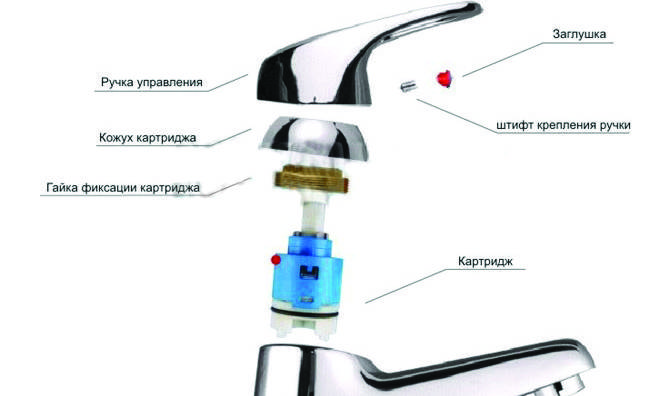

Main types and design

Manufacturers use several classifications of mixers. At the same time, structurally single-lever devices of this type practically do not differ from each other.

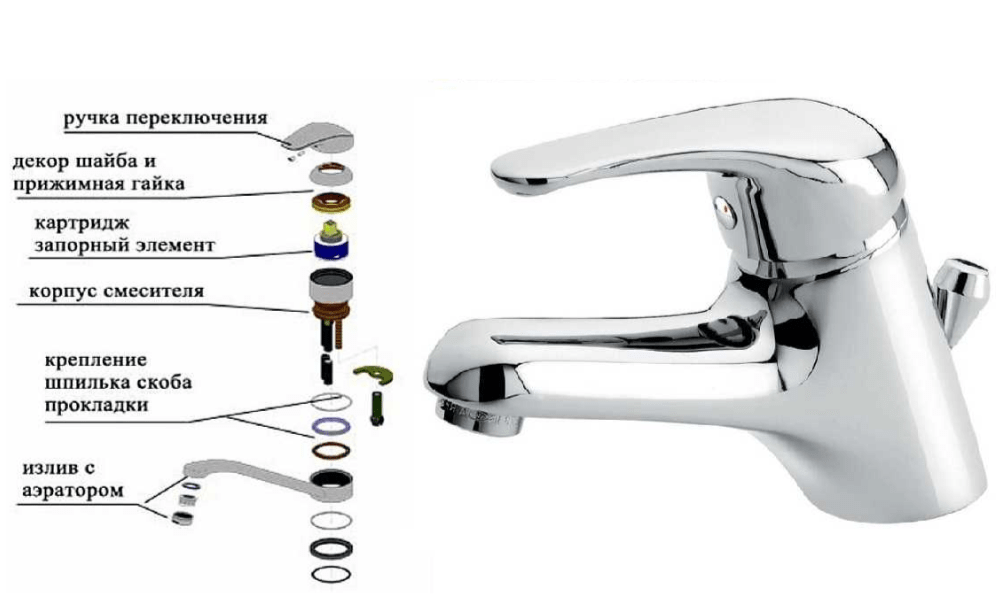

> Regardless of the model chosen, each ball mixer consists of the following components:

- Rotary handle. Through this part, the flow rate and water temperature are regulated. The handle is attached to the body with a screw, which is closed with a decorative cover.

- Cap. This part secures the valve train to the body.

- "Cam". Most often, a part made of plastic, with which the position of the ball-shaped element is adjusted. The latter closes / opens the flow of cold and hot water. The cam is supplemented with rubber seals.

- Body and nut that secures the tap to the sink.

The ball element is non-separable. This part provides three holes, two of which provide cold and hot water supply, and through the third flow enters the tap.

All-welded

It is impossible to eliminate breakdowns of all-welded models. Such cranes are produced in a non-separable body. Therefore, in the event of a malfunction, such mixers must be replaced with new ones.

Collapsible

A more common type of plumbing fixtures. These cranes, due to the design features, do not tolerate long-term operation worse, but can be repaired.

Types of cranes

Before you repair the faucet, you must definitely consider the types of mixers. There is a small list of variations:

Two-valve - traditional type of mixer with the ability to open and regulate the flow of water.

Single-lever - a more complex design, allows one lever to regulate both the water pressure and its temperature.

Thermostatic is a type of tap that can automatically supply water at a certain temperature. This variation is rarely used.

