Tips for choosing a varnish

When choosing a paint and varnish material, it is recommended to adhere to a number of criteria, the fulfillment of which in the future will allow you to get a high-quality coating:

- First of all, you need to understand how intense the mechanical loads on the floors will be. If the impacts are small (up to 2-3 people are constantly in the room), a water-based varnish will be preferable.

- For varnishing the floor in the kitchen or in the corridor, a composition with pigments is best suited. This varnish protects the surface well from dirt and dust. An anhydrous polyurethane mixture is also suitable for the kitchen floor, since it is well absorbed by the coating and does not need special care.

- If you need to varnish the floor in a room where there is a high load on the floor (office, catering, etc.), then mixtures with water-repellent properties will be the best choice.

Yacht varnish

For the processing of wooden yachts, a special (yacht) varnish is used. Also, such a composition can be used in other places, the operation of which takes place in conditions of high humidity. However, it should be noted here that yacht paints and varnishes are not intended for indoor use.

The fact is that manufacturers, striving to achieve the main qualities of yacht varnish - durability and resistance to moisture, use strong toxins for this. We are talking about such toxic components as xylene and toluene. Therefore, in order to avoid poisoning, you should not cover parquet or furniture with such varnish - it is dangerous.

Alkyd compound for metal

Alkyd varnish for metal surfaces is a mixture of alkyds and polymers. The components of the mixture give the metal a beautiful lacquered sheen. You can apply this varnish with a brush, roller or from a spray can.

The advantages of alkyd varnishes for metal include the following characteristics:

- coating strength;

- resistance to aggressive chemical media (alkali, acid, household chemicals, alcohols);

- moisture resistance;

- thermal resistance;

- resistance to wear and other mechanical stress;

- excellent adhesive qualities (the ability to adhere different types of materials);

- the ability to use both indoors and for finishing the outer part of the building.

It is possible to qualitatively varnish the surface only under the condition of a multi-layer coating, which implies filling and priming the surface. Also, do not forget that it is permissible to apply any materials only on a clean, grease-free surface. To achieve the best results, experts recommend using finishing materials from the same manufacturer.

Specifications

The invariable and main component of varnishes is alkyd resin, which acts as a base. Among similar products, alkyd varnishes are out of competition in terms of resistance to temperature fluctuations.

Vibration loads do not in any way affect the quality of the applied alkyd composition, in addition, the adhesive qualities that many representatives of paint and varnish products have are not inherent in the varnish. The product is absorbed directly into the wood and does not penetrate into the genital crevices in the frame. Such characteristics of the products allow minimizing the squeaks of the floorboards when processing the floor with an alkyd mixture.

The first alkyd-based varnish, which began to be produced in Russia, is the composition PF-231. The product is intended for use on all types of surfaces. It is possible to note the external attractiveness of the base obtained after processing with this composition - the film evenly and neatly covers the working surface.

In addition to the positive characteristics, the composition also has some disadvantages. The main disadvantage is the short service life of the coating due to its minimal hardness. Due to this, after 2-3 years, the surface of the wooden floor will have to be processed again.

On other materials, the composition will last many times longer.

PF 283 forms a glossy layer, remarkable for its decorative properties. In fact, these products are a mixture of alkyd resins, fatty acids and naturally occurring solvents. What surfaces can be applied with acrylic varnish? In addition, there is a desiccant among the ingredients.

Most often, such a varnish is sold in a can as a 150 ml aerosol.

PF-170 includes resin in combination with specific additives and aliphatic hydrocarbons. The composition can be used on wood, wood-containing materials, metal and ceramic substrates. In addition, bases treated with paints, enamels and primers are very often covered with these very protective and decorative compounds. The products are allowed for indoor and outdoor use.

The varnish is made in accordance with GOST, resistant to chemical detergents and aggressive environmental factors, allows the surface to "breathe" and is very economical in terms of consumption.

Views

There are several types of alkyd varnishes.

Two-pack

They consist of two components, the second component is the desiccant. Before application, the mixture must be combined into one composition in the ratio specified by the manufacturer. After that, you can start painting. Typically 2 or 3 coats are required for a durable, high quality finish.

