Single Lever Mixer Cartridges

Replacing the seals does not always eliminate the malfunctions that have arisen. In such a situation, it may be necessary to replace the cartridge for the single lever mixer. You can carry out repair work yourself. The main thing is to get a suitable repair part.

Replace the mixer cartridge

How to replace a cartridge in a faucet in a kitchen or bathroom

Let's take a closer look at how to replace a cartridge in a kitchen faucet so you can do it yourself. The work is carried out in the following sequence:

In order for a new cartridge to last as long as possible, you should pay attention to products with good reviews.

Mixer cartridge repair

Before buying a new cartridge, it is worth making sure that the old one cannot be repaired. How to repair the mixer cartridge, consider below:

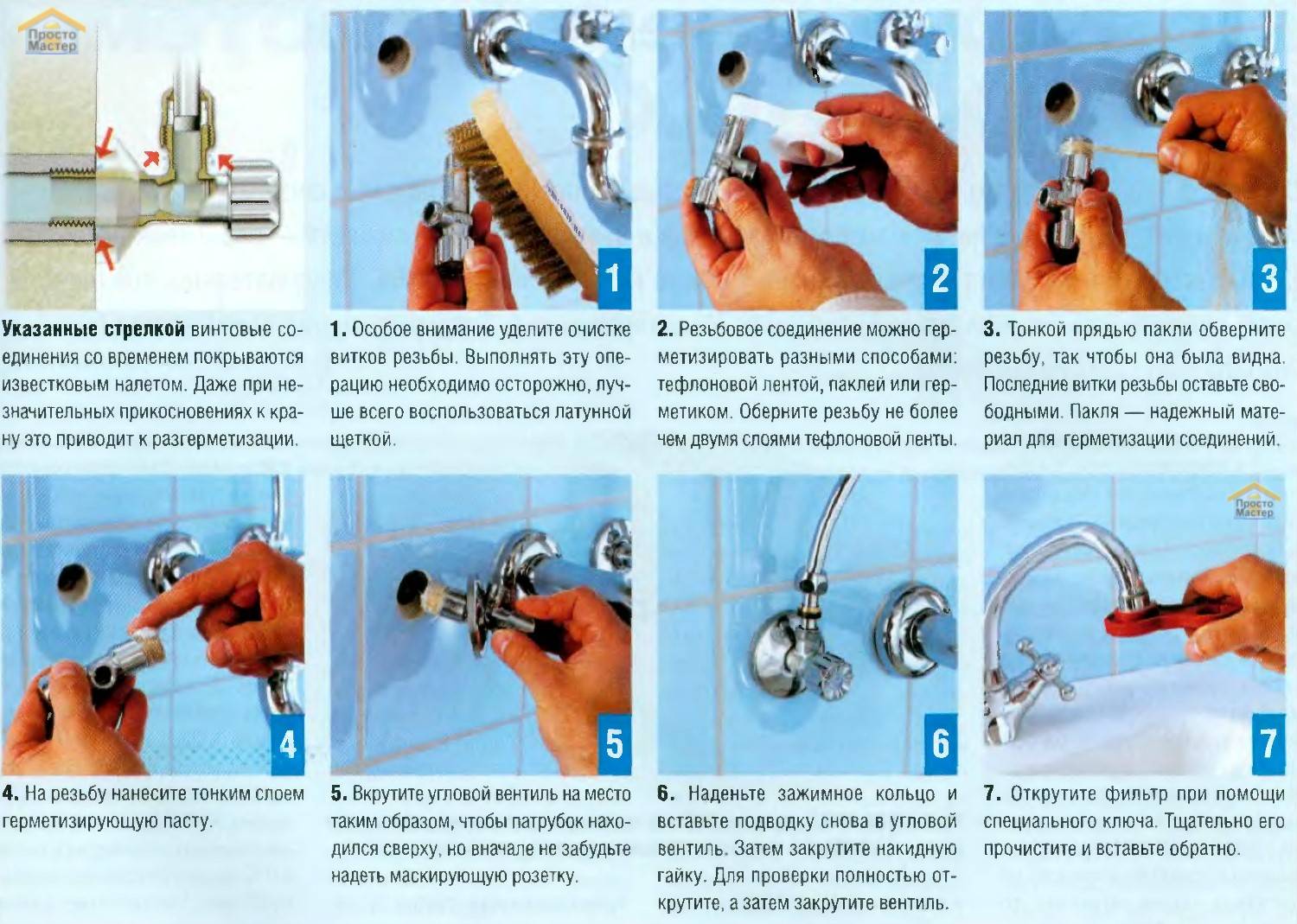

Substitution rules

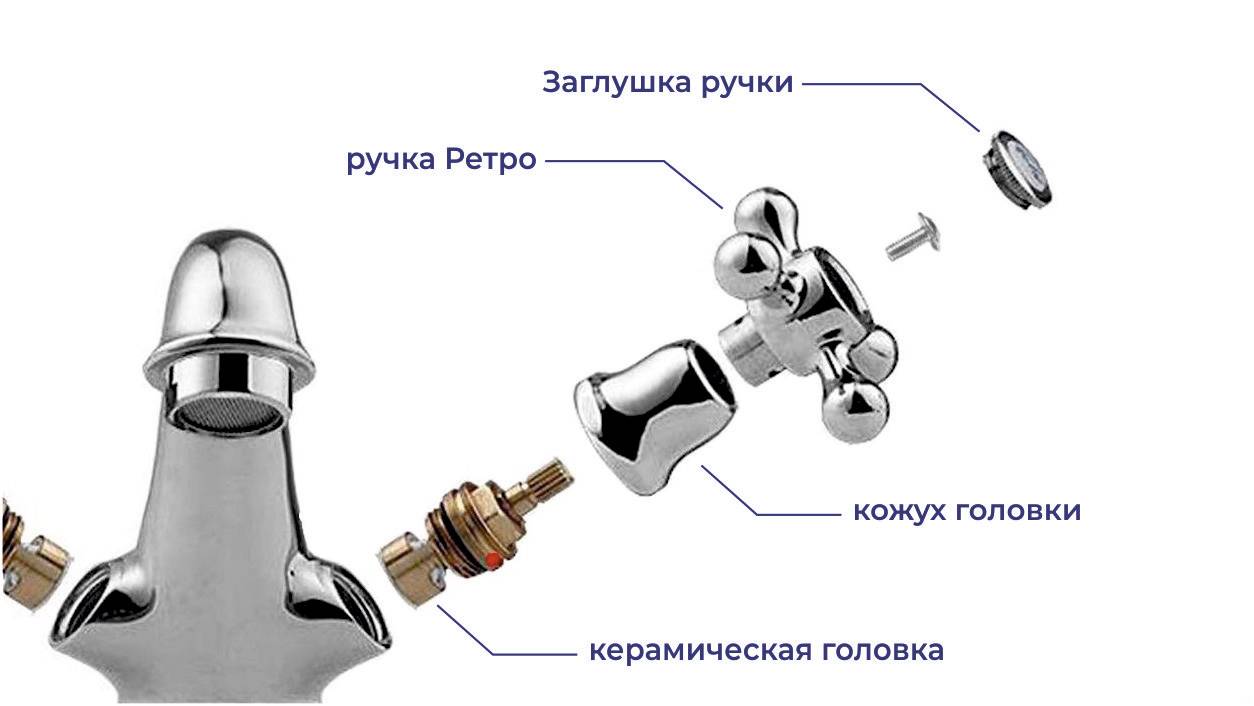

Axleboxes of domestic and foreign production are not interchangeable

Installation of a new crane-axle box is carried out in the reverse order.

It is important that after assembly the mixer does not start to leak, tighten all fasteners. But do not overdo it, otherwise you will unscrew the axle box from the crane, disable the disks or tear the gaskets.

In addition, it will not be superfluous to clean the flywheel and threads from accumulated dirt and the resulting rust before installing a new axle box valve. This can be done using a corrosion solvent by moistening a cloth with it and wiping the threads.

After completing the installation, turn on the water and check the work for correct execution. The valve must not leak, and also must not twist out when the valve is tightly tightened.

