What are masonry mortars?

Ready-made cement mortar can be used for the following types of work:

- Laying bricks, gas silicate, cinder block, shell rock;

- Installation of concrete products of various sizes (slabs, blocks, floors, staircases);

- Manufacturing by vibration casting of various products for construction (vibrobrick blocks, panels, tiles);

- Installation of decorative elements, load-bearing structures, metal structures;

- Repair work (sealing cracks, fixing objects);

- Protection of materials and bases from negative external influences (mechanical damage, rain, abrasion).

Masonry mixes are distinguished by ease of preparation, plasticity, long pot life, fine-grained filler. After setting, masonry mortars are frost-resistant, tolerate short-term contact with water, can be used in a humid environment, as well as in places where temperature changes are observed.

It is very important to follow the technology of manufacture and use of masonry mixtures in order to ensure the strength of the entire structure. Very often, problems arise on construction sites when the technology for preparing the mixture is violated, it is used on an unprepared surface, without quality control of the masonry, and so on.

As a result, the masonry joint may have high strength, but the entire surface of the wall will be covered with defects or may have a loose structure. In some cases, it is appropriate to use masonry mortars as a facing mixture. The material provides good tightness, does not change its appearance for a long time, and provides water resistance.

Some manufacturers and material cost

To prepare the solution, special ready-made multicomponent mixtures are often used, packaged in bags of 25 kilograms each. The most popular manufacturers of these products include:

PEREL, which has a plant in Russia. The price of this ready-made masonry mortar of grade 100 is about 410 rubles;

PEREL

Ceresit. This company manufactures products in Ukraine. The cost of her goods is in the middle price range - about 280 rubles;

Ceresit

Polimin. This manufacturer is considered one of the cheapest. He makes ready-made masonry cement mortar of grade 100, the price of which for 1 m3 is no more than 200 rubles;

Polimin

KREISEL exports its products to the country from Germany. At the same time, the cost of the goods is not very high - about 260 rubles.

KREISEL

Knauf is of good quality, which corresponds to a price of 350 rubles.

Knauf

It is worth noting that the price of ready-made solutions in liquid form exceeds 2500 rubles per 1 cubic meter. That is why it is much cheaper and economical to mix the material yourself.

It is also worth paying attention to the fact that product quality also affects its cost. For example, a ready-made masonry cement mortar of grade 150 has a price for 1 m3 that is 20-30 percent higher than that of M100 products.

Preparation of simple plastering compounds

Cement mortar is the simplest and most common

Cement mortar is the simplest and most common

Simple plasters include those solutions based on one binder. These include the following plaster solutions:

- Cement.

- Lime.

- Clay.

- Plaster.

Cement

This composition is the most common type of finish: its consistency is very similar to laying mortar for bricks. However, the density in this case is different, moreover, the use of various additives and plasticizers is widely practiced.

Although this may sound unexpected, the quality of the sand used is most important for personal control. That is why, before use, it is carefully sieved through a special sieve to remove all impurities and debris.

After cleaning the sand, the mixing procedure begins: while the main components need mix dry first. The proportions of cement mortar for plastering walls outside the room is taken in a ratio of 1: 5 sand to M500 grade cement. As for the interior decoration, in this case, cement is mixed with sand 1: 4, where M400 cement is taken for preparation. After acquiring the required homogeneity with dry components, add water to the composition and stir until mushy. To carry out such a procedure, both a trough and a construction mixer can be used.

Lime

Lime acts as a binder in lime mortar

Lime acts as a binder in lime mortar

This composition differs from the previous one in the absence of cement: lime is used as a binder in this case: it should only be slaked and have excellent qualities. The first step is to grind it thoroughly so that the particles are as small as possible. Then water and sand are added to a bowl with lime powder, with constant stirring of the entire material

It is very important that the resulting lime plaster mortar does not contain lumps, with a mixture similar to that of dough. Then another portion of refined sand is added to the resulting mass, in a ratio of 3: 1. After that, the final stirring of the plaster is carried out with the addition of water: the finished consistency of the solution should resemble thick sour cream

After that, the final stirring of the plaster is carried out with the addition of water: the finished consistency of the solution should resemble thick sour cream.

Clay

This easy-to-prepare plaster mortar is the oldest known. In the course of the development of construction technologies, its composition has undergone some changes, because clay in its pure form is quickly washed off by rains. To strengthen the finish, the addition of cement, lime and gypsum is practiced, which contributes to an increase in its durability and reliability: while the availability of preparation is preserved. In the process of preparing clay plaster, the main component must be thoroughly cleaned of all kinds of debris and impurities. Then, clean and dry clay is soaked in water for 3-5 hours until it is completely soaked: the preparation of the solution is completed by adding sand to its composition, at the rate of 2-4 parts of sand to one part of the clay mixture. Clay plaster is usually used for interior decoration.

Gypsum plaster

Most often, with the help of gypsum plasters, final operations are carried out to level the walls, with the possibility of applying not only to concrete and brick, but also to wooden bases. The first recipe for preparing such a solution involves the use of 3 kg of chalk and 1 kg of gypsum, while the chalk is crushed to a state of dust, followed by mixing with gypsum. In this case, water is not used, since a 5% wood-type glue is used as a solvent. The proportions of the adhesive in this case vary, depending on the required thickness of the final solution. This type of solvent not only makes the mass of the plaster homogeneous, but also makes it possible to somewhat slow down the hardening process. However, the drying speed of gypsum plaster is still quite high.

Working with gypsum plaster requires skill, as the mixture dries quickly

Working with gypsum plaster requires skill, as the mixture dries quickly

The second method of preparing a finishing solution from plaster is especially suitable in cases where it is required to plaster painted bases or chipboard partitions. In this case, you will need to take 2 kg of gypsum, 1 kg of drying oil and 100 g of desiccant: after thorough mixing, the composition should be immediately worked out.The reason for this is the lightning-fast drying of the desiccant: when working in this case, you will need the appropriate construction skill.

