How do anchors work - how do they handle loads?

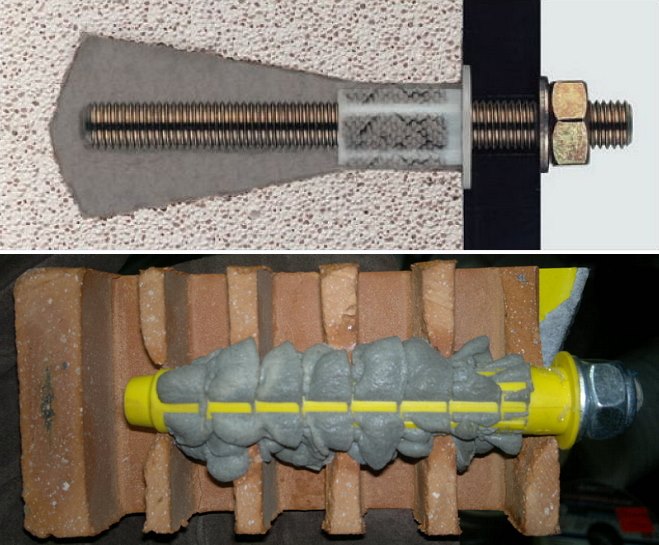

The principle of operation lies in their technology and a special prefabricated structure, due to which the load has a completely different nature. The fact is that the anchor bolt, when installed already in the wall, expands, it cannot be pulled back with any effort, like a nail, dowel or screw.

It is impossible to pull the anchor bolt out of the wall

It is impossible to pull the anchor bolt out of the wall

This distributes the load over the small surface area into which the bolt was installed, rather than at one point, as with standard fixings. To enhance its ability, a metal sheet is additionally mounted with it, which takes up most of the load and spreads it over the entire plane of the sheet, and the larger the area of the sheet, the more load the bolt can withstand.

When anchored, the load is spread over a small area

When anchored, the load is spread over a small area

How to install an anchor bolt

Installation of anchor bolts is not difficult, the main thing is to correctly measure. The effect of the strength of the installation is exerted by the properties of the base substance, the preparation for the installation is correct. When the wall is covered with layers of plaster, the holes are made deeper.

The perforator is taken 0.5 ml smaller than the intended hole D. Read the guide for the anchors, they indicate the permitted pressure and the limit for the number of rotations. When screwing in the pin, do not try to do it to the end - the block will be destroyed.

Eternal fasteners

Anchoring - the dowel is a spacer piece, as far as possible, it is identical to the anchor. For strength, the installation is often produced with needles.

It is used where there are no excessively huge pressures on concrete - rack holder, brackets, lamp, etc. There are rod-nails, used with an automatic pistol. The fastener is made of iron, similar to a bullet.

Nog

Dowels are screws that are installed on fasteners near the edges of the concrete wall. There is no need for an additional eccentric, it is screwed into the hole, after pouring epoxy glue there. No hole drilling required. Screw it in with a pneumatic screwdriver - then the nail cannot be turned back.

Types of concrete dowels

There is a fairly large number of fasteners for concrete, the most famous and effective of them are presented in the table:

| Dowel type and photo | Peculiarities |

| Spacer

|

Such a dowel for a concrete wall differs from others types by the size and shape of the screws. They are usually made in the form of slate, which allows you to hammer parts into a concrete wall with a hammer.

Sleeves or fasteners of a cylindrical or tubular shape are various: with two or three spacers. They often have spikes, which increases the reliability of the fixation. |

|

|

These types of concrete dowels are used when working with thin wall coverings. The sleeve is inserted into the hole, and its back side is folded due to the insertion of the screw into the concrete wall. This is how the dowel is fixed in the wall. |

|

|

This fastener is similar to the spacer type, the fixation is made according to the "butterfly" type. Its peculiarity is the possibility of using it for a wide variety of wall surfaces. |

|

|

Fasteners are used for mounting structures to concrete from different materials. The nail is driven into the wall with a hammer, but it is better if you use a special gun. |

|

|

The facade view tool is used to construct frame structures on a brick and concrete base. The dowels share some characteristics with the spacer type, but they are slightly longer and the head is larger.The shaft and sleeve are made of impact-resistant materials. |

