Composition, production and varieties of oven bricks

Based on the conditions arising from the combustion of solid fuel, the kiln brick must meet three basic requirements:

- Heat resistance at least 1000 ° C without loss of strength after prolonged exposure.

- Low thermal conductivity protects the surrounding building structures.

- Heat resistance The product must withstand a significant number of heating and cooling cycles.

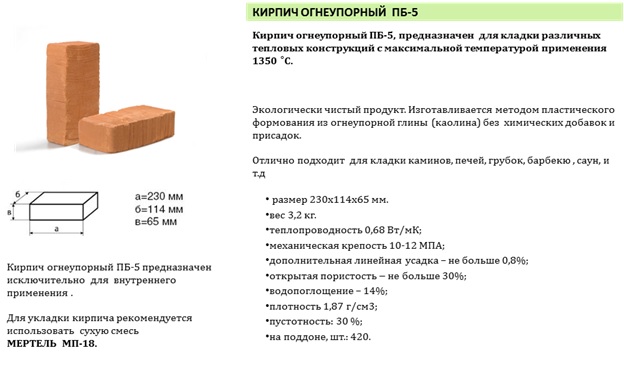

Furnace refractory brick is an excellent energy accumulator, in other words, it heats up quickly enough and gradually releases heat into the environment. Refractory bricks are manufactured at specialized factories according to the technologies provided for by GOST 390-96. The composition of raw materials used for the production of oven bricks as the main component includes refractory clay of special grades up to 70%. The introduction of some types of charge into the molding mass makes it possible to obtain blocks with different properties, additives can be:

- graphite;

- coke in powder form;

- large fractions of quartz powder.

The technology for the production of fire-resistant bricks by the method of semi-dry pressing provides for a number of operations in the following sequence:

1. Preparation of raw materials: grinding and kneading clay, introducing a charge, mixing until a homogeneous composition. During this process, up to 8-10% water is added to the composition to achieve the required moisture content.

2. The finished mass is loaded into the hopper, from which it enters the dosing carriage moving back and forth.

3. The molded brick is fed to the lower punch of the mold, which is lowered along with the workpiece.

4. The upper part of the press is lowered and puts enough pressure on the brick to compact it.

5. When the process is complete, the lower punch pushes the block out of the mold onto the platform. At this moment, the carriage begins to move from under the hopper with the next portion of the raw material moves the workpiece onto the conveyor belt.

6. The pressing process is repeated, and the raw brick is sent as the batch is formed for firing in a tunnel kiln at a temperature of about 1000 ° C.

This technology allows you to exclude the operation of preliminary drying of the product and reduce the time of its production. This method of producing fire-resistant bricks is much cheaper than the method of plastic molding, when a continuous bar is made from the prepared mass with a moisture content of 17-30%. The workpiece is cut by a special machine into separate blocks, which are fed for preliminary drying with subsequent firing.

On the building materials market, there is an extensive range of fire-resistant oven bricks of the following types:

Fireclay kiln brick

Semi-acid refractory brick

Dinas refractory bricks

Mullite refractory brick

Corundum refractory brick

| Refractory brick type | Refractory brick grades |

|---|---|

| Chamotny | SHAK; SHA-I; ShB-I; ShV-I (II); SHUS. |

| Semi-acidic | PB-I; PB-II; PV-I; PV-II. |

| Dinas | DN |

| Fireclay and semi-acid lightweight | SHLA-1.3; SHKL-1,3; SHL-1,3; SHL-1.0; SHL-0.9; SHTL-0.6; SHL 1-6.4; SHL-0.4. |

| Mullite-silica lightweight | MKRL-0.8 and MKRL-0.7 |

| Mullite lightweight | MLL-1,3 |

| Lightweight corundum | CL-1,1 |

| Dinas lightweight | DP1-1.2 |

| Mullite corundum | ISS-72 |

| Mullite | MLS-62 |

Technical characteristics of furnace refractory bricks depend on the type and brand, for convenience they are summarized in the table:

| Index | Normal value for a given brick grade | ||||||

|---|---|---|---|---|---|---|---|

| SHAK | SHA | SB | ШВ | SHUS | PB | PV | |

| Refractoriness, ° C | 1730 | 1690 | 1650 | 1630 | 1580 | 1670 | 1580 |

| Porosity of products,% | 23 | 24 | 24 | — | 30 | 24 | — |

| Tensile strength, N / mm2 | 23 | 20 | — | 22 | 12 | 20 | 15 |

| Content of additives | |||||||

| Al2 O2 | 33 | 30 | 28 | 28 | 28 | — | — |

| Al2 O3 | — | — | — | — | — | 14 — 28 | 14 — 28 |

| SiO2 | — | — | — | — | — | 65 — 85 | 65 — 85 |

Criteria and Requirements

In order for the heating structure to serve for a long time, it is necessary to perform masonry from high-quality raw materials, suitable for specific conditions. The material is chosen individually for each house or room, taking into account the wishes of the owner, based on the main characteristics of brick products. The criteria for which brick it is better to lay the stove from may be different, but the requirements for this building material are the same.

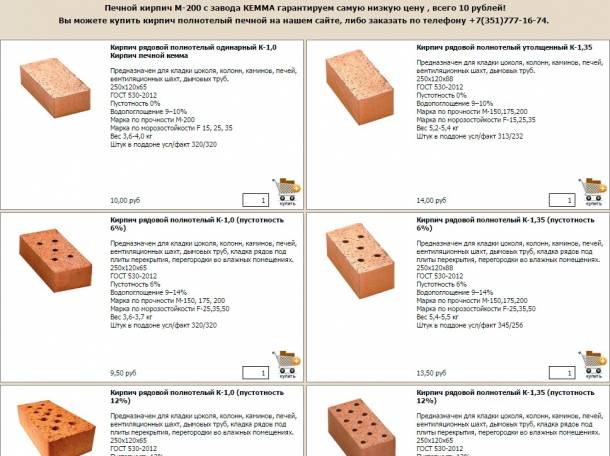

Marking

Blocks for assembling furnaces have a separate marking with the letter M, after which they put a digital designation of the withstand weight load. The numerical parameter is calculated for each square centimeter of the product and can vary from 150 to 250 kg.

It is better to skip other letter designations - the letters U (thickened) or P (hollow, hollow) are completely unsuitable for the construction of furnaces.

Fireclay blocks are designated by the letter W, after which the presence of signs A or B is a direct indicator of the purpose for laying furnaces. When a number is printed instead of the second letter, it means that the manufacturer deviated from the standard procedure during the manufacture of bricks. But this method of release must be carried out in accordance with the approved technical conditions.

Marking

Marking

Heat-resistant bricks for stoves, which are best suited for a heating structure, are most often not marked in any way.