So that replacing the axle box crane does not become a habit, it is important to do all the work correctly and accurately. If, after changing the element, you did not find any changes for the better, then you should think about the malfunction of the mixer itself, or you have picked up the wrong product

The further operation of the mixer depends on the quality of the installed crane-axle box. If all the work was carried out correctly, then you will not soon have to worry about this issue.

How to replace the valve of the axle boxes in the mixer, see the video:

How to repair

There are several recommendations that will help to properly repair a broken part.

Materials and tools

First, you need to start preparing the tools and materials that you will need to use during work.

Screwdriwer set

A screwdriver is a tool that is used when unscrewing and screwing in screws, screws and other threaded fasteners. When disassembling the crane-axle box, it is recommended to use a set of tools, since when performing the work, you may need Phillips, straight and star-type screwdrivers.

Pliers

Pliers are considered another indispensable tool, without which it is impossible to carry out repair work. It is a triangular head shape fitting tool used to grip small iron pieces. Also, pliers are used if you need to bend a thin metal product.

Adjustable wrench

The adjustable wrench is considered a universal tool, as it can replace a whole set of open-end wrenches. It is used by almost all locksmiths and auto mechanics. Experts advise using chrome adjustable wrenches, as they are of the highest quality and most durable.

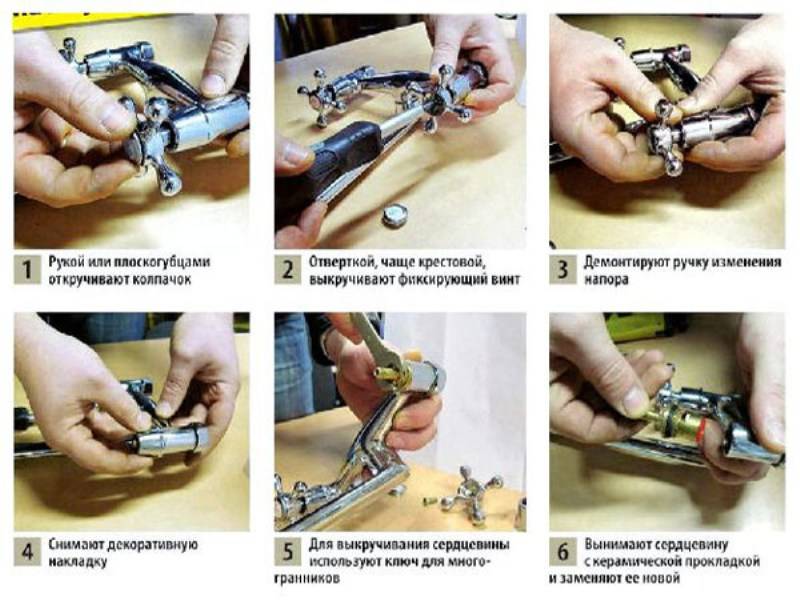

How to disassemble

To remove and disassemble the product, proceed as follows:

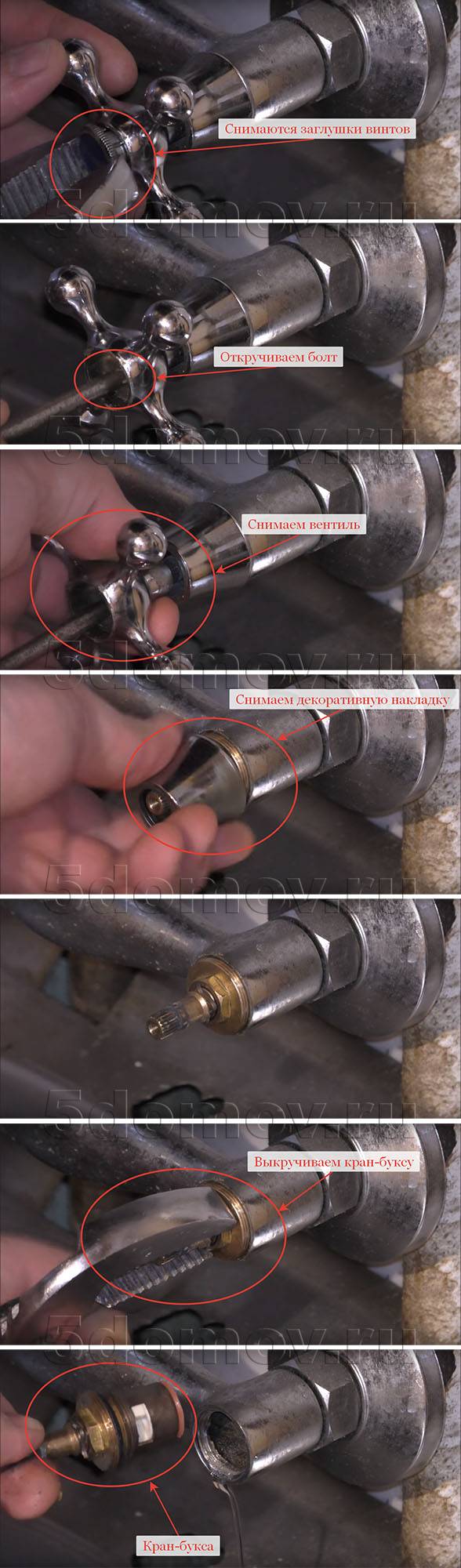

- Removing the cap. First you need to get rid of the decorative cap, which is attached with screws or regular threads.

- Dismantling the ring.There is a ring under the cap, which can be removed with an adjustable wrench.

- Unscrewing the crane axle box. When the ring with the cap is removed, you can get rid of the product itself.