The non-contact faucet is controlled by an infrared sensor that is directly connected to the valve. This option, as a rule, is most often used in public institutions, probably everyone has seen such a design at least once.

Bath-shower switch

Ceramic

Reliable, practical type of switch, unified in the principle of operation and parts of the elements with ceramic crane-axle boxes, the service is identical. For replacement or revision, it is enough:

- remove (unscrew) the lamb cap;

- unscrew the fastening screw;

- remove the lamb;

- turn the head out.

Button

The switch is located on the spout. The spring-loaded button raises the stem when pulled, opening the way for the medium into the shower head. The switch is held in the raised position by the water pressure.

The presence of a spring is potentially fraught with breakage, stem jamming. Typical malfunctions:

- flow from shower and spout at the same time;

- no top fixing or button return.

Eliminate failures by changing the rod gaskets or the spring, respectively. The algorithm explains the video:

Ball

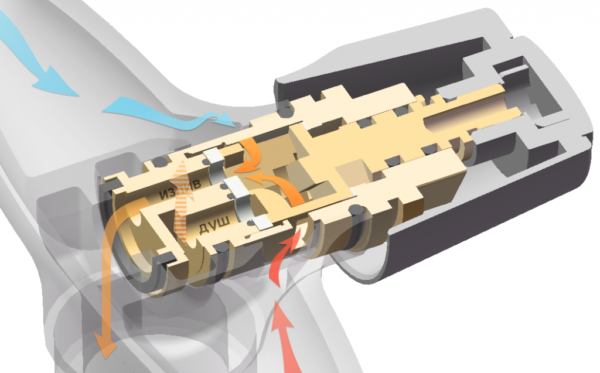

The switch represents a sphere with three holes connecting channels: cold, hot, shower. Introduces the principle of action:

Common problems:

- flow along the stem or butt joint;

- incomplete blockage of the flow to the watering can or spout.

The first reason is the wear of the rod or butt gaskets, respectively. The second situation is caused by a loose fit of the sphere to the saddles. Eliminate by tightening the saddles with saddles, grinding the ball, or replacing parts from the repair kit.

Sequence of operations:

- disconnect the gander, shower head;

- remove the ball handle plug;

- unscrew the screw, remove the handle;

- unscrew the central cover;

- unscrew the inserts with pressed-in saddles with a hex wrench;

- clean the parts from deposits;

- set the sphere to the “shower closed” position;

- install and screw in the inserts until they touch the ball, tighten the central sleeve;

- put on the handle, adjust the force of turning the ball, alternately evenly tightening the inserts with a hexagon;

- fix the handle, attach the spout, shower;

- check the result.

Divertor for two souls

Typical diverters are installed between the body and the gander. The standard shower remains in place, controlled by a central ball or ceramic shutter. The metal hose of the second watering can is connected to the diverter fitting, controlled by the built-in spool or push-button switch. Failures are similar to those of the built-in pushbutton and slide switches.

General view of the spool divertor, main elements.

General view of the spool divertor, main elements.

The slide switch is simple, so it works stably. For disassembly, remove the handle, unscrew the boot, take out the eccentric. By unscrewing the adapter, the plunger is pushed out. Maintenance consists in cleaning the cavity, eccentric, plunger from lime. Leakage is eliminated by changing the gaskets. The leading eccentric finger rarely breaks off. Seals on eccentric stem may need to be replaced

Mixer repair

When all the preparatory information has been studied, you can proceed directly to work.

In general, there can be two reasons for repairing a crane:

- Poor water flow from the kitchen faucet

- Water leaks from the bathroom faucet

If you are faced with the first reason, then the fact is that the pipe is simply clogged in the water supply system. If you use a thing for a long time, then various sand and debris can get there. If you do not have a filter installed, then do not be surprised, such phenomena will occur quite often.

If you are faced with the fact that the valve began to leak, then most likely the matter is in the wear of the gaskets. Mixers usually have three of these gaskets.

So, if they have worked for a sufficiently long amount of time, and they are out of order, then rest assured that tightening the nuts will definitely not solve the problem.

