Advantages of wall cladding with decorative panels

Wall decoration with decorative panels is becoming more and more popular. This type of modern finishing materials has many advantages:

- impeccable appearance;

- resistance to mechanical stress;

- ease of installation;

- profitability of the material;

- security;

- hygiene;

- unpretentious care.

Fastening decorative panels does not require special preparation of the walls, their alignment and cleaning to the base. Therefore, the installation work is carried out in record time. For cladding, you do not need to use special equipment or tools.

This type of finish is truly versatile. It is equally well suited for residential and public spaces, offices, shops, hotels, restaurants and cafes. With its help, you can achieve an excellent level of noise absorption and thermal insulation. Installation of panels is possible in any direction: horizontally, vertically and even diagonally. The choice of color scheme, texture, texture and relief is limitless. Thanks to this, you can embody any design ideas and create an atmosphere of comfort, home coziness and warmth in living quarters, and in the office you can set the right tone for fruitful work.

All the materials from which the panels are made can easily withstand wet cleaning. Therefore, caring for such products does not require a lot of effort, time and money. One wet cleaning per month is enough for the lined walls to get their original appearance. If the relief has many details, small depressions and protrusions, then it will require special care, which will consist in washing with ordinary non-aggressive detergents.

If we compare the cost of various types of wall decoration in the room, then it is obvious that decorative panels are much cheaper. Moreover, they are in no way inferior in appearance, and in many respects even surpass other materials. Considering that for a long period of time you will not need to make major and cosmetic repairs to the walls, the economy of this type of finish is beyond doubt.

What are the panels

Manufacturers offer a wide range of 3d slabs, because wall panels are made from various materials that have their own advantages and disadvantages.

- Gypsum panels. Flexible and plastic gypsum allows you to realize a variety of patterns and textures, and a wall made up of several such panels seems to be solid, since the gaps between them can be easily covered with the same gypsum imperceptibly. In addition, this material is paintable. The disadvantage is the significant weight of gypsum panels compared to plastic or MDF.

- Plastic panels. Considered a budget option. In addition, they are moisture resistant and lighter. Wall panels made of plastic lend themselves to painting, and their installation is quite simple: they are attached to the wall using glue or a metal frame. The downside is their flammability, which makes it impossible to use 3D panels for walls in the living room interior directly next to the fireplace.

- MDF panels. They are made from wood fibers by gluing. The material is environmentally friendly and reliable, but much cheaper than wood. Differs in high performance and reliability. It is used to decorate rooms with a humidity of not more than 80%. Embossed panels made from compressed wood fibers are attached to the wall with brackets. The advantages include high noise and heat insulation. Wall panels made of MDF are paintable and laminated.Of the minuses, we single out the need for careful care for them, since over time it loses its appearance somewhat.

- Bamboo panels. Materials made of natural wood are also popular. The most commonly used for the manufacture of volumetric decorative slabs is bamboo. Low cost, environmental friendliness, ease of installation and excellent appearance open up many opportunities for using bamboo 3d panels in the interior. However, unfortunately, such panels are short-lived and have low moisture resistance, so they are not very suitable for a bathroom or kitchen. They are usually used in bedrooms or living rooms.

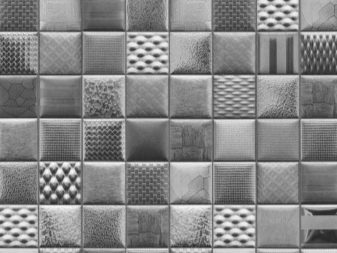

- Aluminum panels. The volumetric image on the surface of aluminum plates is obtained by perforation, and on top is covered with a special film that serves to protect the panel from corrosion. Therefore, aluminum wall panels are sufficiently moisture resistant. In addition, they are fire resistant and very durable. Therefore, it is permissible to use aluminum 3d wall panels in the interior of a living room with a fireplace. This material does not require special care and practically does not get dirty, however, this luxury is worth it.

