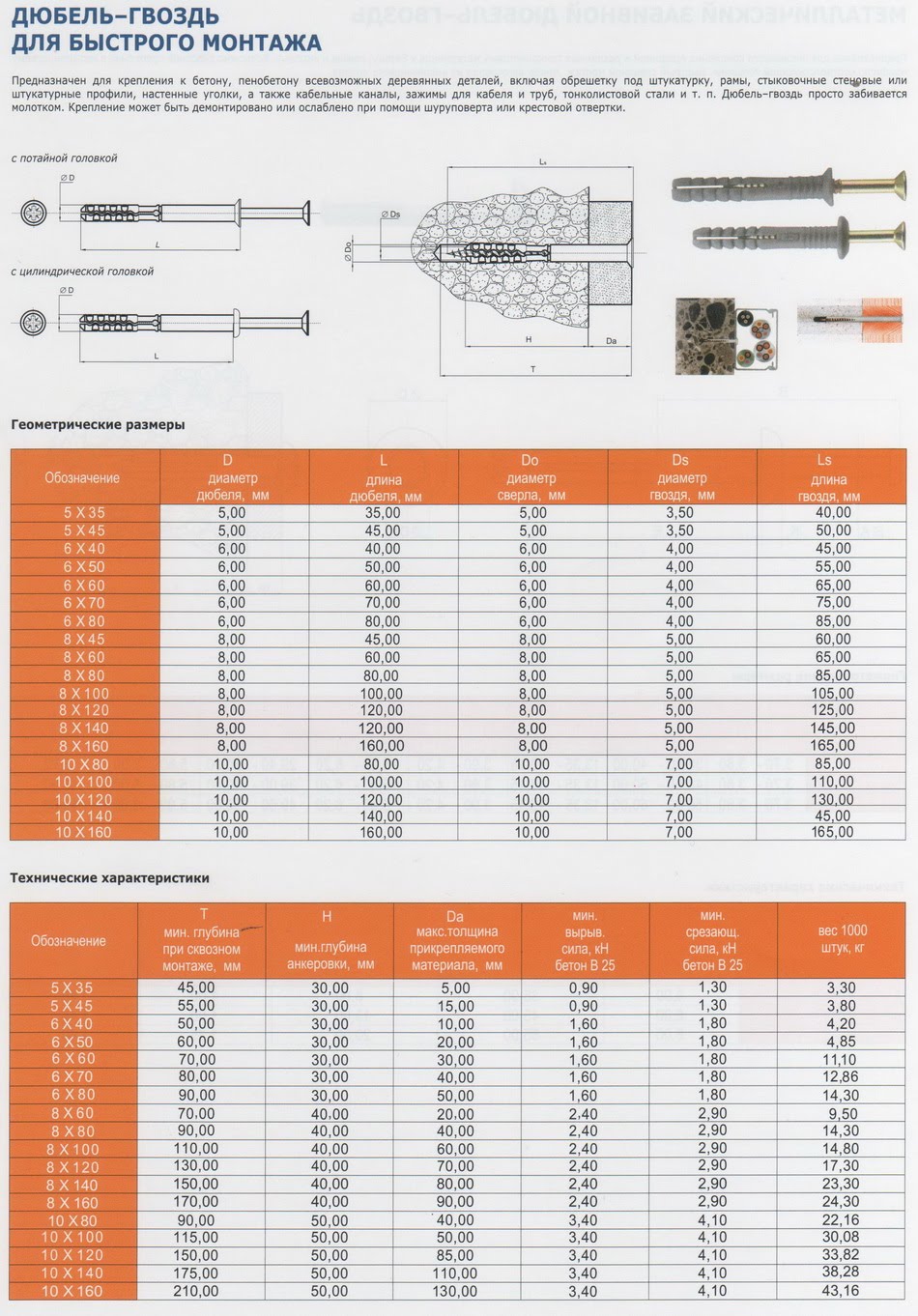

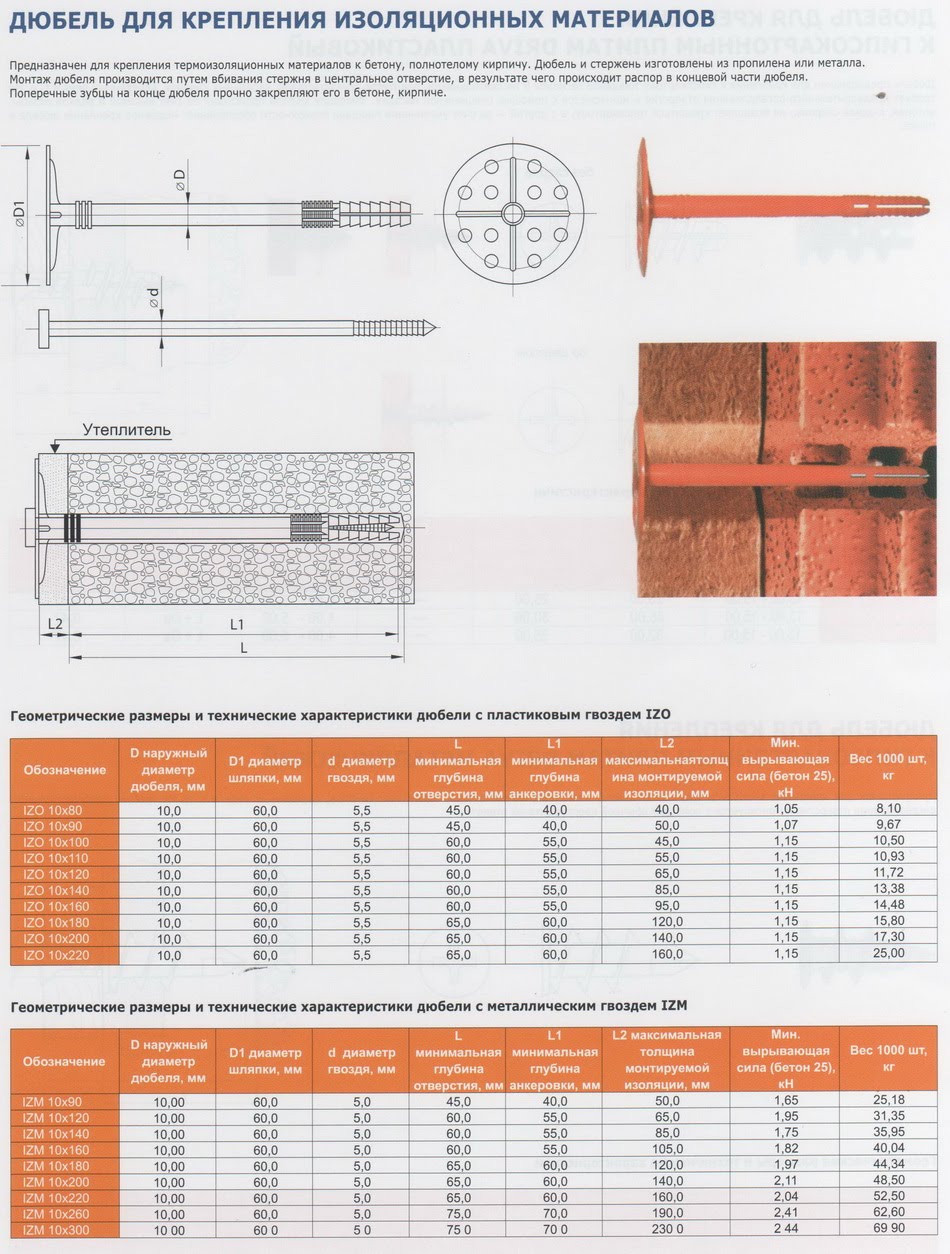

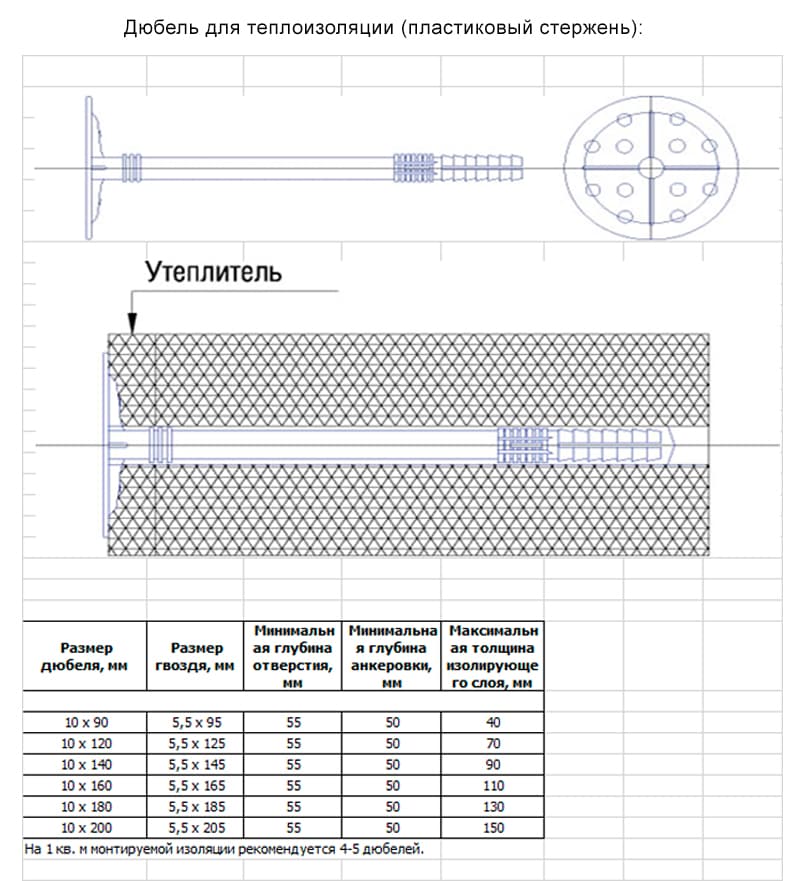

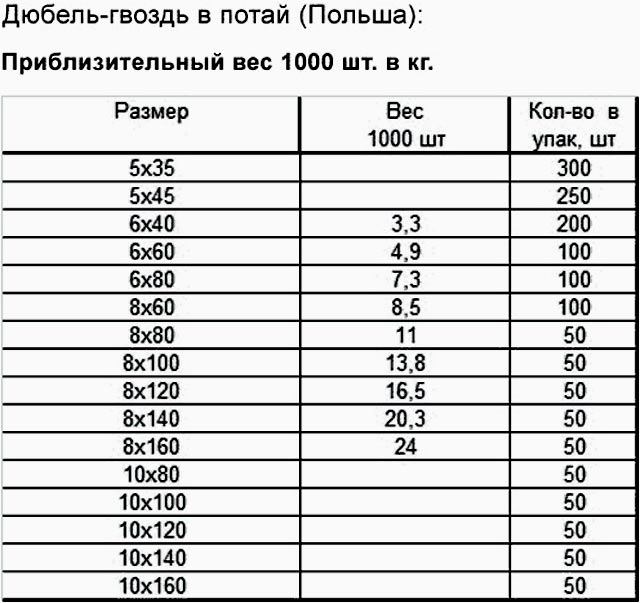

As for the length, it varies from 30 millimeters. The longest specimens reach 160 millimeters in length. It is this kind of dowel-nail that is used for thermal insulation. The wide pressing cap has given rise to the fact that sometimes such a dowel is called a disc-shaped dowel.

The process of fixing the plinth to the wall

So the tools and materials are ready, let's get started!

If you have a wall that is clearly longer than the plinth strip, then you can start with it. For example, let's go from the door. You need to understand that a skirting board with a length of 2.5 or 3.0 meters must be screwed to the wall in several places. For example, I screwed a skirting board 2.5 meters long with 4 self-tapping screws. Accordingly, we need to drill the plinth in 4 places. I would recommend that you step back about 5 cm from the edges of the plinth strip and drill holes on each side. Further, in order for the attachment points to look aesthetically pleasing, it is better to maintain the same distance between the fastening screws. That is, we take a tape measure, mark the drilling sites and drill. The end result is a skirting board with symmetrically drilled holes.

So, we begin the installation of the floor plinth. We take a drill with a diameter of 4.0 for wood and drill:

Next, we attach our plinth to the wall, and we attach it to the edge of the door trim. We take a perforator, install a victorious drill bit for concrete, also with a diameter of 4.0 mm, and outline the first hole in concrete through the plinth:

It makes sense to immediately drill into the depth of the wall for about the length of the self-tapping screw. Then, so that the plinth does not move away from the hole in the concrete, we directly take the self-tapping screw and insert it through the plinth into the hole in the concrete (while without a dowel, just to fix the plinth. Go to the next hole in the plinth and again through it we make a hole in the concrete with a drill with a diameter of 4.0 mm Insert the self-tapping screw again and go to the third and then to the fourth hole.

