Types and parameters of concrete drills

The peculiarity of drills for concrete is that their cutting part is equipped with solders from a special alloy, the hardness of which is very close to the hardness of diamond. Due to its unique characteristics, such an alloy was named "win". Concrete drill bits are the most durable tool for processing this material.

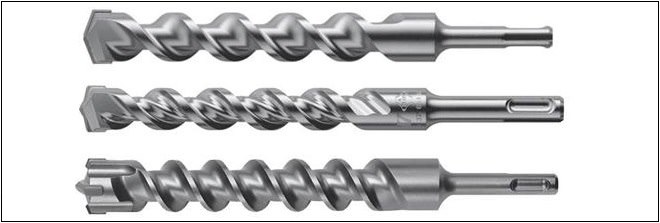

Among concrete drills, there are two main categories:

- a drill for concrete for a drill, the design of which is distinguished by a cylindrical or multifaceted configuration;

- a tool for working complete with a hammer drill, which has a cylindrical shank on which the designation SDS-plus or SDS-max is put.

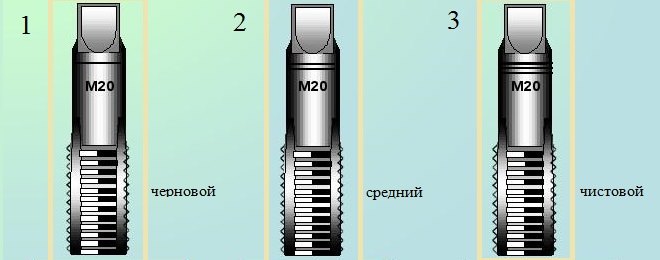

Concrete drill shanks

Home craftsmen often have a question about how to choose equipment and tools for making holes in reinforced concrete structures. A hammer drill with concrete drills for an impact drill is ideal for solving this problem. Drills for this type of drill are often referred to as drills and are classified into three main types:

- screw, with which you can drill holes of considerable depth;

- spiral (they can make holes of large diameter);

- shallow, which allow you to get holes that differ in small diameters and depth.

Rotary hammer drills with various spiral shapes for dust extraction

Thanks to a design feature such as a bump on the shank, the drills are installed in the tool holder by simply snapping in. As a rule, they are chosen by professional builders and installation specialists in order to obtain holes with a diameter in the range of 4-30 mm.

In the event that the question arises of how to drill concrete, having received a hole of a larger diameter, a crown-type tool is chosen. It forms holes with a diameter of up to 12 cm. Core drills for concrete are also divided into several categories:

- diamond drills for concrete in the form of a tube or crown, which are fixed on a solid bar (diamond spraying is applied to the working part of such a tool, which is why it is called a diamond drill);

- Pobedit drills, which have a design similar to diamond ones, but differ from them in the material for making teeth on the cutting part (these teeth are made from Pobedit).

Crowns for concrete

The need for a core drill for concrete arises if it is necessary to prepare seats for electrical outlets and switches, carry out communications and perform other work related to the need to obtain large holes and recesses.