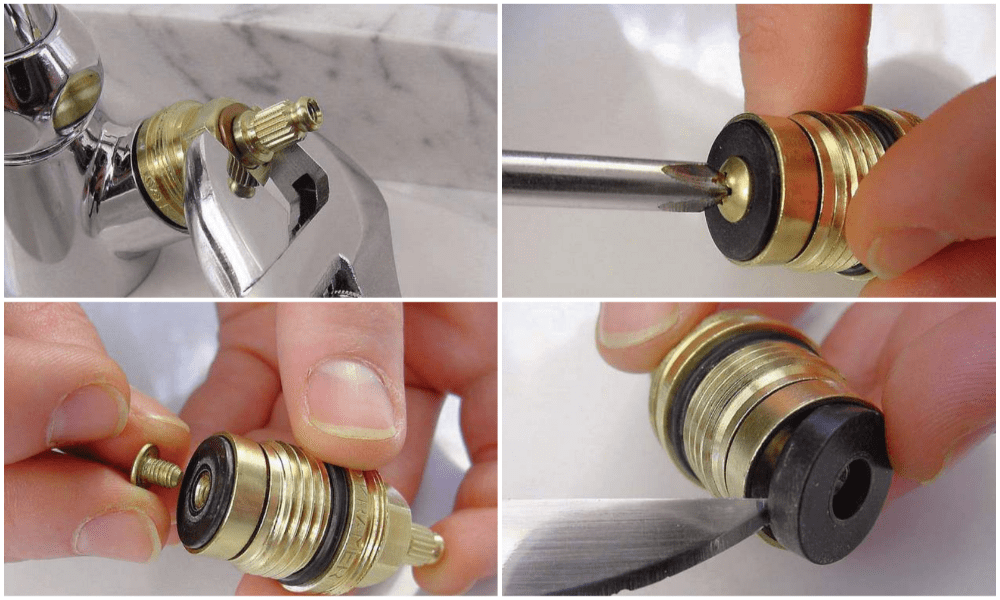

Replacing the gasket in the valve seat

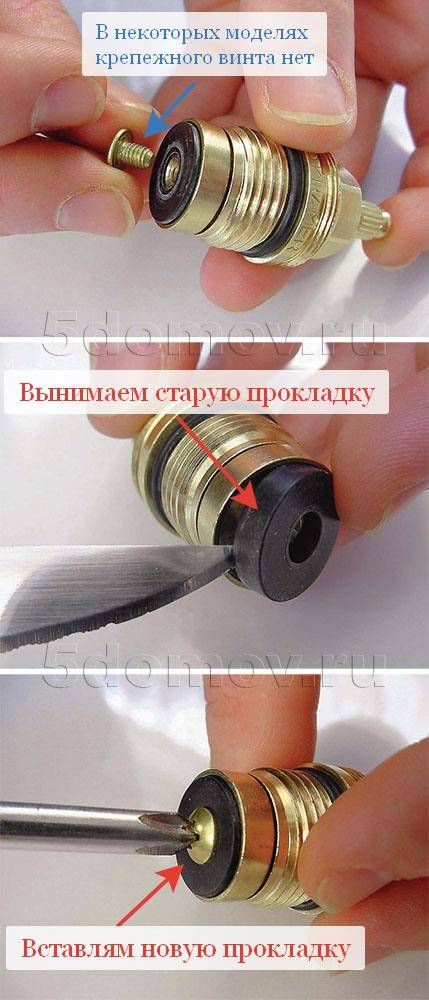

If you need to replace the rubber gasket, you will have to follow these steps:

- Removing decorative plugs. They are located at the top of the structure.

- Removing the bolt. The fastening element is located under the decorative cover. It is unscrewed with a regular or adjustable wrench.

- Replacing the gasket. Having unscrewed the bolt, they begin to replace the old gasket with a new one.

Replacing the pressure washer

If the mixer leaks heavily, it is recommended to replace the pressure washer, which is responsible for the tight connection of the product to the water pipes. To do this, you need to get the axle box out of the mixer and disassemble it. To do this, you will have to remove the retaining and O-ring. Then the pressure washer is removed and replaced with a new one. After assembling and installing the mixer, it is imperative to check whether it is leaking or not.

Removal of foreign particles

Sometimes the leak is not connected with a structural breakdown, but with the ingress of a large amount of foreign particles into the mixer. In this case, you will have to clean the product so that there is no debris left in it that would interfere with the passage of water.

Before cleaning, the mixer is disconnected from the water pipes and cleaned from the inside. When cleaning, you can use detergents that corrode dirt.

What to do if metal elements are damaged

There are several defects in metal products that cannot be repaired. These include the following:

- breakage or wear of the iron axle box body;

- the appearance of cracking on the surface of the product;

- erasing the thread.

If the above malfunctions appear, you will have to completely replace the part.

If a person has disassembled the crane box, he will have to reassemble the product. When assembling the structure, one must be very careful so as not to accidentally confuse the details. Experts recommend that you familiarize yourself with the axle box diagram in advance, which shows the assembly sequence of the main elements of the unit.

Repair of axle box

Gasket for crane axle box

Most often, gaskets fail in the axle boxes - it is because of them that the crane begins to flow.

To replace them, you need to purchase a repair kit, it is available on any market for plumbing equipment.

Replacing the gasket in the valve seat

Such a gasket ensures the sealing of the axle box in the structure itself. It is put on the outer part of the case and is made in the form of a ring. To change it, you don't even need to remove the axle box. This requires:

It is possible to seal the structure "hastily" using silicone sealant

- Turn off the water in the house to prevent unexpected flooding.

- Using a flat screwdriver, pry off the upper plastic valve cover.

- Unscrew the fixing screw and remove the flywheel.

- Unscrew the upper part of the axle box from the saddle.

After that, you should have a bolt in your hands, otherwise a pipe, with a rubber ring put on it. Remove the ring, put a new gasket in its place and carry out all the actions in the reverse order. But before that, you need to make sure that there is no significant damage in the faucet - chips, sinks, otherwise the whole procedure will be in vain, and you will have to change the entire faucet.

You may be interested in information on how to choose pipes for a warm water floor.

Read about how to install a film water floor here.

We also bring to your attention an article on how to make a floor screed with your own hands.

Replacing the ceramic plate gasket

When the gasket is worn out, the crane emits a characteristic hum

If water with a closed valve flows directly from the mixer, and not from under the valve, then the problem is in the gasket of the ceramic disc. To replace it, you will have to completely disassemble the axle box.There is nothing difficult in this, all steps are repeated from the previous paragraph, except for the last one. At the last stage, using a wrench, you need to unscrew the axle box directly from the mixer - the axle box is removed.

Then, with the help of simple manipulations, we separate the upper and lower parts and get access to the ceramic discs. There should be a gasket between the top plate and the body, which is usually white. It is it that needs to be changed. After replacing, carry out all operations in the reverse order.

Replacing ceramic discs

You can try to eliminate irregularities by rubbing them with a pencil lead.

In some cases, ceramic discs can create problems. They are perfectly sanded and ground between each other, due to which when the valve is closed they adhere tightly to each other and do not let water through. If any grain of sand gets between them, the sealing will be broken. Therefore, having disassembled the axle box, take the trouble to check and clean, if necessary, the gap between the discs.

Another serious problem is the formation of scratches and grooves on the surface of the disc. In this case, you will have to change the plates, which should be in the repair kit.

After completing all the operations, assemble the crane and check your work for conscientiousness.