What kind of brick is needed for laying a stove? When choosing raw materials, you should pay attention to the presence of a label about the frost resistance of products, which is also important when building a structure. The optimal indicators are any in the range from 75 to 100

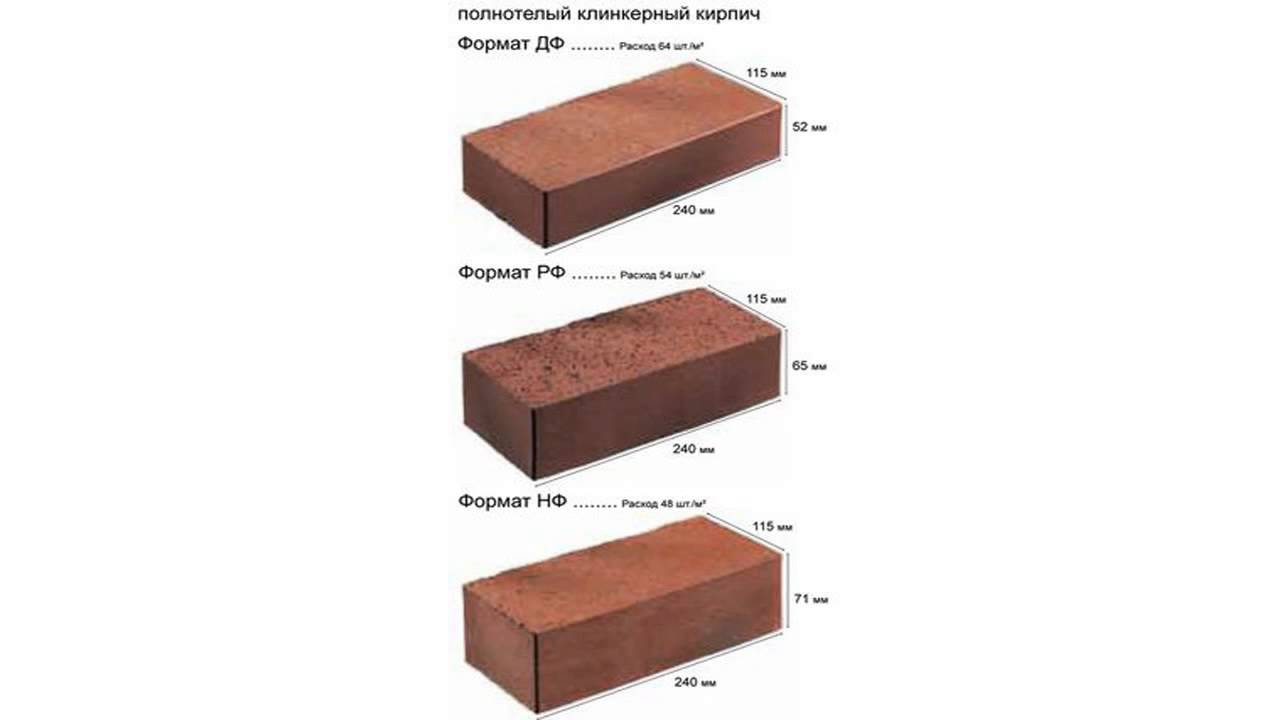

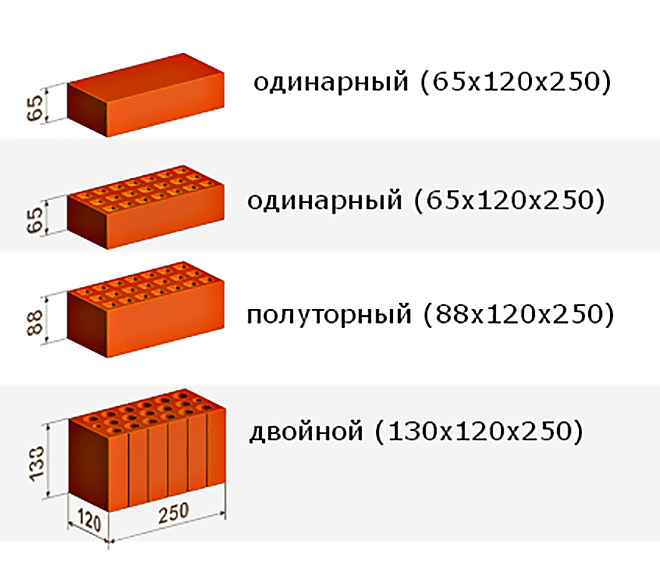

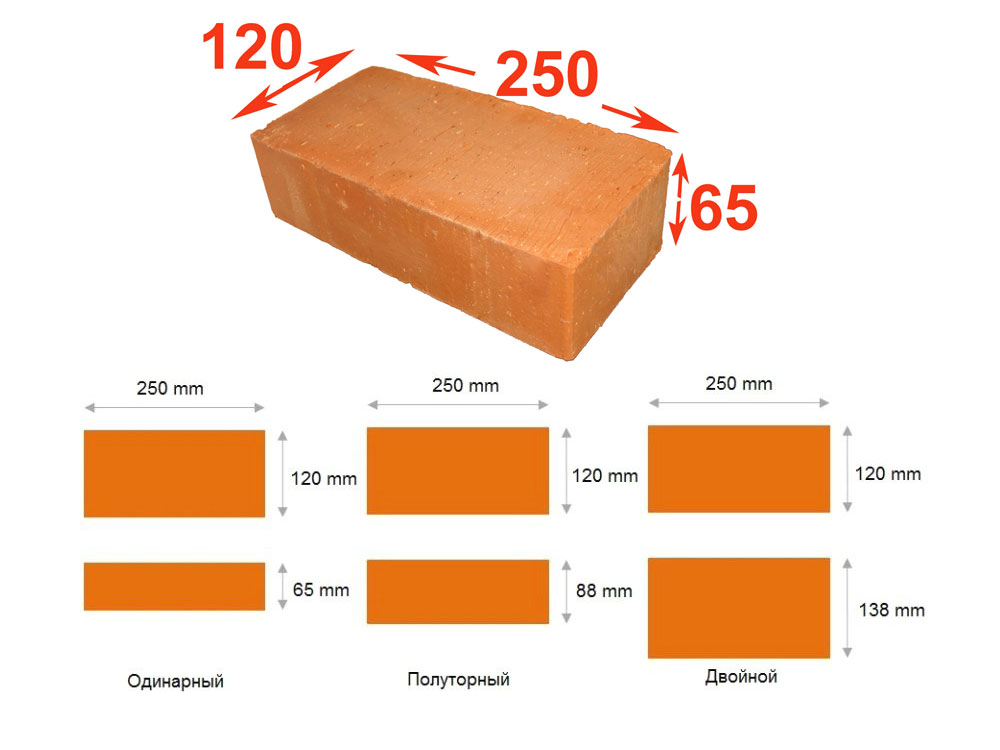

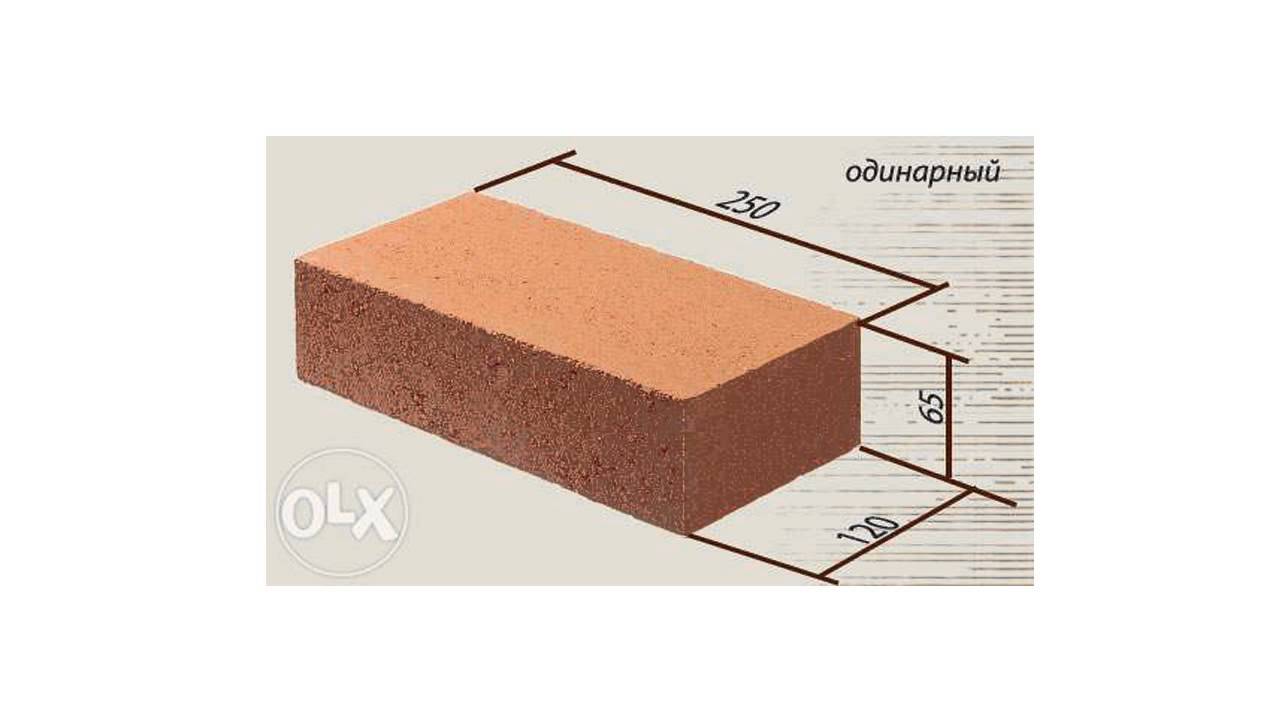

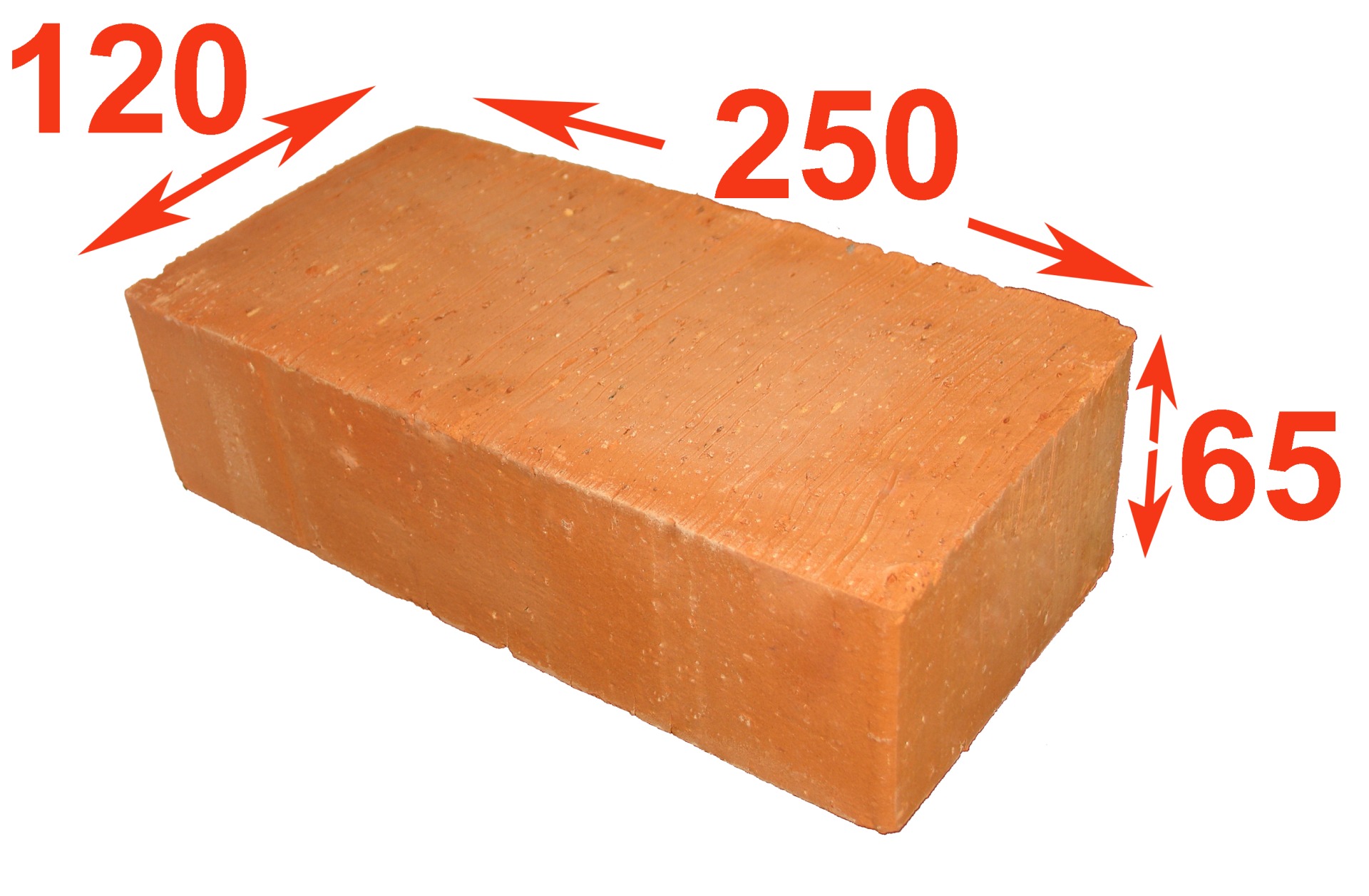

The size

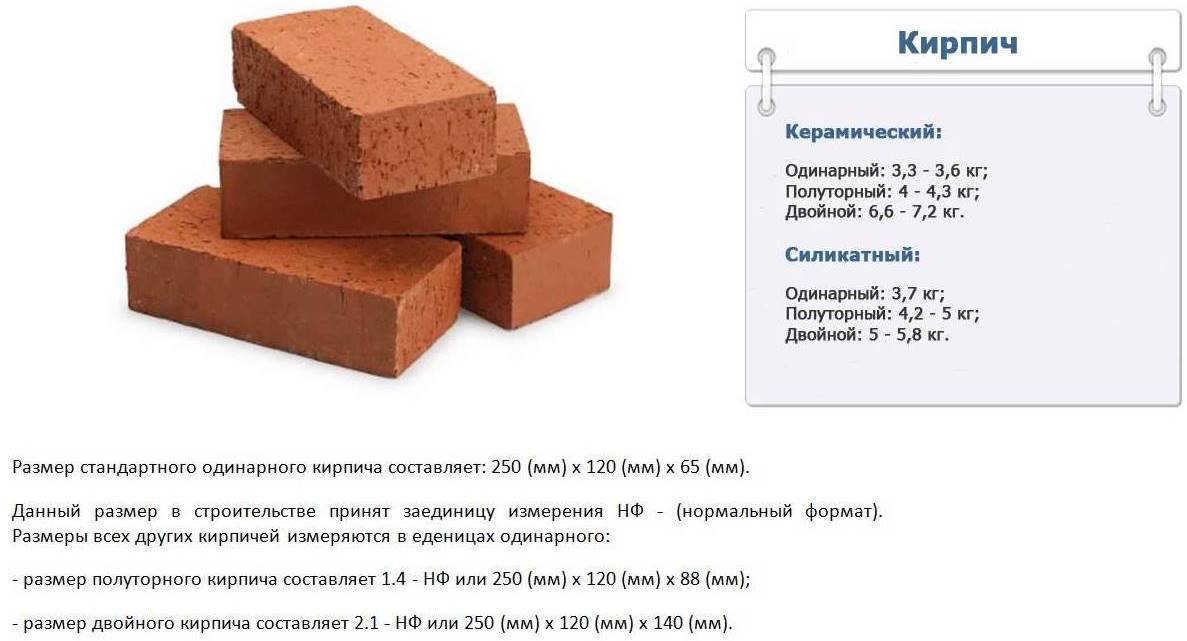

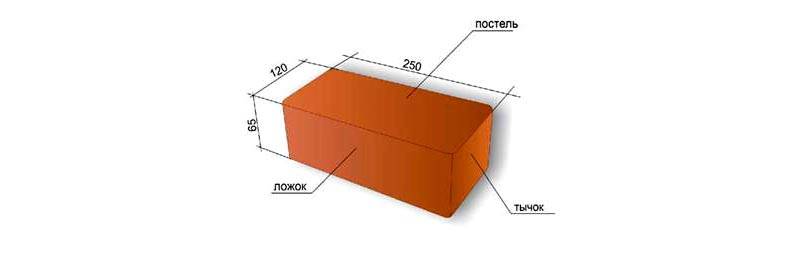

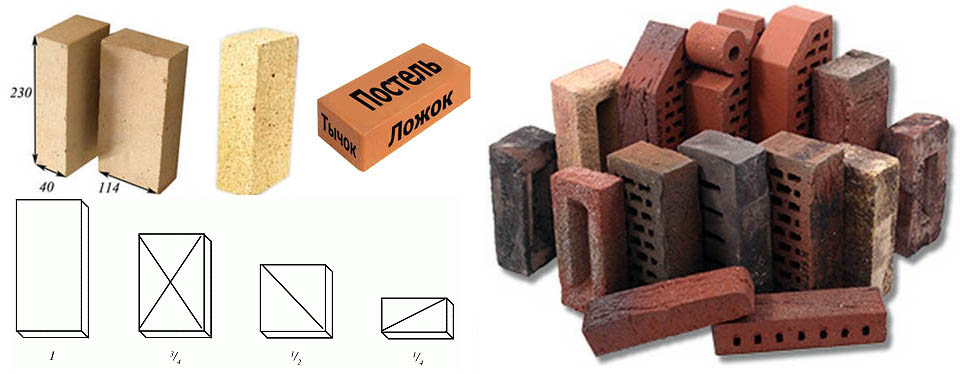

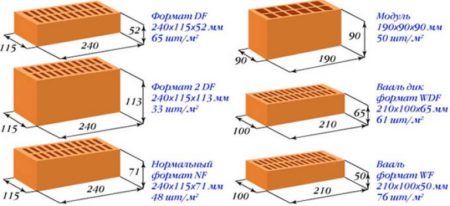