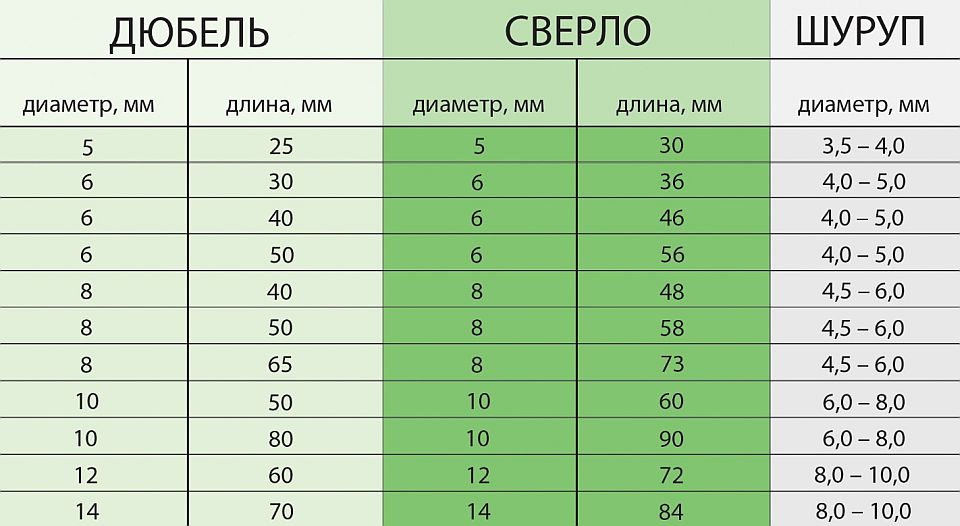

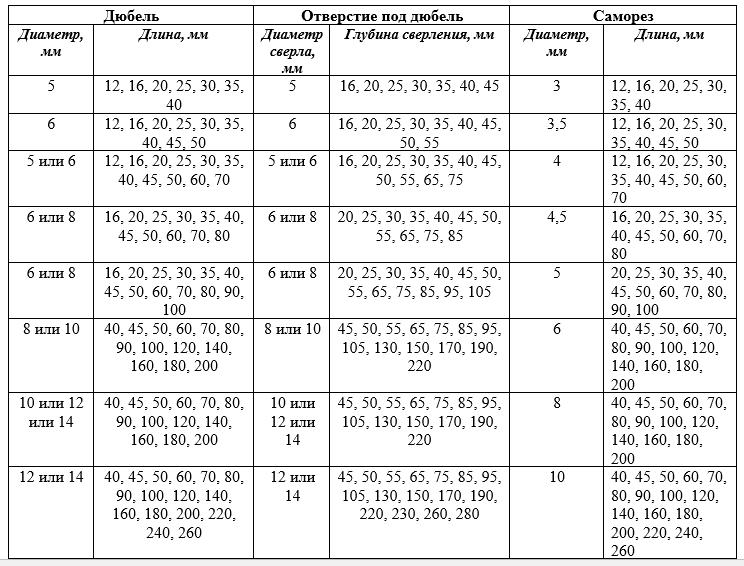

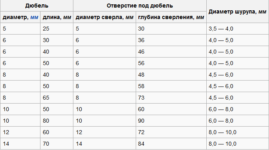

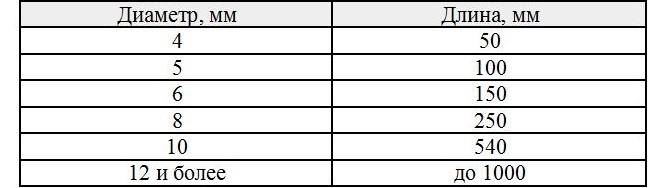

The choice of drill bit for brick and concrete is also determined by the diameter and depth of the holes to be formed. A diamond or victorious drill can have the following diameter to length ratios:

Diameter to length ratio

In the above table, you can see a simple pattern: the larger the diameter, the longer the drill length for concrete. This is because a long and thin tool cannot withstand the perceived stresses.

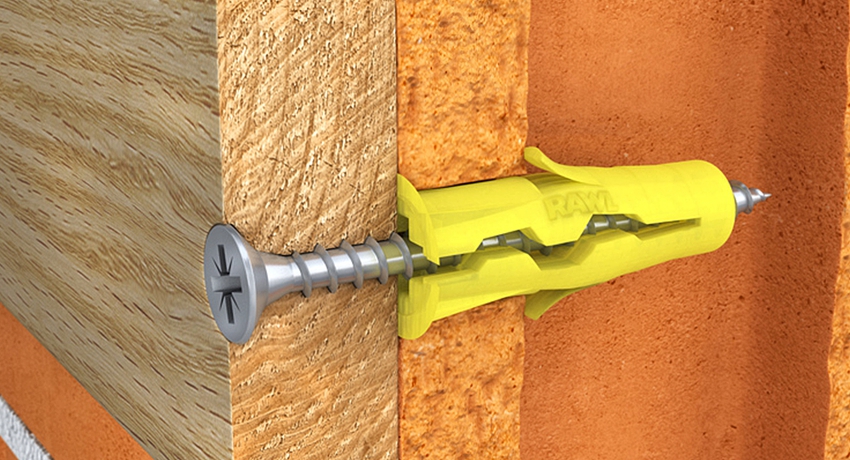

How to mount on unstable surfaces

Very often it becomes necessary to fasten objects on unreliable surfaces, which include plasterboard walls, building structures in old brick houses, etc. When fastening on such surfaces, the following recommendations should be followed.

- It is better to choose dowel elements from nylon, while their diameter should be 10–12 mm.The diameter of the winning drill, with which the hole for the fastener will be made, must be 2 mm smaller than the transverse dimension of the selected dowel.

- Drilling must be performed in one step, without changing the drill, and the impact mode should not be used in order not to destroy the walls of the hole being formed.

Securing items to plasterboard walls with a butterfly dowel

To perform reliable fasteners, it is important to take into account the condition of the surfaces, choose the right cutting tool and competently carry out the drilling process itself

Important parameters that should also be taken into account are the dimensions and weight of the object to be fixed. In addition, it is necessary to choose the right screw for the dowel in order to ensure reliable fastening of the object to the surface of the wall or any other building structure.

A drill is a cutting type tool for making holes. The mechanism of the drill is simple - the product rotates around its longitudinal axis and at the same time moves forward, cutting into the material. The twist drill pattern removes waste from the work area while helping to cool the tooling.

