Advantages and disadvantages

Matte black dye protects metal products from corrosion and other harmful factors.

Advantages and disadvantages

Versatility - the material can be used for coloring different products

The formulations are suitable for application to cars or plastic parts.

Ease of use - particles are easy to spray, which is not the case with other paints that require expensive fixtures.

UV resistance - this helps to maintain a rich shade even after many years.

Heat resistance - the substance is able to withstand the effects of high temperatures.

Resistant to moisture and other natural factors.

Small price.

No toxic properties - in any case, when using the dye, it is important to follow the safety rules.

High drying speed.

The ability to highlight the shape of products well.

The ability to hide mechanical damage and dirt.

The high cost of painting work - even with independent use, the price of the dye is quite high.

Changes in tone after painting the surface - therefore, it is important to choose the right dye.

Difficulty sanding - after this manipulation, the coating does not look very attractive.

Fast Soiling - Matte backgrounds get dirty faster than glossy surfaces. After using such a dye, the surface will have to be cleaned more often.

Black color has an important drawback - it attracts ultraviolet radiation. The fact is that such a shade has a weak ability to reflect color.

How to use

In order for the application of the dye to be successful, it is important to follow a number of recommendations. In this case, it is important to properly prepare for the application of the substance.

Preparatory work

Before starting work, you need to prepare a number of materials. These include the following:

- primer;

- masking tape;

- respirator - helps to protect the respiratory organs;

- gloves - provide protection of the skin from the ingress of dye;

- rag;

- paper, newspaper or oilcloth - used to prevent dye from getting into unnecessary places.

Before using the dye, you need to equip the workplace. In this case, it is recommended to cover the places that should remain unpainted with paper or oilcloth. Then it is worth preparing the surface for applying the substance. To do this, it is recommended to do the following:

- Remove the old coating from the surface.

- Clean material from dust, dirt, rust. The cleaner the coating is, the better the hitch will be. If you cannot remove dirt with a damp cloth, you should use household chemicals.

- It is recommended to sand the polished surface with sandpaper. It will give the material a certain roughness. The use of sandpaper improves adhesion.

- Paste the borders of the area to which the dye is to be applied with masking tape. It should be fixed carefully to prevent paint bleeding.

- Apply a primer to the surface. When choosing it, it is worth considering the type of paint and the base material.

It is important to take into account that it is permissible to apply paint and varnish only after the primer layer has completely dried.

Dyeing

For painting work, it is recommended to do the following:

- Wear a respirator, goggles, gloves.

- Shake the can to obtain an even texture.

- Apply a test coat of paint to the rough surface. A piece of metal or an unnecessary board is suitable for this. This procedure will help you evaluate the quality of the spray pattern.

- Apply the first coat of paint to the primer. At the same time, keep the can at a distance of about 20 centimeters from the surface. Displacing the torch is slow. The dye layer should not be very thick.

- Wait for the coating to dry. This usually takes a day. After that, it is permissible to apply a second layer.

If the substance is used for outdoor work, it is permissible to paint the surfaces only in dry and warm weather. Otherwise, it will not be possible to achieve a good grip.

Completion

After painting the surface, it is important to wait until it is completely dry. This usually takes 1 day.

However, a specific period is indicated in the instructions for a specific dye.

Top 7 refractory paints for metal up to 1000 degrees

To protect the heating radiator, metal stove or other objects from corrosion and aggressive external influences, they are covered with heat-resistant paint and varnish enamels. The paintwork can withstand up to 1000 degrees C. The enamel not only protects, but also gives an aesthetic appearance.

It is difficult to make a choice in favor of this or that paint. A fresh coating will give the items a new look. We have compiled for you a rating of the most popular paints and varnishes. All submitted candidates have been verified by operational practice and experience.

