Technical standards

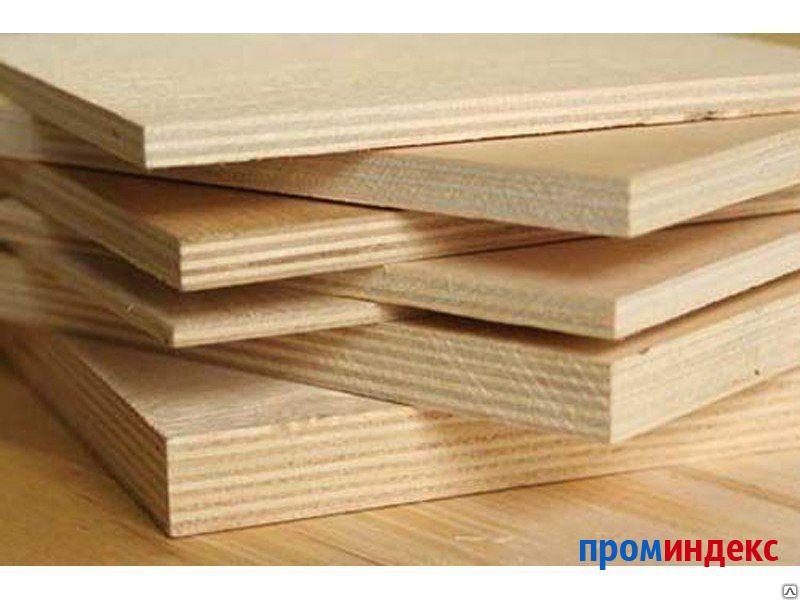

According to GOST, birch plywood is divided into five grades. The higher the grade, the less knots on the product. Consider the difference between varieties.

Grade 1

Flaws for this variety:

- pin knots, there should be no more than three pieces per 1 sq. m;

- healthy knots connected, not exceeding 15 mm in diameter and in an amount of not more than 5 pieces per 1 sq. m;

- dropping knots with a hole, not exceeding 6 mm in diameter and not more than 3 pieces per 1 sq. m;

- closed cracks, not exceeding 20 mm in length and not more than 2 pieces per 1 sq. m;

- damage to the edges of the sheet (no more than 2 mm in width).

Grade 2

Compared with the first type, this variety allows the presence of defects in an amount of no more than 6, these include:

- healthy discoloration exceeding 5% of the plywood sheet surface;

- overlap of the material on the outer layers (no more than 100 mm in length);

- seepage of the adhesive base (no more than 2% of the total sheet area);

- notches, marks, scratches.

Grade 3

Unlike the previous type, the following flaws are permissible (there should be no more than 9 of them):

- double wood inserts;

- tearing out of the constituent particles (no more than 15% of the plywood sheet surface);

- glue mass flowing out (no more than 5% of the total area of the plywood sheet);

- holes from falling out knots, not exceeding 6 mm in diameter and in an amount of not more than 10 pieces per 1 sq. m;

- spreading cracks up to 200 mm in length and no more than 2 mm in width.

Grade 4

In addition to the defects of the previous grade, the following shortcomings are permissible here without taking into account the quantity:

- wormholes, accrete, falling out knots;

- connected and spreading cracks;

- leakage of adhesive, gouges, scratches;

- pulling out fibrous particles, grinding;

- waviness, hairiness, ripples.

Plywood is produced only from healthy plants. At the same time, from May to September, the source material must be treated with special moisture-protective agents. The material used must be of a high quality level.

Areas of use

Due to its high strength, birch plywood is widely used in many industries.

Construction

Even taking into account the high cost, the material is popular when carrying out such construction and finishing works as:

- construction of monolithic structures;

- installation of plywood as a substrate under the laminate when arranging the floor;

- wall decoration in individual construction.

Mechanical engineering

Due to its lightness and strength, birch plywood is used for the following works:

- manufacture of side walls and floors in passenger and cargo vehicles;

- finishing of the body of freight transport;

- use of a moisture-repellent FSF sheet in rooms with high humidity.

Aviation plywood is used by engineers in the design of aircraft.

Furniture industry

Birch plywood is widely used in this industry. Taking into account the type of material, it is used to produce furniture for the kitchen, for bathrooms, garden and summer cottage products, various cabinets, tables and much more.

For more on the features of birch plywood, see the next video.

What happens?