Profile hangers

With the help of hangers, the profiles are attached to walls or ceilings. Any suspension is designed so that its length can be changed. In total, there are 5 options for suspensions for drywall profiles.

Direct suspension. Suitable for fixing profiles to both walls and ceilings.

Straight profile hanger

Straight hangers are sold unfolded and are easily bent by hand during installation, forming a U-shape. Attached to the wall with threaded dowel nails. In rare soluchay, if the wall or ceiling is crumbly, a wedge anchor is used.

Vibration suspension. This is the same straight hanger, but with a special rubber insert, which excludes direct contact between the metal hanger and a solid wall.

Vibration suspension for a profile

The rubber insert dampens sound vibrations, increasing the sound-insulating properties of the room finish. Together with the vibration suspension, a soundproofing material is placed in the cavity between the wall and the drywall.

As well as a simple direct suspension, vibration suspension is used for both walls and ceilings.

Suspension with a clip. This fastener is also called an anchor or sliding suspension. It is used for mounting the frame on the ceiling.

Profile hanger with clip

This hanger consists of two parts - a rod and a hanger with a spring clip. The rod length can be up to 1 meter. Such a suspension is used in the event that you need to greatly lower the ceiling or make it multi-level.

Clamped hangers, due to their construction, are used only on the ceiling.

Suspension vernier. It looks like an anchor suspension with one difference - step fixation. Instead of a rod, this suspension has a strip with holes into which a cotter pin is inserted for fixing.

Suspension for vernier profile

The Vernier suspension is also used only on the ceiling.

Fastening to an unreliable surface

Modern homes have many surfaces made from materials that are not very durable. These include drywall, old bricks, wood planks, or pressed sawdust slabs. When working with them, it is better to use nylon fasteners with a diameter of more than 10 mm, the installation depth should not be less than 6 cm. It is better to choose a bit smaller in size.

Read also: How to change the coil on a doffler trimmer

The drilling process must be shock-free, as excessive stress can damage the surface. Using the impact mode may not leave visible damage, but the internal structure of the wall may suffer. If the drill diameter is too large, the fasteners will move freely in the hole, gradually increasing its diameter, especially if the work was carried out with aerated concrete.

For drywall walls, it is not necessary to use a drill of a smaller diameter, the main thing is not to press on the drill and do not use the impact mode.Drywall is a very delicate material, even a small load can lead to the destruction of a section of the wall. The hole should be drilled with light force to match the size of the plastic dowel with a self-tapping screw.

It should be understood that it is not necessary to attach heavy structures to such surfaces, even if the material initially copes with the load, over time, under heavy weight, collapse may occur.

If you take into account the material from which the wall is made, choose the right dowel and drill for it, and also having a quality tool in your hands, you can make a high-quality installation, and not worry about the safety of your furniture or household appliances. Observing the recommendations, even an inexperienced master will cope with such an installation.

If you find an error, please select a piece of text and press Ctrl + Enter.

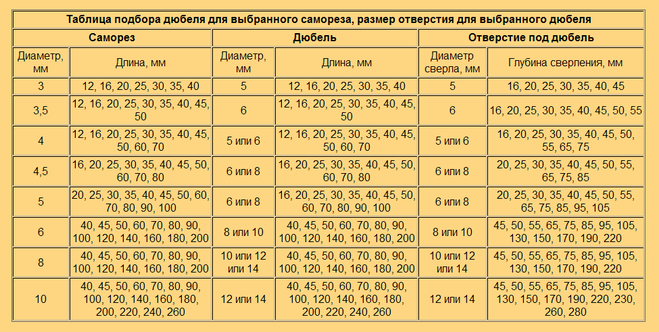

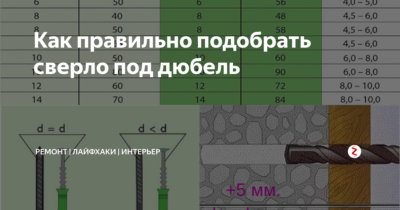

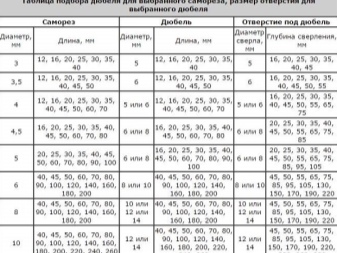

What are the basic principles for choosing a drill for a dowel? How should correlate dowel and drill diameter?

There are several options for selecting a drill for a dowel. This moment of choice should depend on the type of work envisaged and the quality of the work surface.