Tikkurila termal silikonimaali

Country of origin Finland and Russia. Used for painting metal products. Based on silicone resin. Suitable for indoor and outdoor use. Resistant to high temperatures up to 400 degrees. This property provides protection for chimneys and dampers. Used for painting a car muffler. Black color. After drying, a semi-matt sheen is formed. Protects the structure of the metal.

Apply by brush or spray. The time of complete drying at a temperature of +230 C is exactly 1 hour. You can use the surface cleaners after one month. One liter of enamel is designed for 16-20 square meters. If the paint is applied in one layer. The price matches the quality. The only negative is heat treatment after application for complete drying.

Celsite-600

Black paint. Withstands exposure to temperatures up to +600 degrees. High degree of protection when using metal under the influence of high temperatures and moisture. Resistant to the influence of petroleum products, oil, gasoline. It is used for painting: electric motor, transformer, household heating appliances, bridge, tank, metal structure, railway tanks, calipers. Can be applied to reinforced concrete, asbestos-cement, brick, plastered surfaces. The enamel is applied in three layers. The color is black, the surface takes on a matte shade.

Certa KO-85

Certa is used for items that operate at temperatures from -50 to 900 degrees C. Heat-resistant enamel. It tolerates temperature changes well, including high temperatures. Protects against aggressive environments and high humidity levels. Prevents corrosion, moisture ingress. It is applied at minus 30 degrees Celsius. Transparent paintwork material. Used instead of varnish for covering bricks, concrete, ceramics. Apply in three coats to achieve a matte finish. In one layer, the brick acquires a wet effect.

Elcon

To obtain the desired color, it is mixed with a color scheme. At the same time, the pigment contained reduces the level of protection and durability of the painted coating.

The color palette is very rich. Gloss is matte and glossy. The product, painted in classic black color, can be heated up to 1000. And all other colors are not higher than 700 degrees. You can create beautiful patterns on the stenciled walls without involving specialists. In addition to metal surfaces, it protects concrete, brick, asbestos products from the influence of an aggressive environment.

Kudo

The composition does not include toxic components.When used, no harmful substances are released into the air. Can be used inside living space, stove or fireplace, chimney. No primer is required before application. Complete drying time 2 hours. It is considered to be slightly flammable, difficult to ignite. The room temperature is not lower than + 3C. The service life is not less than 20 years. Universal, used on products of different surfaces.

Dali

Matt paint for interior and exterior use. It is used for painting the exhaust systems of a car, chimney, chimney. Black color. Before opening the can, the manufacturer recommends mixing the contents well. Apply by brush or spray. Drying time from 1 to 3 hours. If you want to apply several layers to the product, then the time interval for each layer is 1 hour. Thermal hardening for 2 hours at a temperature of 200 degrees.

Serebryanka heat-resistant Novbytkhim

Heat-resistant universal. Used for glass, brick, concrete, plaster surfaces. The formed layer protects against oil, gasoline, water, and vapors, salt fog in the range from -50 to +600 degrees Celsius. Withstands sudden changes in temperature, but within the range indicated on the package. The enamel is waterproof, dries quickly. No more than three layers are applied. Stir not only before application, but also during application. Prepare the surface in advance. Remove dust and dirt. The composition includes organic substances.

Staining principles

You can paint a metal surface without any practical skills. It is enough to prepare the required materials, tools, cover the working surfaces with a primer, apply paint.

Tools and materials

For painting work, you need to prepare:

- set of brushes, roller;

- container for paint;

- stationery knife, masking tape;

- thick plastic wrap;

- primer;

- metal brush, sandpaper.

Sandpaper (Photo: Instagram / abraziv.by)

Preparation

Stages of preparing metal surfaces before painting:

- Rough metal processing. This removes serious dirt, scale.

- Surface grinding. It is necessary to process the metal with fine-grit sandpaper.

After cleaning the metal, you need to cover the surrounding surfaces with a film so as not to get dirty.

Putty

If the surfaces to be covered with paint are uneven, have many depressions, they must be putty. To do this, you need to buy a special mixture at a hardware store, apply it according to the instructions on the container.