An important feature of such formulations is the short shelf life of the finished mixture - the solution is suitable for operation for 8 hours. According to their characteristics, the compositions are distinguished by the highest rates

However, the varnish has a pungent odor, and also a low index of resistance to sunlight.

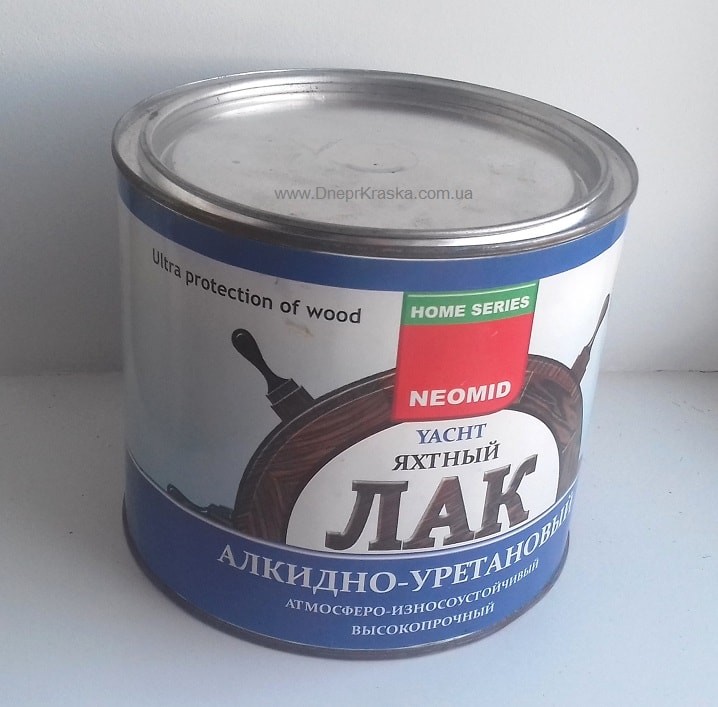

Alkyd-urethane

It becomes in demand due to the peculiarities of the mixture in which alkyds react with polyurethane. The mixture is improved due to a special component - toluene diisocyanate, due to which the drying process of the varnish is carried out in a slightly different way. First of all, the solvent evaporates, and after that the mixture hardens when exposed to oxygen. The drying time of the surface with this drying mechanism is reduced, in addition, the indicators of resistance to abrasion, temperature effects and high humidity are improved.

However, due to the fact that half of the alkyd-urethane varnish consists of an organic solvent, its toxicity increases. Also, products are unsafe in terms of fire, therefore, the operation of coatings requires additional safety measures. In addition, if the coating does not dry out completely, and the base is already in use, situations are inevitable in which the varnish is deformed, forming serious defects. They can only be removed with a grinder.

Matte and glossy

Compositions differ only in what texture the dried base has after processing. The matte composition forms a more practical surface, since dirt and traces are less noticeable on it, there are also semi-matte mixtures. Gloss is best used in rooms with minimal lighting, as it reflects light perfectly. In terms of the set of components, both products do not differ at all, which is why the choice of a mixture will be based only on the taste preferences of the consumer.

Yacht

Based on the name, the scope of use of the products becomes clear - the mixture is produced for coating wooden yachts, but in addition to processing ships, such a specialized composition can be used on bases that are operated in a humid microclimate

However, it should be noted that yacht varnish can only be used for outdoor work.

This limitation is explained by the chemical composition of the material - to increase the indicators of resistance to moisture during the production of varnish, toxins, for example, toluene, are included in its main set of mandatory elements.

For metal

By its composition, it is a mixture of alkyds and polymers. The substances provide shine and attractive appearance to metal substrates. The mixture has high resistance to chemically aggressive substances, high humidity, thermal effect on the surface, in addition, adhesion to various types of material makes it possible to operate the varnish inside and outside the premises.