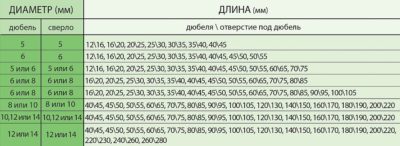

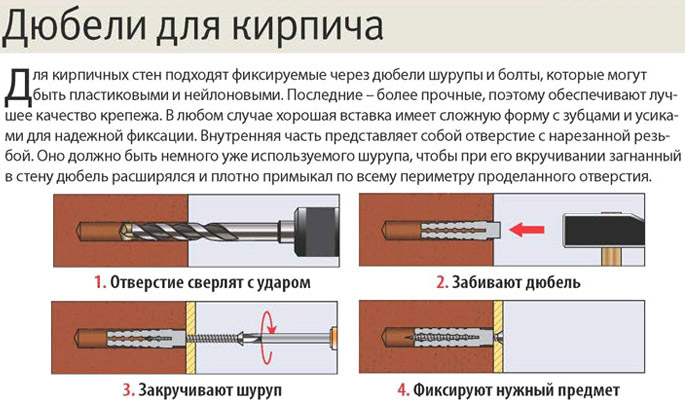

if the wall is reinforced concrete or brick, solid masonry and it is supposed to hang a light object, then it is best to choose an impact dowel with a diameter of 6 mm and a victorious drill of the same diameter. In this case, the dowel should go into the wall by at least 40 mm, and into the ceiling - by 60 mm. The minimum number of dowels is 2 pcs.

If you are going to fasten medium-weight objects (5–10 kilograms) to a reinforced concrete or brick wall, then it is recommended to use an impact dowel (8 mm in diameter) and an 8 mm drill bit. In this case: the dowel should go 60 mm into the wall, and 80 mm into the ceiling. The number of dowels used should not be less than 4 pieces.

if you intend to fix a heavy / bulky (static) object to a reinforced concrete or brick wall, you should choose an impact dowel and a victorious drill with a diameter of 10 mm. In this case, the dowel should go 60 mm into the wall, and 80 mm into the ceiling. The minimum number of dowels is 6 pcs.

When attaching heavy objects, in addition to those with a high dynamic load (for example, stair treads, horizontal bars, etc.), it is advisable to use anchor bolts with a diameter of 8 mm and a winder drill of the same diameter. The bolt should go 60 mm into the wall, and 80 mm into the ceiling. The number of bolts for this type of work should not be less than 4 pieces.

in old houses and buildings, when choosing a pair of dowels - drill, it is recommended to adhere to the following rule:

1) for fastening, you need to use nylon dowels with a diameter of 10 or 12 mm. It should fit into the wall by about 60 mm.

2) you need to drill a hole with a winder drill, the diameter of which will be 2 mm less than the diameter of the dowel used. This is done because the drill severely "breaks" the hole in the soft material of the walls of old houses / buildings.

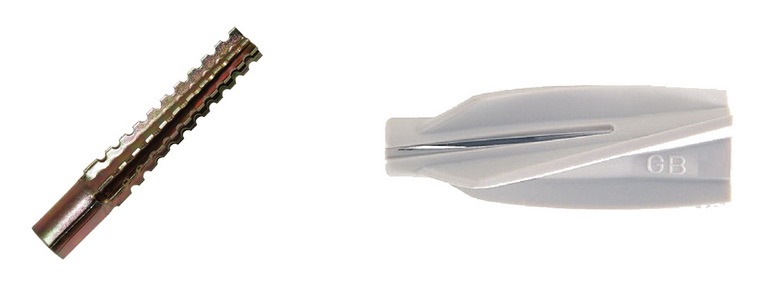

Types of dowels

Drive type dowel

Perhaps the most popular plasterboard fastener. It can be with or without a drill, metal or plastic. Making a hole for its fastening, use a drill with a diameter of 8mm. The manufacturer declares the shear workload that the gypsum board can withstand using this dowel, 25 kg, while the maximum load is up to 50 kg.

The popularity of the Driva dowel is due to its fairly high reliability and relatively low price. The strength of such an attachment is achieved by distributing the load over a large area, which is provided by the shape of the dowel.

Drywall dowel for drywall is simple and effective

Flat dowel-nail

Such a dowel is made of refractory steel, it is quite simple and convenient to use, since it does not require additional drilling and, accordingly, will get rid of dust. It can be hammered into drywall with a hammer or pressed by hand if you can.

The principle of operation of the dowel-nail is that when a self-tapping screw is screwed into it, the initially flat front part opens up, forming a reliable stop.

It is used for sheets with a thickness of up to 12.5 mm inclusive. Self-tapping screws are chosen with a diameter of 3.5-5mm. The working load for pulling out, declared by the manufacturer, is 15 kg, for shear - 30 kg, the maximum shear load, obtained empirically, is 48 kg. Among other things, the dowel-nail is reusable, that is, it can be dismantled and mounted in another place several times.

The flat dowel-nail for drywall is very easy to install, since it does not require drilling

Universal expansion dowel Butterfly

The butterfly dowel is suitable for both drywall and concrete base. The hole for its installation is drilled with a drill with a diameter of 8 mm, the diameter of the complete self-tapping screw is 4.5 mm.