Padding

Surface priming is necessary to increase adhesion, increase the durability of the decorative coating

It is important to choose a suitable composition so that the decorative layer retains its integrity for a long time.

Views

Types of primers:

- Inhibitory. If rust begins to form on the metal, the primer will stop the material from breaking down.

- Protective. They are made on the basis of phosphoric acid. After application, a strong, durable film is formed.

- Phosphating. Suitable for working with non-ferrous metals.

- Insulating. They are made on an alkyd, epoxy base. Forms a strong film.

Metal primer (Photo: Instagram / birgroupcompany)

Application principles

The principle of applying the primer is simple:

- Remove any dirt, dust from the surface.

- Dilute the primer with water.

- Apply the composition with a roller. If a roller is not available, a wide brush can be used.

Paint application

The paint can only be applied after the primer has dried. Most colorants are applied in one coat. For coloring, you can use a spray gun connected to a compressor, a brush or a roller.

Safety engineering

Safety regulations:

- Work should be done in protective clothing, gloves, respirator.

- There should be no heating devices in the painting area.

- Do not use paint near open flame sources.

Girl in a respirator (Photo: Instagram / tkani_cochonnet)

For painting unprepared surfaces, anti-corrosion coatings must be used. You can read the instructions on the packaging. It is better to use powder paint, but this requires a special camera and appropriate equipment.