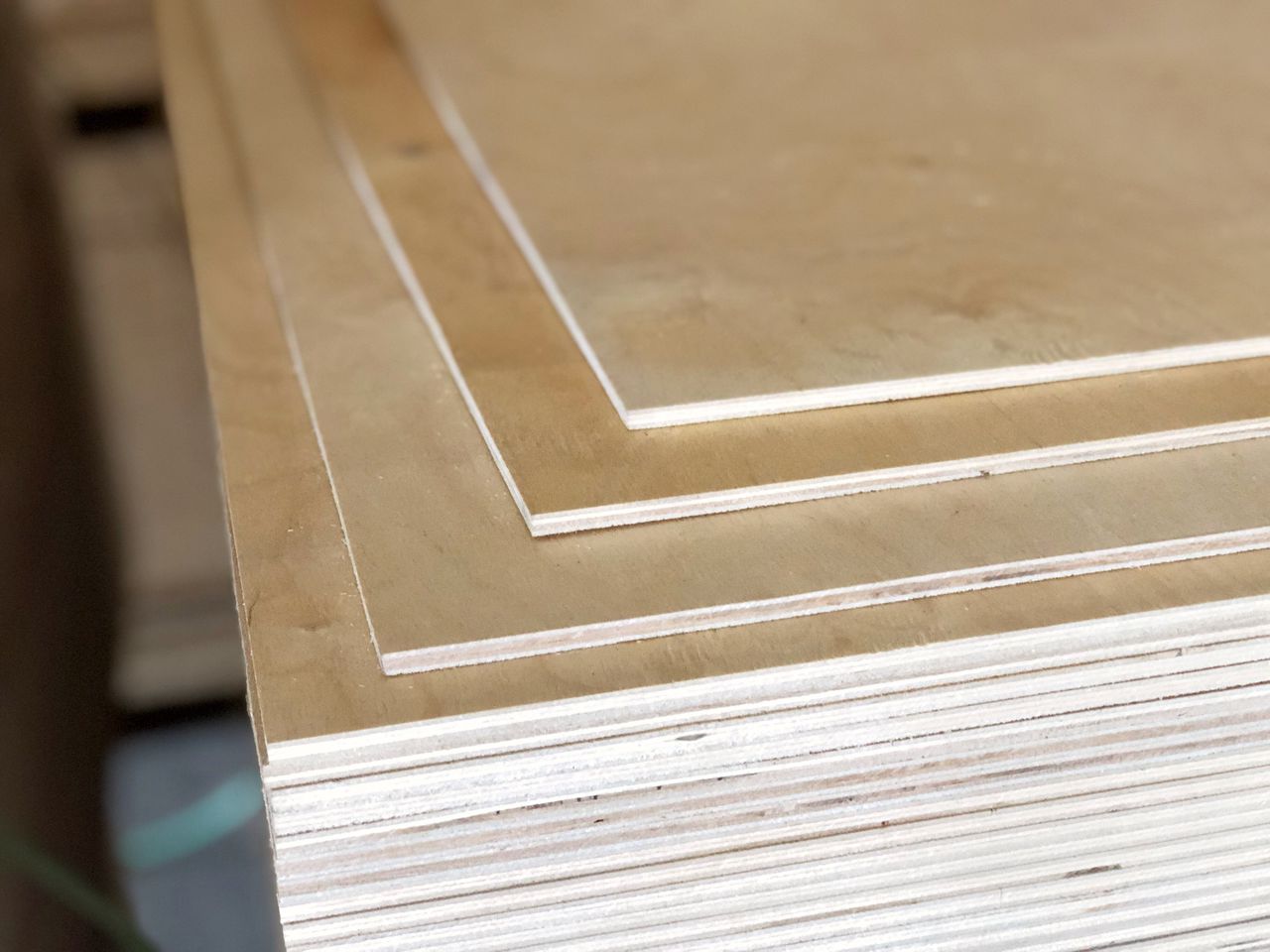

Birch plywood has a high degree of strength and a multi-layer structure, the sheets are connected to each other using special adhesives. There are certain types of plywood.

- FK - to connect the veneer sheets to each other in this version, urea resin is used. This product has a low moisture resistant effect and is recommended for indoor use.

- FKM - this type is made using environmentally friendly melamine resins, has increased water-repellent characteristics.Due to its ecological qualities, such material is used in the manufacture of furniture and in the interior decoration of premises.

- FSF is a moisture resistant material. Gluing of veneer sheets in this embodiment is carried out using phenolic resin. Such a product is used for outdoor finishing work.

- Laminated - as part of this type, there is a FSF sheet, covered on both sides with a special film material. This plywood can be used repeatedly. It is usually used in the construction of formwork.

- Bakelized - the gluing base of veneer sheets in this version is bakelite resin. Such a product is used in aggressive conditions and during monolithic works.

Birch plywood sheets come in several standard sizes that are in the highest demand:

- 1525x1525 mm;

- 2440x1220 mm;

- 2500x1250 mm;

- 1500x3000 mm;

- 3050x1525 mm.

Specifications

Birch is the most demanded material in the production of plywood, since, unlike other options, it has the following advantages:

- excellent level of strength;

- moisture-repellent effect;

- simplicity of the processing process;

- special decorative quality of the texture.

The main criterion when choosing birch plywood is its density, which is 700-750 kg / m3, which exceeds the indicators of coniferous analogues. Due to their high density, birch veneer sheets are the best option for many design decisions.

An important indicator in planning is the specific gravity of the plywood sheet, since when used in a structure, it will be necessary to calculate the expected load on the future structure base. The weight of one sheet, as well as its density, depends on the source material used in the base (the birch version will be heavier than the coniferous one). The type of glue used does not affect the density of the plywood.

An important indicator is the thickness of the plywood sheet. In the case of using the material for interior work (for wall decoration), panels 2-10 mm thick are used.