There are many options for bricks, among which there are standard sizes of red bricks for laying the stove - 25 * 12 * 6.5 cm. This option is optimal for oven equipment, it is very convenient to use.

There are wedge-shaped blocks, one half of which is 2-3 cm narrower than the other. This option is used at turning points, when laying out the outer part of the crucible, if it is supposed to cook or heat food using an oven.

Dimensions (edit)

Dimensions (edit)

It is possible to use europroducts of a thickened or modular type, which differ slightly in dimensions: 25 * 8.8 * 6.5 cm.

The form

Brick blocks may vary slightly in shape. The best option is a standardized rectangular look, but for a more complex look, you can use one of three options: wedge-shaped, ribbed or end blocks. The wedge shape assumes smoothing one corner, which helps to make the corner sections as beautiful as possible or lay out interesting decor. For the end and edges, the blocks differ mainly in thickness.

Form options

Form options

Most often, wedge-shaped bricks are used in the formation of an arched vault, in which one side is narrowed, which helps to perform a neat turn.

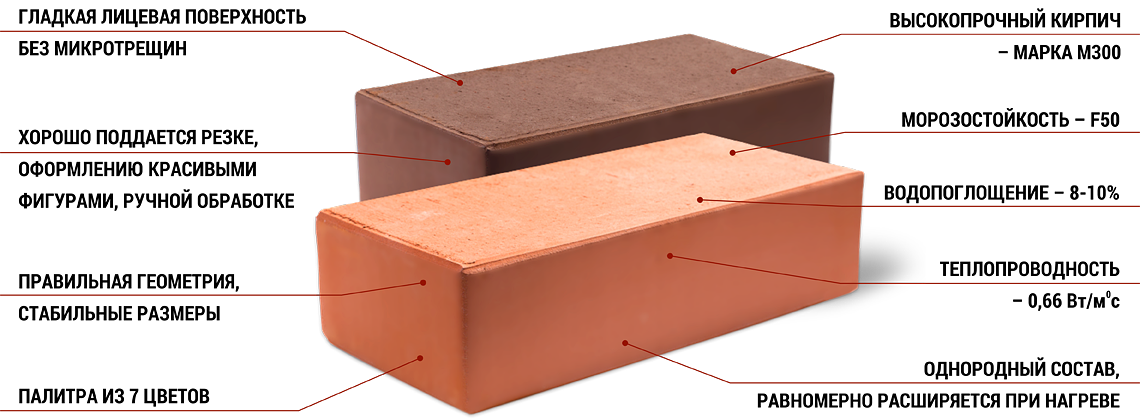

Colour

Brick color is a direct indicator of the quality of production. Uneven color or stains indicate a defective product.