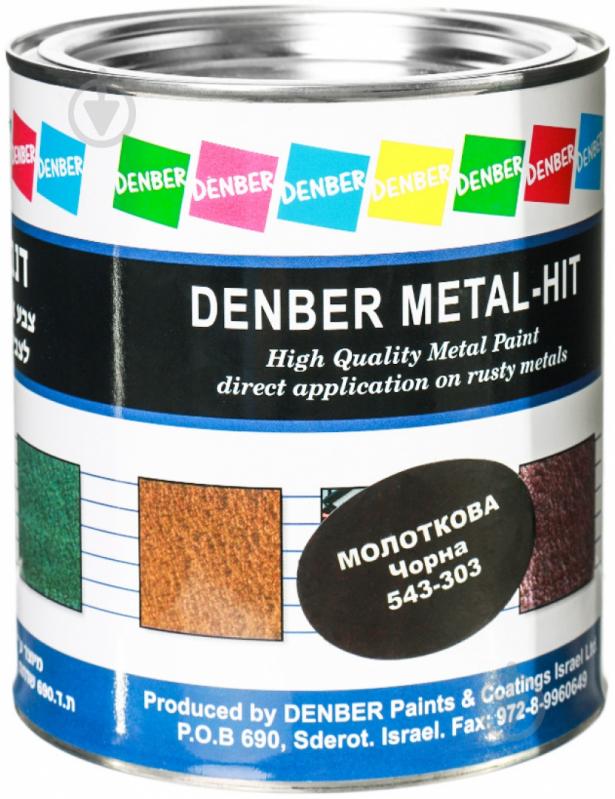

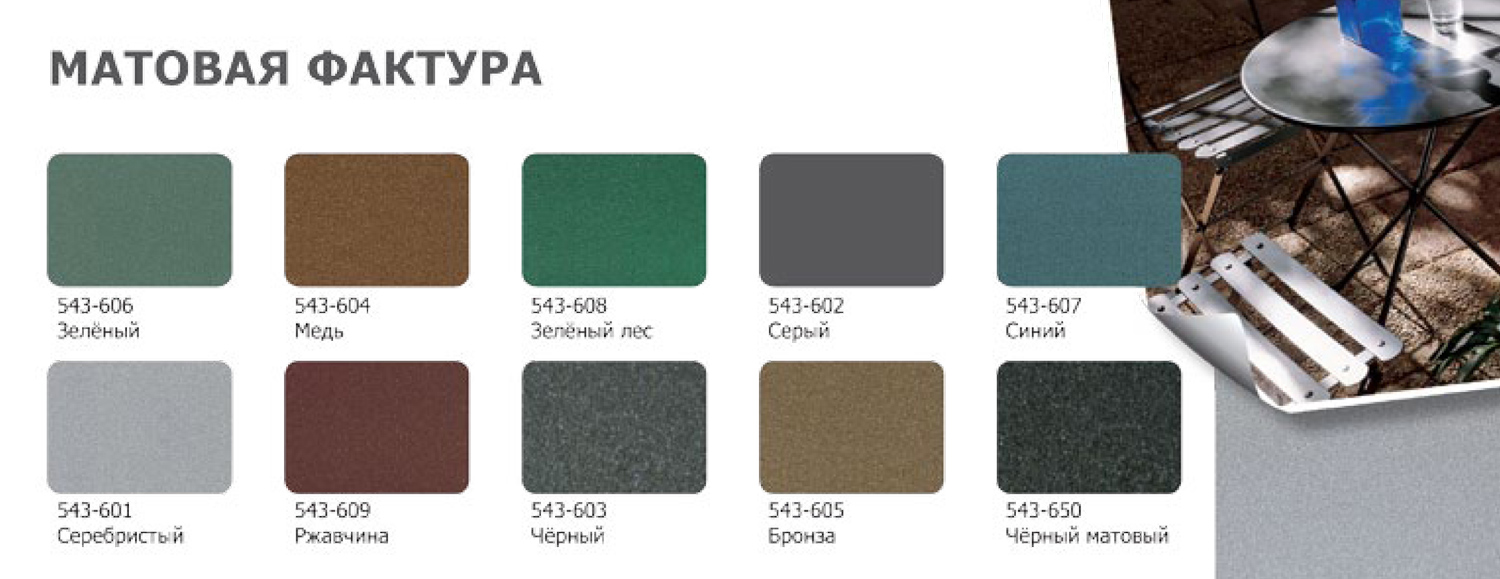

Popular rust paints

Among the many brands of special rust paints, there are those that are especially popular. It is determined not only by positive customer reviews, but also by sales.

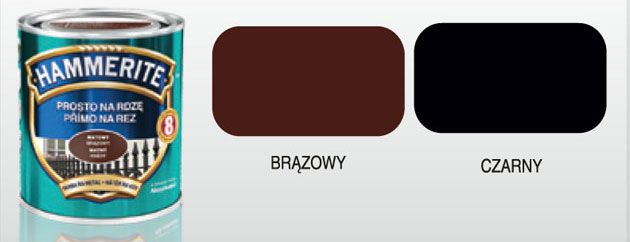

Hammerite

This brand is confidently leading, despite the rather decent cost. This is due to the quality of the coating, its durability, beautiful texture and versatility. Hammerayt anti-corrosion paints are used for decorative finishing of ferrous, galvanized and non-ferrous metals, wood, plastic. They are used for finishing external and internal structures. Apply to new and previously painted surfaces with a different paint.

Hammerite paints

When choosing a paint of this brand, you should pay attention to the series.