|

|

This is not an ordinary fastener. It contains a special capsule that contains chemicals, so the screw is made of metal. A lightweight concrete dowel is used. When screwing in the element, the chemicals play the role of glue, so you need to wait until the base hardens. This usually lasts from two hours to a day. |

|

|

Works only for aerated concrete surfaces. A feature of this type is the wide thread, which guarantees strength when using similar dowels for porous surfaces. |

|

|

This fastening is used for polystyrene concrete wall blocks. Its sleeve resembles a spacer, but has a spiral shape. The GB type dowel can withstand quite heavy loads. They can be effectively used to fix hanging cabinets, hoods, shelves and other heavy household items. |

How to install an anchor bolt?

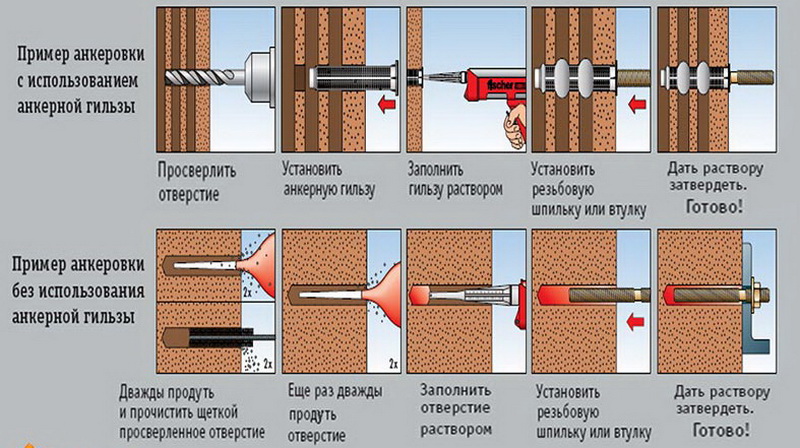

As an example, consider how to anchor a spacer anchor in a concrete wall.

- Concrete walls are often covered with plaster. For reliable fastening, the anchor bolt must be in the concrete layer at a certain depth, usually at least 50 mm. Therefore, before proceeding, how to fix the anchor, you should determine the thickness of the plaster and select the appropriate length of the anchor sleeve.

- The diameter of the hole for the expansion anchor must be fairly accurate so that the sleeve can be pushed into the wall with little force. The perpendicularity of the hole must also be observed. Its depth should be slightly more than the length of the sleeve.

- Hole marking must be done as accurately as possible. After installing and fixing the anchor, it will be impossible to pull it out.

- After drilling, the hole must be thoroughly cleaned of dust and concrete crumbs. This can be done with a brush, vacuum cleaner, can of compressed air, or simply by blowing with a rubber bulb and straw.

- An anchor is driven into the prepared hole with light hammer blows. If it does not enter without effort, you should go through the hole again with a drill with slight wiggles.

- When the nut at the outer end of the stud or the head of the bolt has reached the surface of the wall, you can start tightening it with a wrench. After one or two revolutions, the force usually increases markedly. This indicates that the tapered bushing fits into the sleeve. If the package contains the maximum torque specified for the anchor, it is best to use a torque wrench.

In any case, do not twist "all the way" in order to avoid the destruction of the wall material. This is especially true for lightweight, porous or foam concrete, as well as bricks.

It often happens that nut or bolt head When twisting, they begin to go deep into the layer of plaster. If it is a nut on a threaded rod, you can continue tightening until it is completely deep into the wall, and fasten with another nut on top. The bolt should be unscrewed and a washer of a larger diameter should be selected for it.

This video shows examples of the installation of anchor bolts (how to fasten different types of anchors).

There are also more exotic designs of anchor fasteners, for example, frame ones, which wedge at the same time from both ends, or with a tear-off head for anti-vandal protection.

Specialized anchors with hook or ring, anchors for suspended ceilings of the rack or grid type and many others.

Concept, purpose and application of anchor fasteners

Anchor is a type of fastener that is driven in, screwed in or inserted into the base and is able not only to be fixed in it, but also to hold an additional structure.