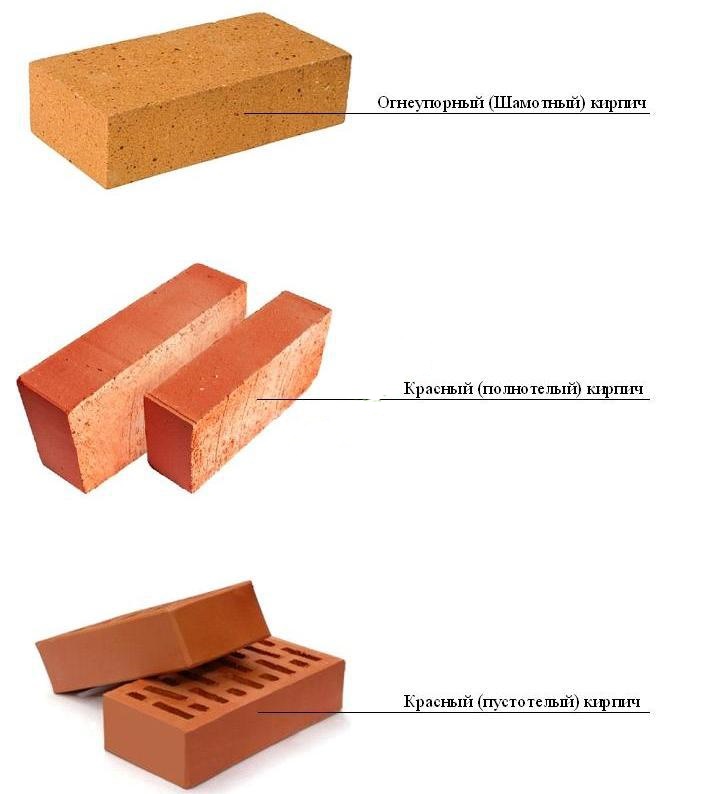

Also, the color scheme helps to determine the intended purpose of the manufactured products: which ones are used for the construction of buildings, and from which brick ovens are often laid. For the laying of furnaces, red refractory blocks are used, since they are characterized by resistance to temperature extremes, thermal pressure without violating the integrity of the structure.

Color spectrum

Color spectrum

At the places where the firebox and ash pan are formed, yellow bricks are used, since there is no direct effect of fire and heat at these places. Otherwise, such blocks are called chamotte.

The white chamotte block is excellent in all characteristics as the main material for the oven masonry, but it costs noticeably more than the red analogue. If there are general parameters, it does not always make sense to overpay for a shade.

A more detailed analysis of brick products for building stoves is shown in the following video review:

Which brick is suitable for the oven

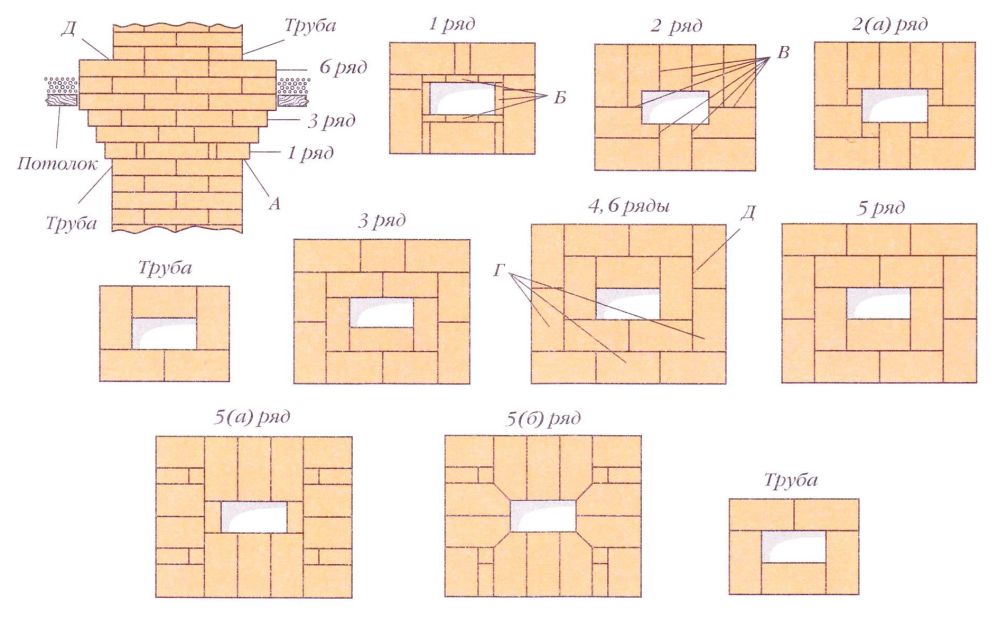

Furnaces are laid from solid bricks, without voids inside and single, single height, corresponding to the module of this type of brick. Modules and characteristics differ for different types. It is impossible to use bricks of different modules for one furnace, since in this case it is impossible to perform the correct laying of the seams and the structure will not be strong. In an extreme case, a firebox is laid out of a brick of another module, since it already needs to be built as a result of thermal deformations in the form of a block built into the structure of the furnace.

What brick can not be used for the oven

Absolutely unsuitable for the construction of the stove, silicate, unbaked raw and cast using slip casting. The raw material is hygroscopic and will disintegrate from the breath of the oven. The former conducts heat very well and is not heat-resistant. In the latter, the binder does not bake, but shrinks and crumbles during the heating from constant thermal shocks.

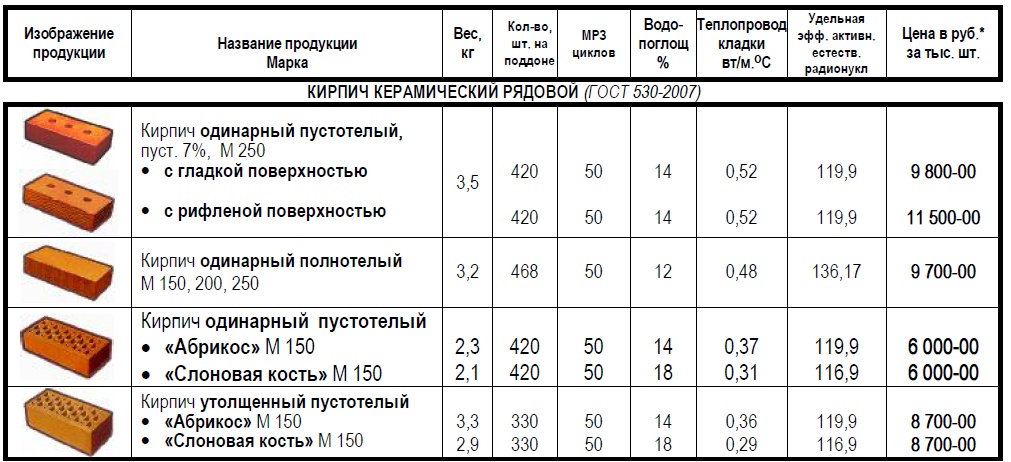

Clay red kiln brick

For ceramic red bricks for the construction of a stove, the option of its manufacture is very important. There are two options: semi-dry pressing and plastic molding. In the latter case, before firing, the molding mass is passed through a profiled die, creating a layer of the required configuration in the section, and cut it into pieces to size according to the required modulus.