-

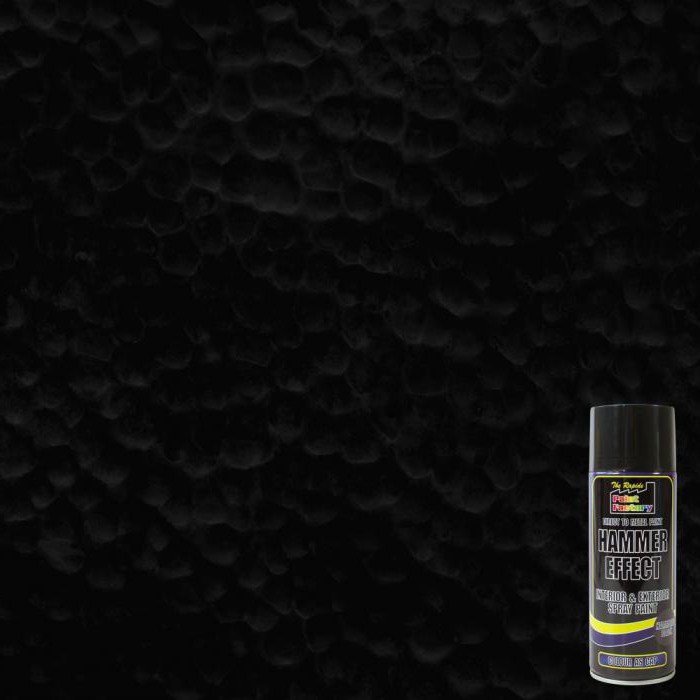

Hammered are hammer paints that create a hammer effect on the painted surface. It turns out to be shiny, but textured and rough, which perfectly masks minor defects. This effect is achieved by adding aluminum powder and fine fractions of glass to the composition. Hammer compounds are ideal for painting ferrous metal.

Anti-corrosion hammer enamel for rust

Hammered paint shades

-

Smooth - a series that forms smooth glossy or semi-matt films. In addition to ready-made paints of standard shades, you can purchase a base composition for tinting in your own color.

Hammerite Metal Paint Smooth

"Lacra" Hammer Effect

Another effective protective agent with a hammer consistency. Made on an alkyd-styrene base, it has a low price and good adhesion to metal surfaces with a rusty layer thickness of up to 0.1 mm. It can also be used for painting wooden structures, creating a coating on them with a metallic sheen.

"Lacra" Hammer Effect

Alpina Direkt Auf Rost

Universal paint from the well-known company Caparol for decorating metal surfaces indoors and outdoors. Differs in ease of application and good resistance to fading.

Alpina Direkt Auf Rost

"Nerzhamet"

Alkyd paint Stainless steel is available in the usual form and in aerosol cans. It contains polymer inclusions, is very easy to apply, dries quickly and adheres well to rusty surfaces, forming a hard semi-glossy film. Its service life without the need to renew the coverage is six years.

Anti-corrosion paint for metal

"Prestige". Primer-enamel

Another inexpensive domestic product, characterized by a high drying rate, high resistance to moisture and other aggressive media, and an economical consumption of a maximum of 120 grams per square meter. It is diluted with solvents such as xylene or P-4 to the desired consistency.

"Prestige". Primer-enamel

This paint is widely used for finishing galvanized metal roofs, external pipelines and fences.

"Stop rust"

Like most other alkyd enamels, this composition can be applied in any way. Available in packaging of different sizes: buckets, cans, aerosol cans. It is used to paint external structures made of steel and cast iron, including those with an old paintwork. It penetrates well into the decaying structure of the metal and blocks the spread of rust.

"Stop rust"

"Cycrol"

Even galvanized steel under the influence of precipitation, sunlight and corrosive impurities contained in the air corrodes over time. For its protection, a special 3-in-1 "Cycrol" product has been developed, which has high adhesion to such surfaces.

High-quality anticorrosive primer-enamel based on acrylic resins with polymer additives in organic solvents

It contains acrylic resins, organic solvents and additives that increase the resistance of the enamel to wear, moisture, low temperatures, corrosion and other atmospheric influences. It is characterized by good hiding power, water repellency and the ability to dry quickly after application.

Paints and enamels for rust

Advantages and disadvantages

Matt black paint has many advantages:

- Versatility (paintwork materials can be used to paint a wide variety of products, including cars and plastic products).

- Ease of application.

- The particles are well sprayed, unlike many other paints, where the same effect can be achieved only with the help of expensive professional equipment.

- Resistant to ultraviolet radiation, due to which the surface retains a rich color even after many years.

- Heat resistance.

- Resistant to moisture and other environmental factors.

- Low cost.