To achieve a high quality result, it is better to use products from one manufacturer. Parquet alkyd compounds can be classified as follows:

- Water-based mixtures. The advantage of solutions is the absence of odor and environmental friendliness of the product. But such paints and varnishes are of high cost.

- Two-component varnishes.

- One-component formulations.

Based on the type of coating, alkyd varnishes are divided into the following subspecies:

- glossy;

- matte;

- semi-gloss;

- semi-matt.

Manufacturers

Several brands are in great demand among buyers:

- White house

- Parade

- Tikkurila

Parade alkyd-urethane mixtures were able to win a large audience, since this manufacturer sells varnishes with increased elasticity. Buyers leave reviews in which they report that the film that forms after applying the product does not crack or deteriorate for a long time. Alkyd products are able to emphasize the naturalness of the wood material and make the floor more effective. Parade offers its customers mixtures for outdoor and indoor use.

White house won buyers over for its affordable prices and low odor. The manufacturer produces high-quality varnishes, which are distinguished by high wear protection, fast polymerization and a decorative component. The varnish is able to preserve the natural shade of the wood. Just like Parade, the manufacturer produces products for outdoor and home surfaces.

Tikkurila is considered a trusted manufacturer of many building materials. The brand has won the respect of customers and is known as a manufacturer of reliable and high-quality products. Tikkurila yacht varnish receives good reviews, which is distinguished by fast polymerization, excellent spreadability. The low price helps this brand to become a leader among the manufacturers of alkyd varnishes.

Popular brands

PF-231 alkyd varnish belongs to one of the first series of Russian-made parquet varnishes. The composition is easy to apply, and the film looks neat and provides decent protective performance. However, the main disadvantage of PF-231 is very significant: the coating does not have a long service life and must be replaced after 2-3 years.

MCh-0163 is a two-component agent that includes alkyds, urea-formaldehyde resin, and an acid hardener. In comparison with PF-231, this mixture is more competitive: it resists moisture more reliably, and takes mechanical loads better. The disadvantages of MCH-0163 should be considered instability to ultraviolet radiation, insufficient elasticity of the film coating, a rather pungent odor, the possibility of bubbling on the surface during its varnishing.

EP-2146 belongs to one-component formulations with good performance properties. Epoxy resin is used as a modifier. EP-2146 has decent indicators of hardness, resistance to moisture and abrasives. EP-2146 is used for varnishing parquet, veneer, fiberboard, chipboard, plywood.

Specifications

Almost every type of varnish goes through testing before it hits the counter. Each sample is kept under normal conditions for two weeks prior to testing. Testing consists in examining external characteristics using special devices.

The device defines the following technical characteristics:

- the thickness of the varnish when applying two layers;

- the period during which the varnish completely hardens;

- resistance to mechanical stress;

- resistance to moisture;

- consequences from contact with detergents;

- term of use.

Only those mixtures that meet the stated requirements are allowed for sale.

Customers receive a reliable and high-quality product that, after use, will significantly transform the surface to be treated. To carry out internal work, you should rely on your personal requirements, which are necessary for the implementation of a specific goal.

Typically, alkyd varnishes are used on wood surfaces.

Alkyd urethane varnish can be divided into two main categories:

- yacht;

- parquet;

Yacht material is used for painting ships. According to statistics, this product is considered the most popular. Buyers are attracted by the low cost of the product along with its increased resistance to wear and tear.

Parquet varnish is used for working with wooden floors. Both varnishes are suitable for all other wood surfaces. Yachting is often purchased to work with gazebos, verandas and other forms of architectural character.

Parquet lacquer is relevant for measures for interior treatment of premises. Besides floors, it does a good job with furniture, frames, railings and doors.

Alkyd varnishes for parquet are divided into several types.

- Water based solutions. This product is popular because it is odorless. The advantages include such properties as environmental safety and resistance to high temperatures. However, such products are distinguished by their high cost, which is not suitable for every buyer;

- Two-component. Such mixtures create a film on the parquet. They have a low cost and a pungent odor during drying. It is not possible to store the material in open containers for long, so you need to use up the varnish immediately;

- One-component varnishes. They can be stored for a long time in a closed container. Polyurethane mixtures are not afraid of contact with chemicals;

Also, such a varnish can be divided into several subtypes:

- matte;

- semi-matte;

- glossy;

- semi-glossy.