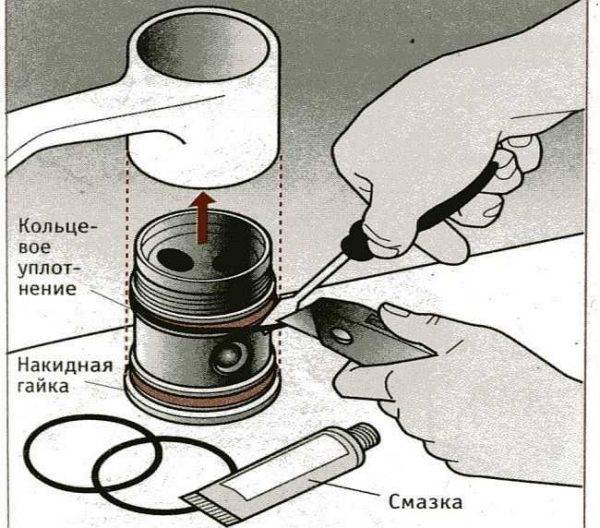

Here you need to find out the reason. First unscrew the nut on the gander using an adjustable wrench. In the body part of the pipe, you will see a rubber O-ring, and another ring that just holds it.

The rubber band must be changed and the mixer is assembled in the same way in the reverse order.

Recommendation! If you want to eliminate the possibility of a choice error, then take the worn out nut and bring it to the store and show it to the seller. He will tell you the same new nut.

Otherwise, you run the risk of buying a thing that simply does not fit your mixer, you hardly need it.

Recommendation! Timely check the mesh through which the water flows. Over time, it becomes clogged with dirt, which has a rather bad effect on the operation of the device.

Unscrew the nut in time and rinse this very mesh, so you will provide yourself with the most pleasant water pressure.

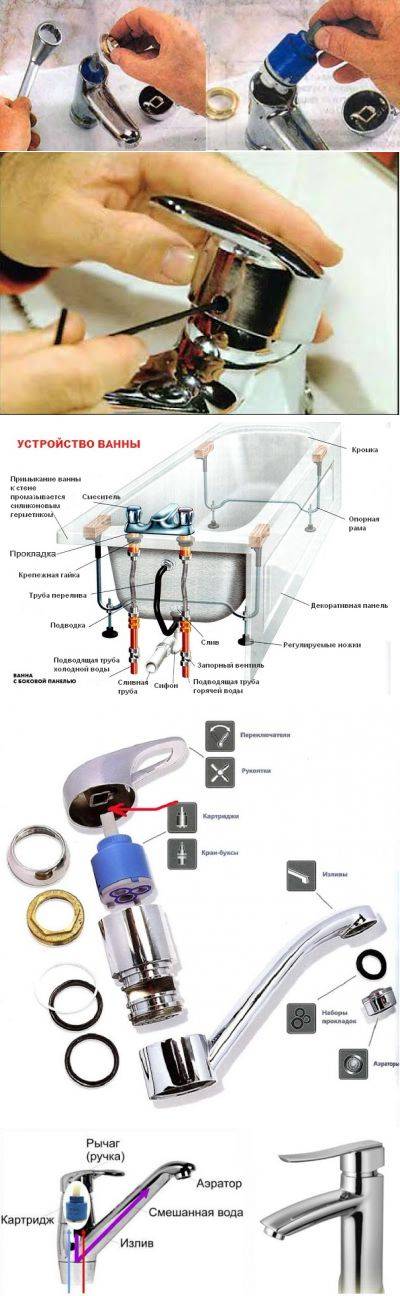

Repair of a single-lever mixer with swivel spout

Faucets with a swivel spout are placed on sinks in the kitchen or on the bathroom. Periodically begins to flow from under it. The locking mechanism in this case is not to blame, it is just that the gaskets have lost their elasticity or the lubricant has dried out.

Repair of a single-lever mixer with a movable spout

In this case, disassemble the mixer as described above, then remove by pulling up the spout. Remove all old gaskets. If they are stuck, you can use a flat screwdriver or even a knife blade. You need to remove them, but they still need to be replaced. Select new ones from the removed gaskets. It is desirable that they be made of silicone, not rubber. Silicone is more elastic, retains its properties longer, and better tolerates contact with water.

Lubricate new gaskets with plumbing silicone grease, install in place. Replace the spout.It must be well pressed down so that it rests against the union nut on the mixer body. Next is the assembly of the rest of the mechanism.