For the butterfly dowel, we recommend using self-tapping screws without skipping the thread, because when screwing, reaching the smooth neck, the screw will start to scroll, and the dowel will not take the desired shape in the form of a stop.

In general, the plastic butterfly dowel works roughly like the others, creating an emphasis behind the gypsum board when screwing in the self-tapping screw. In shape, such an emphasis is somewhat reminiscent of a butterfly, hence the name of the fastener. The design working load for the dowel is 25 kg, the maximum working load is 55 kg.

The Butterfly dowel for drywall is the most popular because it is equally inexpensive, convenient and effective.

Dowel molly

The Molly dowel, or rather the Molly anchor (after all, this is an independent fastening unit that does not require an additional self-tapping screw) is another popular type of fastening for drywall, made of metal. This dowel, unlike the previous ones, is produced in various sizes and, accordingly, for different loads.

For example, for Molly, the minimum size marked 4/16/38 (4 is the screw diameter, 16 is the neck length and the maximum sheet thickness for which it can be used, 38 is the total length of the element), the working load is 25 kg, the maximum shear is 47kg.

To make holes for Molly, choose a drill 2 times larger than the diameter of the neck (the first number in the marking), that is, for a four it will be 8 mm, for a six - 12, etc.

To install the Molly dowel, you need a special tool that brings the fastener to "combat readiness". With its help, the screw is slightly pulled towards itself, while the hooks are bent. Then you can turn the screw with a screwdriver, bending the hooks until they stop. All this should be done by inserting the dowel into the hole in the drywall.

If there is no special tool, you can put the anchor into action using nippers (side cutters) or even an ordinary flat screwdriver.

Molly drywall plug - the solution for professionals

Fischer's twisting plastic dowel

When screwing a self-tapping screw into such a dowel, the latter twists, forming an emphasis behind a sheet of drywall, hence the name of the fastener. The drilling diameter for such a dowel is 8 mm, the diameter of the self-tapping screw is 5 mm.

When tightening the self-tapping screw, the main task is not to squeeze too hard, otherwise it will begin to turn, and the fasteners will need to be done again. For this reason, when using a screwdriver for tightening, set the minimum speed on it.

The working load for the detachment of the twisting dowel is 10 kg, for the cut - 25 kg, the crash load - 70 kg.

A twisting plastic drywall plug is an interesting and effective solution, backed by Fischer's reliability

How to choose a drill for a dowel

So that the dowel does not turn in the wall, you need to start drilling with a drill of a smaller diameter, for example a dowel for ten, start drilling with a six, then an eight. After this comes the "interesting moment", important, so more precisely. If the wall is concrete, then we insert a six into the perforator and drill with a blow, then an eight with a blow.After all this, we insert a ten millimeter drill (this is the size of our dowel), but we drill without hitting.

This is the only way we will get a hole of the required diameter, because a blow (drill in punch mode) breaks the hole.

Anyone who says that you need a drill of a smaller diameter is wrong, a plastic dowel simply will not fit into such a hole. Gypsum walls are drilled in the same way, but from the very first drill, without a blow, the gypsum walls are too capricious, if you drill with a perforator, whole pieces may fall out, then there will be no place to hammer the dowel.

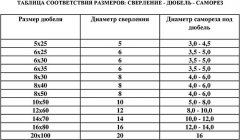

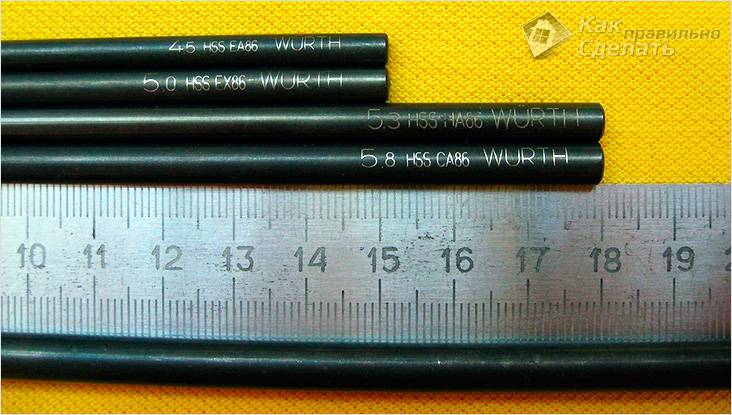

There is nothing simpler, there is a marking on the dowel, the thickness and length are written there, for example 8 X 50 or 10 X 100, often they even indicate that it is millimeters.

When buying dowels, they are signed in boxes, if you really don't know the thickness at all, then you need to take a measurement, it is measured with a caliper under the crown or at the very beginning, where there are still no extensions or slots.