Matt products are optimal for surfaces that get dirty quickly during use, as the matte film is easy to clean.

Gloss reflects light well, therefore it is suitable for use in dark rooms.

PF-231

This varnish is considered a high quality alkyd-based product. It creates a gloss on the surface that is resistant to wear. The solution is transparent, has decorative and moisture resistant qualities. Such material is purchased for working with surfaces made of metal and wood, as well as for processing parquet indoors.

MCh-0163

Such a product belongs to the category of two-component varnishes, the composition of which consists of urea-formaldehyde and alkyd resins, acid hardeners.

If we compare MCH-0163 with the previous version, this type of varnish has improved characteristics:

- high level of water resistance;

- strength;

- resistance to the influence of abrasive substances.

EP-2146

The brand is considered a one-component alkyd-epoxy compound that has improved characteristics. The improved element is epoxy resin. The product is characterized by increased hardness, resistance to abrasives and water.

PF-283

Used for processing wood and metal surfaces.When applied, the solution forms a highly glossy layer that has good decorative qualities. PF-283 is a mixture containing alkyd resins, modified vegetable oils, fatty acids of vegetable oils, tall oils in organic solvents. Also in the composition of the components there is a desiccant. Apply the varnish with a brush or use an aerosol in a can for these purposes.

You can find out more about the varieties of alkyd varnish by watching the following video.

Types and categories of protective coatings

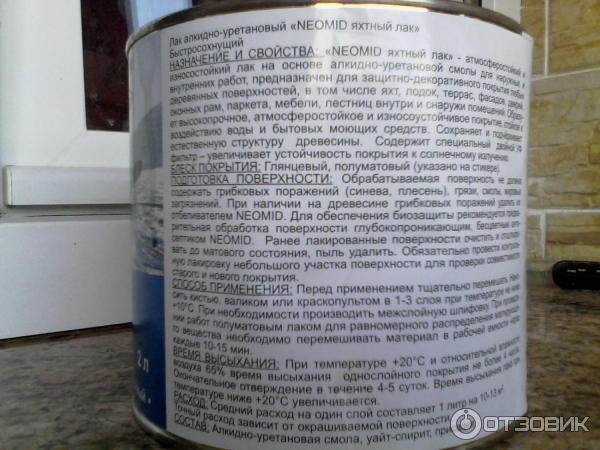

The degree of toxicity, chemical composition and technical parameters of each common category, called yacht varnish, differ, depending on the needs for which certain characteristics are intended. In order to choose the right degree of strength and resistance to impacts, it is not enough just to read the inscription "deck varnish" on the bright label.

You need to choose from several categories really suitable, and for this you need to know the composition and properties, the degree of reliability and decorativeness, rational target use. In terms of composition, all varnishes for this purpose are divided into:

alkyd;

alkyd-urethane;

from urethane and alkyd;

acrylate.

A good varnish for wood will not only protect the material from external influences, but also give the surface a picturesque and decorative effect, make wood an independent element and a semantic accentuation of a certain interior.

Wooden country houses, comfortable wooden cottages with underfloor heating or interior cladding of the room will acquire a more expensive and picturesque look if the natural parts of the interior are varnished. Correctly selected composition will avoid the troubles associated with toxic fumes.

For future decorativeness and picturesqueness, it is of no small importance which of the 2 categories the developer chose: matte or glossy surface. Matte composition is more practical and does not get covered with dust, glossy is good as a decorative component, but it gets dusty and requires additional care

Glossy varnish is common where appearance is considered the main determining factor, and not the strength of the coating, but not every paint will look good under a matte layer.

Advantages

Ship varnish has a wide range of significant advantages. Let's consider the most relevant ones.

- Excellent adhesion to wood. It has a high degree of adhesion to the surface material. Immediately impregnates the surface material, stays in wood structures for a long time and acts for a long time.