Translated from German, anchor means "anchor". By the method of action on the base, fasteners of this type really resemble an anchor - the working part of the anchor expands when fastened and holds the connection on the base.

Fasteners of this type are used when working with solid base materials - concrete, brick, natural stone. The anchor allows you to hold sufficiently massive or dynamically loaded structures, for example, sanitary ware, air conditioners, wall-mounted TVs, sports equipment, suspended ceilings, etc.

Expert opinion

Torsunov Pavel Maksimovich

The versatility and reliability of the anchor connection allows them to be used when working with other materials. For example, there are anchors for fixing in porous and lightweight materials, for connecting furniture elements. This type of fastening connection has found its application even in dentistry - the anchor pin is fixed in the root canal of the tooth and serves as a support for a filling or microprosthesis.

Instructions for use

To perform a reliable and durable fastening, before hammering in the anchor, it is necessary to calculate its resistance to pulling out of the wall under the influence of the mass of the structure. You can perform such calculations if you use professional tables containing the technological characteristics of anchor hardware. Another prerequisite for high-quality fasteners is to install them correctly. The fastening strength indicators are influenced not only by the weight of the structure, but also by the density of the wall material.

The distance of the hole, measured from the outside edge into the wall, is also important when installing.

During construction work, the installation of anchors is carried out even before the concrete is poured or after that, already on the completed monolithic base. When pouring concrete, the anchor structure must be fixed to the reinforcement frame using a welding joint or using a knitting wire, after which the concrete composition is poured. To protect the threaded connection, it is wrapped in plastic wrap. The following installation steps are performed after the monolithic surface has completely hardened.

To do this, make a markup where the hardware will be located. Then, using an electric drill or punch, a hole is made that will be 10 mm longer than the length of the anchor. As for the diameter of the anchor, it must match the diameter of the drill.

After the hole is ready, dust and debris are removed with a vacuum cleaner. When there is a thick finish on the wall, the length of the hole must be increased by the thickness of the finish, because the finish is not a dense monolithic structure. When making a hole in order to hammer the anchor as tightly as possible, the diameter of the drill can be taken 0.5 mm less than the diameter of the hardware. The most convenient way to work in this case is a hammer drill with a drill, which has a victorious tip.

Installation of a mechanical type of anchor with a nut - the bolt rod is placed into the prepared wall hole and hammered into it with a hammer, then the nut must be tightened using a wrench. This must be done carefully so as not to spoil the outer part of the anchor, where the thread is located. When you need to pull the hardware out of the concrete wall, it will be enough to unscrew its nut in the opposite direction.

If it is necessary to perform hanging fasteners on a vertical surface, then use anchors equipped with a bracket in the form of a hook instead of a nut. The bracket will need to be screwed all the way into the anchor structure, making sure that the hook head is in the correct position to hang the structure. Each anchor is supplied with an accompanying user manual. Before installation, you need to study it and find out how many revolutions of the bracket can be performed during installation.

Installation of a chemical anchor - in hardware of this type, the adhesive can be located inside the capsule or in a separate container.The installation of such an attachment consists in placing the capsule in the prepared hole, and then screwing in the stud or bolt of the anchor. At the same time, the glue comes out into the cavity of the hole and begins to polymerize. It is necessary to wait for complete polymerization, the time of which is indicated in the instructions attached to the chemical anchor. It will be impossible to get the anchor out of the wall after the adhesive has hardened.

If the adhesive is located in a separate container, then the glue cartridge is installed in the construction and assembly gun and, pressing the trigger, squeeze the contents of the container into the hole, completely filling it. Then the anchor hardware is screwed into the adhesive composition and wait for the complete polymerization of the composition. After that, the suspension structure can be hung on the mount.

What is an anchor bolt, see below.

Varieties

When choosing anchors, you can find several types of such fasteners. All of them are designed for different tasks, so before buying, you should figure out where and how the bolt will be fixed. Having studied the features of such products, you can understand how to properly remove the anchor from the wall. All of them are divided into several types:

- Nut products. These anchors are the most common. They consist of a cylinder, inside which is a tapered bolt. The principle of operation of the structure is based on the fact that when twisted, the sleeve wedges. This ensures reliable fastening of the structure to the wall.