Room interior with 3D panel

Room interior with 3D panel

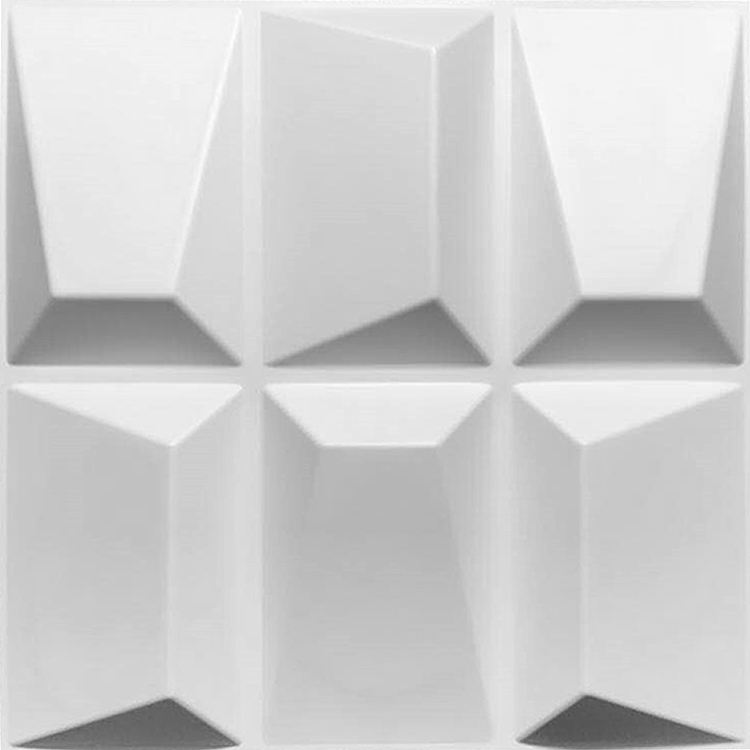

Squares in 3D panel

In order to make it easier to decide on the choice of panel material for your interior, we will give their comparative table:

|

Gypsum |

Plastic |

MDF |

Bamboo |

Aluminum |

|

|

Ease |

— |

+ |

+ |

+ |

+ |

|

Moisture resistance |

— |

+ |

+ |

— |

+ |

|

Fire resistance |

+ |

— |

— |

— |

+ |

|

Durability |

+ |

+ |

— |

— |

+ |

|

Price |

Depends on the complexity of the drawing |

Average |

Average |

Low |

High |

|

Mounting |

Self-tapping screws |

Adhesive or metal frame |

Brackets |

Glue |

Special profiles |

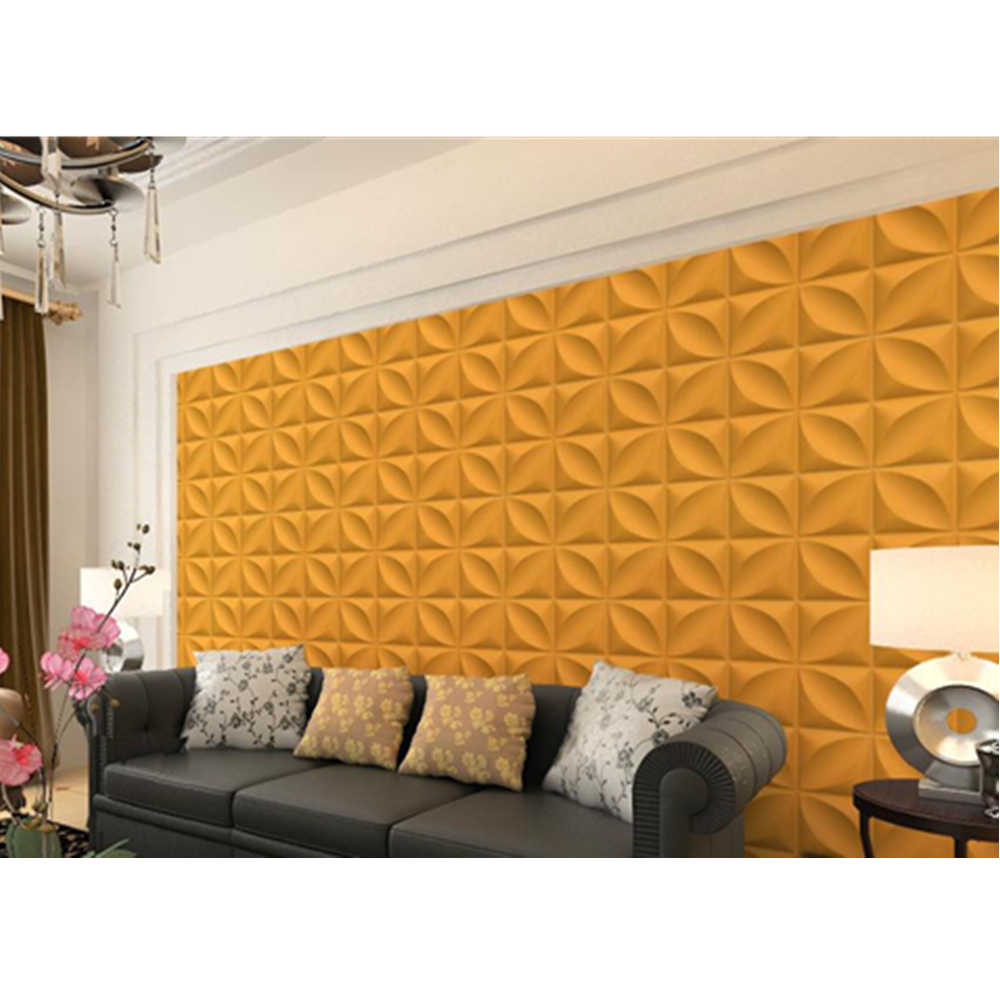

Living room interior with 3D panel

Living room with 3D panel

Bedroom with 3D panel

Beautiful examples of finishing

Decorative PVC panels are considered the most popular among buyers today. Indeed, thanks to the cladding of various surfaces with such products, you can independently create a unique look in the interior.

Bedroom

The bedroom requires soothing and relaxing shades, so in this case, choose panels in light shades. Glossy surfaces with a reflective effect are not recommended. Such a design will only tire the owners. An excellent option is considered wall decoration with panels that imitate wood.

You can also sheathe one of the walls in the room, while all the attention will be paid to it.

Bathroom

If you decide to decorate the walls and ceiling with plastic products, then be careful with color schemes. It is undesirable to use more than 2 shades in a given room. It is also worth abandoning too defiant colors; it is better to opt for neutral colors (gray, beige, white).

In this case, choose seamless types of products so that moisture does not get inside the structure, thereby preventing the appearance of mold and mildew. Tiled plastic panels in combination with natural stone can be used in the bathroom. For a large room, it is possible to use sheet products that imitate mosaics.

Kitchen

Usually, owners use PVC trim in this room in those places that are subject to constant pollution (above the sink and washbasin). It is also appropriate to use zoning here. Thus, you can highlight the dining area in the room. If the kitchen unit is made in light shades, you can use bright shades of the finishing product to dilute the boredom in the interior. When decorating the ceiling with PVC panels, you can install built-in spotlights or lighting.

See below for more details.

Installation rules

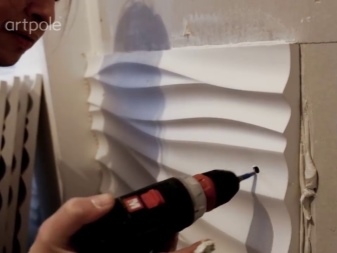

You can mount 3D gypsum panels directly on a wall or on a pre-prepared frame system, sheathed with plywood sheets or drywall. Installation is carried out using an adhesive, and additional screwing of the panel with self-tapping screws can be performed.