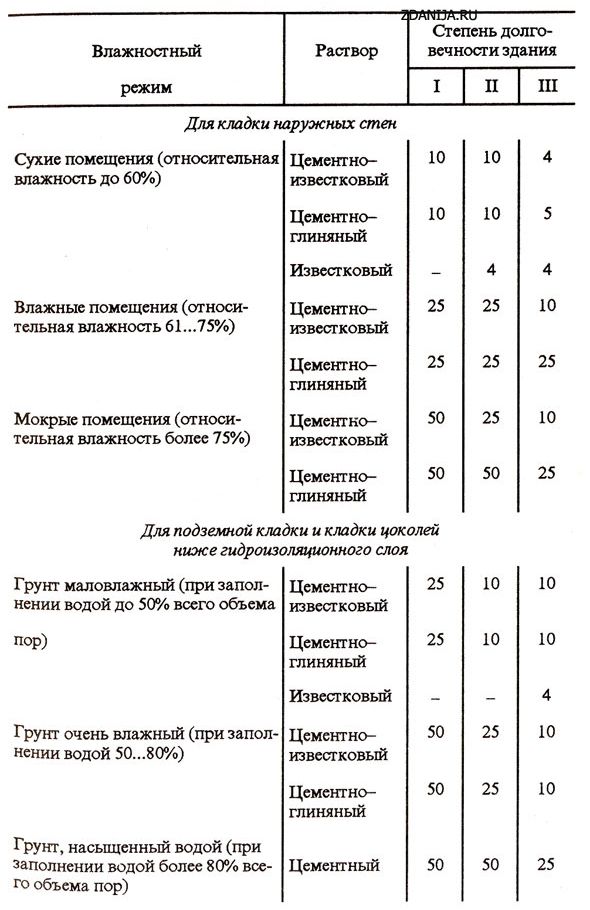

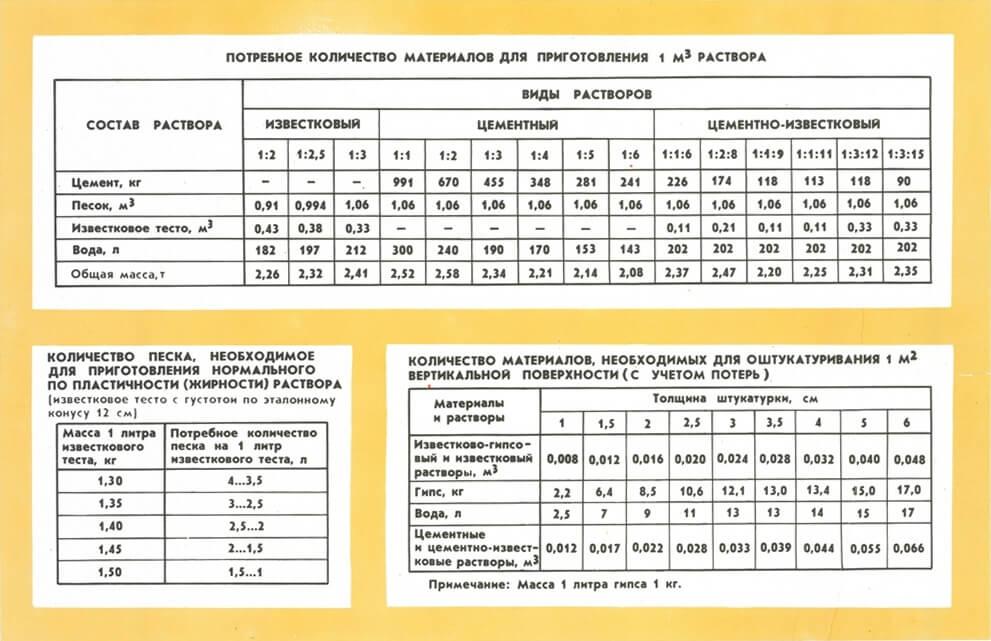

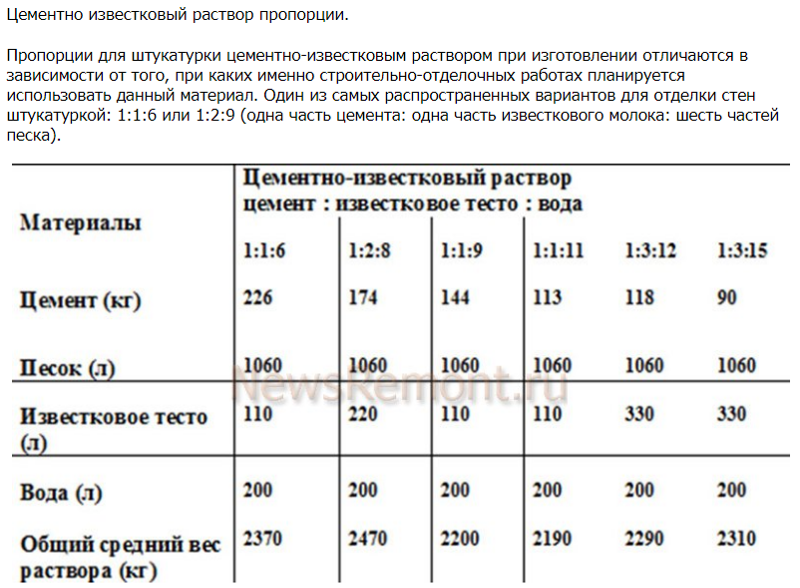

Helpful dosage guidelines

It should be remembered that for different types of building materials it is required to mix mixtures with different ratios of sand and cement. for laying bricks... For solid bricks, one composition is needed, and for hollow bricks, another. Mixing water should be used only clean, with a temperature of + 15-20 ° C. If there is dirt or mold in it, it will later show up in the finish. For cement-sand, the ratio of water to cement is as follows - 0.5-0.8 to 1 part of the binder (depending on its brand). The sand is selected with a fraction of not more than 2.5 mm.

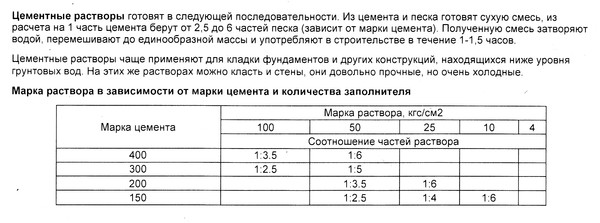

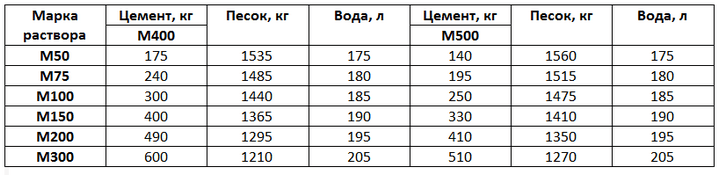

The proportions of cement consumption vary based on its grade (the higher it is, the greater its viscosity). If M500 is used to mix the cement-sand composition, then 1 part of cement must be added to three parts of sand. For M400, their ratio will be different: 2.5 parts of sand to 1 part of the binder. The amount of sand can be more, up to 8 parts - it depends on the purpose and brand of cement.

The finished mixture can be used within two hours, since after that the cement becomes less plastic and hardens. Therefore, mix exactly as much as will be consumed. mortar on masonry During this time.

How to cook with your own hands?

First, the dry composition is mixed, sand is poured into the container, and then cement. First, it is better to sift everything so that there are no lumps. The mixture is thoroughly mixed and water is added, after which everything is mixed again until the consistency is homogeneous. It is better to choose a capacity in terms of volume almost the same as the amount of material required for a one-time job.

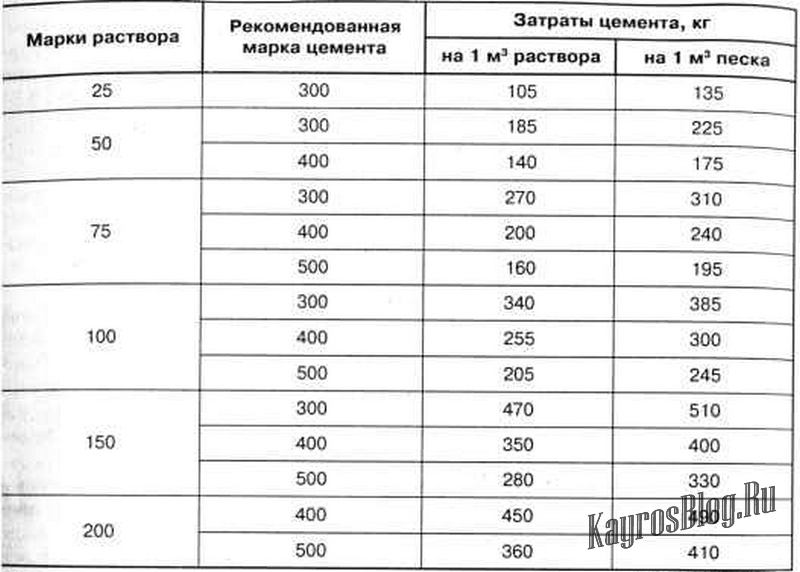

For greater strength and reliability, it is recommended to add detergent (50-100 g), it will increase its plasticity. Cement consumption depends entirely on its brand. For 1 m3, 510 kg of a binder of the M300 brand, M200 - 410 kg, M150 - 330 kg will be required. The consumption for masonry is affected by the building material used. For a solid brick, it will be required less than for a hollow one. For 1 m2 of surface for a single brick, about 0.2 m3 of the composition is needed, for one and a half - 0.25 m3.