- With a hook. Anchors of this type differ only in that on the upper part there is not a nut, but a hook. It provides the convenience of working with fasteners. Hardware is often used when fixing lamps and chandeliers, as well as elements on which water heaters and other devices are installed.

- With a ring. In the upper part of such products there is a ring, which is designed for convenient fixation of various objects. Typically, these anchors are purchased for indoor installation.

- Double-spaced. They differ from the others in that they have 2 bushings at once. When tightening the nut in such bolts, one of the bushings enters the other and releases it. In this case, the first also wedges.

Anchors are divided into 3 types according to the fastening characteristics, which will be described in more detail below.

There are several ways to remove the double-expansion anchor from the wall, so you need to prepare the necessary tools in advance.

Classifications

Anchors are distinguished according to the service life:

By size, fasteners are divided into:

- Small (up to 5.5 cm long and up to 0.8 mm in diameter).

- Medium (up to 12 cm long and up to 1.2 cm in diameter).

- Large (up to 22 cm long and up to 2.4 cm in diameter).

Anchors are distinguished according to the material of the base:

- For dense concrete, brick or stone materials.

- For hollow brick and concrete substrates.

- For sheet materials - plasterboard, chipboard and fibreboard.

By the method of attachment, the following are distinguished:

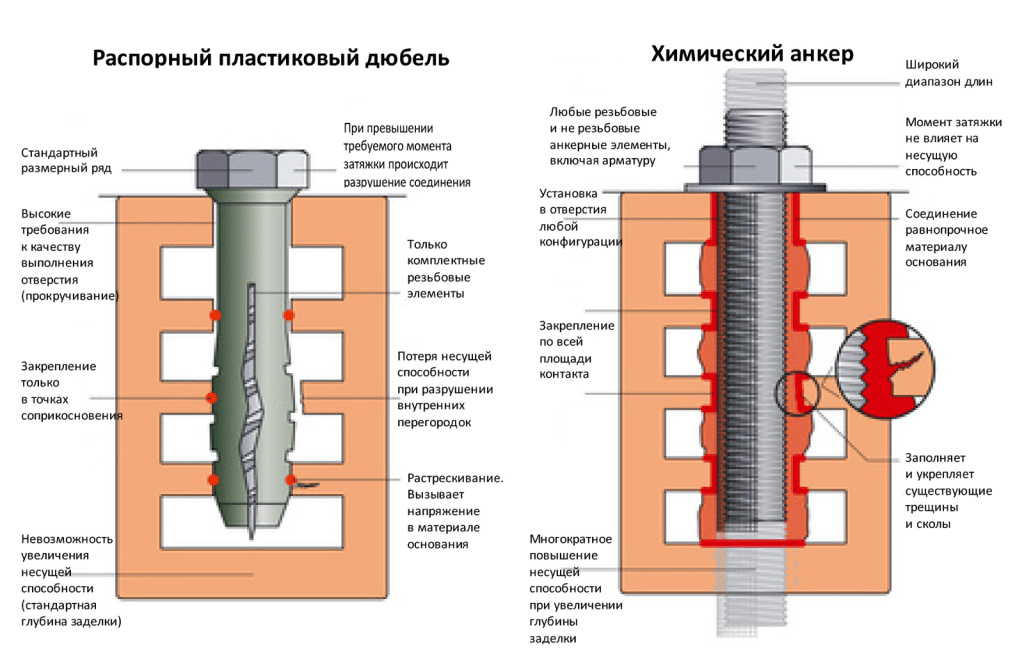

Fastening is carried out due to the direct mechanical action of the working part of the anchor on the base (wedging, friction, stop, material resistance, etc.).

Additionally, a gluing mechanism (force) is used; when fastening, glue based on polyester resins is used.

What anchor do you use?

ChemicalMechanical

Mechanical anchors, according to the technique of insertion into the base, are divided into the following types:

- Wedge.

- Spacer.

- Driving.

- Screw.

- Sleeve.

- Expandable.

- Spring loaded.