Features of repair of a single-lever mixer

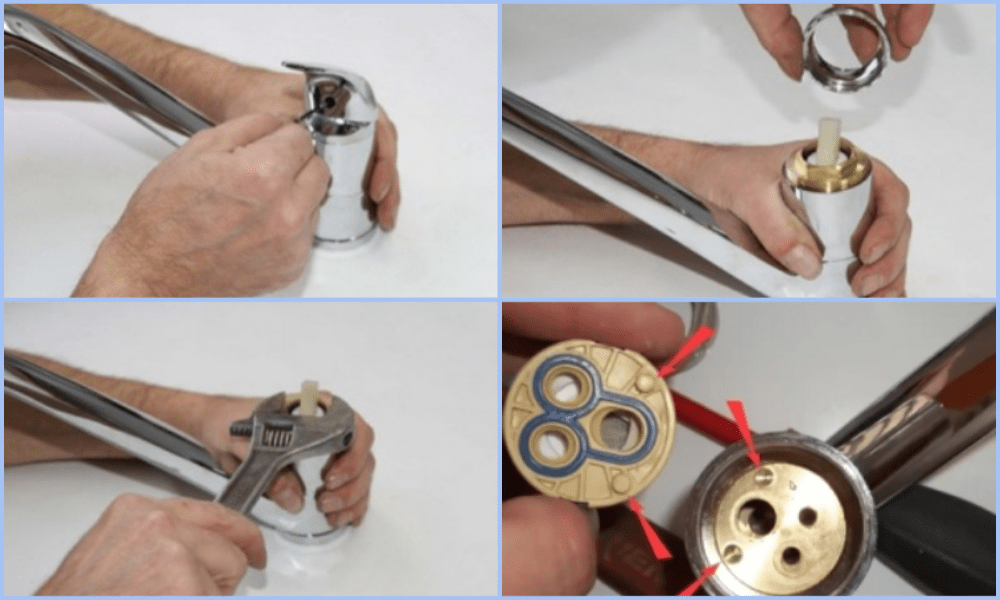

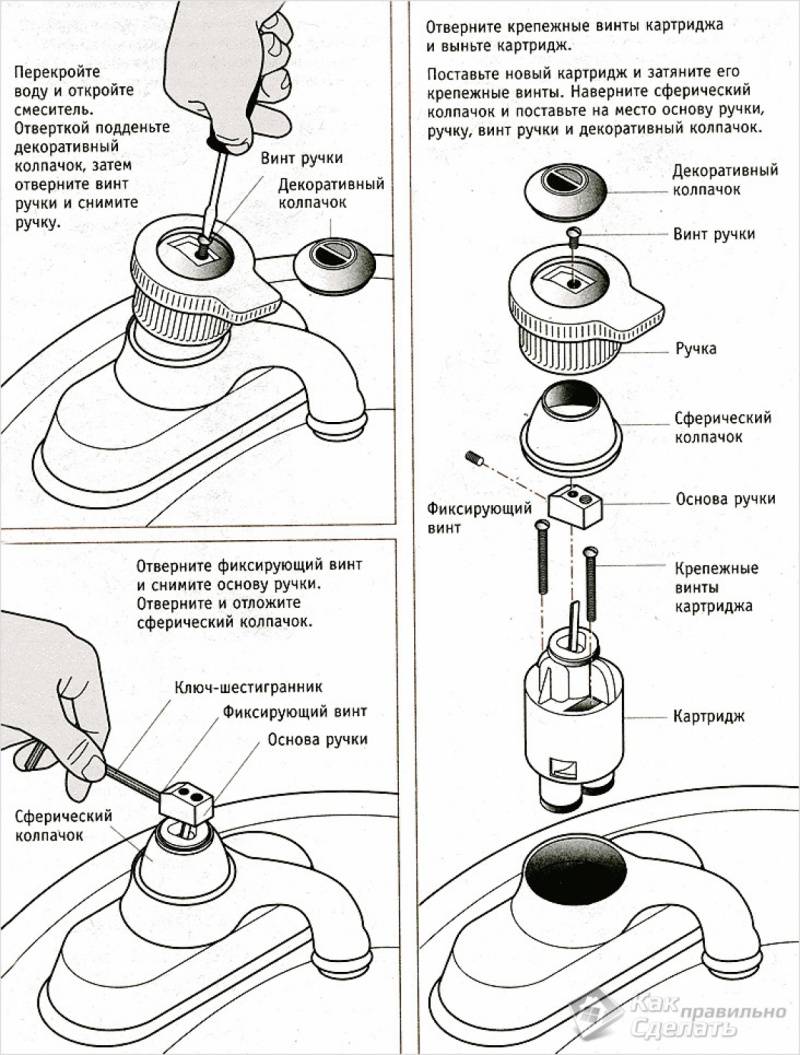

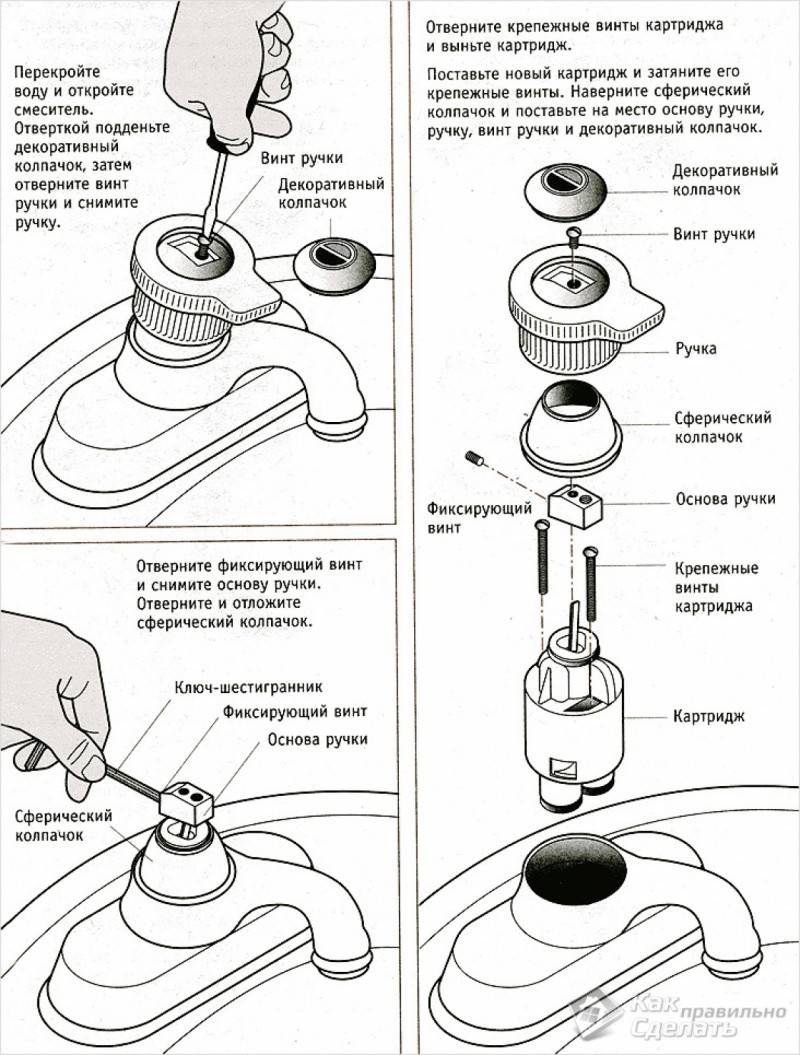

Due to the fact that single-lever models are structurally similar to each other, plumbing fixtures are repaired according to a single algorithm. To eliminate the problems that have arisen, you will need to disassemble the crane, for which you need to perform the following steps:

- Using a knife or flathead screwdriver, remove the plastic plug on the handle and loosen the screw. If necessary, the latter must be processed with WD-40.

- Unscrew the decorative metal nozzle. No effort is recommended during this procedure. Otherwise, scratches or other defects will appear on the tip.

- Unscrew the hex nut with an adjustable wrench and remove the ball mechanism.

If water flows from the tap under low pressure, it is recommended to first check the condition of the mesh located in the drain hole. This part quickly becomes clogged with small particles that are contained in the water. For some faucet models, to clean the mesh, it is enough to remove the decorative strip attached to the drain hole. To do this, use an adjustable wrench.

Operational problems

Even high-quality plumbing fixtures fail over time. The service life of a faucet depends on the material from which it is made, the quality of tap water and the intensity of use. The most common problems encountered when operating single-lever models are:

- Cracks on the body of the device. They arise due to the poor quality of the material and installation errors.

- Clogged aerator. The cause of this malfunction is the poor quality of the tap water.

- Wear of rubber gaskets. Seals are consumables, they wear out over time due to the high intensity of use of the device.