As a result, we have outlined 4 holes in the concrete wall through which we will fix the plinth. Now we take out the self-tapping screws, remove the plinth and install a 6.0 mm diameter drill into the hammer drill.

Yes!!! I almost forgot! Before drilling a concrete wall, do not forget to place an emphasis on the hammer drill on the length of the self-tapping screw. In this case, when drilling a wall, the depth of the hole will not exceed the length of the self-tapping screw. So, we make 4 holes for the dowels:

If you do not remember at all how to drill the wall and fasten the dowels, then take a look at.

Well, the holes are ready. We insert our dowels into the holes. Now everything seems to be done and you can install the skirting board. But wait! We forgot one thing. On the plinth, you need to countersink all the holes. Let's get down to it.

NUANCE!

We have an expensive veneer skirting board.When countersinking holes, you need a very firm hand, which will drill the holes for the screw head. Ideally, have a drilling machine for such purposes :). But not everyone has it, so you have to work with a drill. If the hand trembles, then the veneer around the hole is pulled off unevenly and the plinth can be damaged:

In the figure, you can see an unsuccessful countersink result. Therefore, if you have an expensive plinth, I strongly recommend that you take one plank (you still buy a plinth with a margin) and practice: drill several times from the edge of the plinth, put your hand, maybe change the drill or experiment with a countersink. After some torment, you will achieve the result, but then also carefully make holes on the prepared plinth:

After we have countersinked all 4 holes on the baseboard, it's time to screw it to the wall.