The drill is selected exactly of the same thickness, no more, no less, the drills are also signed (marked), if the marking is not visible, then you need to measure the diameter - Attention! they need to measure the width of the victorious soldering, it is this that gives the diameter of the hole, the drill itself is thinner!

More questions on your topic:

leave a comment

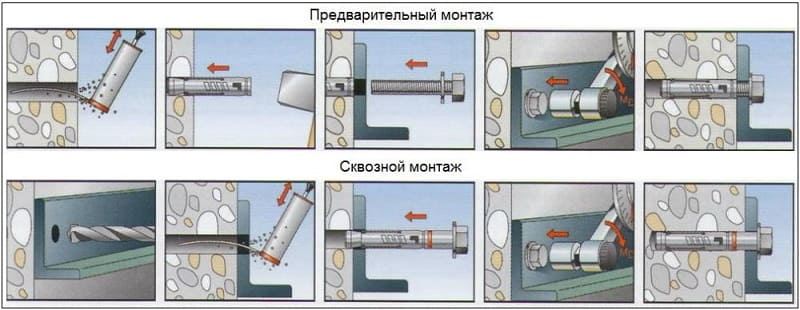

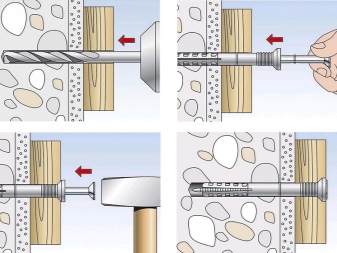

Fastening technology

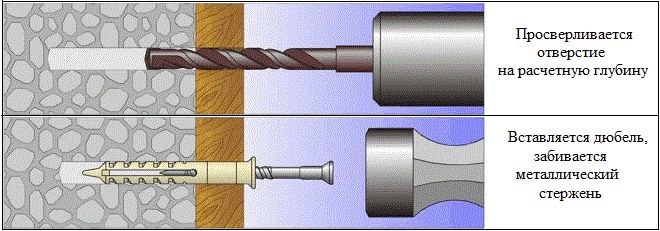

Like any other work, fixing something with a dowel is done in a specific sequence.

- Drill a hole.

- Install the dowel.

- Tighten the screw.

- Fix the desired item.

It will not be superfluous to first mark with a pencil the point where you plan to make such an installation. It would be absolutely ideal to make a small hole in this place (with a knife, nail, pin, etc.), which will allow you to set the drill as accurately and correctly as possible for work. A drill or hammer drill must be kept strictly perpendicular to the surface during operation! Under no circumstances should they be tilted at an angle. It is advisable to clean the resulting hole from dust and cement (brick, etc.) chips, either as shown in the video above, or with a vacuum cleaner. If not removed, they will interfere with the mounting of the fastener as expected.

Definition of MOLLE and PALS

You may have heard the term "MOLLE-Compliant" when it comes to gear carrying systems, but this is very incomplete information. MOLLE stands for Modular Lightweight Load-carrying Equipment. It is a military technical standard that refers to the design of cargo carrying equipment used by NATO military forces. This versatile design allows you to attach and detach smaller bags and cases as needed using the attachments provided on your gear.

