Mechanical damage and ways to eliminate them

Knowing how to fix a hand or stand blender can save you a lot, as most problems do not require a lot of investment. In some cases, mechanical damage can block the operation of equipment. For diagnostics, you can use different methods, such as: disassemble the blender bowl or body.

Leaking engine gaskets and bowl

If during operation a leak has formed between the body and the bowl, do not hesitate to repair it. To do this, apply the following algorithm:

- remove the bowl from the body;

- unscrew the spindle;

- replace the old gasket with a new one.

When repairing a Scarlett blender with your own hands or another brand, please note that the spindle has a left thread

Damage to the lid latch mechanism or attachment

If during operation the lid latches or attachments have broken, they cannot be repaired. The problem can be solved only by purchasing a new component.

Please note that not every manufacturer offers spare parts for their models. Consider this point when choosing a technique, otherwise, after a bowl, lid or nozzle breaks down, you will have to buy a new technique

Damage to the blender body

If the body of the blender is damaged during operation, it cannot be repaired. The problem can be solved only by purchasing new equipment.

Damage to the blender bowl

Due to careless use, the bowl clamps may fail, which not only hold the container, but also bring the device into operation. Trying to fix it is not worth it, because it cannot be returned to its previous state. The only way to solve the problem is to buy a new bowl.

Leg repair

Most models, ELENBERG BL-3205 G, are equipped with a leg that cannot be restored. If it is made of metal, you can try to bend it manually. Even after returning to its previous shape, the leg will no longer work as it did before.

Please note that the monolithic leg cannot be restored. In the event of a breakdown, you will need to buy a new one, compatible specifically with your device model