Installation of a gypsum panel can be done according to a certain algorithm.

The wall for the installation of gypsum panels is pre-cleaned of the old coating, putty, leveled very carefully. A well-prepared vertical surface will guarantee a neat and high-quality installation, good adhesion of the panel to the wall, as well as protection against mold or mildew on the decor.

Install gypsum panels starting from the center of the wall to the periphery or from the corner of the wall. The elements are installed from top to bottom, while it is necessary to ensure that the picture of the drawing is complete and symmetrical, the fragments must be located in the same plane relative to each other.

An adhesive composition is used for installation, intended for products made of gypsum material.

If the panel is attached to the frame, then self-tapping screws are additionally used, and fastening holes are made in the panels using a drill.

The glue is diluted according to the instructions, mixed with a construction mixer and applied to the wall surface with a notched trowel in an even layer 0.5 cm thick.

When attaching the panel to the adhesive, it is important to ensure that it does not go outside, outside the finishing material. During installation, you must observe the pairing of the picture

If necessary, trim the outer panels with a fine-toothed saw.

After installation, it is necessary to close the joints, as well as the holes from the screws. For this purpose, the finishing putty is diluted. After the composition is used and dries, it is sanded with fine emery paper so that traces of installation are not noticeable on the common surface.

Features, advantages and disadvantages

Plastic panels with a 3D effect are a great alternative to sleek but expensive tiles. This is a relatively new material on the market that even a beginner can work with. PVC panels for walls are dense sheets in the shape of a rectangle. There are special relief holes on the back of the cladding material, which ensure strong adhesion and good ventilation. A 3D drawing is applied to the outside of the tile.

Plastic panels have a lot of advantages that allowed the material to quickly become in demand.

Among their advantages:

- large size, thanks to which the installation will take place many times faster;

- no requirements for thorough cleaning of the walls;

- the possibility of independent high-quality installation;

- good protection from the wet environment of the bathroom;

- long service life;

- a huge assortment of various designs;

- low price.

Along with such seemingly indisputable advantages, the panels have several disadvantages:

- when ignited, the material releases toxic toxic substances;

- plastic is quite fragile, will not withstand an accidental blow;

- is not environmentally friendly;

- some people associate with office space.

Decorative 3D panels for walls - fashion compositions designed to become the center for the entire interior idea

Painting, decorative elements and wallpaper for walls - all this

has been relentlessly improved over the years and seemingly

it is no longer possible to invent something fresh. But the finishing materials industry is growing

as swiftly and tirelessly as the entire civilized world.

We have already considered an equally popular type of finishing material - 3D wallpaper, now we will add to them an overview of panels with a volumetric (convex) texture, which also claim the ability to change

the boundaries of the dimension of space.

The latest development of designers, which shook the whole world, was embossed 3d panels for walls, photos and videos of which allow you to choose the best option for decorating any space on the world wide web. Such three-dimensional compositions are perceived especially effectively

in spacious rooms with limited furniture.

3D picture creates a unique feeling

infinity and the illusion of living walls.New 3D textured decorative effect

panels threaten to transform a simple interior into a breathtaking sight.

Views

Depending on the parameters, PVC lamellas come in several varieties.

Tiled

The tile material is similar in appearance to ceramic tiles. The standard dimensions of this product are 30x30 cm, 98x98 cm, 100 x 100 cm. Their thickness can be from 1 to 5 mm. Tiled panels can be used in combination with plain tile variations that mimic natural stone.

Wall

Wall slats are used to decorate wall surfaces. Thanks to the large assortment of products, it becomes possible to create an original image in the interior of the room. The width of the products varies from 15 to 50 cm, the size is 2.6 m, 2, 7 m, 3 m, the thickness is from 6 to 10 mm.