Spacers

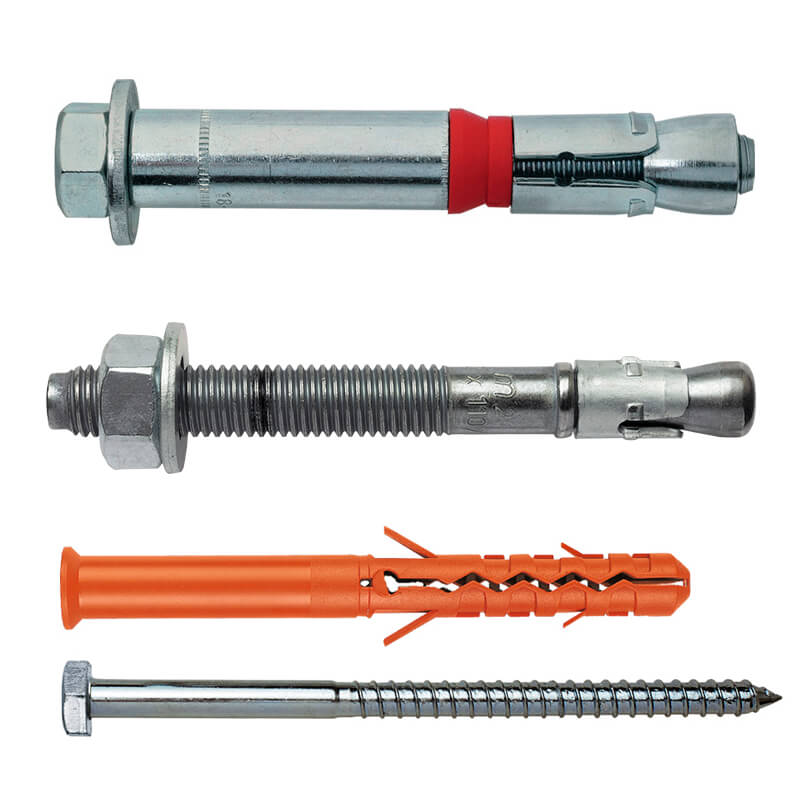

Expansion anchors are a classic version of this type of fastener. They are a rod in the form of a bolt or a stud with a tapered end and an external element in the form of a sleeve, sleeve or spring ring. The conical element under the influence of the translational movement of the rod expands the sleeve and fixes the structure in the base.

Expanding

Expanding anchor consists of a threaded rod, which can be a bolt, stud or screw, and a sleeve consisting of 4 longitudinal petals with a spring washer and a flare nut on one side. When the rod rotates, the flare nut expands the sleeve petals, as a result of which the anchor expands and is fixed in the base due to the frictional force.

Wedge

Wedge fasteners are a long rod, at the end of which a deformation sleeve is placed. After screwing the rod into the drilled hole, the sleeve petals expand. This type of fastener is able to withstand heavy loads.

Spring loaded

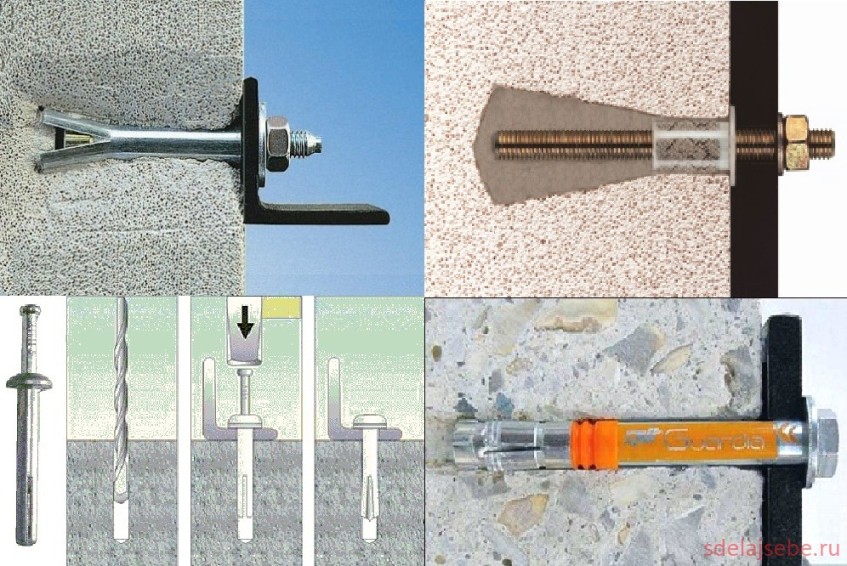

Spring anchors are used when working with thin-walled bases, for example, when decorating an interior. Spring anchors are often used as ceiling anchors and are equipped with a hook. The anchor is secured by unrolling the spring.