In the first embodiment, the molding mass with a small amount of water is placed in a mold, pressed in, squeezing out the water, and fired. Semi-dry molding makes it possible to make dimensions more precisely.

The furnace requires only plastic molded ceramics. Since water not only gives elasticity to the mass, during firing it takes part in the chemical processes in it. Simply put, the clay in the pressed products is baked dry, which results in a lot of pores. This module does not hold thermal loads well, and also breathes, figuratively speaking, like a running horse.

Refractory bricks

This module is manufactured by firing and pressing at an elevated temperature. In furnace construction, fireclay bricks are often used and, very rarely, quartz bricks. The second has a small coefficient of thermal expansion, therefore, masonry is made from it in areas of contact with load-bearing steel embedded elements - pallets, beams, etc. But, since it is absolutely contraindicated to install loaded metal in the furnace, and quartz brick is expensive and is afraid of substances that have an alkaline or acidic reaction, it is undesirable to use it.

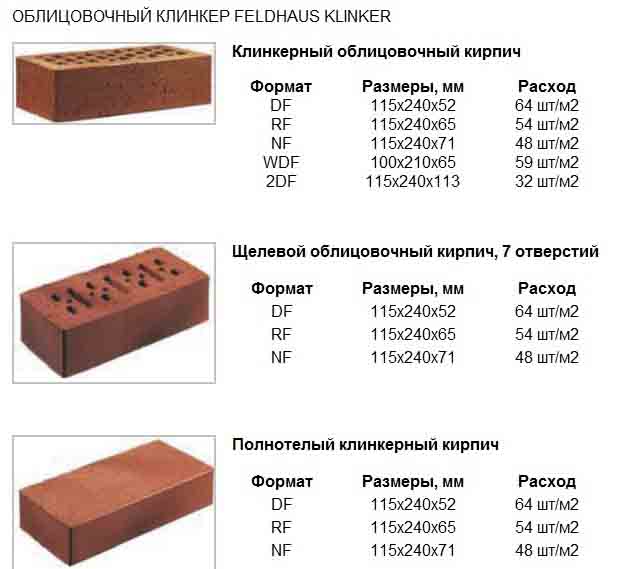

Clinker brick

It is made from a special composition based on clay - clinker - and fired at a high temperature. By and large, this is an ordinary specially burnt brick. It is heavy, dark in color, often on its spoons dried tarnishing colors are noticeable.

Heat resistance is about 1200 degrees, it has high thermal conductivity and is quite durable. As a result of the almost complete absence of pores, it is quite frost-resistant. It is not afraid of most chemicals, it fits perfectly with ceramic red bricks. It is rarely used in the construction of furnaces, since it is expensive, and in terms of heat resistance, it is worse than chamotte.

Technical parameters of bricks

Brick size and shape

Brick size and shape

One of the unchanging rules for the construction of furnaces is the accuracy of the design. Most of the projects are designed for specific brick sizes. Therefore, from which brick is it better to lay the stove, the question is very important.

Brickwork plans usually indicate not only the number of brick units, but also its dimensions. It is generally accepted that the standard dimensions of a brick correspond to the dimensions of a single type - length 250 mm, width - 120 mm and height 65 mm. This is considered to be the "gold standard". True, it is worth noting that these are the dimensions established by the Soviet standard. Today, in addition to this traditional size, there are other sizes used for laying stoves:

- "Euro standard" - with the same length and height as the normal standard, its width is 85 mm (it is often denoted 0.7 NF);

- Thickened brick (KU) - differs from the usual format in height, it is 88 mm (designation 1.4 NF);

- Single modular brick (KM) - length is 288 mm, width is 138 mm, height is 65 mm (designation 1.3 NF);

- The thickened brick with horizontal voids (CUG) has the dimensions of the thickened brick 250x120x88 mm (designated 1.4 NF).

There is one more specific brick for laying stoves - the stove module, its dimensions are 230mm x125mm x65mm. Despite the fact that this standard is considered outdated, many successful furnace designs have schemes designed specifically for this size. The popularity of this kiln standard is such that many manufacturers of refractory bricks for individual kilns still produce bricks with dimensions for the kiln module - 230x114x40 or 230x114x65 mm.

There is also a specific type of brick - wedge-shaped or arched for the construction of the vaults of the furnaces and arches of the cladding. Its peculiarity lies in the fact that the dimensions indicate both the wide side and the narrowed one, for example, 230x114x65 / 45 mm.

Ceramic oven bricks used for decorative purposes can have different shapes. For example, have rounded corners, convex or concave sides, and have a glossy surface. The use of this type of material must necessarily be indicated in the ordinary scheme of the oven masonry.

Brick strength

The second point that you need to pay attention to when choosing a brick for laying ovens is the brand strength. This characteristic shows what kind of load a brick can withstand without showing signs of deformation. The marking is usually indicated by the letter designation "M" and a numerical corresponding to the ultimate load expressed in kilogram / square centimeter

So the M150 marking is allowed for the construction of most furnace designs. M 200 is suitable for the construction of a stove for heating two floors. But higher grades, for example M-300 or M-500, are usually not used for the construction of furnaces. The fact is that special chemical additives are used to form a material of this density, therefore, when heated, such a material partially loses its properties, which negatively affects the state of the structure.

Frost resistance, thermal conductivity and hygroscopicity

Frost resistance of bricks is especially important for the construction of stoves in houses where permanent residence in cold weather is not planned. Usually it is denoted by the letter F, next to which is indicated the minimum number of freeze-thaw cycles without loss of strength and the beginning of the process of mechanical destruction

This indicator is important for such structural elements as the base and head of the chimney.

When choosing a brick for masonry, it is worth paying attention to such an indicator as thermal conductivity - the ability of a material to retain heat

This is especially important for laying the walls of the firebox and chimney. For these purposes, material is taken with indicators of at least 0.61 W / m × ° С

For these purposes, material is taken with indicators of at least 0.61 W / m × ° C.

But as for hygroscopicity, then the material should be chosen with the lowest indicator. The lower the coefficient, the less the brick is able to absorb moisture. For the base and chimney, this is a very important indicator of the quality of the brick, since it is these parts of the structure that are most susceptible to moisture.

Recommendations for the selection and use of oven bricks

One of the disadvantages of fireclay bricks is that it is able to absorb moisture with its long subsequent release. Therefore, it is not recommended to store it outdoors.To lay out the main parts of the furnace structure, it is required to choose only red brick, and not burnt or unburned, since in this case its quality properties are lost. The brick must have an even shape with sharp edges and dimensions declared in accordance with GOST.

The surface of the fireclay should be matte, without any film, which may indicate that the adobe can collapse with possible temperature drops.

When struck with a hammer on the surface of a brick block, a clear, sonorous sound should be emitted. A dull sound indicates the presence of voids, as well as poor quenching and drying. No traces should be left at the impact site.

When chamotte is split in half, one can judge its quality: the structure should be dense and homogeneous. It should not contain any foreign inclusions, including small pieces of clay - this indicates a violation of technology in the manufacture of brick material.