- Non-toxic (this still does not mean abandoning safety measures when applying paint).

- When sprayed, no solvent is required to achieve the desired viscosity.

- Fast drying.

- The black color emphasizes the shape of the object well.

- The matt black color makes mechanical damage and dirt less visible.

There are relatively few downsides to matte paint, but they are still there:

- The cost of painting services is quite high. But even if you do the work yourself, painting will not be cheap.

- Matte coatings often change their tone after being applied to the surface. Therefore, choosing the right paint is a very demanding task that requires experience.

- The matte finish is difficult to sand. After sanding, the surface usually does not look very attractive.

- Matte backgrounds, as opposed to glossy ones, get dirty easily. This surface will have to be cleaned more often. In addition, mud stains always stand out against a matte background, which does not add attractiveness to a painted product.

- Black itself also has a drawback - it attracts the sun's rays, since the reflectivity of this color is very weak. All things being equal, a black car will always be hotter than a white or red one.

Types of paints for metal

Paints are classified according to composition, purpose and properties. For metal, not only specialized coatings are suitable, but also some universal ones, which can also be used for painting wood, concrete and other types of surfaces. The basis for the manufacture of the coating is of paramount importance - it determines the strength, durability and heat resistance of the composition.

The composition of the following types of paints is distinguished:

- Epoxy. They are extremely toxic, therefore they are not used for internal work. Produced on the basis of silicone resins with a hardener. The coating withstands high temperatures well.

- Oil. Less toxic. The composition is based on natural oils or drying oil. They are used for interior work, as they are unstable to large temperature ranges. Not able to protect metal from corrosion. Therefore, the surface to be painted must be primed.

- Alkyd. They have a low level of toxicity. Used for interior work. They adhere well to the surface even without priming. Cannot withstand strong heating, combustible.

- Acrylic. Non-toxic, odorless. Produced on the basis of polymers. Diluted with water. Versatile in application. Suitable for painting parts that are exposed to heat. Provides protection against corrosion.

- Rubber. These paints are ideal for metal roofs. Toxic, suitable for outdoor use only. Provides additional protection against leaks.Easily removable if necessary.

There are specialized coatings for metal, they are divided according to their properties:

- Anti-corrosion - compounds that protect the metal from moisture and oxygen. Does not require a primer coating.

- For rust - applied directly to oxidized iron. Such paints significantly reduce the time and financial costs for metal processing. Quick drying. Produced on the basis of synthetic epoxy resins with the addition of anti-corrosion pigment.

- Hammerheads - when dried, they form potholes on the surface, similar to hammer blows. They can be produced on an alkyd, acrylic, epoxy base with the addition of small particles of glass and aluminum powder. Resistant to mechanical damage.

- Primer-enamels are formulations that combine the properties of a primer, an anti-corrosion coating and an enamel.

- Nitro paints - such compositions are most often produced in spray cans. They are toxic, so the paint in spray cans is used only for outdoor work. Its advantage is that staining does not leave streaks.

- Blacksmiths are made on the basis of polymers. One of the most durable. They have the highest adhesion rates to the base surface.

As a rule, the more expensive the composition, the longer it will last. The most affordable - oil ones - can lose their appearance and crack in just a couple of years. Nitro paints fade in the sun in one season. The hammer has the greatest durability - even after 10 years of operation, it will not change its appearance, but if necessary, it is almost impossible to remove it. The best paint for metal is blacksmith paint, but given its high cost and high consumption, it is not always advisable to use it.

When choosing, be guided by the following indicators:

- Purpose (for indoor or outdoor use);

- Toxicity;

- Consumption and cost;

- Duration of operation;

- The need for preliminary preparation of the metal.

The condition of the metal surface is also important. If it is required to paint ferrous metal with rust, the choice of compositions is narrowed

Also in the case of products that will be exposed to heat or weather conditions.