Screw

Screw anchors, or Molly bolts, are used when working with hollow structures with a low load-bearing capacity - hollow bricks, drywall, chipboard and fibreboard, etc. material on the back.

Bushings

Sleeve type anchors consist of 3 or more elements, the main of which is a collet - a spring split sleeve. The sleeve anchor also includes a proppant and a threaded rod. When the anchor is screwed in, the proppant enters the collet and expands it, thereby securing the fastener in the base.

Hammered

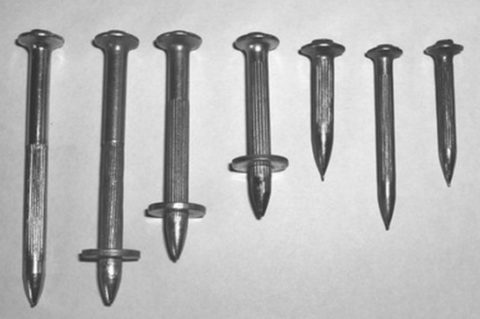

The base of the drop-in anchor is a metal expansion sleeve with a tapered bore, cuts on the body and an internal thread. A striker is installed at the bottom of the sleeve. The sleeve is installed in the drilled hole manually or with a pneumatic pistol. When struck at the outer end of the sleeve, it is deformed, after which a bolt or stud is screwed into the sleeve, which is necessary for fastening an object.

The base of the drop-in anchor is a metal expansion sleeve with a tapered bore, cuts on the body and an internal thread. A striker is installed at the bottom of the sleeve. The sleeve is installed in the drilled hole manually or with a pneumatic pistol. When struck at the outer end of the sleeve, it is deformed, after which a bolt or stud is screwed into the sleeve, which is necessary for fastening an object.

Specifications

Anchor device with nut

Anchor device with nut

The features of the anchor bolt with nut determine the technical characteristics and load-bearing capacity of the structure, the main element of which is the stud. A nut is screwed onto its threaded part located at the top, and the lower part is made in the form of a cone.

The second most important structural element is the bushing; on its lateral surface there are longitudinal slots in the form of petals. The sleeve, put on the pin, leaves only the upper part open, where the product nut is located.

The principle of operation of an anchor bolt with a nut is as follows:

- When tightening the nut, which is located in the hole of the anchor bolt, the stud begins to retract into the hole in the sleeve;

- The tapered end of the part expands the petals;

- High reliability of fixing the bolt in a pre-prepared hole is ensured by a cast spacer sleeve that does not have welds on the surface that can weaken its structure.

Any anchor bolt for concrete has a designation in which its dimensions are indicated in millimeters, for example, 8 × 10 × 50, where:

- 8 - thread size;

- 10 - diameter;

- 50 - product length.

Standards have been developed for anchor bolts for concrete, their dimensions:

- Diameters of the flat part of the stud from 6 mm to 24 mm;

- Thread diameter, from M5 to M20;

- Product length, from 18 mm to 400 mm.

Other bolt specifications include:

- The force that pulls the anchor out of concrete is from 10.5 kN to 18.3 kN. In this case, the departure of a part of the product may not cause damage to the structure, or finally destroy the connection point;

- Torque - from 10 Nm to 40 Nm;

- Bending moment - from 5.2 Nm to 25.7 Nm.

Anchors are also non-standard, if necessary for the construction of the object. In this case, the project of the part must comply with special SNiPs.To protect products from destruction and rust, they have a zinc coating.

Standard anchor bolts

Standard anchor bolts

Installation instructions

Before securing the pin, it is required to assemble the toolkit. You will need: a wrench, a car industrial vacuum cleaner, drilled acting as a drifter or a drifter, a sturdy gimbal, banging.