How to repair a broken crane box, see the video:

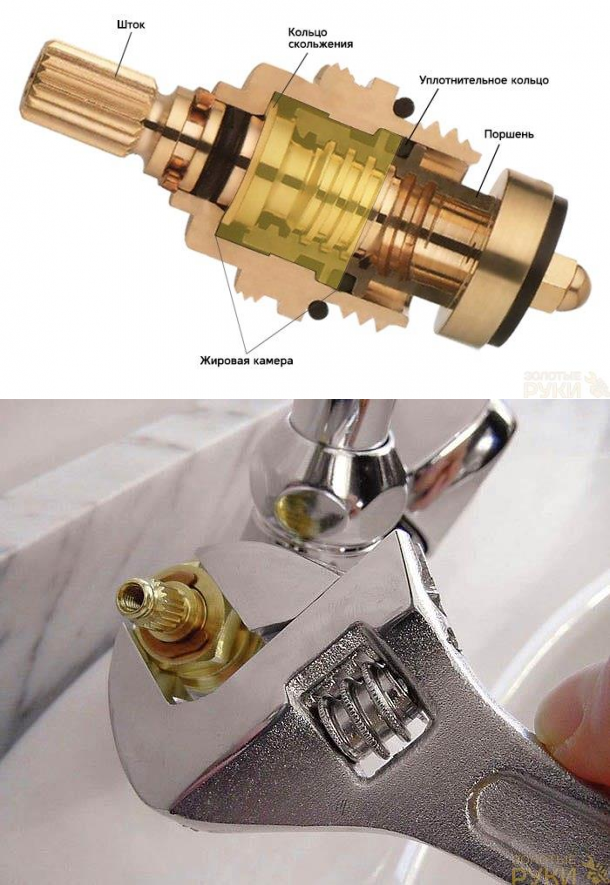

Crane axle box with rubber inserts

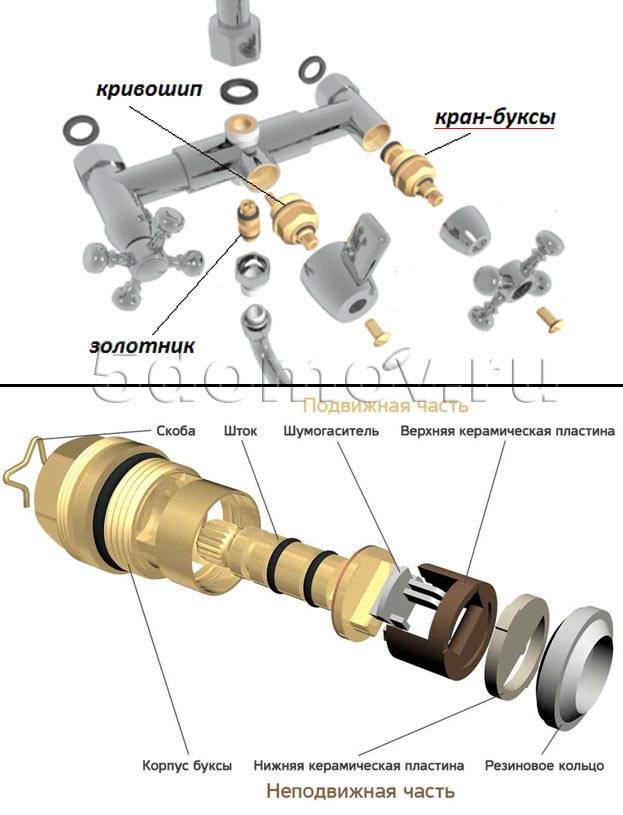

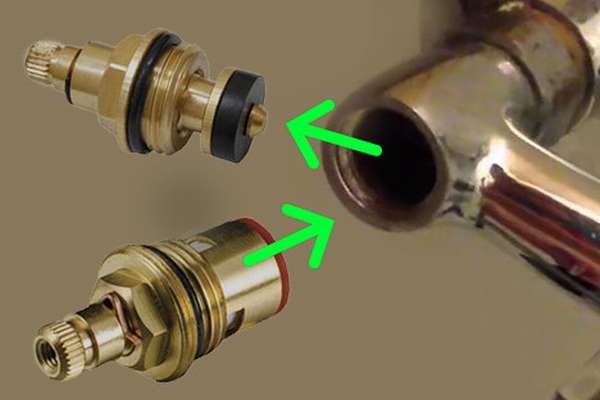

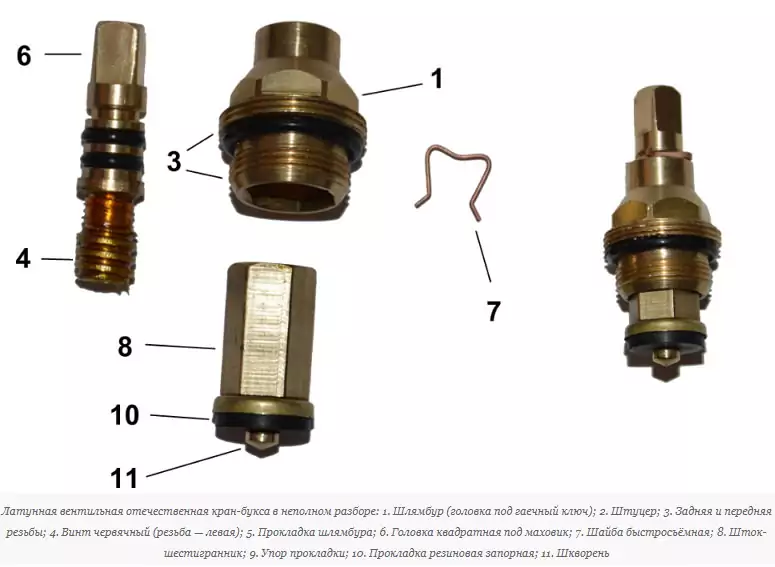

Fig. 1 Crane axle box rubber

In fig. 1 we see the crane axle box assembly. This is an axle-box valve for an old-design mixer. A rubber insert is visible at the bottom. It is her that needs to be changed. In addition to the bottom insert (gasket), there is also a rubber O-ring on the thread at the top. It should be borne in mind that if two pipes with hot and cold water are connected to the mixer, then there will be two valve boxes in the mixer, and the one that is out of order must be changed. The picture shows the valve box for the mixer "under the square". Its stem in the upper part is in the shape of a square. In case of emergency, the rubber gasket can be made from scrap materials yourself.