Choosing the best paint for metal

Of all the colorants previously listed, hammer effect coatings have the highest performance in terms of basic quality criteria. In terms of external characteristics, the coating has similar features to rubber dyes, since both have a similar consistency. However, these materials have completely different compositions, and a different binder component was used for their manufacture.

In order to protect forged products from the effects of atmospheric agents, it is worth choosing the right paint for metal

In order to protect forged products from the effects of atmospheric agents, it is worth choosing the right paint for metal

The significant disadvantages of hammer paint include only the high price. Its use will be profitable only if a small surface is processed, because the application of this composition is accompanied by a high consumption. If, in financial terms, there are no restrictions, then it is hammer paint that can be considered as an ideal option for finishing metal surfaces in the open air.

Important! Hammer paints must be used in combination with the same brand of primer. Provided that this requirement is maintained, the service life of the coating will be at least 20 years.

Comparative characteristics of dyes

| Characteristic | Types of dyes | ||||

| Aerosol | Alkyd | Rubber | Powder | Molotkovaya | |

| UV resistant | 1 | 2 | 2 | 3 | 4 |

| Moisture resistance | 1 | 2 | 3 | 3 | 4 |

| Resistance to mechanical stress | 1 | 1 | 2 | 3 | 4 |

| Adhesion level | 1 | 2 | 2 | 3 | 4 |

| Price | 1 | 1 | 2 | 3 | 4 |

The table clearly shows the advantages and disadvantages of various types of dyes according to the main parameters, where 1 is the lowest and 4 is the highest.

Regardless of the type of paint chosen, the surface should be pre-cleaned from the top layer of rust and dirt

Regardless of the type of paint chosen, the surface should be pre-cleaned from the top layer of rust and dirt

Popular paints for galvanized metal

Not every type of dye is suitable for finishing galvanized metal surfaces. That is why there is a separate category of materials intended for these purposes. Moreover, such paints are produced both in the form of a powder, which needs to be diluted, and in the form of a ready-made mixture. The composition, which does not require preliminary preparation, is packaged in cans, buckets and aerosol cans.

According to consumer reviews, Cycrol paint for galvanized metal is the most demanded in this category. Customers appreciate the ease of use and high quality of the coating on any application, including brush, roller and airless.

No less in demand are the compositions of Zinccomet, which are noted by users as convenient dyes to use with optimal parameters and cost. The only drawback is the only limitation for application to coatings at low temperatures, but most users on the forums consider this nuance insignificant.

Due to its anti-corrosion properties, metal paint is able to protect the roof of a private house from negative external factors.

Due to its anti-corrosion properties, metal paint is able to protect the roof of a private house from negative external factors.

Basic colors are presented in a small number of shades, which, as a rule, include white, silver, black, brown and green. A separate place is reserved for anti-corrosion silver paint for metal, the price of which is more than affordable.

Possibilities of Hammerayt hammer paint for metal

Among hammer coatings, Hameright metal paints from the manufacturer Akzo Nobel are especially popular, which offers customers a lot of advantages:

- protection of metal surfaces from corrosion damage both indoors and outdoors;

- spectacular appearance is provided due to an unusual texture and a variety of colors, including standard and exclusive shades;

- a high level of adhesion even over rust and maintaining an attractive appearance for at least 8 years;

- operating temperature range in the region from -20 to + 85 ° С.

A thin coat of hammer paint can be used to create an interesting effect on metal fittings.

A thin coat of hammer paint can be used to create an interesting effect on metal fittings.

Under the condition of a short exposure to high temperatures, the coating will retain its attractiveness (up to + 150 ° C). For at least 5 years, the finish will not undergo any changes in shade under the influence of UV. These and many other benefits have made Hammerayt so popular in the market.

The modern range of paints and varnishes offers hundreds of quality finishes. However, there is no universal composition. When choosing a finish, first of all, you should be guided by the type of material of the surface to be treated, the budgetary possibilities and the advantages that the dye can offer.