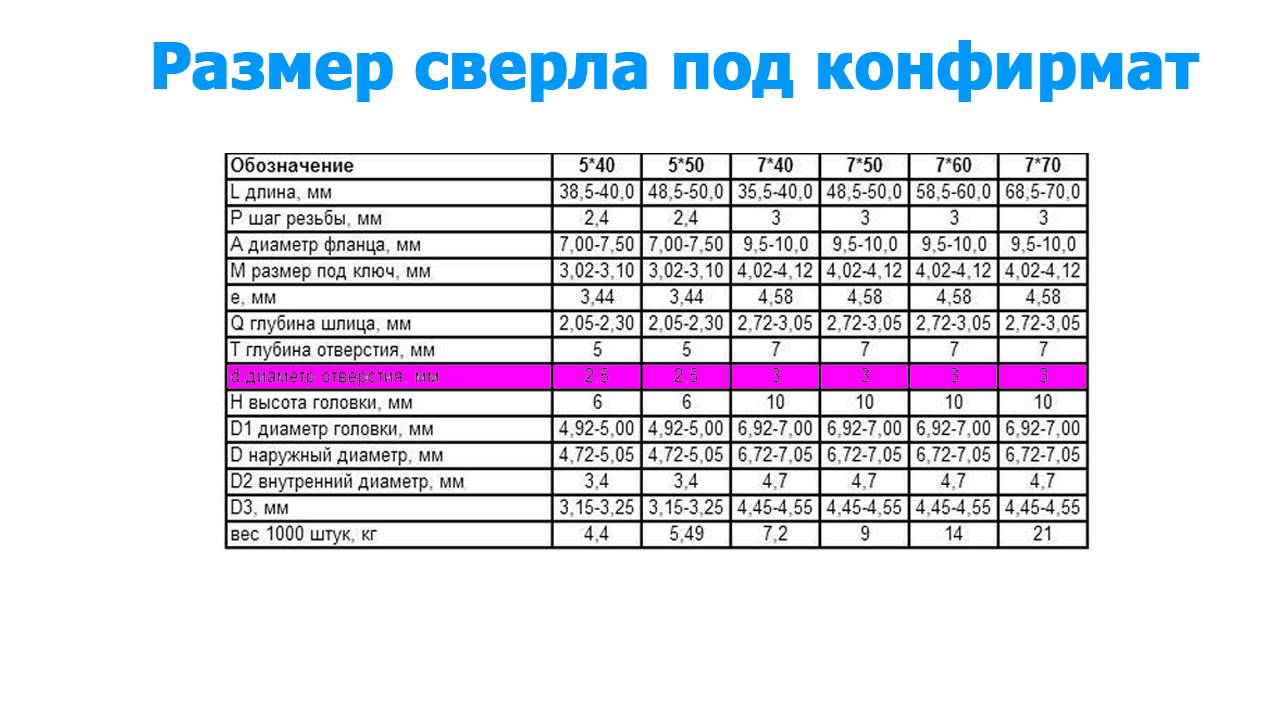

Tap application

Before proceeding with threading, the diameter of the preparation hole must be determined and drilled. To facilitate this task, the corresponding GOST was developed, which contains tables that allow you to accurately determine the diameter of the hole for the thread. This information makes it easy choose drill size.

To cut a metric type thread on the inner walls of a hole made with a drill, a tap is used - a screw-shaped tool with cutting grooves, made in the form of a rod, which can have a cylindrical or conical shape. On its lateral surface there are special grooves located along its axis and dividing the working part into separate segments, which are called combs. The sharp edges of the dies are precisely the working surfaces of the tap.

Tap: design and parameters

To make the threads of the internal thread clean and neat, and its geometric parameters correspond to the required values, it must be cut gradually, by gradually removing thin layers of metal from the surface to be treated.That is why, for this purpose, either taps are used, the working part of which is divided along the length into sections with different geometric parameters, or sets of such tools. Single taps, the working part of which has the same geometric parameters along its entire length, are needed in cases where it is necessary to restore the parameters of an existing thread.

The minimum set, with the help of which it is possible to perform sufficiently high-quality machining of the holes for the thread, is a set consisting of two taps - roughing and finishing. The first cuts off a thin layer of metal from the walls of the hole for cutting metric threads and forms a shallow groove on them, the second not only deepens the formed groove, but also cleans it.

Varieties of thread taps and their differences

Minimum set of taps

Combined two-way taps or sets of two tools are used for tapping small holes (up to 3 mm). For larger metric holes, use a combination 3-pass tool or a set of 3 taps.

To manipulate the tap, a special device is used - a knob. The main parameter of such devices, which can have a different design, is the size of the bore, which must exactly match the size of the tool shank.

Some types of tap wrenches

When using a set of three taps, differing in both their design and geometric parameters, the sequence of their use should be strictly observed. They can be distinguished from each other both by the special risks applied to the shanks and by their design features.

- The tap, with which the hole for tapping metric threads is first processed, has the smallest diameter among all the tools in the set and cutting teeth, the upper part of which is heavily cut.

- The second tap has a shorter nose and longer flanges. Its working diameter is intermediate between the diameters of the rest of the tools from the set.

- The third tap, with which the metric hole is machined last, is characterized by the full ridges of the cutting teeth and a diameter that must exactly match the size of the thread to be formed.

Set of three taps

Taps are mainly used for tapping metric threads. Significantly less often than metric taps are used for processing the inner walls of pipes. In accordance with their purpose, they are called pipe, and they can be distinguished by the letter G, which is present in their marking.

Fastening objects of different weights

Before drilling a hole for a nail dowel or plastic spacer fasteners, it is worth clarifying the loads to be taken by the element installed in the wall. The heavier and more massive the suspended structure is, the larger the fasteners will be required. A light shelf can be fixed on a 5 mm dowel, a heavy rack - on its counterpart from 10 to 12 mm in diameter.