Leafy

These panels differ from the previous variations in large parameters. When working with this type of product, a large area of the working surface is covered. The standard width of the lamellas is 50-122 cm, the size is 0.9-2.44 meters, the thickness is 1-6 millimeters.

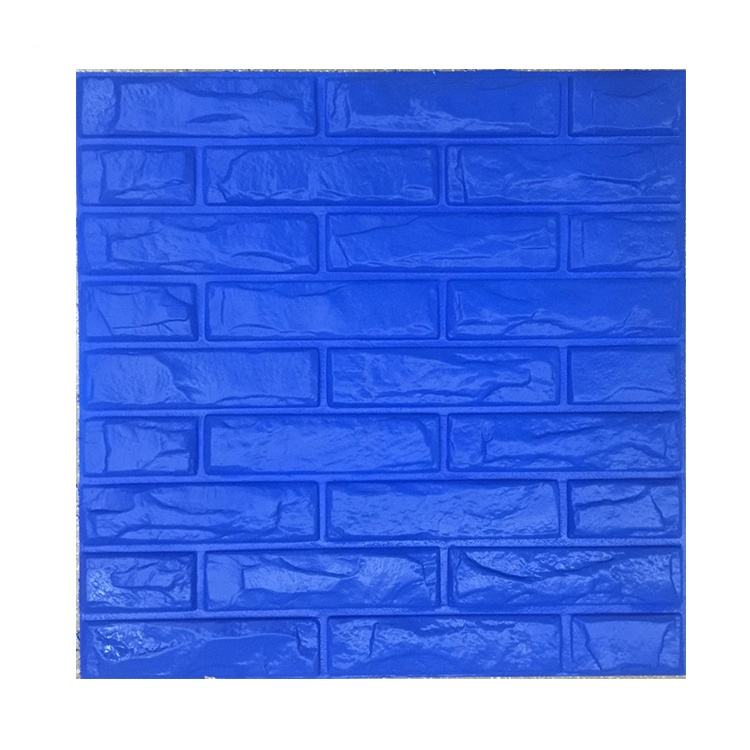

Sheet products often imitate various materials:

- wood;

- brick;

- mosaic;

- tile.

Lining

This type of plastic product has a sanded surface. Manufacturers make lining of various colors and textures. The connection of the products is carried out by means of the existing spikes, as a result of which even an inexperienced craftsman can perform the assembly. The width of the products is 10-30 cm, the size is 90 cm - 3 m, the thickness is from 4 to 8 mm.

PVC lining is made in 2 variations:

- "Euro lining" is a product of a standardized size with a wide locking structure. Width - 10 cm, width - 3 m.

- "Polka" is a product of a standardized size with a narrow locking system. Length - 3 meters, width -10 cm.

PVC wall panels also differ in the connection method:

- embossed lamellas;

- seamless plastic building materials;

- panels that are chamfered.

Seamless type finishing materials are commonly used for ceiling cladding in various premises. With a correct installation, you can achieve an effect in which the joint between the parts will be almost invisible. The seamless joining method allows you to create continuous lines and patterns when covering various surfaces.

Beveled panels are somewhat reminiscent of seamless products. The only difference is that in the first version there is a chamfer in the end part of the building material. A chamfer is a recess designed to join plastic panels into a single whole.

Embossed lamellas are commonly used for wall surfaces. In appearance, they are similar to the clapboard. Embossed products differ from the previous variations in a high coefficient of strength and wear resistance. Thanks to such technical characteristics, they have a high cost price.

3D effect

This type of product is used not only in the design of residential buildings and apartments, but also in office buildings and shops. The original drawing allows you to create a unique design in the room. Lamellas with this effect imitate natural wood, natural stones, ceramic tiles. Standard parameters: width - 25 cm, 37 cm, 50 cm, size - 2.7 m, 3 m, thickness - from 8 to 10 mm.