Truly working legal way to save money. Everyone needs to know this!

How do you know if the mixture is properly mixed and ready?

You can determine the readiness of the cement mortar with your own hands using a cone or by touch

You should pay attention to the degree of adhesion to the brick, as well as how mobile it is. Its readiness can be determined by making a dent in it: if its shape remains, then it is ready for use.

You can also tilt the container 40-45 °, it should not flow out.

You can use a cone, its height and width - 15 cm, weighs 300 g. The readiness of the composition is determined by immersing the cone in it. The sinking depth depends on the purpose of the mixture. For an ordinary brick, it should plunge by 9-13 cm, for a hollow brick - by 7-8 cm, but no more.

The quality of the mortar is determined by the amount of moisture in it and its plasticity. Too dry has poor adhesion to building materials, and too wet spreads strongly. If it sticks to the trowel, then add dry ingredients and mix everything thoroughly again. Mobility depends largely on the fraction of sand: the smaller it is, the less mobile the composition.

Density can also be determined using a cone or by plasticity. If it spreads under its own weight, then it is not suitable for use, if it crumbles heavily, then it also cannot be used for masonry.

The cost of ready-made mixtures

In order not to knead by hand, you can buy a masonry mortar. The use of such building materials greatly simplifies the work and time costs, since there is no need to do the dosage.

The purpose depends on the proportion of the binder.An improperly prepared one not only complicates the work, but also significantly degrades the quality of the structure being erected. So, for example, a wall made of poor quality compound can become brittle and cracked. As a result, the heat capacity of the room decreases, in the heat it quickly heats up, and in the cold it cools down. Mixing the solution, you need to accurately observe the proportions. If they are violated, then cracks may appear in the masonry.

The production of building bricks has long been affordable for small businesses.

White sand-lime brick is a building material used for construction.

Today, gypsum tiles are increasingly used in cladding work. WITH.

Projects houses made of aerated concrete

Projects houses made of aerated concrete

Choosing a foundation for a house from foam blocks

Choosing a foundation for a house from foam blocks

What is better foam concrete or aerated concrete?

What is better foam concrete or aerated concrete?

Pros and cons of aerated concrete blocks

Pros and cons of aerated concrete blocks

Concrete grades overview

Concrete grades overview

Application of DSP in construction

Application of DSP in construction

Photo of masonry mortar

We also recommend viewing:

- Finishing putty

- Knauf plaster

- DIY floor screed

- Foam Adhesive

- Adhesive for foam blocks

- Cement

- Self-leveling floor mix

- Penetrating waterproofing

- Bituminous mastic

- Dropout

- Building mixtures

- Waterproofing mixtures

- Adhesive for ceramic tiles

- Tile adhesive

- Latex putty

- Polymer putty

- Wood putty

- Tile grout

- Ready putty

- Putty consumption

- Which putty is better

- Facade putty

- Putty

- Gypsum plaster

- Decorative plaster

- Construction sand

- Special mixtures

- Textured plaster

- Plaster consumption

- Facade plaster

- Insulation adhesive

- Self-leveling floor consumption

- Which plaster is better

- Floor leveler

- Plaster putty

- Mechanized plaster

- Plaster bark beetle

- Venetian plaster

- Floor screed mixture

- Which tile adhesive is best

- Drywall adhesive

Material requirements and mortar quality document

The materials that become the basis in the preparation of CDS must fully comply with the standard characteristics, as well as the technical conditions of the document in question.

How to use a connector:

- CaSO4 • 2H2O according to standards 125;

- Ca (OH) 2 according to standards 9179;

- Pozzolanic and sulphate-resistant constituents according to 22266;

- Cement for building mixtures according to standards 25328;

- CaSO4 • 2H2O according to item "B";

- Others, including combined elements, which correspond to the established acts for a particular type of materials.

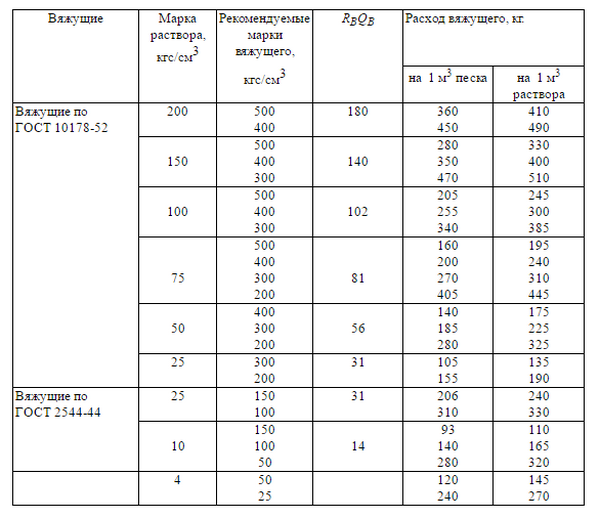

The connecting components, which will soon become the basis for the preparation of solutions, must be selected based on their purpose, type of structure and operating conditions. Consumption of cement per cubic meter of sedimentary rock in the corresponding mixtures must be at least hundreds of kilograms.

Calcium components are used in the form of calcium oxide hydrate, calcium oxide dough, calcium oxide milk. The density of the latter cannot be less than 1200 kilograms and not less than thirty percent of the total mass.

The constituents of calcium oxide for plastering and tiling work cannot contain particles of unslaked lime. In this case, the dough from calcium oxide should stand out with a temperature indicator of at least five degrees.

See also the quicklime formula.

Lime-gypsum solutions

If there is a need to obtain a composition that sets quickly, then prepare a lime mixture with gypsum (curing time is about 10 minutes):

- we prepare a regular composition based on fluff and divide it into two parts;

- Combine the first part with gypsum in a 2: 1 ratio and mix;

- add to this composition with gypsum the second part of the composition based on fluff and mix again;

- use the resulting mixture for 5 ÷ 8 minutes (while continuing to constantly stir the mixture).

Advice! We recommend working with lime plaster solution quickly and mixing it in small portions.

Such compositions are characterized by: fine grain size and no shrinkage.Disadvantages: the need to use them in the shortest possible time and the impossibility of using them in wet rooms. Most often, such mixtures are used for indoor plastering of premises (they are rarely used outside).