- Not affected by the harmful effects of UV. The sun has almost no harmful effect on the material covered with yacht varnish, since it contains special components that absorb this radiation, as well as light stabilizers that convert ultraviolet rays into heat. This keeps the protective film intact.

- Makes the surface attractive. The decorative component of the coating plays an important role in drawing attention to the product. This coating looks well-groomed.

- Hydrophobicity. This tool increases the moisture resistance of wood, helps to get rid of the destructive effects of rot, the appearance of mold or fungus that destroys wood.

- Wear resistance. The film ensures durability and abrasion resistance of the material. At the same time, the coating is protected from scratches and chips.

- Resistant to chemicals. There is no reaction with acids, alkalis, salts. This allows, if necessary, to wipe the surface using household chemicals.

- Elasticity. The surface covered with this varnish can bend without significant damage to the film. Moreover, it will not crack.

- Relatively low price. Availability at purchase is another advantage of yacht varnish among other properties.Saving money makes these products in demand among a wide range of buyers.

Photos of the best yacht varnishes

We also recommend viewing:

- Which parquet varnish is better to choose

- Which solvent is better to choose

- Quick-drying, odorless paint for interior use

- The best spray paint in spray cans

- Best water based paint

- How to choose a facade paint for outdoor use

- Which oil paint is best

- Best interior wall paint

- What paint for wallpaper for painting is better

- DIY paint tinting

- How to choose an epoxy paint

- How to choose the best wood wax

- Best Heat Resistant Varnish

- Which decorative paint is best

- The best enamel paints

- Which drying oil is better to choose

- Best Waterproof Bathroom Paint

- How and how to remove or remove old paint

- How to choose an impregnation for wood

- Instructions on how to paint the walls with your own hands

- Which varnish for wood is better to choose

- How to choose a bituminous varnish

- How to calculate paint consumption per 1 m2

- What is alkyd paint and how to use it

- Types of liquid glass

- Water-based dispersion paint

- Best Fire Retardant Paint

- How to choose a color for paint

- Fire retardant composition for wood

- Powder painting at home

- Glue-based paint

- Best wall paint

- Painting tools and accessories

- How to choose the best paint roller

- Tips for choosing floor paint

- What is the advantage of Tikkurila paint

- The best textured wall paints with effects

- Types and applications of spray paint

- How to choose white paint

- The best varnishes for metal

- Step by step instructions on how to paint the ceiling

- Best acrylic primer

- Types of the best paints for metal

- The best paint for wood

- How to choose the best ceiling paint

- Varieties of wood stains

- Review of the best rust converters

- What is the best wood preservative

- How to choose a paintbrush

- The best water-based paint for walls and ceilings

The best yacht varnishes for outdoor use

The composition of the coatings contains a greater amount of toxic substances, therefore, it is prohibited to apply them without a mask and gloves. At the same time, outdoor products are highly resistant to negative external factors. After finishing, wooden structures will be reliably protected from moisture, UV rays, which significantly increases their service life. The analysis of user reviews allowed us to single out the 2 best yacht varnishes from the 5 nominees.

V33 Vernis Bateau glossy

The coating with a urethane-alkyd base is enriched with resins that increase the resistance of the surface to the aggressive effects of the marine environment. It protects wooden structures from the negative effects of a humid climate. Paintwork materials are used for finishing various types of wood. The next layer is applied after 6 hours. It is released in containers with a volume of 0.75 l, 2.5 l, 5 l.

Dignity

- Colorless;

- Makes the coating waterproof;

- Resistant to abrasion;

- Gives the surface a glossy shine;

- Low consumption;

- Not susceptible to sea salts.

disadvantages

- High price;

- For outdoor use only.

Users confirm the quality and reliability of the product. All characteristics correspond to the parameters specified by the manufacturer. LKM protects the surface from negative mechanical and atmospheric influences, prolongs the service life of wooden structures.