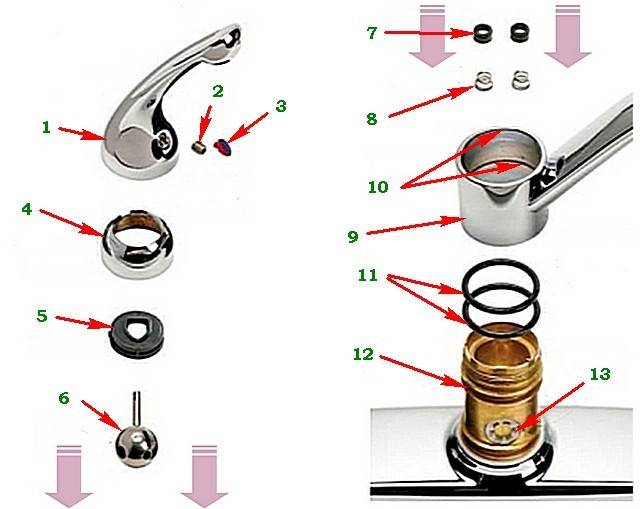

Single lever mixer design with ball switch

Alas, modern mixers, like their valve assemblies, fail from time to time. Indeed, in their production, the same materials are used: metal, rubber and plastic, which can wear out during operation or under the influence of external factors.

To repair a ball valve, you need to understand its device and be able to dismantle it if necessary. The ball device includes:

- rotary handle; At its core, it is a lever that is sometimes called a "butterfly."

- stock; The stem seal is adjusted with a nut and washer, which are also included.

- body with nut; Inside this body, the ball cartridge and stem are located.

- ball cartridge; It is secured with rubber saddles.

This mixer can be repaired independently without the help of specialists, only if the case is mechanically damaged, you will have to buy a new mixer

This mixer can be repaired independently without the help of specialists, only if the case is mechanically damaged, you will have to buy a new mixer

A ball cartridge is a non-separable element that has three holes: for incoming cold and hot water and for outputting mixed water of the required temperature and pressure from the device.

The operation algorithm of a crane of this design is quite simple:

- when the lever is lifted, the ball starts to rotate;

- the holes in the ball cartridge begin to line up with those in the seats;

- depending on the area of coincidence of these holes, the jet pressure changes.