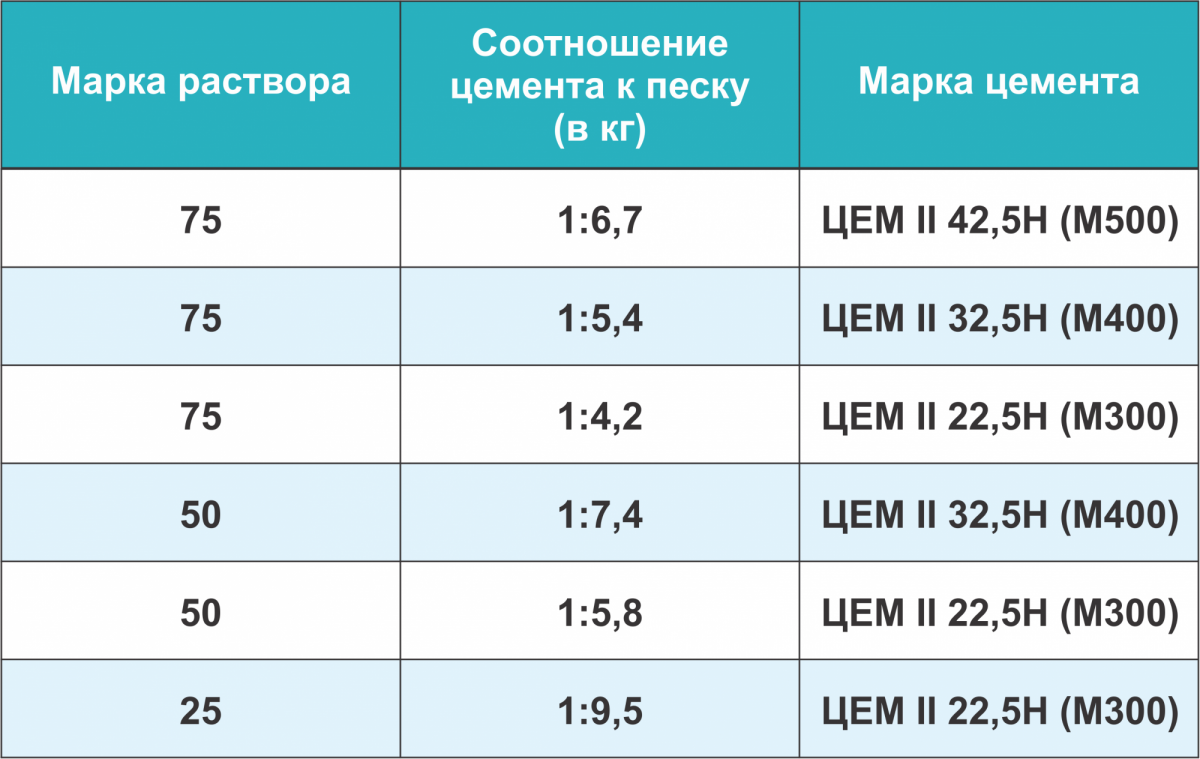

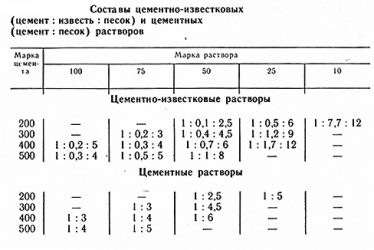

Sand to cement ratio

You can even prepare a cement-sand mortar at home, since it consists of available components. It is quite easy to get them in almost any hardware store. But the solutions differ in the ratio of cement and sand, on which the consumption and physical characteristics of the material depend.