Fig. 2 Crane axle box in section

Home repair of the valve box in the mixer will not be a problem if you know its device. The section shows its basic design. Cutting off the water in the pipeline occurs when the "lamb" of the crane is rotated to the right or left. The rod with a rubber insert is lowered and blocks the movement of water. In this figure, an imported product has a spline stem. All threads in the valve axle boxes are right-hand. That is, we close to the right, open to the left.

Rubber inserts are cheap but fail quickly and require frequent replacement.

How to replace a crane box?

It is necessary to change the part in the mixer to an identical one.

To replace, in addition to screwdrivers and keys, you need to arm yourself with pliers - a multifunctional tool that can act both as wire cutters and pliers and pliers.

How to remove and disassemble a part?

- Turn off the tap with the valve. Pipeline fittings related to shut-off and control products are located in front of the mixer.

- Look for a small shut-off valve if there is no valve on the supply pipe. This is a large diameter ball valve in the form of a metal ball with a hole in the top.

- In the absence of such an element, shut off the water in the riser.

- Remove decorative caps. Use a screwdriver.

- Unscrew and remove the screw. It is easy to "calculate" it. The part fixes the flywheel.

- Remove the bushings. They are located at the top of the crane axle box.

- Unscrew the axle box. Apply the key.

Nuances of work

When unscrewing the old crane-axle box, you may encounter some problems. If it is thoroughly stuck to the body and it is impossible to disconnect it with handy tools, you must apply the following:

Use a pipe wrench to grip the edges of the bolt. Try to rip it off, moving it from side to side, as if rocking

It is important here not to overdo it, namely not to harm the threads and not eventually break the mixer.

Use chemical containment products. They will help to loosen the threaded connection.

Use some vinegar, Cillit detergent, or other acid-containing compounds. If they didn't help, then try sculpting a small plasticine container around the bolt. After that, pour in the liquid again.

Slide the threads using the thermal method. Use a building hair dryer to warm up the threaded portion. It is necessary to achieve complete weakening of the bolt.

If the tried methods did not help, you should remove the crane-axle by drilling. To do this, cut off the protruding part of the bolt, and drill out the remaining elements. The drill can be replaced with a cutter.

Installing a new

Installation of a newly purchased or repaired part does not require anything complicated. The same actions are performed as when unscrewing, only in reverse order:

- Check if the water is shut off.

- Screw in the crane-axle by hand and only then use a wrench or pliers to make sure that it fits snugly against the rest of the structure. Do not “press” hard on the product, as the gasket may deform. Violation of the integrity of the element leads to the closure of the water intake channel.

- Be careful not to damage the seal on the valve seat with the tool.

- Tighten the lock nut and secure the entire body of the part from turning.

- Open up the water. The absence of smudges indicates that everything was done correctly.

Advantages

Most of the details have advantages and disadvantages. Crane axle boxes have four main advantages that you need to familiarize yourself with in advance.

Durability

For many people, the main advantage of a part is its durability. Most of the product models are made of high quality materials that deteriorate for a long time. Therefore, the service life of the crane axle box often exceeds the service life of the mixer itself, in which it is installed.

However, sometimes there are defective parts that break down much faster, within a year or several months after purchase.

Control speed

Another important advantage of a part is its control speed. It is much easier to use such a product than mixers in which a worm head is installed.

When using the axle box, a person does not need to turn the flywheel for a long time. To completely shut off or open the flow of water, you need to turn the tap just half a turn. At the same time, turning such a valve does not even have to put much effort.

Easy repair and replacement

There are times when the axle boxes fail and you have to repair them or completely replace them with new ones. Some people think that it is difficult to carry out repair work, but this is not so. It is very easy to repair this part, and therefore any person can handle such work. However, before that, you must familiarize yourself with the recommendations for carrying out the work.

Noiselessness

Some types of mixers start to make noise during operation. However, models equipped with a crane box do not make any noise or make any sounds. If extraneous noise appears during operation, it is better to disassemble the product and inspect it.

Replacing the valve axle box

You can only change the valve to the axle box in the mixer for an identical one. To do this, the mixer must be disassembled. Before disassembling it, it is necessary to shut off the water in the pipe to avoid a small flood. To do this, close the valve. It is located in front of the mixer and may look like this.

These are modern ball valves. In this position, water flows freely in the pipe. To block the water, its petals must be rotated 90 degrees.

If there is no such valve on the supply pipe, then it is necessary to look for a shut-off valve on a pipe of a larger diameter. It may look like this.

To shut off the water, the handle must be turned 90 degrees.If there is no such valve, then it is necessary to shut off the water on the riser, which goes from the bottom up from the first to the last floor.

Good advice: Do not repair the faucet without shutting off the water. This is fraught with a scandal with neighbors from below.