We take a screwdriver, and if not, then a drill, install the bit and fasten the plinth:

Nuance!

Do not fully screw in the screw with a screwdriver or drill. You can inadvertently miss the moment when you need to stop screwing, which will lead to unnecessary drowning of the screw in the baseboard. And since the veneer is removed at the countersink, then when the self-tapping screw is deeply drowned around its head, white wood under the veneer will be visible. Therefore, it is better to tighten the main part with a screwdriver or drill, and in the end, manually tighten it with a regular screwdriver.

Well, here we are with you and screwed the first plinth strip. If you have a cable running along the wall, then it is clear that it needs to be hidden behind the skirting board:

Related Posts via Categories

- Bolt strength class - how well do the hardware resist shattering?

- Anchor bolt with nut - proven fastening option

- Anchor bolts - a special type of fasteners for complex structures

- Bolt designation in accordance with GOST - we are guided in the world of hardware

- How to rivet a rivet - automatic and manual methods for different materials

- Bolt manufacturing - straightforward workflow

- Spring Cotter Pin - Eared Fastener for Mechanical Engineering

- High Strength Bolts - Complete Fastener Information

- Blind rivet sizes - what should you think about when calculating?

- Spring washer - connections will never spin spontaneously!

Product classifications

When choosing a mount, 5 main factors are taken into account:

- load value - on the dowel, on the surface, on the structure;

- the nature of the load - stationary, dynamic;

- type of fixation;

- the nature of the material - stone, concrete, brick, drywall;

- surface construction - wall, ceiling.

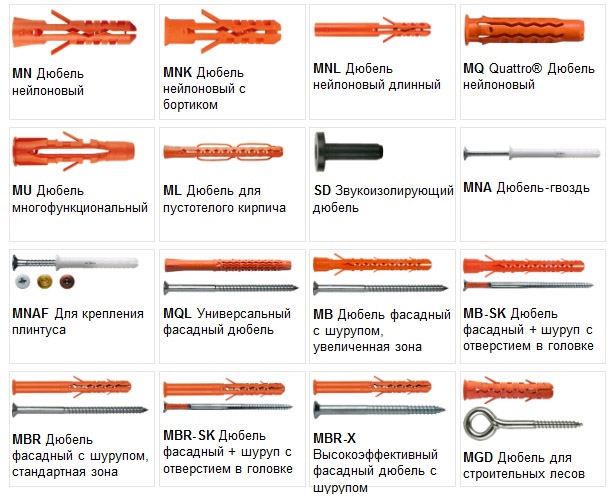

Actually, there are several types of fasteners for different methods and materials.

The video below tells about the rules for choosing dowels:

By type of installation

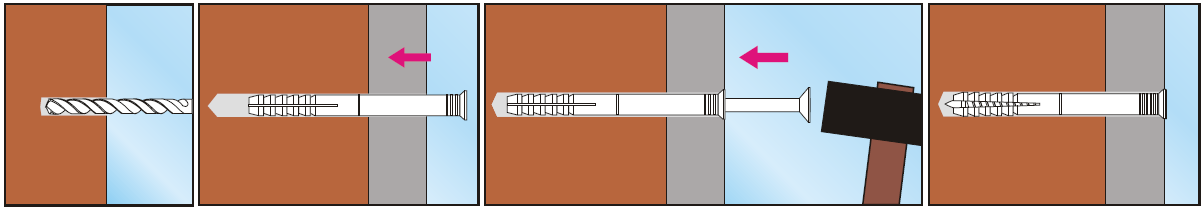

The dowel, or rather, the nail, can have a slightly different structure, due to which you need to work with it with different tools.

Manual assembly - that is, using mechanical tools. Nails for such work are divided into 2 types:

- without thread - the nail is hammered in with a hammer, there is no way to unscrew it;

- threaded nail - driven in or screwed in. Its main advantage is the possibility of dismantling.

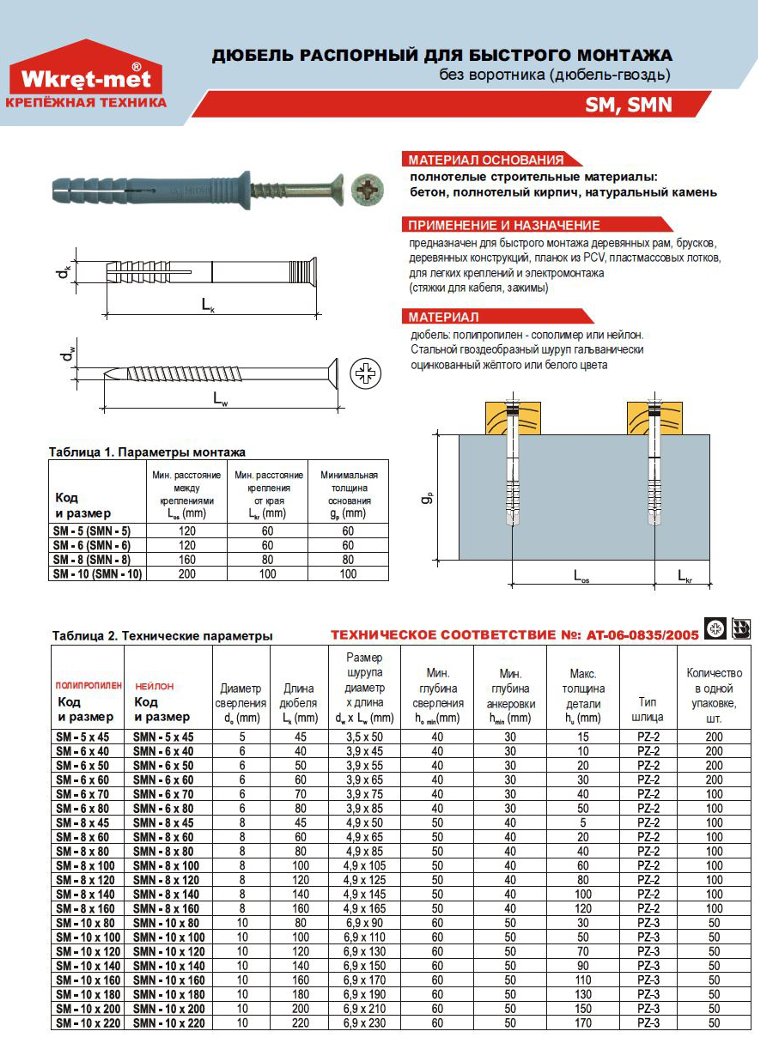

Installation using a construction and assembly gun - the nail has a restrictive collar, but does without a spacer body. This option provides a much faster installation and, moreover, is designed for a higher load.

By surface material

More interesting from the user's point of view, as it allows you to determine which fasteners are suitable for which wall or ceiling.