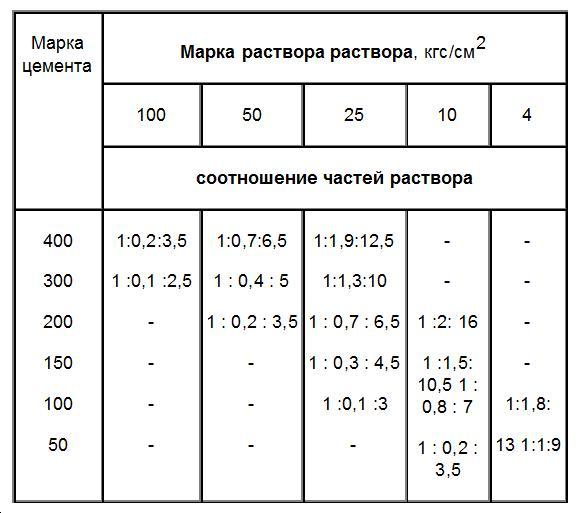

Brickwork

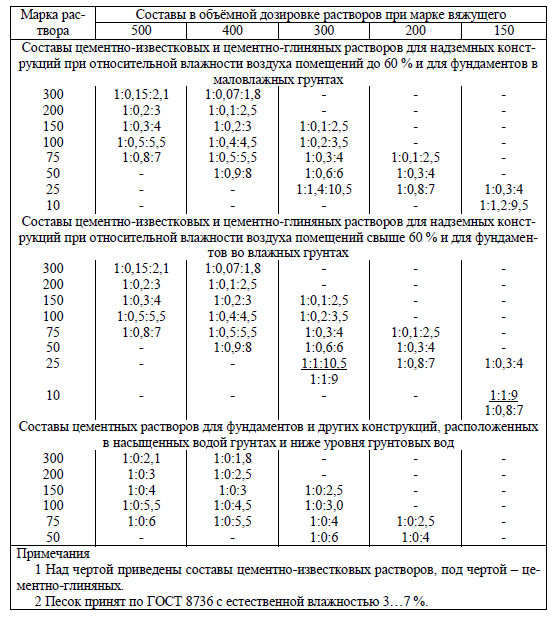

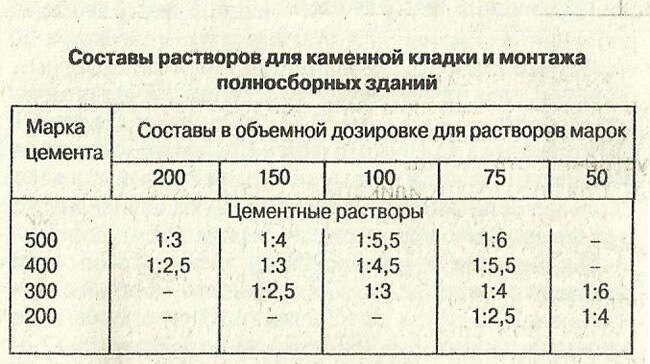

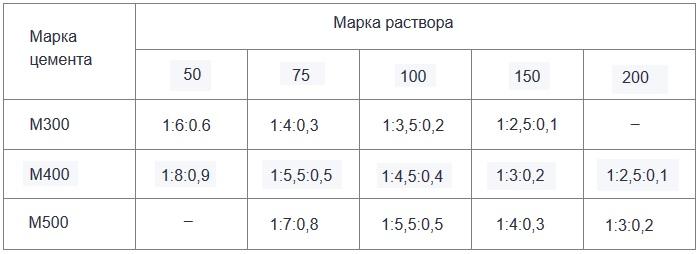

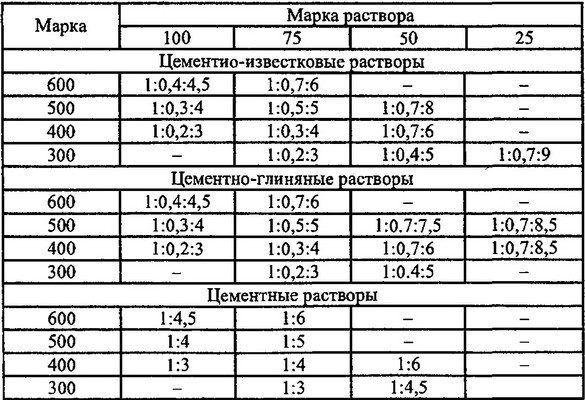

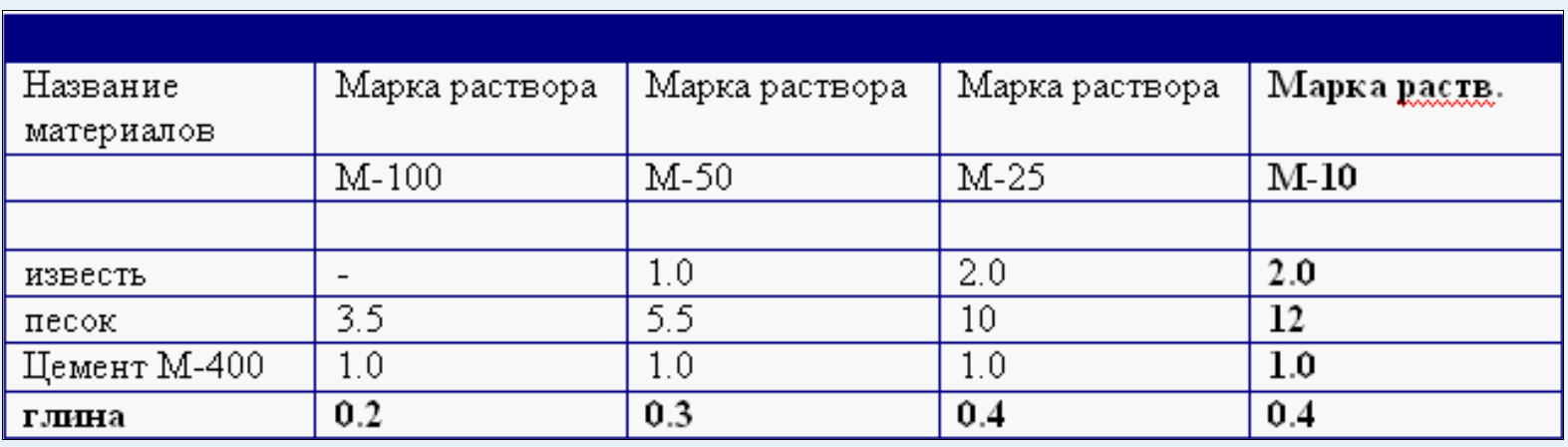

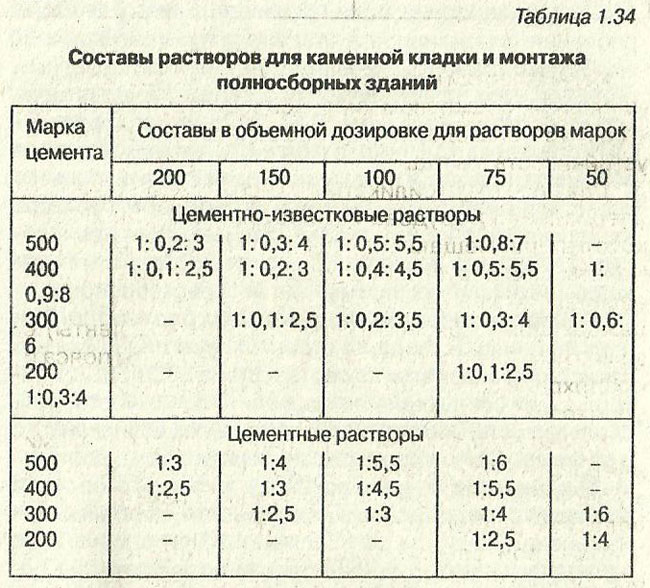

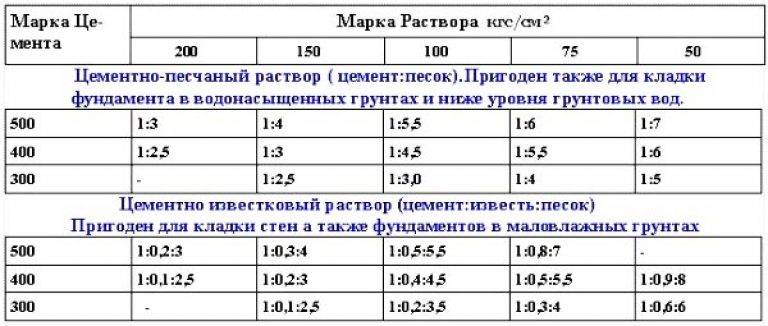

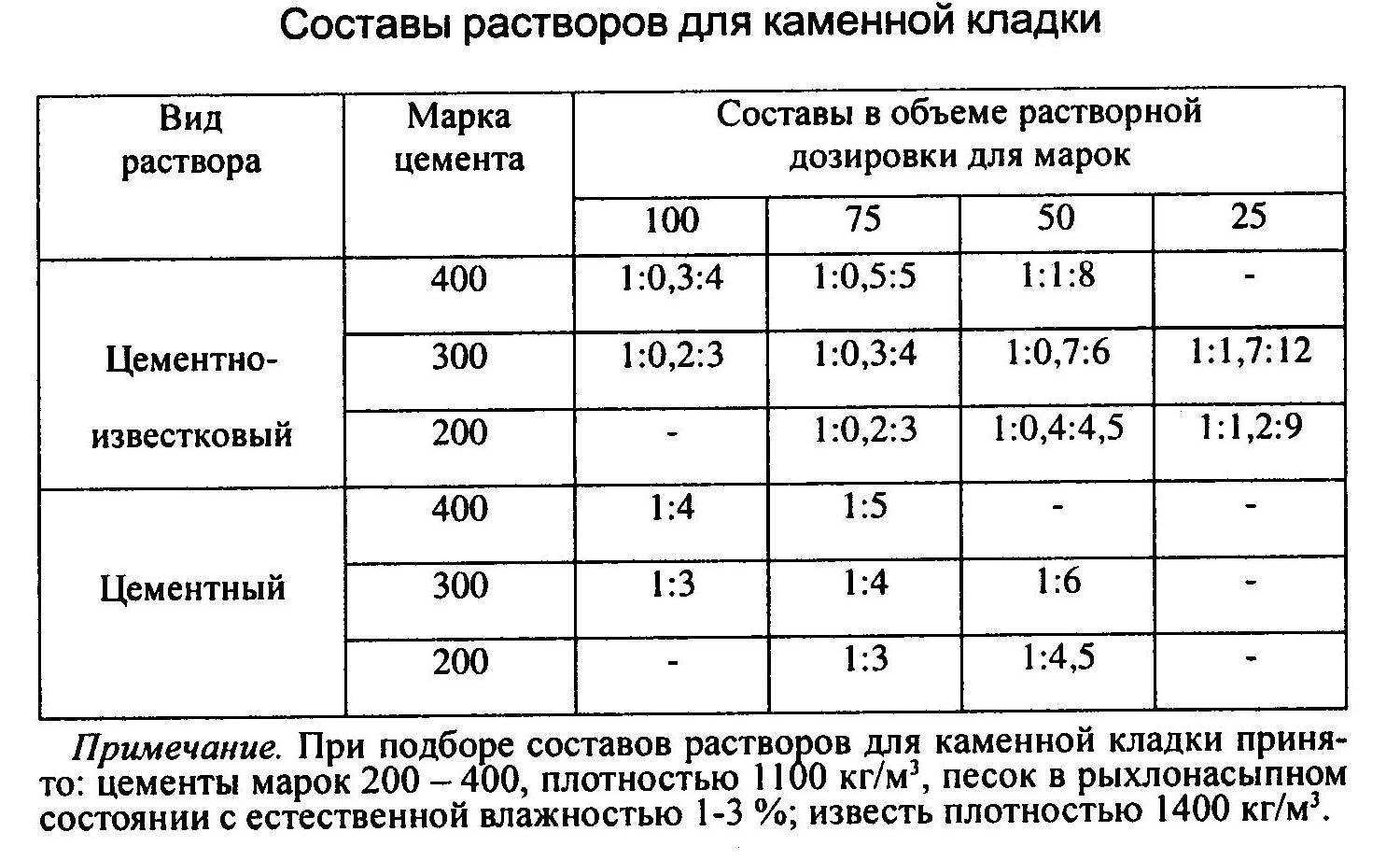

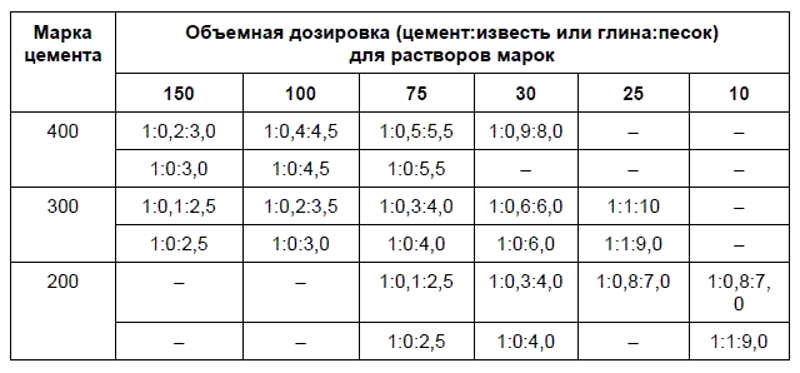

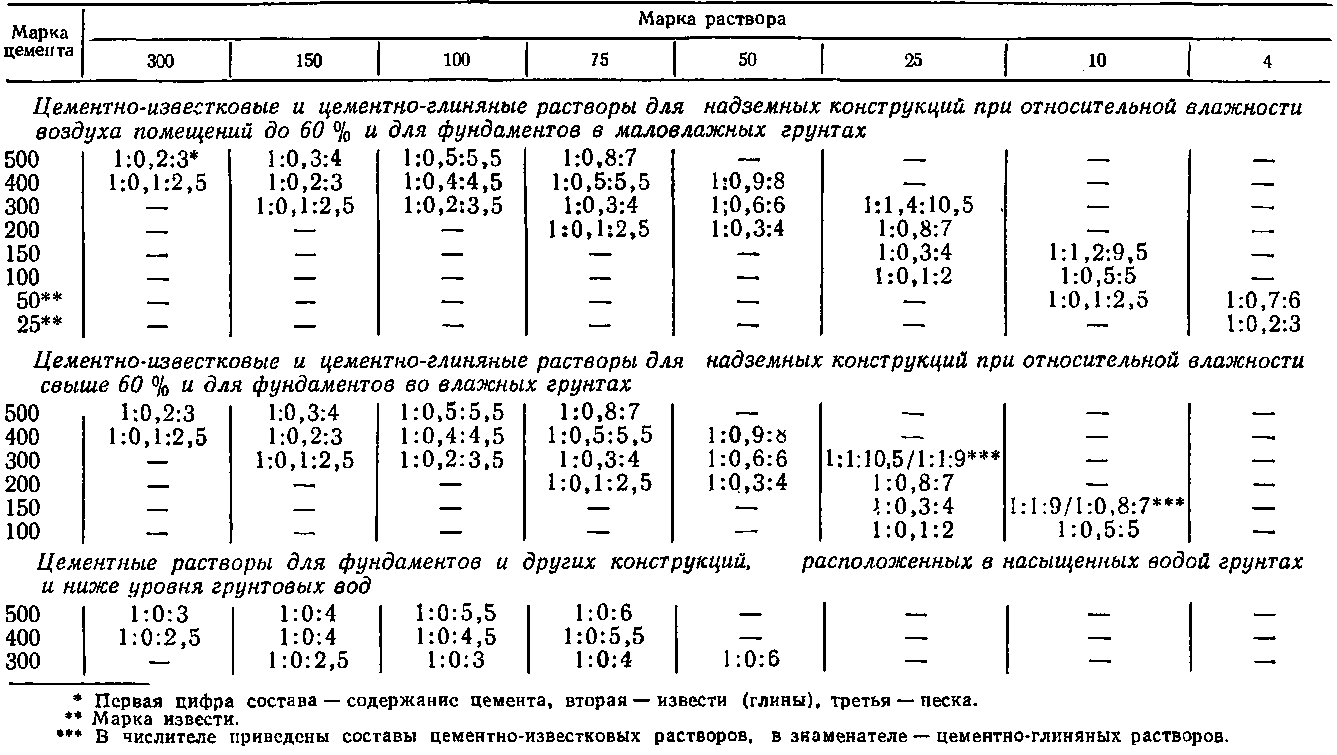

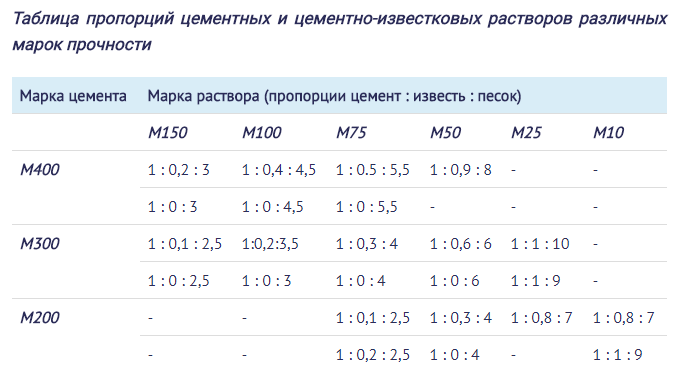

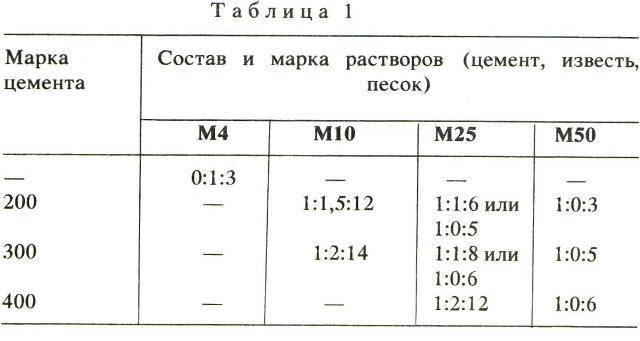

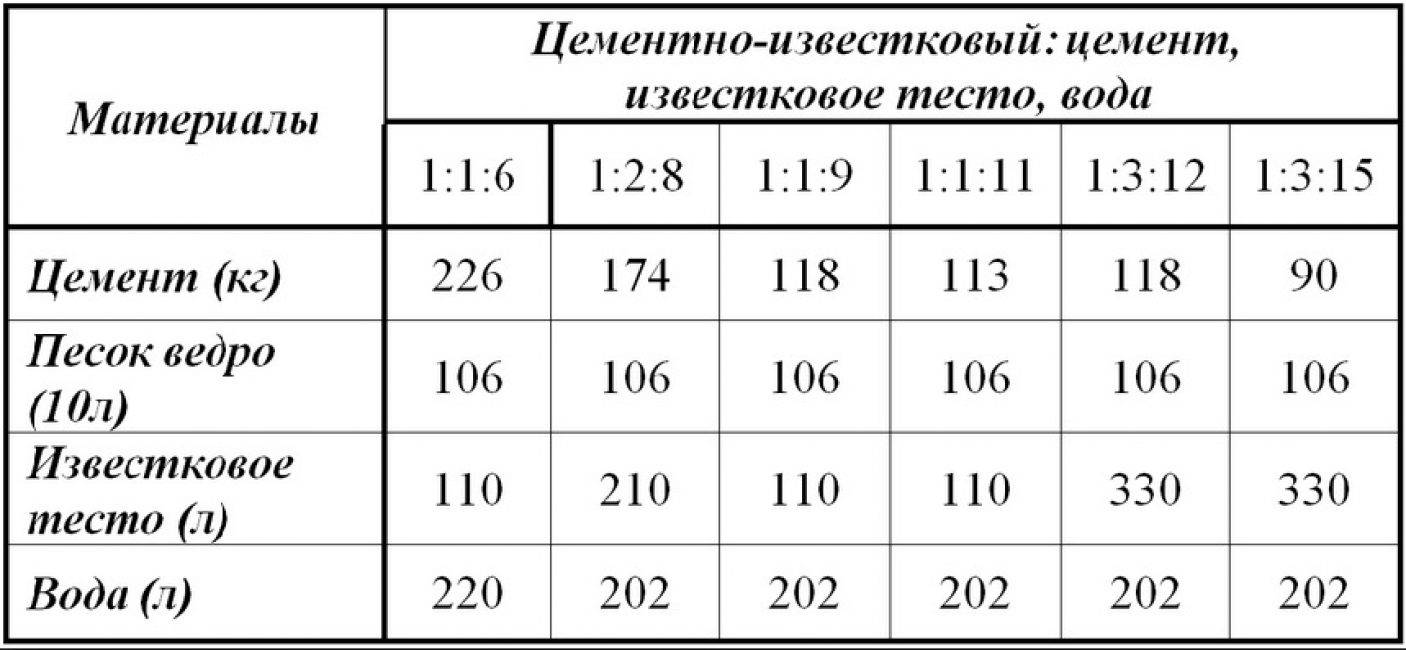

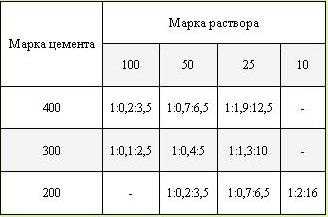

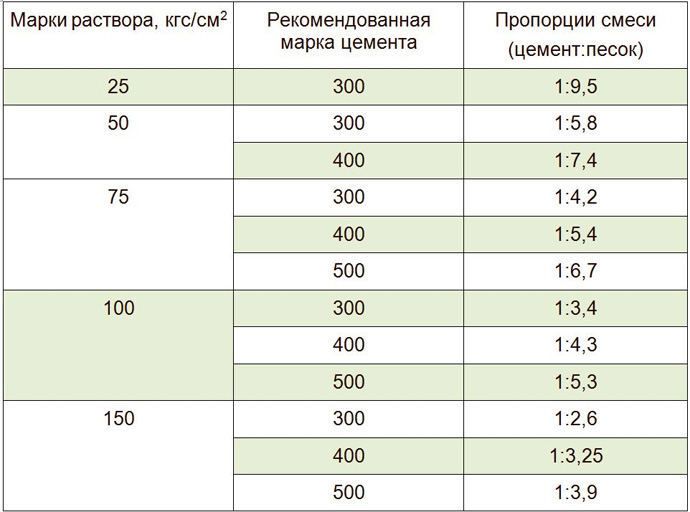

Bonding bricks is one of the main tasks of cement mortars. For such purposes, not particularly strong brands are used (up to M400). To obtain such a mixture, experts