For the construction of the furnace, it is enough to use the brand of chamotte M250, the denser structure will warm up for a very long time.

When choosing a material, one should pay attention not only to the size of the red brick for the stove, but also the brand of its frost resistance, since it indicates the ability of moisture absorption and moisture separation, which is especially important when arranging a chimney. For the construction of the furnace foundation, it is recommended to choose a brick with the lowest hygroscopicity index, i.e. water absorption

water absorption

For the construction of the furnace foundation, it is recommended to choose a brick with the lowest hygroscopicity index, i.e. water absorption.

Hyper-pressed adobe can be used when laying outdoor barbecue ovens, but it is not recommended to use it for home ovens, since its limestone is unstable to high temperatures and begins to deteriorate under the influence of emitted carbon dioxide.

Stove brick

Stove brick

Red brick with a density of M200 cannot be used for laying the combustion chamber and chimney, as well as the street part of the chimney, since it can collapse within one to two years.

You can use old chamotte remaining after the dismantling of buildings and structures, provided that its structure is not destroyed, and the surface is intact. At the same time, the old masonry of the used bricks had to be clay or cement. If the old masonry was on a limestone base, such adobe can only be used as a base for a fireplace or pipe heads. Old chamotte used for laying stoves can also be used, provided that its surface is well cleaned of soot, otherwise, with new laying, black spots will appear on the outer surface of pipes and the front of the stove elements.

Suitable brick for masonry

Foundation

There is no unambiguous answer to the question "What kind of brick is it better to make a brick oven from?" For each part of the oven, a specific type must be used.

The base of the oven is one of the most important parts. After all, it must withstand the entire structure. In addition to strength, such a material must have moisture-repellent and frost-resistant characteristics, because it is located near the ground. Ceramic bricks of the first grade have such qualities. It is very durable and can withstand even massive construction. Sometimes clinker bricks are used for laying the foundation. It is also durable and frost-resistant.

Use ceramic bricks for the foundation.

Firebox

The most suitable brick for the furnace is fireclay. In its composition, it contains chamotte particles, which have refractory qualities. The inner walls of the firebox are laid out with such material, and a simple ceramic is taken for the outer ones.

You should not lay out the base of the firebox with ordinary bricks, since the temperature in this compartment sometimes exceeds a thousand degrees, and in this case such material will be deformed and will not last long.

For the firebox - fireclay brick

Smoke ducts

Hot air from the firebox passes through the smoke ducts to the chimney. This means that the temperatures are also high here. This part of the furnace is also laid with fireclay refractory bricks.

Chimney

This part of the furnace device is affected by precipitation and wind, and hot air comes from the bottom of the furnace. The brick for the pipe must be heat-resistant and frost-resistant, because it can withstand temperature surges from minus forty to three hundred degrees. To choose for laying a stove in this area is a ceramic brick with the highest frost resistance.

Frost-resistant ceramic brick is suitable for the chimney

There is another option: lay out a two-layer pipe. The first layer is made of clinker, and the second is made of hollow ceramic, which is strictly forbidden to use in other parts of the furnace.

Cladding

Exterior masonry can be done with facade or facing material. Not as stringent requirements are put forward for it as for the rest, since it is exposed to significantly low temperatures.

Clinker bricks are suitable for cladding and masonry

Its only role is to maintain the temperature and return it to the room. For this purpose, building ceramic, facing or clinker options are suitable.

Bricks for the stove in a bath or sauna

The laying of stoves in these rooms has some differences:

- not fireclay is used for the firebox - this brick is needed for laying the stove in the house. Instead, you should take a ceramic refractory. Fireclay can withstand humidity of no more than 60 percent, and for ceramics this figure is higher;

- clinker building material will give great heat transfer, which is much more appropriate in a bath;

- in the course of work, you need to use only premium bricks. Putting a stove or any of its parts from second-rate is unacceptable.

Methods for determining the quality of oven bricks

Verification of the compliance of this type of building materials with the requirements of regulatory documents is carried out according to the methods approved by the GOST series. Each of them is designed to determine the individual characteristics of refractory bricks:

- GOST 5402.1-2000. Method for determining residual deformations after heating.

- GOST 4069-69. A method for controlling the refractoriness of products.

- GOST 151136-78. Methods for measuring damage to corners and edges of ceramic blocks.

Brick research is carried out in laboratories using special equipment. At home, it is impossible to check the quality of refractory bricks using the methods described in the standards. The buyer has to rely on the certificates and qualifications of the master, whom it is desirable to involve in deciding the choice of material for the construction of the furnace.

Experienced stove-makers are able, in many cases, to determine the quality of refractory bricks by some criteria. Furnaces are built only from solid ceramic bricks with grades from M150 to M250. In this case, the certificate must contain a record that the specified product is intended for this type of work.

To determine the properties of a brick, the following techniques are used:

Vibration and sound. On a large face of a brick that is held in weight, a weak blow is applied with a hammer. The tool should bounce off the surface with a ringing sound. This indicates the absence of internal cracks.

Examination of the appearance. The brick must have the correct shape with a maximum deviation from the standard size within 2 mm in one direction or the other.

Internal structure. It is assessed by the state of the chip, while the color of the section should be uniform over the entire area. The presence of spots indicates the presence of stress areas in the brick mass, which can cause its destruction when heated. Chipping of chamotte should not occur from the internal structure of the material.

The use of the above methods for assessing the quality of refractory ceramic bricks for construction in a furnace will allow you to select the material required for this.The use of building bricks that meet the requirements of GOST will provide the heat engineering unit with an appropriate level of strength and reliability.

What properties should a brick used for laying a furnace have?

The kiln brick must meet the following technical requirements:

- Resistant to high temperatures and open flame.

- The ability to accumulate heat and keep it for a long time.

- Sufficient mechanical strength.

- Resistant to significant temperature fluctuations.

Solid fuel furnaces are built of ceramic bricks that meet the requirements of GOST 390-96. This standard was put into effect on July 1, 1997 and establishes the technical conditions that these products must comply with in terms of shape and size. The normative document also defines the requirements for the use of products depending on the maximum ambient temperature.

For ceramic bricks intended for the construction of heating units, more stringent requirements are applied than for other building materials. In the furnace of furnaces, the flame temperature can exceed 1000 ° C, respectively, its walls are exposed to significant thermal loads. The thermophysical parameters of the material used must be higher than the specified value.

During the operation of the furnaces, they are regularly cooled in some cases and to subzero temperatures. At the same time, the brick is exposed to a significant temperature difference in the external environment, which leads to thermal expansion followed by contraction. The product must have a sufficient margin of safety to successfully withstand this phenomenon and avoid deformation and destruction. The brick used for the laying of stoves must have a sufficiently high thermal conductivity and the ability to accumulate heat. The first property is necessary for the rapid heating of the room and the transfer of the energy of the burnt fuel to the external environment. The second quality allows you to maintain this process after the cessation of combustion in the furnace for a long time. This allows you to maintain a comfortable thermal regime for a long time.