With thermal transfer

The manufacturing technology of this type of product is carried out in such a way that an image or a pattern is displayed on a polymer film, after which, on specialized equipment, this image is transferred to a plastic building material under the influence of high temperatures. Panels with thermal transfer are considered the most popular among homeowners, because they have a high resistance to high temperatures, and installation will not cause much difficulty even for a novice builder.The width of the panels is 25 centimeters, the size is 2.7, 3 and 6 meters, the thickness is from 8 to 10 mm.

Laminated products

The method of manufacturing laminated panels is that a film with an image and dressing is glued to the front part. Such a manufacturing method gives the finishing material additional performance characteristics; such a pattern or image is rather difficult to spoil. Laminated panels are treated with an antiseptic, which prevents small dust particles from settling on the surface of the products. The quality of panels of this type is certified by the appropriate quality certificate. Width - 25 centimeters, size - 2.7 and 3 m, thickness - from 8 to 12 mm.

Pros of 3d panels

- Versatility. The possibilities of using embossed panels are almost endless. They are used for decoration or as partitions when zoning rooms. Thanks to the volumetric slabs, you can hide the flaws and unevenness of the walls, hide the insulation or various communications.

- Originality. Decorative wall panels are capable of creating bold designs and a unique look for a room. The use of such finishing materials has become relatively recent, so not everyone has yet managed to appreciate their advantages, and 3d panels for walls in the interior of an apartment will become a rather unusual solution that will definitely surprise your guests.

- Durability. Most of the wall panels are made from high quality materials.

- Usually they are moisture resistant, durable and resistant to mechanical stress, which guarantees a long service life of the panels.

- Ease of installation. Installation of panels does not require additional preparations, as well as special tools or skills. To install the slab, you do not need to bring the wall to an impeccable condition, because the installation is carried out even on uneven surfaces. You can decorate the walls of a room with decorative tiles without involving professionals using glue or liquid nails.

- Heat and sound insulation. Volumetric patterns on panels made of various materials are used for decoration, but can also play the role of insulation or soundproofing partitions.

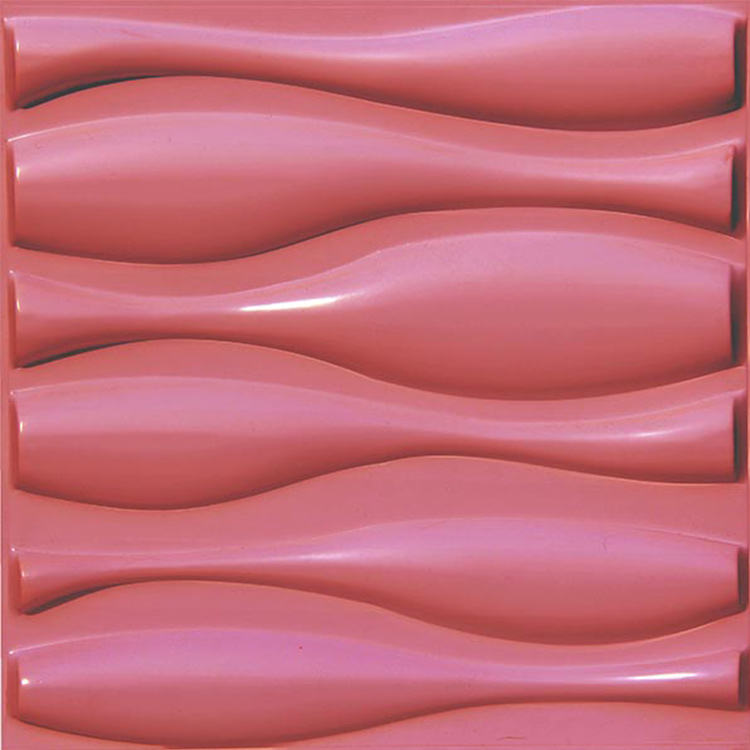

Wavy 3D panel in the interior of the room

Room interior with 3D panel

Large room with a beautiful 3D panel

Popular manufacturers of 3d wall panels

Despite the fact that 3d panels are a new finishing material, they are produced by more than one factory. Among the manufacturers, as always, there are those who produce quality products and those who, trying to reduce the cost of its market value, use not the best material for production.