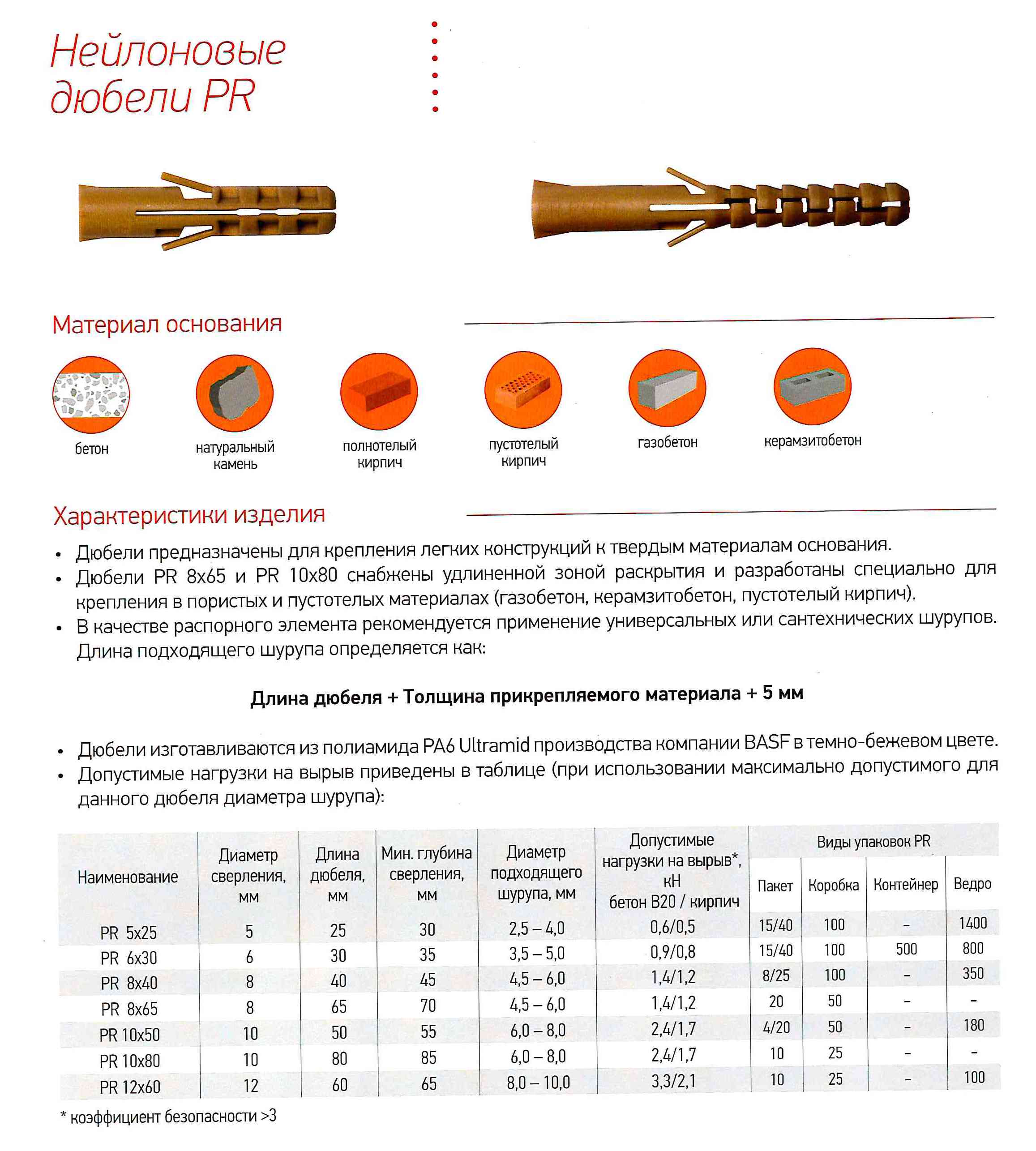

- The most common are threaded or non-threaded nylon plugs with diameters ranging from 2 to 16 mm. They are used for fastening to standard building stone - brick, concrete, and can withstand from 200 to 450 kg of stationary load.

- Dowel for aerated concrete - the material is considered to be relatively low-porous, so such an attachment is quite acceptable.The dowel is held by spiral ribs and wedging when driving a nail.

- Frame - have a great length, from 60 to 360 mm. They are produced in 2 types: for solid solid material and for hollow slotted material. The expansion part of the dowel is lengthened and is designed so that when passing through the slotted base, the dowel will hook several jumpers, which will provide fasteners.

- Distance dowels allow you to fix elements - lathing, for example, at some distance from the wall. The distance can vary from 1 to 30 mm. The distance plug is divided into 2 parts - one for the rail, the second for the material, and connected with a screw of a special design. In this way, numerous irregularities in the wall can be compensated for and a perfectly flat surface can be obtained.

- Universal - able to "independently" determine the presence or absence of voids. When fixed in solid material, the spacer body expands and is tightly fixed, and when it enters the voids, it bulges and adheres to the support.

- Metal dowels behave in the same way, that is, with a metal case. They are designed for attachment to thin-walled surfaces, but at the same time they hold a sufficient load. When the screw is screwed in, the metal dowel bulges and presses against the thin support.

- The nail dowel provides quick installation of battens, skirting boards, battens and other things, when it is necessary to strengthen a large number of elements. The nail here is knurled in the form of reverse cones. It is inserted together with the dowel into the drilled hole through the rail and hammered in with a hammer. Cannot be dismantled.

- Products with spring-loaded folding strips - butterfly dowels, are used to fix objects to a hollow surface - to false ceilings, for example, when installing a chandelier. Having passed the hard layer, the dowel opens under the action of the spring, rests against the skin from the inside. Typically, the model is sold with hooks or threaded rods.

- For fastening structures with a large weight to concrete and solid bricks - garage doors, sun-protection awnings, and so on, metal dowels with threaded rods or bolts are used. The fasteners are designed for a very heavy load - up to several tons.