recommend using medium-fraction sand with a minimum moisture level. Masonry mortar can be prepared using various brands of cement. But this will already change the ratio of cement and sand. Some proportions are presented in table 1.

Table 1. Ratios of components depending on the brand of cement

|

Cement brand |

Part of the sand |

Part of cement |

Lime |

|

M500 (without lime) |

3 |

1 |

— |

|

М400 (without lime) |

2,5 |

1 |

— |

|

M300 |

3,5 |

1 |

2/10 |

|

M400 |

2,5-4 |

1 |

1,3/10 |

|

M500 |

3 |

1 |

2/10 |

Concrete preparation

Concrete structures are also very commonly used in modern industry. These materials are manufactured in factories or directly on construction sites. The strength of such products also depends on the cement to be used. Technically, concrete can also be made from M100 grade mortar, but it will not withstand loads and have a minimum service life.

Another feature of concretes is the presence of crushed stone and other auxiliary components in the composition. They are introduced with the aim of changing the technical characteristics of a product.

Today, many experts use such a ratio of components of concrete solutions as:

- 4 pieces of rubble;

- 1 part cement;

- 2 pieces of sand;

- ½ part water.

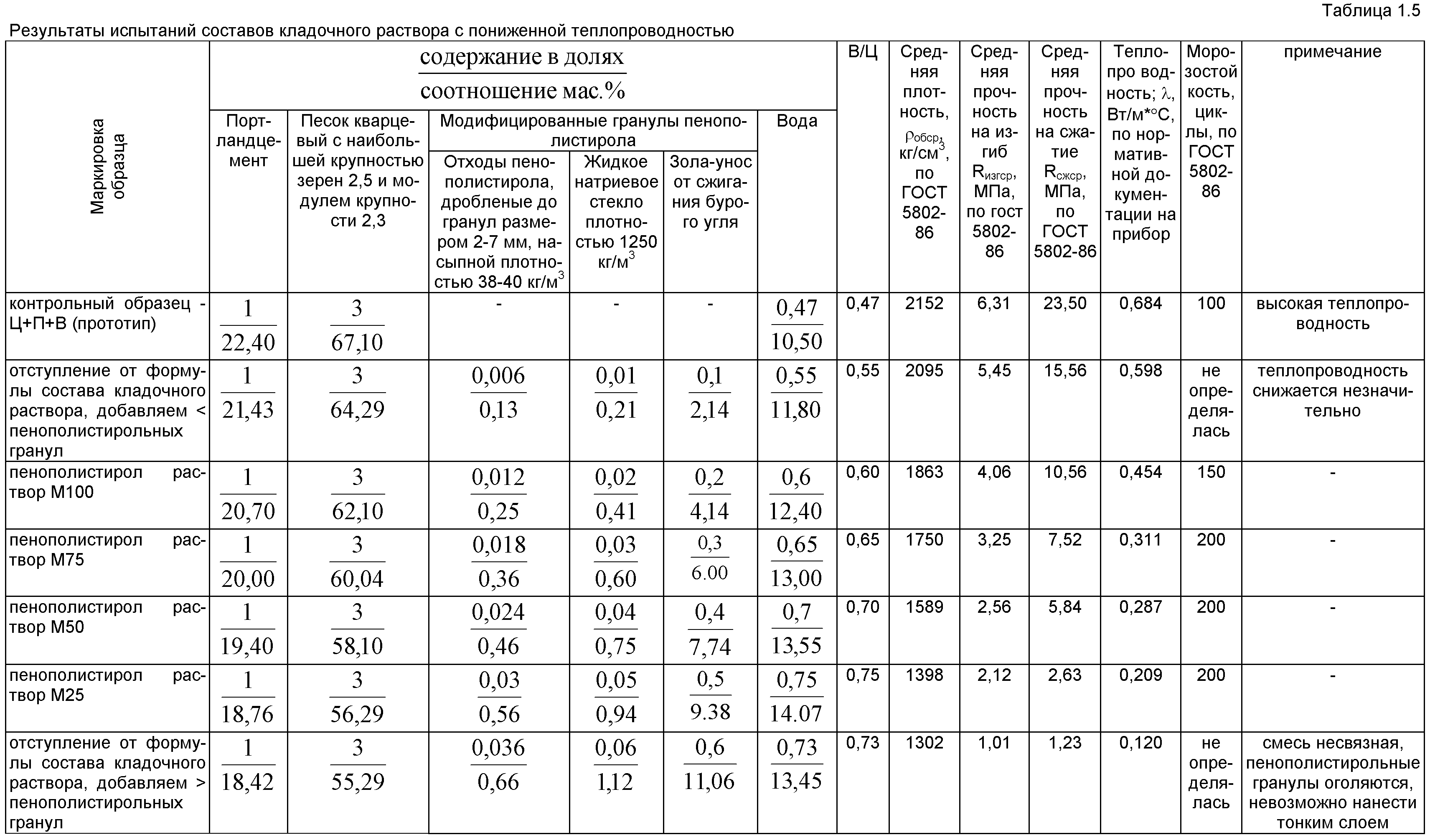

For plaster and screed

Floor filling very often involves the use of relatively liquid cement mortars. This consistency allows you to evenly distribute the mixture on the substrate and obtain a horizontal surface. Plaster, on the other hand, almost always consists only of pure sand, cement and water. Its density can be different, since it all depends on where it is planned to be used.