Instruments

To repair a mixer, you must have the following tools:

Adjustable wrench

Any nut can be unscrewed with this sliding jaw wrench.

In addition to the key, you must have a screwdriver and pliers.

Tips: In order not to buy a key, you can borrow it from any familiar car enthusiast.

The process of replacing the crane axle box

The question of how to remove the valve box from the mixer may arise unexpectedly. Before disassembling the mixer, make sure there is no water in the pipe. To do this, open any other mixer or tap on the line. If the water does not flow, you can start working. In order to change parts in the mixer, you need to do a few simple operations:

- Remove decorative caps or trims with a screwdriver or knife. They are made of plastic or can be metal and fit into the hole with a slight interference.

- Unscrew the screw that secures the flywheel and remove it.

- On top of the crane axle box there can be decorative bushings. Take them off too.

- Using the key, unscrew the axle box and inspect it.

- If the rubber gasket is worn out in it, then replace it with a new one. To do this, you must unscrew the screw that holds it.

- Replace the valve with the axle box in the mixer and insert decorative bushings, flywheel, screw, decorative caps in reverse order.

- Open the flow valves on the pipe and check the mixer for water leaks. If installed correctly, the mixer works immediately.

Advice:

- before replacing mixer parts, drain the water from the pipe,

- all parts must be folded in the order of their dismantling, so that later after assembly there are no "extra" spare parts,

- you need to tighten the mixer parts "with a sense of proportion" so as not to rip off the thread,

- if we install the old valve to the axle box after replacing the gasket, then we clean the thread, if necessary, from layers.

Replacing the ceramic faucet axle box

The process of replacing the ceramic axle box is similar to the above. They are collapsible and you can change worn out ceramic inserts if you can buy suitable ones in the store. It is easier to buy and replace the valve with the axle box in the mixer assembly, and not in parts.

How to buy and not be mistaken?

Before buying, it is necessary to understand which valve of the axle box is to be replaced. Ours or imported? Imported ones have slots on the stock in the amount of 20 or 24. The domestic valve of the axle box for the mixer does not have such slots. Their stocks are square. All plumbing products are measured in inches. They are available in sizes 0.5 and 3/8 inches.

Advice:

- when buying an imported axle box crane, you need to make sure the quality of the water. To do this, you need to collect water and let it settle. If there is sediment, then you need to either buy a spare part with a rubber gasket or put a fine filter in front of the mixer,

- in order not to confuse anything when buying, you need to take the crane box with you to the store and show it to the seller,

- mixers with rubber seals to shut off the water make 2-4 turns of the flywheel,

- faucets with ceramics to shut off the water make half a turn.

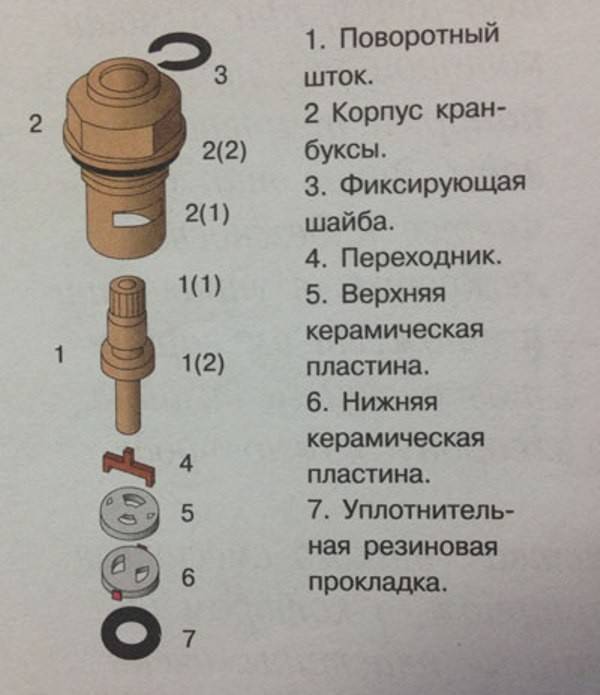

Crane axle box ceramic, device, purpose

The main difference between this part and the “classic” worm gear valve of the axle box is that, as the name implies, it contains special ceramic inserts. These elements are directly responsible for the supply of water and its shutoff. They are made of cermet - aluminum oxide. The mechanism is quite simple - it consists of two ceramic plates with holes.The aluminum oxide, from which the plates are made, is a very strong material, due to which, during work, there are no scratches on the working surface of the elements.

When the tap is turned, the plates converge in one plane, thus forming an opening through which the water flow enters, which can be adjusted as needed. When opening / closing, a tap with a worm axle box must be turned in one direction or another several times, the ceramic axle box allows you to start up and shut off the water with one easy movement.

The main disadvantage of taps with a rubber gasket is frequent breakdowns, since they twist in a few turns with the use of force. As a result, the rubber quickly wears out the tap, begins to "cough", hiss and leak. The principle of operation of the ceramic valve axle box is to displace the ceramic plates relative to each other. The axle box valve contains two plates - one is tightly fixed in the body, the second, a movable plate is located inside the rod, which is connected to the mixer handle. When the handle is turned, the stem with the plate is displaced, forming a hole. When closed, the plates separate and the water stops flowing.

The service life of the axle box crane is long, but it costs an order of magnitude more expensive than the usual one, with a rubber gasket. In addition, ceramics do not like hard water with impurities very much, so it is advisable to install a coarse filter on the water supply.