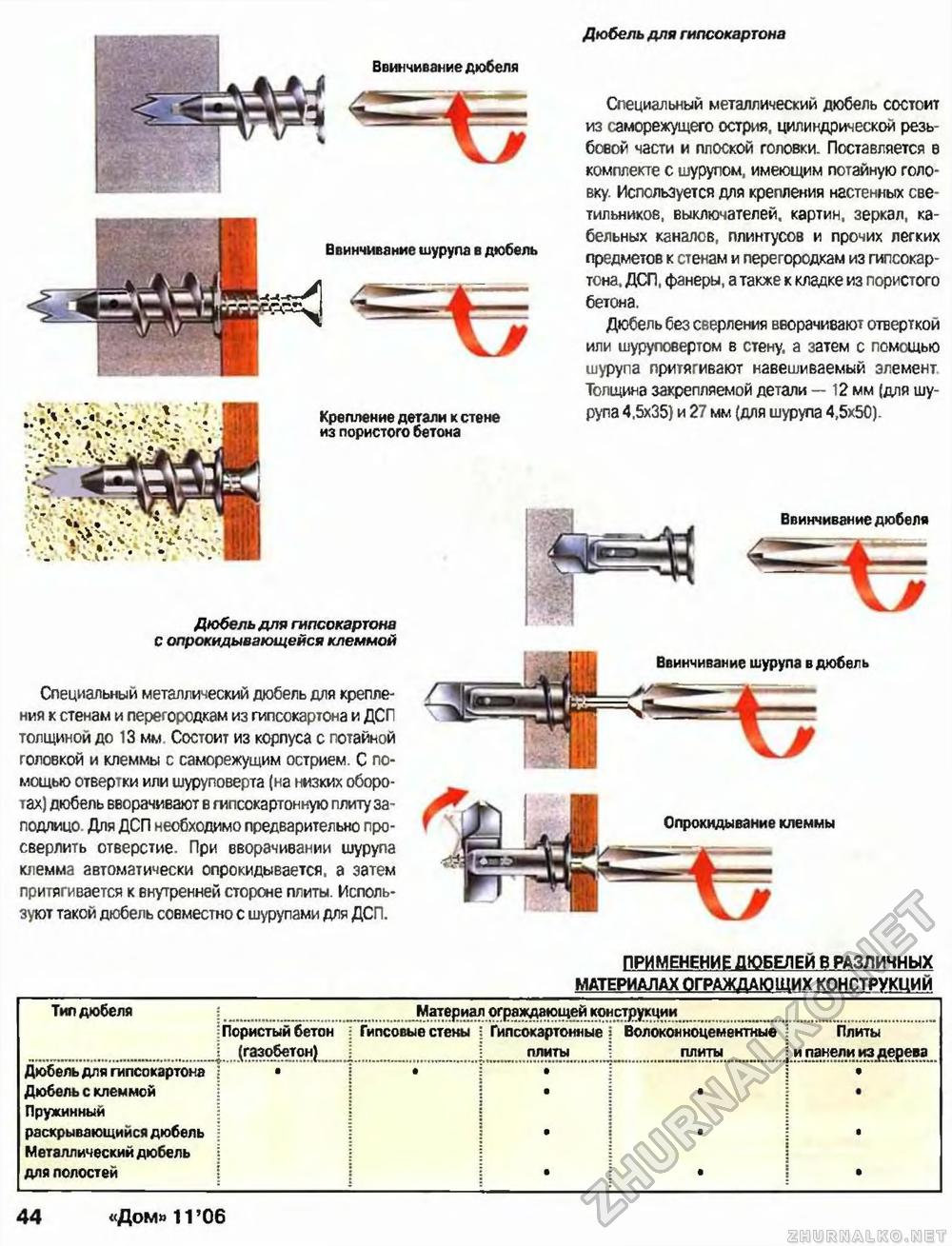

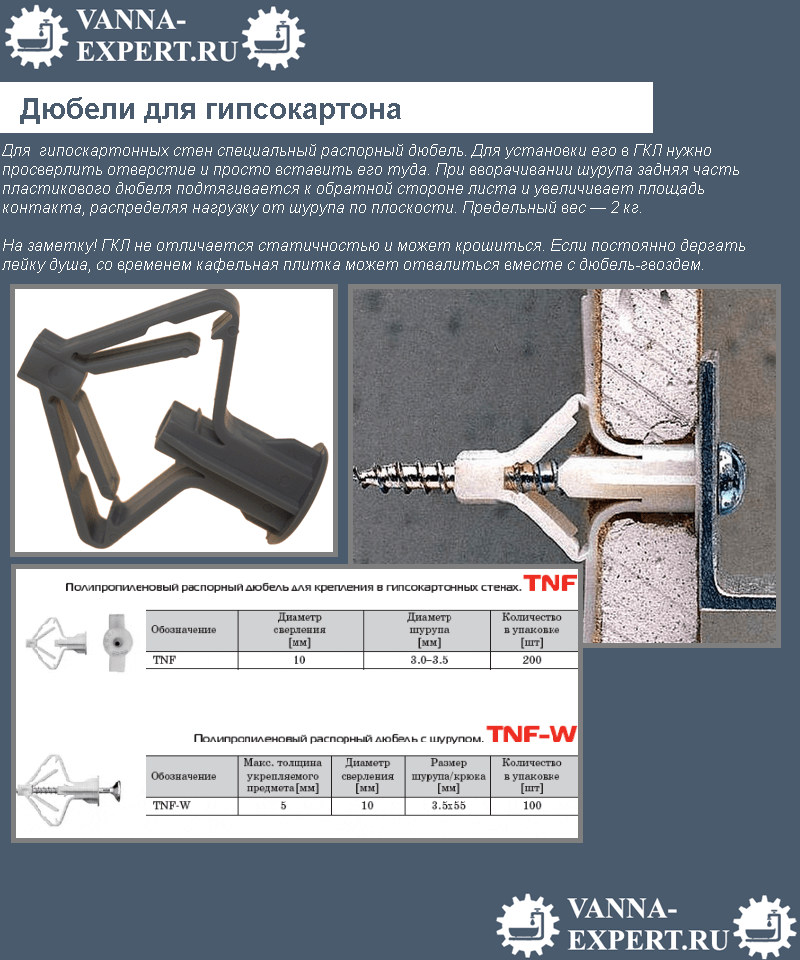

- Dowels for drywall and aerated concrete - both metal and plastic, have a tip in the form of a pinned drill and a large thread on the spacer body. For such dowels, the hole is not drilled, but the entire structure is screwed in with a regular screwdriver.

- Insulation holder - a special dowel for fixing a heat insulator or solid foam material. Holes for it are drilled in brick and concrete, but the dowel itself is hammered in without a nail.

- A very specific type is the injection dowel. A mesh anchor is inserted into the hole for the fasteners, then a dowel is driven in and a quick-hardening compound is injected through a protective sleeve with a syringe. Under its pressure, the anchor mesh inside the material expands, forming an anchor in the form of a ball. When fixing in a slotted brick, it is allowed to use a dowel without a grid.