Drilling

Initially, the base is carefully distributed under the drilling zones. Further, along the mark, holes of the required length are drilled in the concrete (measured by the spacer), placing a stopper on the borer.

The distance from the edge of the wall must be 2.5 times greater than the depth of the hole. After the hole, you need to clean it with a vacuum cleaner. When it did not work out completely to remove the remnants of dust, it is allowed to make a hole 1-2 cm deeper.

Installation of anchor with nut

A spacer piece of the pin is inserted into the foundation, hammered with a hammer until deep diving into the wood concrete (the edges are flush with the wall). Then a pin is introduced, the nut is screwed on, and the scrolling later became unrealistic. Manufacturers prescribe the utmost effort to screw in - a power wrench is required here.

Tightening to an accent in operation with separate bases (reinforced gas concrete, reinforced foam concrete) can be a circumstance for bending and breaking of the substance.

Installation of a chemical anchor

When collecting chemical. pin, a slightly different range of tools is required: drifter, wrench, construction vacuum cleaner, threaded pins, special. glue, prefabricated pistol. For the sake of a huge share of fasteners, they mainly pick up paste.

First, they mark the base, drill and clean the holes. Before pouring the adhesive into the concrete, it is necessary to screw in the openwork quill, as a result of which the chemical. the material will be fixed in the base body. After that, the holes should be filled by 2/3 specials. glue, placing the pin, screwing it in little by little for an even position of the gluing product. After drying, special. glue - screw the nut with a wrench.

Types of anchors by installation method

Ampoule is a glass capsule with a two-component mixture and is intended for single use. Requires mixing directly in the hole.

Cartridge - the adhesive is located in the bottle and is mixed immediately upon delivery. A special gun is required to enter the hole.

If the technology is observed during construction work, it is excluded that the anchor pulls out without damaging the material itself. It is one of the strongest anchors to withstand high vibration and dynamic loads. It is allowed to use a chemical anchor under water and on an unprepared surface.

Adjustable. Shrinkage compensating fasteners include an adjustable height anchor. It is made in the form of a screw and has two square plates made of the same material with perforated holes for fastening with screws.

The adjustable anchor is installed under the posts and is able to adjust the horizontal surface relative to the vertical one.

Varieties of anchoring connections for concrete

One of the most widely used types are products based on a mechanical principle.

Metallic

Metal anchors are mainly used for anchoring in hard materials. Their surface is made of carbon steel and coated with a special zinc compound, which completely eliminates the possibility of corrosion.

Hammered

A drop-in anchor is a device by means of which a fastener is connected to an array of a base. It has a tapered wedge and an internal thread and is excellent for use in concrete floors.

There are several types: with and without notches. Installation work can be carried out manually or with a pneumatic tool.

It is important to consider that it is not possible to loosen the fastening, therefore a careful planning approach is required.

Brass

A push-in anchor made of brass belongs to brass, it is also called a collet. The characteristic feature is the absence of a propping element and anti-corrosion resistance.

The brass anchor (collet) is inserted into the prepared hole and secured with a hairpin or bolt. The ribbed surface of the sleeve allows it to withstand significant loads and guarantees a strong connection.

The cost of this type of fastener is much more expensive than steel, but thanks to the brass design, the reliability of fixing the structures increases.

Spacers

This anchor belongs to the type of jamming elements. It has a metal sleeve, at one end of which there is a spacer part of four segments, and at the other end there is a thread with a nut and washer.

The expander anchor withstands high loads and can be used in cracked areas of cracked concrete. For a more reliable connection, double-expansion anchors with two sleeves are used. The spacer sleeve, in turn, has several wedging zones: at the head of the screw (bolt) and inside the bearing base.

Chemical

The fastener, the principle of which is based on the forces of cohesion and adhesion, is called a chemical anchor

It is important to take into account that the hole to be prepared must be 2 mm larger than the diameter of the fixing device itself.

For fastening, the intended adhesive is poured into the mesh sleeve. Then a suitable size anchor bolt is inserted. Before the glue cures completely, it is possible to adjust the position of the chemical anchor in relation to the structure.