Rust-Oleum Marine Coatings Spar Varnish

Transparent varnish provides chemical resistance, protection of wooden structures from water, UV rays, sea salts, mold. It can be applied to surfaces that have previously been stained or painted. Before the procedure, the product is diluted with white spirit. Paint and varnish materials are produced in cans with a volume of 0.95 liters. Full hardening occurs after 72 hours.

Dignity

- Low consumption;

- Increases the strength of coatings;

- Easy to use;

- Good adhesion.

disadvantages

- High price;

- Persistent unpleasant odor.

The product can be applied at temperatures from +10 to +32 C and humidity less than 85%. In this case, direct sunlight must be avoided. The coating dries quickly, but when finishing structures made of cedar or other species with a high oil content, the time may increase.

Working with varnish indoors

Before applying varnish, the surface must be carefully sanded, then cleaned of the remaining particles and dust, otherwise ugly bumps will remain on it. All holes (for example, from nails) are first putty, then sanded.

The next step is to apply a primer varnish. This operation is especially important before varnishing the parquet. The primer will provide better adhesion of the base material to the surface, remove the remaining dust particles, and additionally protect the wood from moisture. In order for the choice to be correct, several rules must be followed.

- The first step before priming is checking the composition on a small area of the floor covering. So you can establish how the composition acts on the wood.

- Equally important is the compatibility of the base coat with the base coat. For example, if you decide to use a water-soluble varnish, then the same should be the primer.

- Drying of the primer takes between 15 minutes and 3 hours, so this process will not take long anyway, since most basecoats take much longer to dry.

- Apply a primer varnish to the cleaned material along the fibers, evenly. The main recommendation is full compliance. The primer and base material must be from the same manufacturer. In this case, there is a guarantee that there will be no unpleasant "surprises" (for example, dried bubbles).

The primer and base varnish are applied either by hand - with a roller, with a wide brush, or with a spray gun. Drying time for different compositions needs their own. The fastest varnishes (alcohol-based) require speed from the master, since they begin to set after 10-15 minutes. "Slow" formulations (water-based) dry from several hours to several days. The period indicated on the product packaging is the time that must be waited before applying the next layer.

To improve the appearance of wood, to give tone or to enhance the pattern, use tinted varnish, stain. The latter liquid is released on a water, wax, organic or alcohol basis. Her task is to make the drawing more expressive, contrasting.

Characteristics and purpose

When choosing a yachtlak, they must pay

attention to its composition. When choosing a dye, it is not recommended to be guided by

price, as it is not a guiding factor

Outdoor work is carried out

polyurethane compound with acrylic. He

resistant to moisture and atmospheric influences, abrasion, scratches and

other mechanical stress.

Special material based on acrylic has good

adhesive properties. It dries quickly, which shortens the holding time.

repair work. If the outside temperature is above zero, then it is allowed

reusable cover of the yacht boat on the plane per day. The coating dries in 4 hours

thanks to the polyurethane-acrylic dispersion that is included in the composition.

The alkyd urethane finish consists of

toxic substances. Despite the presence of plasticizers that eliminate

the possibility of drying and evaporation of the yachtlak, its use indoors

is prohibited.

If the room temperature is above zero, then

finishing is carried out by yachtlac, the main components of which are alkyd or

urethane. Urethane plasticizers reduce evaporation and

the flexibility of the lacquer film is ensured. The finish is able to withstand changes

temperature.

Alkyd compounds are marked yacht, which

testifies to their improved technical characteristics. From their

external finishing is carried out, as it is capable of releasing harmful

toxic compounds during drying and during heating during operation.

Yacht varnish properties

Protection against moisture - the main function of this coating, leads to a number of additional effects. The elastic layer of waterproofing protects against temperature extremes and mechanical wear, exposure to sunlight.

The colorless composition favorably emphasizes and preserves the natural texture, giving the wood not only strength, but also aesthetic durability.

The choice of different degrees of reflection - from mirror to matte, and the ease of maintenance of surfaces give undeniable advantages to this varnish. But the content of toxic elements makes it impossible to use it in closed spaces.

Poor resistance to low temperatures limits the scope of outdoor use. Modern manufacturers offer special compositions of yacht varnishes with improved characteristics.