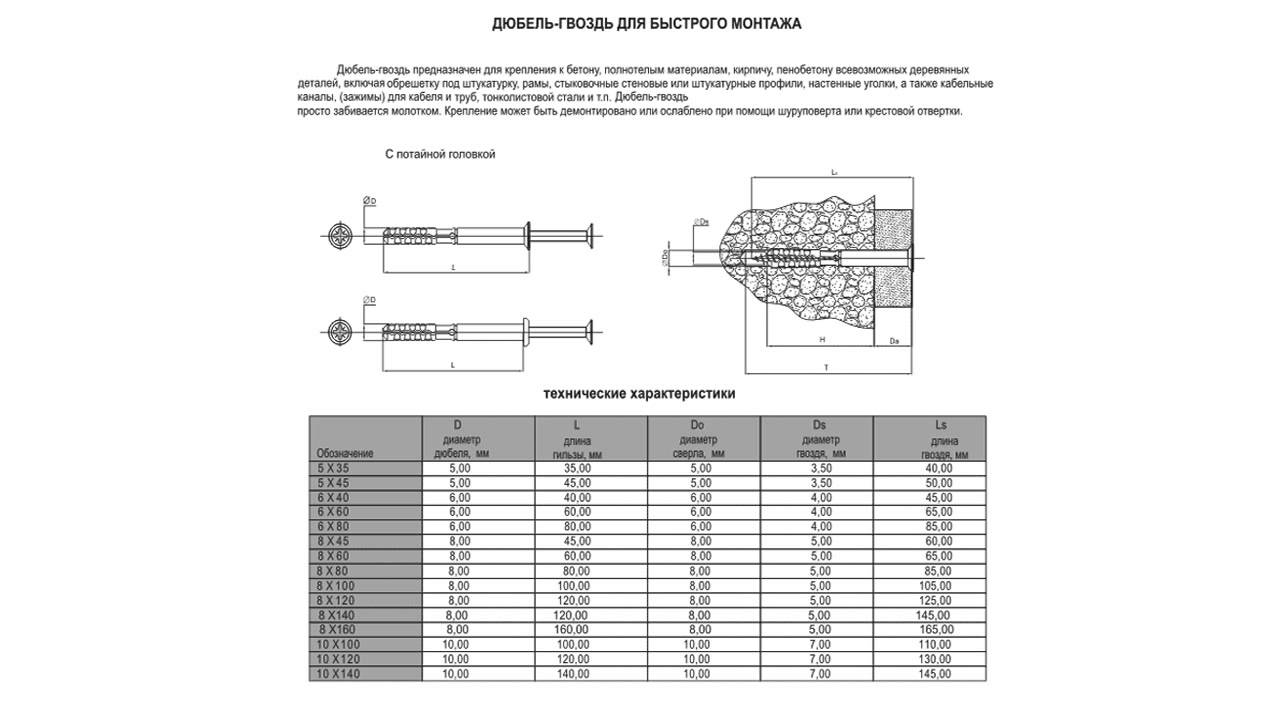

The length, thickness, weight of the dowel-nails are discussed below.

Mounting features

It is quite simple to use fasteners in the form of a dowel-nail with minimal skills in working with an electric drill and a hammer. It is quite possible to install fasteners for household needs on your own, without inviting hired craftsmen to perform these works. Before you start fixing, you need to calculate the number of dowels, their diameter and size. To complete the work, you will need to use a hammer, an electric drill with a victorious drill or a perforator with a drill, and you also need to prepare the selected number of dowels-nails. To use the fasteners correctly, you need to know whether the dowel fasteners will have to be tightened, or they will need to be hammered.

On a brick

A hole is made in the intended section of the wall surface, and, in order to avoid the formation of cracks in the body of the brick, they begin to drill at low speeds of the drill, gradually increasing them, but only when the depth of the hole reaches 8-10 mm. Before installing the dowel, dust and small brick chips are removed from the hole, and then the dowel is driven in with a hammer.

On concrete

The area for the hole is marked with a center punch, after which they take a perforator and drill the hole to the required depth. The diameter of the drill or drill bit for drilling is required to be taken equal to the diameter of the dowel fastener. As for the length of the hole, it is made 5-6 mm longer than the dowel you have chosen. Further, dust and fragments of material are removed from the hole using a household vacuum cleaner. Then the dowel is hammered into the hole with a hammer, and the screw itself is screwed in or hammered into the dowel structure. When hammering in a screw, you need to leave 3-5 mm of its free edge of the head in order to suspend the structure to be mounted.

On drywall

Great care is required from the installer when working with this fragile material. First, a hole of the required length and diameter is made in the drywall, and then the dowel fasteners are inserted all the way, lightly tapping on its head with a hammer, after which it is required to screw the screw into the dowel structure with a screwdriver. When working with plasterboard surfaces, you need to measure the mass of the structure attached to them.

On ceramic tiles

During installation work, the ceramic material should be treated with care, as it has increased fragility. A place for drilling a hole is marked on the surface of the tile, then a metal drill is taken and a depression of 0.5 mm is made, that is, a layer of enamel is removed. Next, they take an electric shock drill and drill a hole of the required depth. The structure of the dowel fastener is placed in the hole until it stops and the screw is tightened.

The listed installation methods imply that the dowel-nail will be screwed or hammered into the working hole. But, in addition to these options, there is another way to mount the dowel attachment. To implement it, you will need to take a special construction and assembly gun, with which the structure is "shot" to the working monolithic surface. This is most commonly used for concrete. In the work, they use a special dowel, which is equipped with a special washer, which is responsible for the tight fit of the fasteners in the wall. The construction and assembly gun has a peculiar device that, after pressing the trigger, shoots the dowel into the wall, and this action moves the washer from the end of the dowel fastener to its head, securely fixing the mount in the wall.

For information on how to install the dowel-nail into the wall, see the next video.

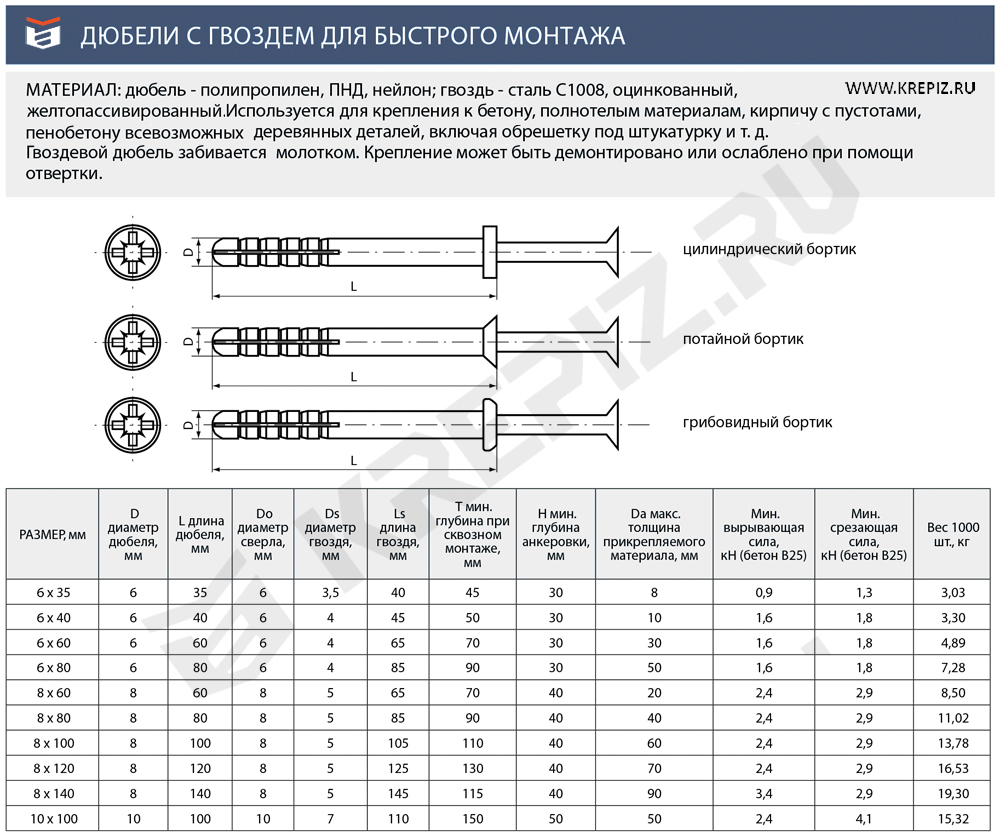

1 Technical characteristics of dowels - what are the standards of GOST and TU?

Based on the standards that are prescribed in GOST 28457-90, various technical conditions can be changed in the production of dowel nails. Sometimes it is allowed to change the weight, diameter, structure and length of the fastener, if the manufacturer has sufficient technical grounds.