Types and types of anchors and methods of their fastening

Anchoring on concrete structures can be very diverse, apply a single or many influencing forces - a support, a molecular link in the stage of adhesion, friction, fracture, contraction, etc.

By design, the types of anchor bolts for concrete structures are made: frame, ceiling, support and multifunctional. By configuration - curves and straight lines, with an assembly or a complete system. The type of anchor can be wavy or smoothed.

According to the assembly method, the foundation bolt can be through fastening, wedging, driving in, screwing in, etc.

Significant meaning contains the substance from which the product is made. In the case of steel, the strength level of 6.8 or more, treated with an anti-corrosion agent, then it will withstand much longer. Brass, on the other hand, will not bear harsh vertical stresses.

Spacers

The expansion anchor of building concrete is quite often used with nuts, in this method Ftr works. They look like a not very large threaded rod with a sleeve and cone-shaped cap.

If the fastener is screwed into the foundation, it diverges and holds the element firmly in the concrete block.

Expansion anchors installed in walls will not be able to be used next time.

Expansion anchors are also sleeve and sleeve. They are used for dense foundations of concrete structures. A small contact area sometimes with a small caliber of the model provides an option to maintain significant overloads.

Anchor bolt with nut is electro-galvanized, hot-dipped galvanized, and has acid-resistant property. This includes screw anchors made of stainless steel.

Hammered

Drop-in anchors are selected for strong concrete.

The foundation bolt is mounted using this type of pins - when assembling boxes, upper air intakes, placing technical equipment.

Before driving the staple into the stone wall, drill a suitable hole. Later, a metal product is hammered in, it is bred with a rim, a rod with a thread of the required length is screwed in.A similar foundation bolt, touching the dowel rod, the upper (on the ceiling) anchor.

It is practical to strengthen suspensions, supports, Armstrong ceilings on them. Usually, the fastener is used as a security fire or against vandalism, since the pin is permanent and cannot be removed.

Framed

They are used to separate openings where window and door frames are placed. The quill is made with a cut along the length, a slight disconnecting sleeve during pulling effectively supports the opening of the system, passing to a suitable place.

In order to protect it from displacement and screwing near its point, there are accents at the top of the quill.

Self-tapping screws for concrete

Here, the strength of the installation occurs with a thread made along the integral length of the pin. In the stage of screwing into the concrete support, a massive resistance to the separation or displacement of the mechanism is formed. When using such a sample of the fastener, there is a rather large load-bearing capacity (up to 100 kg).

Expanding

Can be used to anchor curtain rods, racks, light sources, canvases and other items in hollow structures with low load-bearing capacity. The clamp on the screw or pin is designed as a divergent skirt; during the screwing of the pin into the foundation, it sticks into the inside of the base.

Along the outer part of the clamp, special needles are immersed in the arbolite, which do not allow the pin to move or twist during assembly.

Chemical anchor

This concrete anchor bolt is a semi-liquid part, it hardens easily. It is with this part that the pin wedges into a block of concrete. In view of this composition, it turns out to guarantee a strong adhesion of the base and the pin with a uniform loading order along the full length of the fastening material.

Chem. Monolith anchors do not induce latent loads, significantly reducing the risk of collapse and degradation.

Material for the manufacture of drop-in anchors and their principle of operation

Most of them are made of brass or high carbon steel. To protect against environmental influences, a protective anti-corrosion compound is sprayed on the surface of structural elements.

To achieve greater mechanical strength, anchors are produced in one piece, without the use of welding and soldering. The internal thread of the product has the shape of a cone, and from the sidewalls it has technological slots necessary for the formation of petals that act as spacers when the spacer is driven into the anchor.

When it is introduced into the sleeve, it acts on its conical walls and expands the petals. Thus, a strong adhesion to the supporting structure is achieved - wall, ceiling, floor.

The pressure of the petals on the supporting structure can damage it, therefore it is not recommended to use anchors for bulkheads made of foam and aerated concrete, it is very prudent for shell rock, but can be safely used for structures made of rubble or concrete.

Butterfly

Butterfly Universal

Universal Dowel-nails

Dowel-nails Façade

Façade Chemical

Chemical Kwt

Kwt GB

GB