Therefore, several of the most well-established brands can be distinguished:

Considering the popularity that 3d panels have gained, it is not surprising that their range is becoming wider. Therefore, when making a choice, it is necessary to focus not only on the brand, but also take into account how high-quality finishing material is presented in the window. After all, you can often simply find a fake. Conversely, 3d elements offered by a little-known manufacturer can pleasantly surprise you with their quality.

Advantages and disadvantages

The use of decorative 3D panels is due to a number of advantages.

- Ease and simplicity during installation. No special preparation is required for fixing this finishing material.

- Facilitated preparatory work. Before installation, you do not need to level the walls, fill up gaps or joints - an excellent disguise for the shortcomings of the base. The panels cover any surface irregularities and even out corners.

- Original design. The room, in the decoration of which this material is present, acquires a touch of luxury and chic and cannot leave anyone indifferent. The room immediately takes on an extraordinary look.

- Correction of imperfections in the geometry of the room. Depending on the pattern used, the visual boundaries of the room can vary greatly: the ceiling can appear taller, and the space can appear larger.

- Good thermal insulation.3D panels perfectly retain heat, which has a great effect on the thermoregulation of the room, especially in the cold season. And when using additional heaters laid behind the panels, you can perfectly reduce heat loss by 50–70%.

- Excellent combination with other materials. These wall materials are perfectly combined with wallpaper, tiles, and wood, therefore they are used in a wide variety of interiors.

Despite such a wide range of advantages, 3D panels have some disadvantages.

Production of 3d panels - features of manufacturing technology

Embossed wall coverings are made from the most

various materials: gypsum, glass, MDF, cellulose, plywood, aluminum,

polymer composites or precious woods, bamboo. Before you appear

in front of customers in finished form, three-dimensional panels will have to go through several

important processing steps:

-

The whole project is working on the sketch of the 3d panels.

a team of designers and professional artists. Armed with fantasy

current trends and innovative computer technologies for modeling,

they are preparing a perfect product that will be completely different from

familiar flat decorative panels. -

Technological

the stage of manufacturing embossed panels includes processing the material on

modern equipment to create the appropriate relief. it

quite a complicated process. Sometimes, in order to achieve that very

unique depth and maximum precision of processing of plates, for specialists

have to complete the mechanized process manually (of course, this

concerns the production of custom-made design panels, and

mass production is more prosaic). -

Completes

the process of creating a volumetric effect on wall panels cladding

outer layer. Depending on the type of coating (enamel, PVC film, leather

or veneer) manufacturers receive: glossy or matte, metallic or

fluorescent surface, as well as all sorts of amazing

special effects. Durable protective coating makes 3D wall panels durable

in a modern interior.

Artpole panels 3d

Dignity

Until recently, only ceramic tiles were used for wall cladding in the bathroom, and plastic was considered an economy-class material unsuitable for repairing the decoration of rooms with a difficult microclimate. Modern panels made of PVC and aluminum at an affordable price have become a real alternative to ceramics, not inferior in terms of service life and decorative potential.

This material has the following advantages:

- High speed of installation. It is possible to sheathe the walls of the bathroom with this material without the help of professional craftsmen. In addition, there is no need to carry out a thorough and lengthy surface preparation before installing the panels. If necessary, they can be fixed even over the old finish, which speeds up and reduces the cost of the repair process.

- Affordable cost. The price of 1 square meter of 3D panel covering is on average cheaper than finishing with decorative ceramic tiles, so the use of this practical material can reduce repair costs.

- Long service life. High-quality textured plastic can last more than 15-20 years, and aluminum panels are used even longer.

- Actual design. Three-dimensional finishing material opens up endless possibilities for creating a modern, attractive.