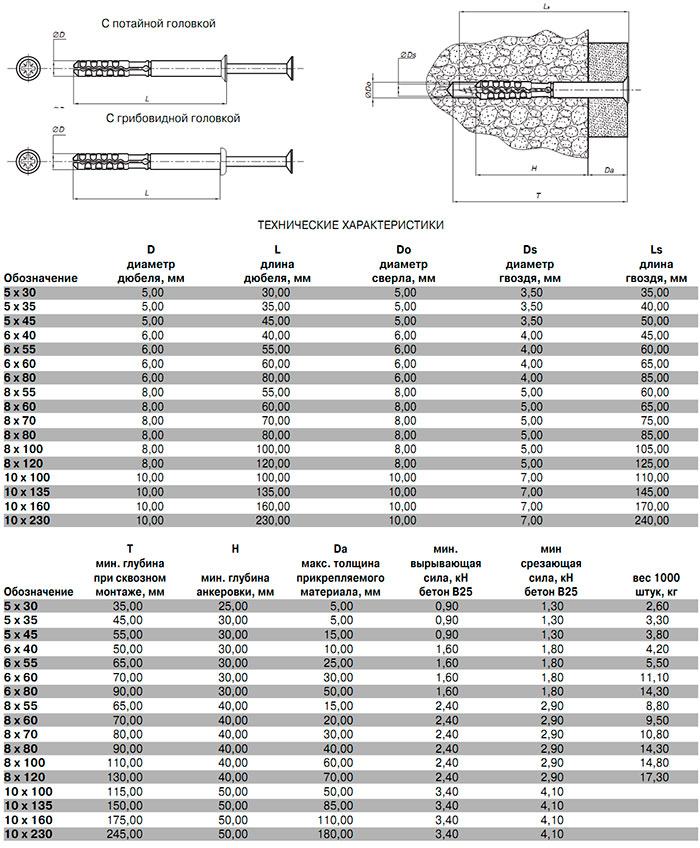

Technical characteristics of nail dowels

Technical characteristics of nail dowels

However, there are several norms that must be constantly observed by the dowel manufacturers, regardless of new technical conditions, namely:

- Production material. Dowel-nails must be made of low-alloy steel (wire rod), which corresponds to the VK or KK classes, with the obligatory passage of the appropriate heat treatment of the material. The strength index of finished products must be at least 53 HRC according to the strength table.

- Minimum and maximum curvature of the rod. With a rod length of more than 50 mm, a maximum curvature of 0.1 mm is allowed, and for a length of more than 50 mm, a curvature of no more than 0.15 mm. The rod should not have cracks along the base, while the bluntness of the point of more than 0.8 mm is not allowed.

- Galvanized. The thickness of the protective layer that covers the nail must be at least 6 microns, while the layer must be applied strictly in compliance with the recommended galvanizing and passivating technology.

- Compliance with the norms of misalignment of the metal rod and the diameter of the washer. This indicator should not exceed 0.4 mm for various types of dowels. In the presence of corrugation, its depth cannot exceed 0.15 mm.

Dowel clamp.

Dowel clamp is a fastener designed for fastening wires of different diameters, metal hoses, flexible and rigid pipes, cables, corrugated hoses to solid walls, for example, brick or concrete. It combines the functions of an embedded part - it is mounted into the wall, and the functions of a clamp - fixes the wire (cable, pipe, etc.). The dowel can be made of nylon, polyethylene and polypropylene. Such dowels are round and flat in shape.

According to the shape, the dowel clamp can be divided into three types:

1. Bracket - a plastic toothed strip, used to fix wires with a diameter of 6-25 mm.

2. Expansion dowel clamp - "helicopter" or "herringbone". This is a dowel with a loop or arc, into which a plastic expansion rod is inserted. Withstands a higher load - up to 8 kg.

3 The mounting platform with a clamp is a plastic dowel of the usual type with teeth, at the end there is a rectangular loop. The clamp is threaded through the loop and secures the pipe or cable. This dowel can be tightened into a bundle of wires or pipes of different diameters.

Types of dowel-nails

Builders have to use different tools depending on the conditions. For example, fastening an object to a concrete or plasterboard wall has a significant difference.

In some cases, the reinforced strength of the rod is important, in other places - thermal conductivity and moisture resistance. Even a simple seemingly driven dowel-nail has several varieties that differ not only in size and material, but also in the method of installation

Common types of dowel nails:

- Dowel-nail for manual installation.

- Dowel-nail for pistol - installation is carried out using an automatic device, which greatly accelerates the progress of work. He has no spacer part. The nail is made of the strongest steel (hardness 53-56 HRC, bending no more than 0.1 mm).

- Acoustic dowel-nail - in the manufacture of fasteners, not metal is used, but plastic and fiberglass, which prevents corrosion or the passage of cold. Consumables of this type are used for the installation of thermal insulation, sound insulation, cable ducts, decor.

- Dowel-nail "umbrella" - has a wide head and a long body, used for fixing thermal insulation.

Plastic dowel nails

The plastic cup has a spacer and non-spacer surface. The plastic dowel-nail is equipped with a collar that prevents the fasteners from falling into the surface. The presence of toothed elements prevents the product from scrolling in the hole. We list the common types of plastic fasteners:

- Universal dowel - used together with wood and chipboard screws, screw-screws, suitable for hollow and solid materials.

- Expansion plug S - nylon fasteners have a double-sided spacer. The absence of a stubborn edge allows you to hide the dowel inside the plaster.

- Expansion plug M-S - Suitable for working with standard bolts or threaded rods.

- Dowel for aerated concrete GB - the presence of spiral ribs allows to provide the strongest fit in soft material.

- Dowels for mounting TV / TVV steps - have a good surface geometry to prevent squeaking, vibration. Fasteners of the TV brand have a small spacer for installation in a steel profile.

Metal dowel-nails

The use of a steel spacer sleeve increases the cost of the estimate, but allows an increase in the design load.A metal dowel-nail for a foam block, brick structures or concrete structures is installed in the same way as plastic fasteners. We list the advantages and disadvantages of such a product:

- High load-bearing capacity.

- Metal does not stretch over time.

- Galvanized or stainless steel sleeve is corrosion resistant.

- Large selection of fasteners.

- Simple installation.

- The cost of metal dowel-nails is higher.

- It should be borne in mind that steel fasteners can create more stress, so it is better to place them further from the edge.

Some helpful tips

- It is better to hammer in the nail with medium-strength strikes, doubling the effort only after it stably enters the base in the correct position. The hammer is held by the end of the handle. When making a blow, you need to look at the head of the nail.

- To perform work on a plastered surface, it is advisable to use a punch: it is applied to the head of the nail and hit. A hammer can cause defects.