The most common proportion for producing plaster mixes is the ratio of cement to sand 1: 5. The consistency is adapted to the needs of the master.

Particular attention should be paid to screeds that lend themselves to significant and constant stress. For such surfaces, materials should be used that have a threshold strength not less than 10 MPa

This is achieved through the use of concretes of a grade not lower than M150. The proportion of preparation of the screed solution depends on the following factors:

- using mixtures to hide various communication elements;

- surface leveling thickness. If you just need to strengthen the floor with small differences, then use more liquid formulations. For thicker layers, it is advisable to use strong types of mortars.

Table 2. Proportions of sand and cement in screeds

|

Solution grade (result) |

Cement grade |

Quantity of cement (parts) |

Amount of sand (parts) |

|

M100 |

M200 |

1 |

3 |

|

M150 |

M300 |

1 |

2 |

|

M200 |

M300 |

1 |

1 |

|

M150 |

M400 |

1 |

3 |

|

M200 |

M400 |

1 |

2 |

|

M300 |

M300 |

1 |

1 |

How much powder and sand to take

The proportion of the constituents is largely determined by the grade of the starting materials. Sand, cement are the leading ingredients. The higher the brand, the more cement powder will be needed, and the better the mixture will be. As for the brand, it is selected individually, depending on the type of construction work. When forming foundations and building serious objects requiring high strength, it is recommended to use a solution of higher grades.

Types of cement mortar.

There are 3 types of solutions: for masonry, plaster and cladding. In the latter case, grades M-200 and M-300 are suitable. For masonry work, it is preferable to take mortar of the M-150, M-300 and M-400 brands. Often there are situations when it is necessary to carry out a cement floor screed. For this, a mixture based on cement and sand of the M-150 and M-200 brands is suitable.

The proportion of cement and sand depends on the grade of the cement powder itself. In most cases, powder grades 400 and 500 are taken. To make a solution of the M-100 brand, the ratio of sand and cement should be 1: 4, provided that 400 powder will be taken. This proportion is determined in mass equivalent of the substance. In the event that the cement powder is grade 500, then the proportion is 1: 5. No gravel or crushed stone required. If you need to get a mixture of the M-200 brand, then the amount of raw materials will be different. Here, for 1 kg of cement, only 2 buckets of sand are needed. Everything suggests that the higher the required grade of the solution, the better the cement needs to be taken, and the more its consumption will be.

Mixing proportions for concrete

To knead a cubic meter of concrete, you need to stock up on raw materials. Not everyone knows how much rubble is in a cube of concrete. Crushed stone is a coarse-grained raw material that gives strength and rigidity to the structure when solidified.

Concrete mixing scheme.

To obtain reliable concrete, for example, of the M-300 brand, you will need cement, sand and crushed stone in a ratio of 1: 1.9: 3.7. This rule only applies when 400 cement is used. If grade 500 powder is available, the proportion will be 1: 2.4: 4.3. In the construction of critical structures requiring special strength and wear resistance, it is preferable to use concrete M-400 and higher. To get a cube of concrete, you need a lot of raw materials. In this case, the ratio of the three main substances is 1: 1.2: 2.7, taking into account the fact that concrete grade 400 will be obtained (in the presence of powder 400).

It is also important that when mixing concrete, the following factors must be taken into account:

- size of sand and coarse material (crushed stone or gravel);

- the quality of the future concrete;

- density of raw materials.

Don't forget about water. The latter is the link between all bulk components. If there is a lot of it, then the solution will turn out to be liquid and less durable.

It is also important to mix the raw materials correctly. In this case, concrete or cement-based mortar will have a homogeneous structure, reminiscent of sour cream.

If you plan to mix a large volume of components and get a cube of concrete or more, then you cannot do without a concrete mixer.

A situation may arise when it is required not only to calculate the consumption of raw materials, but also to determine the brand of the resulting solution. This will require accurate data on the mass of the raw materials used. If it took 1 bucket of cement 400 and 4 buckets of sand to make the mixture, then you need to divide the brand by 4 (400/4 = 100). As a result, it turns out that there is a grade 100 solution available. The same is true if there is a grade 500 cement and 5 buckets of sand.

Conclusion on the topic

As you can see, cement-sand mortar is not just a common mixture of two ingredients. There are several types of it, each of which is intended for specific construction work. At the same time, it is not only the quantitative ratio of the main ingredients that matters, but also the content of water and special additives that increase the qualitative characteristics of the material. Mortars based on cement and sand are most often used in construction and repair work. Therefore, everyone who is going to build a house or renovate his apartment should know their composition and proportions of components.

One of the main components of mixtures for plastering surfaces, or for concrete solutions, is cement. Cement is currently considered a very popular material, because it has sufficient strength and ductility.

I must say that in the process of construction or the production of repair and construction work, cement is almost never used in its pure form. It is expensive, and the hardened clean cement is very fragile, so the brickwork on it does not differ in strength. Therefore, at construction sites, it is customary to use a cement-sand mortar. Moreover, the ratio of the components depends on the purpose for which such a mixture will be used.

In other words, if it is necessary to lay bricks, then one type of sand-cement mortar must be used. For plastering surfaces - other types, etc. I must say that complex and simple solutions are used in construction. Although they differ, first of all, in the number of components used. Those. if a simple solution can be easily prepared from water, a certain part of cement and sand, then complex solutions consist of more ingredients.

Brickwork is usually laid on lime or complex sand-cement mortar. Lime mortar is a cheap and convenient type of mortar, which is why it is used most often. However, it should be noted here that its strength in some cases leaves much to be desired, therefore it is not recommended to use this type for strong masonry. For this, cement-sand mortar m100 or m150 is more suitable.

M100 is the most popular among all other mixtures of this kind and is often used in the construction of houses and in repair and construction work. It can be used for masonry, masonry of concrete blocks, slag and foam blocks, as well as for arranging screeds on concrete bases.

Even more popular is the cement-sand mortar m150. It contains a fine filler, and as for crushed stone or large fractions of filler, they are not in it at all. The main components of this solution are sand and cement, and a little more cement is taken than in the manufacture of concrete of the M150 brand. It is usually called mortar, cement mortar, plaster mortar. Moreover, in the latter case, a certain part of lime is necessarily added to its composition. In some cases, clay can be added to the cement-sand mortar to give it elasticity.

Special building codes have been developed that determine the correct ratio of sand and cement for the preparation of such mixtures. It must be said that the strength of the solution, due to the addition of sand to it, increases, but at the same time its plasticity also decreases. Most often, 3 parts of sand and one part of cement are added to the solution. This solution is considered classic and is used most often.

In order for the mixture to be of high quality, you must first mix the components dry, but as for water, it should be added in small portions to the dry mixture. It is necessary to add water until a creamy consistency is obtained. After obtaining such a mass, the solution should be left to thicken for 15 minutes, and then mix well again. In principle, cement filled with water is capable of setting in an hour or two, therefore, large volumes of mortar should not be prepared in order to avoid waste of materials.

In conditions of high humidity or frost, special additives are usually introduced into the sand-cement mortar.