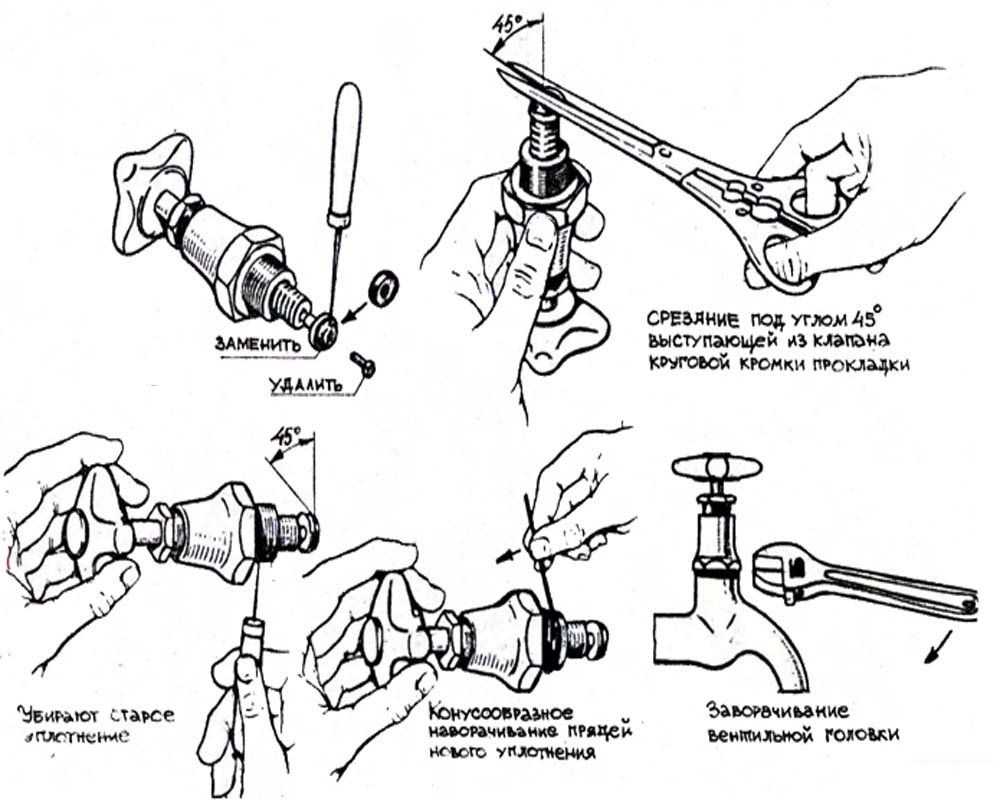

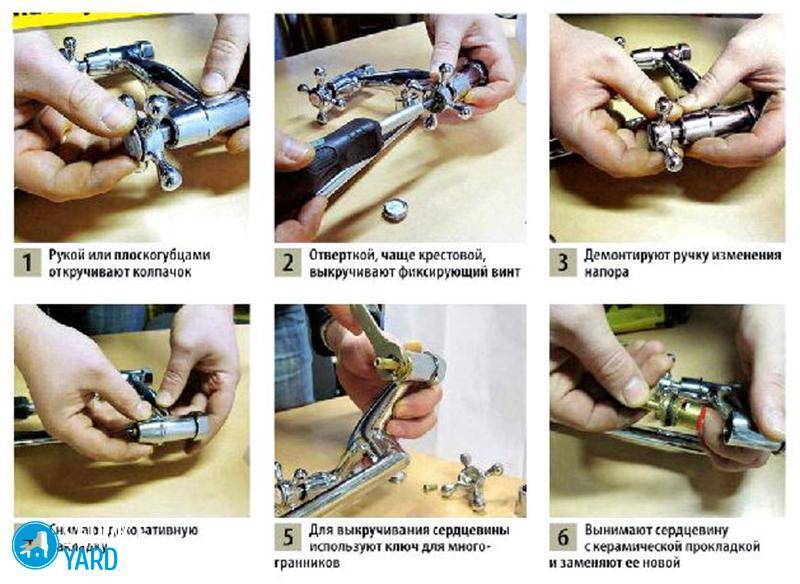

Repair of a two-valve valve - top tips

How to fix this type of mixer? It is necessary to disassemble and replace the worn out elements - the crane box and / or the gasket.

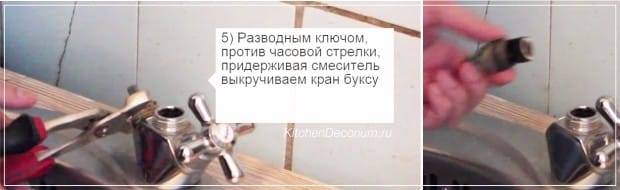

The sequence of work in this case will be as follows:

- The water is completely shut off, after which the valve flywheel is transferred to the operating position so that excessive pressure does not act on the parts.

- Next, you need to disassemble the structure - for this, the decorative caps are removed and the screw fixing the flywheel is turned out. This requires a screwdriver.Further, the old crane-axle box is replaced with a new one of a suitable size, and the structure is assembled back.

- If the gasket is worn out, then it is simply removed, and a new one, lubricated with plumbing grease, is installed in its place.

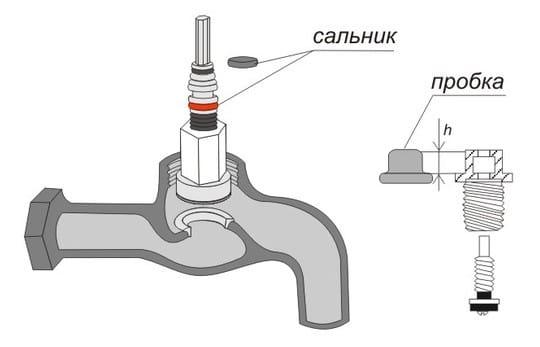

Often, valve mixers need to be repaired due to the fact that an oil seal has leaked in them. Then it must be disassembled according to the same algorithm and the worn-out packing must be replaced.

And sometimes, in order to establish a valve valve, it is enough just to fix the stuffing box sleeve tighter, as shown in the video:

Advice! Replacement of the packing is needed only when the sleeve is tightly tightened, and the leak is still present. Used as packing (for old mixers):

- Rubber tube of appropriate dimensions;

- Burlap threads;

- Twine impregnated with linseed oil.

If you see that the threads have worn out on the details, then this indicates that it is time to update the plumbing.