- To nail the telephone wires, they are first pierced with fasteners where there is no contact with the veins, and only then they do the work.

- Well, a little stupid advice: you can drive a nail with your bare hands only into soft surfaces - clay, for example. So do not try to do that with harder materials for your own safety.

Using the advice of the masters and taking care of all the necessary tools, subject to the correct choice of the nail in accordance with the type of base, tasks and sizes of fasteners, it is quite possible to do all the work quickly and efficiently. A nail correctly driven into concrete or other surface will be able to withstand optimal loads and ensure a secure attachment.

Dowel material and design

The patent for the invention of the dowel was issued in 1913 by D.D. Rawlings in London. It was invented earlier, but by whom - history is silent. These days, most buildings are built of concrete and stone, so with only a hammer and nails, hanging anything on the wall in such a building is unlikely to work. For these purposes, a lot of different fasteners are produced today.

Until recently, wooden chopiki were used as a dowel, under which holes were drilled in the wall, and nails were driven into them or screws were screwed in. Today this technique is falling out of use.

Dowel manufacturers produce metal and plastic products. Most often, in everyday life, nylon driven dowels with self-tapping screws are used; with their help, you can solve most of the problems of fixing something not too massive to a wall made of almost any modern material.

Nylon is suitable for both internal and external work, which cannot be said about polypropylene. Its use is limited to indoor areas, since it is very sensitive to temperature changes, cracking at already insignificant frosts.

The spacers of the dowel are tendrils on the sides of its surface, which reliably wedge the dowel with a screw in the wall and prevent them from turning together.

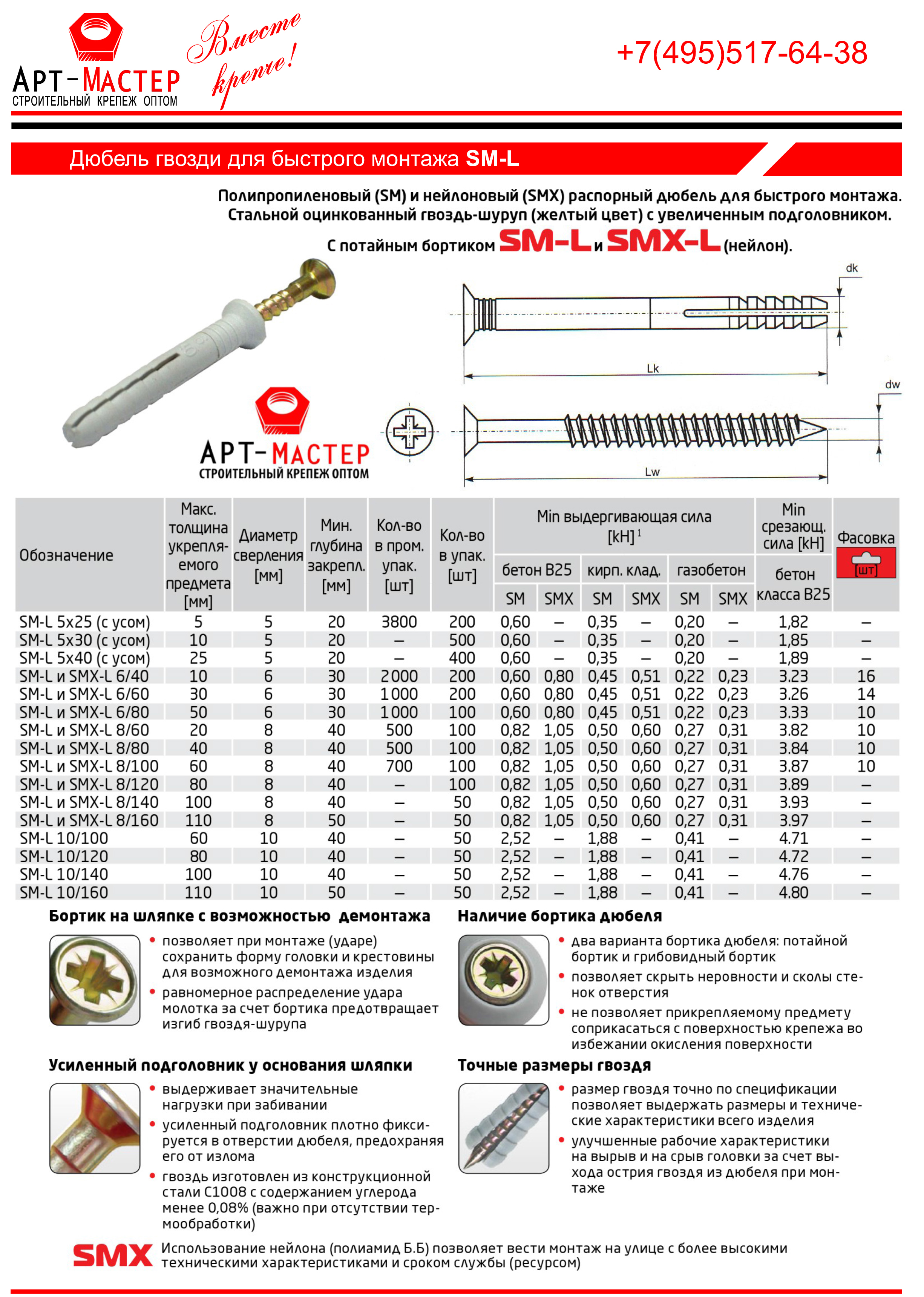

1 The structure and principle of operation of dowels-nails

Using dowels-nails makes it equally easy to work with concrete, wood or brickwork. Especially quickly it is possible to carry out such operations as fixing skirting boards, finishing external walls with cladding or working with plasterboard structures. Fasteners are also often used for thermal insulation of a house, installation of gutters over windows and balconies.

For proper operation, it is important to understand what a dowel-nail is, its principle of operation and features of working with various materials. Dowel-nails for various materials

Dowel-nails for various materials

Dowel-nails for various materials

The dowel-nail is a special-shaped fastener designed to increase the installation speed. Its main components: a nail with a tapered thread, narrowed towards the tip, which allows you to work with it without problems not only with a screwdriver, but also with a hammer, and a plastic dowel.This type of fasteners is widely used in work with brickwork, concrete walls, as well as for drywall, natural stone and other materials.

The main difference between the nail dowel and other types of dowels is that the main fastening element acts on the principle of a nail, not a screw. Although some manufactured products have a cross recess in the head, working with dowels is much faster with a conventional hammer.

The plastic part of the fastener, when a nail is driven into it, expands and provides a reliable and durable fastening. One of the edges of the dowel has a special expansion - a collar, which does not allow the dowel "headlong" to go into the intended hole. The cuff can be of different shapes, depending on which there are several types of dowels:

- Fungus nail. This type of plastic part of the fastener has a rounded end, which, at first glance, resembles a mushroom. It is used in cases where the structure requires increased downforce. Due to the large thickness of the cuff, the pressure is evenly distributed and does not lead to destruction of the fastener or the pressed material.

- Dowel nail-sweat. Used in places where you want to hide the screw head flush with the wall.