How to choose a quality brick?

When buying, be sure to selectively inspect the entire batch of blocks, we carry out a visual inspection of the material

Experienced builders recommend paying special attention to several points in the table.

| Colour | It should be evenly painted over all surfaces and in places of chips or in a section. If you saw enlightened areas, such material did not withstand a certain place under the influence of high temperature during firing. Dark spots at the fault points indicate a violation of the temperature regime, such a brick has been exposed to high temperatures. |

| Blotches. | If small inclusions of a different color are found in the places of the fault, an admixture is present in such blocks, which is not always useful. If areas covered with mica are found on the surfaces, it is not recommended to buy such material, this is 100% scrap. |

| Block shape. | It must be geometrically correct with right angles. There are significant chips or other defects on the edges - this is a re-grading or marriage. |

| Dimensions. | If a 2 mm deviation from the block size is found during the measurement, such products are made in violation of technology. |

| Sound. | If the brick, upon impact, “sings” with a clear sound and there is no significant dent on the surface, you can safely pay for such a product. |

Important! Before building a furnace, we advise you to buy the entire set of materials from one manufacturer. Ideal - bricks from the same batch

In this case, they will not be 100% different in color.

Barbecue bricks - which one to use when building ovens

Regular bricks, facing bricks and refractory bricks are used to create barbecue ovens.

The need to purchase cladding material arises if special oven bricks are not used in construction or to maintain an attractive appearance while saving through the use of old bricks.

The marking of the optimal solid oven bricks is M-250, M-200 or, in extreme cases, M-150.

The main types of bricks - we decide on the choice

To understand what materials to use for a brick-built barbecue oven, you must first understand the characteristics and basic parameters by which they are distinguished.

By application:

- ordinary construction;

- refractory;

- clinker - facing.

By composition:

- silicate brick;

- fireclay;

- ceramic;

- hyper-pressed.

By internal arrangement:

- hollow;

- corpulent.

It can be difficult to distinguish materials for a barbecue made of bricks by their appearance, so you need to pay attention to the markings. The following information is encrypted in it:

- Strength grade - the higher the indicator, the stronger the brick, the better it is able to withstand the load without mechanical damage. It happens in the range from M-25 to M-500;

- Internal structure - no designation for corpulent, "P" for hollow, "U" for thickened;

- Mass, size - for calculating the future load on the foundation;

- Manufacturer's abbreviation or name;

- Frost resistance - from F-15 to F-75, indicates the ability to withstand a certain amount of freezing and thawing without losing strength;

- Water absorption (%) - a minimum indicator is required for the construction of the foundation, not particularly important for the rest of the structure of the barbecue oven;

- Manufacturing material.

Choosing a kiln brick manufacturer

The market for this type of building materials is extremely saturated with products of domestic and foreign companies. In this segment, products manufactured by enterprises from Russia, Belarus and the Baltic republics are widely represented.

Vitebsk brick factory shop №1.

Ceramic bricks from this manufacturer meet the requirements for the material for furnaces in terms of density grade. Frost resistance of products is extremely low. Density grade 180 - 200. The brick can be used for facing the stove and chimney ducts, it is unsuitable for other elements. We can say that this is one of the most common, today, materials for the construction of a furnace. It cannot be used for laying the firebox and the first chimney of the stove. It is required to lining the furnace and the first chimney with refractory fireclay bricks.

With constant direct contact with fire, this brick collapses quickly enough. Since the products have low frost resistance, the use of this brick for laying the outer walls of a chimney street pipe is also excluded. The advantages of this material include the fact that this is one of the most budgetary options and, given all the nuances, it is quite possible to use it for laying the stove. Has 2 working surfaces. In general, the quality of this brick can be described as satisfactory.

LODE.

LODE bricks are produced in the Baltics. Ceramic brick has a high density grade - 500 and frost resistance. The product is used for cladding the outer surfaces of the stove and chimney. The brick of this brand has various shapes and is often used to create all kinds of decorative elements of the stove. According to its main purpose, it is a facing brick.

Borovichi brick factory.

Products of the Borovichi brick factory located in the Novgorod region. The mass production of products began in 2011, experts assess its quality as good. Density grade of ceramic bricks M-250, frost resistance indicators at the level of F25. Significant deviations of products from the sizes established by the standards are noted, up to 10 - 12 mm in one batch.This must be taken into account when laying the stove and it is best to take a little more bricks than necessary. Further, it all depends on the professionalism of the stove-maker and his ability to select the necessary products. The brick has rounded top and bottom edges and 3 work surfaces.

Refractory or fireclay bricks of Russian production.

The quality of products varies greatly, ranging from outright marriage to quite decent products. Fireclay brick has an even cream color and high density, the shape is correct with right angles. As we have already found out earlier, this brick is necessary for the lining of the combustion chamber of classic furnaces, hearths and fireplaces. But it is rather difficult to single out certain manufacturers here.

The answer to the question of which brick is best for the furnace is usually decided by the customer in agreement with the master. It takes into account several factors, among which the main ones are compliance with the requirements of standards and cost. The operational properties of the structure depend on the correct choice of refractory bricks, saving at the expense of quality is expensive.

Features of the use of oven bricks

clay for oven bricks

The quality of the oven also depends on the choice of clay from which the mortar will be made. It happens:

- oily. Here the sand ratio is 1:10.

- Average-1: 8.

- Lean sand is more than 1: 3.

Check the clay for fat content in this way: Roll a finger-thick sausage out of it. If it bends and does not break, and does not crack after drying, it is oily clay. A skinny one does not roll into a sausage.

To build a stove, you need oily or medium clay.

face red brick

To build a stove in a house, you need to purchase solid ceramic and stove bricks. The top chimney can be made with silicate. A brick that can withstand temperatures up to 1000 degrees can be called stove.

What are the types of full-bodied red bricks ?. They are:

- Facials have a uniform structure in color and quality.

They can be angular, with rounded corners and with a relief surface.

2.Not facial. Here you can often see all kinds of swelling.

Refractory bricks consist of refractory clays, coke and quartz powders or graphite chips.

Not all construction stores keep refractory bricks in warehouses, therefore they often order them at the enterprise where they are made.

pallets for storing bricks

JSC "Borovichi Building Materials Plant" produces furnace bricks Borovichi M-250, refractory bricks, fireclay Ш-5, Ш-8, corpulent bricks Borovichi and red borovichi bricks.

For storing refractory bricks, wooden planks are needed. It is stacked on the edge, followed by bandaging. The height of such stacking should be no more than 1.6 ‑ m.

Transportation is carried out on pallets, laid in a herringbone pattern. Workers unload the brick, handing it over to each other.

For laying the stove, you can use a brick that has already been in use. Before that, the old solution and soot are cleaned.

One of the old ways to construct a hearth was to lay a stove. During the manufacture of products, each owner of the production, marked with a special family hallmark. Now there are a lot, you can see advertisements that old bricks with the "Moscow" brand are for sale and there are many other seals on the old bricks.

Video instruction on the selection of high-quality bricks for the oven