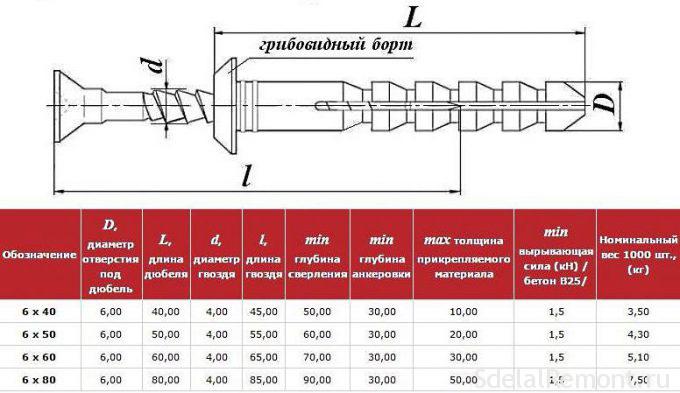

Lungs

For items of light weight, light mounting elements are used; a quick-install dowel-nail is also suitable. The hole in the walls made of concrete, reinforced concrete, solid bricks is drilled under them the same as the diameter of the fasteners. For an outer size of 6 mm, a length of 40 mm is enough. When hanging chandeliers, ceiling lamps, it is better to deepen the dowel more. Fasteners with parameters 6x60 mm are suitable here.

Middle weight

If you have to hang a shelf or other medium-weight item, you will have to take a more reliable type of fastening. Impact dowels with a diameter of 8 mm or more are suitable. The depth, respectively, and the length of the product used are determined at the place of installation.If a 60 mm dowel is fixed to the wall, then its analogue 20-30 mm longer will be needed in the ceiling.

It is important to correctly calculate the number of retainers. Each dowel, with its correct installation, should have a load of no more than 2.5 kg of the object's weight

That is, 4 holes or more will have to be drilled in the wall for a shelf or rack weighing 10 kg in order to provide for additional risk factors.

If you have pets that can jump onto the suspended structure, it is worth laying an additional safety load of 4-5 kg. The number of dowels will increase proportionally by 2 units.

Heavy

Massive interior items that do not have a floor support require careful fixation. The diameter of the dowel and drill here will be at least 10 mm, deepening can be done 60 mm or more into the wall, 80 mm into the ceiling. The fastener itself should be of the shock type - the counterpart is nailed into it. For hollow and cellular walls, certain restrictions are imposed on external loads, as well as on the fasteners used - it is better to use chemical or special anchors with an increased opening area.

If you have to fix the elements of home sports equipment on the wall, ceiling, they are also hung separately. Anchor bolts are used here, the selection of the diameter of which is carried out individually, but not less than 8x60 mm.

What is the dowel for?

The dowel is a specialized fastener designed for mounting and connecting various structures. There are many different types of dowels, each of which is suitable for a particular material: concrete, stone, drywall, wood, and others.

This mount is most often used when there is no access to the edge of the connecting rod of a conventional screw. That is, when it is necessary to make a blind hole, for example, for mounting a cabinet in the kitchen or a shelf in the living room. Dowels are also ideal for hollow walls. Other fasteners in this situation will simply be ineffective.

The principle of operation of the dowel is very simple. The dowel is a kind of buffer between the self-tapping screw and the wall, fixing the entire structure due to the presence of special ribs and "hooks". That is, it works like a spreader.

The dowel is a cylindrical rod made of polypropylene, nylon, polyethylene, or even metal. Structurally, the dowel has two parts: spacer - expands during installation, securely fixing in the working material, and also non-spaced. Some types of dowels are equipped with a stop collar to prevent them from falling into the drilled hole.

Features of the use of dowels

When choosing a dowel, it is not enough to be guided by its shape, it is also important to know what size (length, diameter) to choose. For each work surface, you need to choose your own fasteners

The dowel "six" (6 * 40) is suitable for the installation of profile structures in cinder block houses. By choosing a different size, repairs will not work, since all the fasteners will simply fall out of the drilled holes.

For panel houses (as well as those where there are no voids in the walls), the best option for dowels is 6 * 60 or 6 * 80. With them, everything will be securely fixed, nothing will fail and will not fall out even on the ceiling.

When choosing the length of the dowel, it is worth remembering the load that the fasteners will be subjected to during operation in the future. The shorter the dowel and self-tapping screw, the less load it will withstand. Diameter is also important. For ordinary housework (hang a cabinet, mirror or wall bars), dowels with a diameter of 8-10 mm are enough.

The only difference is in the depth of the drilled hole, since the load on the dowel is different. For a cabinet, 3-5 cm is enough, and for a Swedish wall or a heavier cabinet, a shelf is 8-10 cm.

Another important question that arises before the master is what kind of drill is needed for the dowel.

To answer it, you first need to know which surface will be drilled and what load on the structure is planned in the future after the end of the work.

How to choose a drill for a dowel?

The most important rule is that the number of the drill must match the number (size) of the dowel. T

That is, ideally, the dowel should hardly be hammered into the wall, otherwise, a situation is possible when the dowel will simply fall out or fall through. As for the quality of drills, experienced craftsmen advise using win-win drills, since buying more expensive ones does not make much sense.

It is easy to make a hole for the dowel (for example, take dowel 10):

First, take a smaller drill, for example an 8-ku. Make the hole slightly shallower than necessary using the hammer mode.