The mixer with a ceramic journal box works completely silently, which adds to the comfort of use. The plates inside the valve can be displaced 90 or 45 degrees, depending on how much pressure is needed.

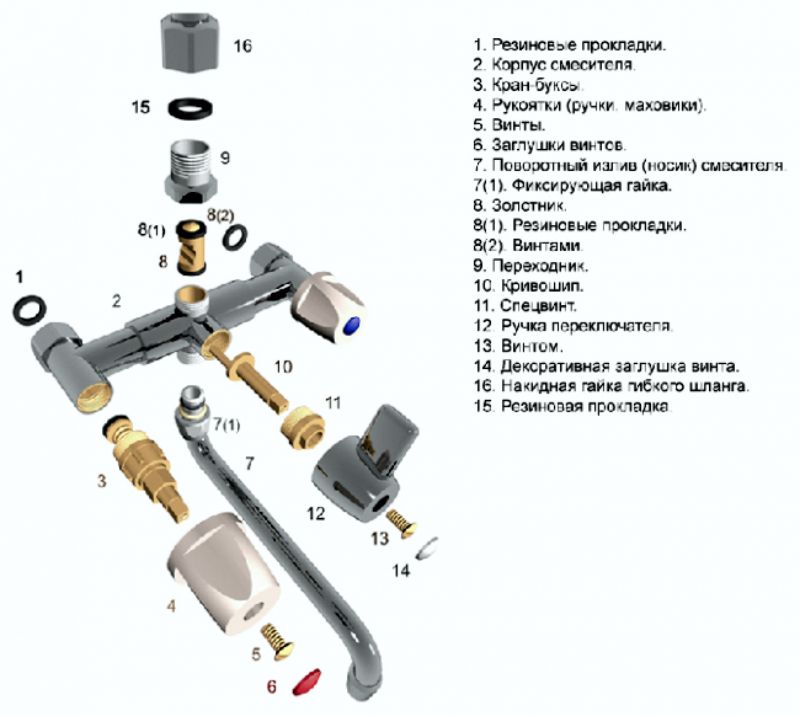

Crane axle boxes: device features and typical malfunctions

The crane-box is called the most important and critical unit of any valve mixer, thanks to which it is possible to quickly turn on or off the water supply. It is this simple mechanism that allows us to regulate the amount of flow and thereby set the temperature and pressure we need. The basis of the locking device is a stem with sealing elements installed inside a metal body with a threaded part.

Depending on the size of the threaded part, there are valve boxes with a diameter of 1/2 and 3/8 inches

The following malfunctions indicate breakdowns of the crane axle box:

- leak from the tap when the valve is closed;

- water leakage from under the flywheel;

- weakening of the force of the jet;

- "Jerks" and "blows" when the pressure is turned on;

- lack of valve fixation in extreme positions.

And even if the crane works normally, but after turning on the pressure, the pipes begin to make noise and rumble - the crane box may also be to blame for this.

Varieties and design of locking devices

Today the plumbing equipment market offers household plumbing fittings with two types of taps:

- with rubber cuff,

- with ceramic liners.

To understand what kind of mixer you are dealing with, it is enough to unscrew the flywheel. Cocks of the first type assume multiple valve rotation, while the second open in half a turn.

Crane axle boxes with rubber seal

Devices with a rubber insert are also called worm gears due to the presence of a worm pair in them. The operation of the rubber seal assembly is very simple. When the handwheel rotates, the threaded gear moves the stem with an elastic washer, due to which the valve disc is tightly pressed against the seat installed in the mixer body - the water flow stops. When the flywheel is unscrewed in the other direction, a gap appears between the valve parts, through which the liquid flows out.

The crane box works thanks to a worm gear and an elastic sealing collar

The amount of flow is controlled by the width of the gap between the disc and the seat. The worm gear was chosen here for a reason - thanks to it, it is possible to achieve a movement of the stem by a fraction of a millimeter, which allows you to very accurately set the required pressure.Breakage of crane axle boxes with a rubber washer most often occurs due to wear of the elastic seal. The second malfunction most often occurs due to excessive forces applied to the flywheel, and much less often due to natural wear of the threaded part. Usually, the breakdown of the worm gear occurs soon after the failure of the rubber cuff - in order to turn off the valve, you have to turn the valve with great diligence.

The advantage of devices with a rubber seal is the low price. In addition, a leaky gasket can be easily replaced if necessary. As for the shortcomings, there is only one - sooner or later, but a leak will happen. It all depends on the density and wear resistance of the rubber from which the sealing washer is made.

Crane axles with ceramic pair

Today, rubber-gasket cranes have been replaced by locking units with ceramic inserts. It is thanks to the more wear-resistant parts that such devices are more reliable and durable.

Ceramic crane axle boxes are reliable and durable devices

The design of the ceramic valve box is based on a body with a fixed ceramic disc, in which there are several holes. The second wear disc has the same openings and is mounted on a pivot rod. Having turned the valve half a turn, align the holes on both plates and open the water. Due to the fact that the discs are tightly pressed against each other, the liquid passes only through the channel intended for this. To regulate or shut off the flow, just turn the handwheel slightly. In this case, the holes are partially aligned or mutually overlap.

The advantages of crane boxes with ceramic parts are in their durability and convenience, because to turn on the water "to full" does not require multiple rotation of the valve. The downside is the relatively high cost and sensitivity to the presence of impurities. The latter factor forces the installation of a water purification filter.