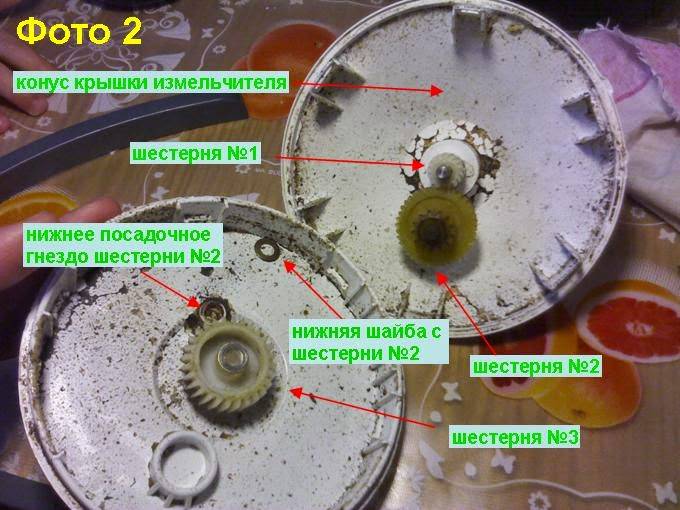

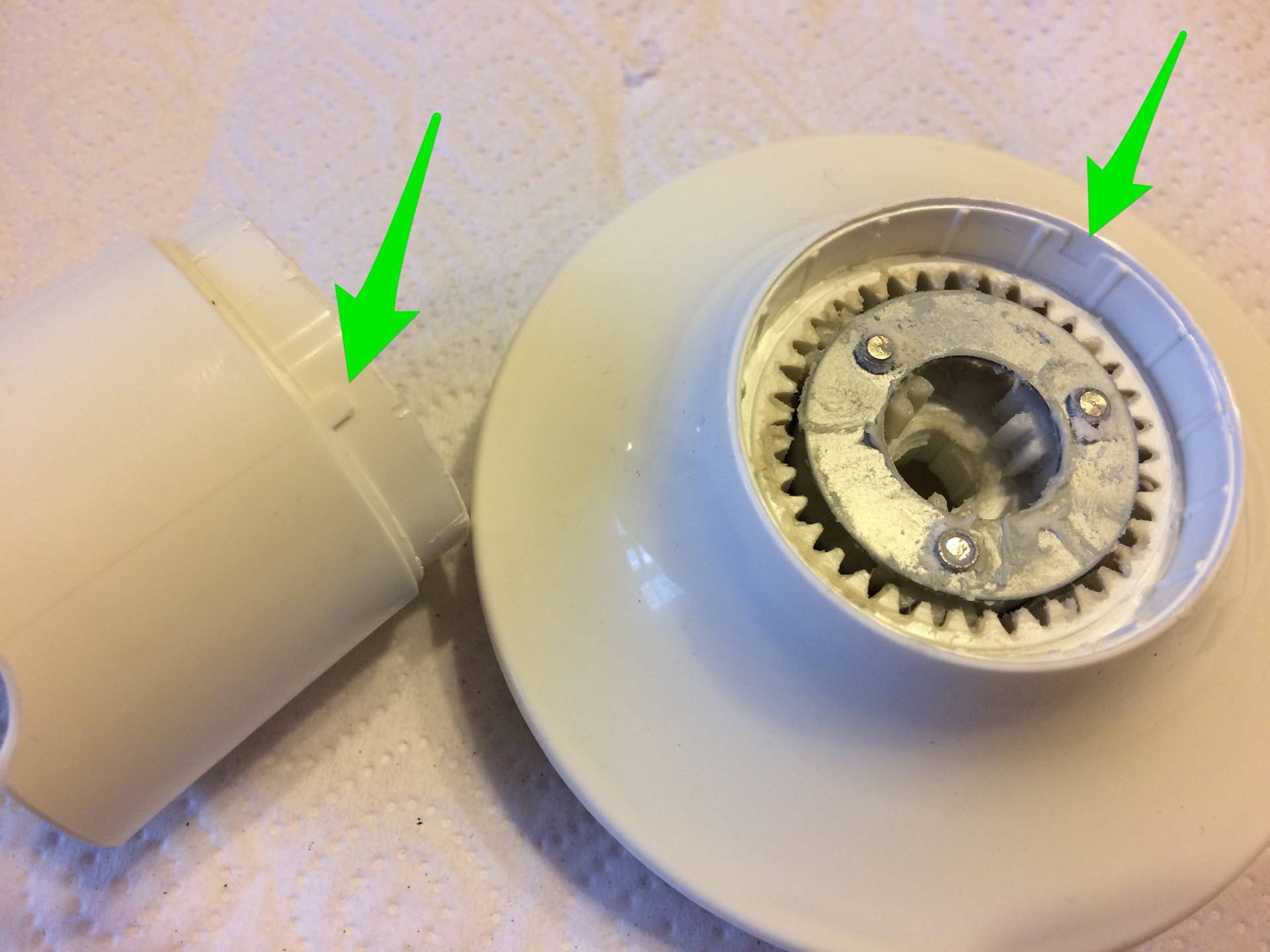

Gearbox repair

Repairing a blender gearbox is a problem that you may face in cases where the equipment will work beyond its capabilities. This nuisance arises due to overheating: the heated shaft melts the gear seat assemblies, which leads to its jumping off. To eliminate the breakdown, the device must be disassembled and visually inspected. If the gear is intact and just came off, it needs to be put back by replacing the fasteners or landing on superglue.

If during the repair you find that the gear is broken, you need to purchase the same one. No analogs or similar models will work.

How to disassemble a blender Brown (Scarlett, Polaris, Philips, Bosch)

We want to warn our readers right away. If your blender (mixer) refuses to work fully for reasons you do not understand, and its warranty period of use, which is obligatorily provided by a trade organization for products of well-known brands of kitchen appliances, in our case, a blender, has not expired, you do not need to pretend to be homebrew Lefty or Kulibin!

Just take it (mixer) to a service center, where the device will be fixed when you provide the appropriate warranty. In the case when this is impossible for the reasonthat the device honestly and efficiently fulfilled the period specified by the manufacturer of a well-known brand in the warranty (as a rule, from 1 to 2 years), just buy a new one.Moreover, these devices are not very expensive, and uninterrupted operation for 1.5-2 years is a very decent period for such equipment.

We, of course, will give an example of how to disassemble a Philips blender (another brand), but we warn you in advance. In most cases, you are unlikely to be able to assemble the device in its original form. Due to the fact that some companies (Brown, Philips, etc.) produce disposable models. So, choosing the answer to the question of how to disassemble a Brown blender, we came across an example in which the user of the named device had to disassemble the blender by sawing it. It was not possible to more accurately divide the device into its component parts due to the fact that some elements of the mechanisms are sealed into the case even in the factory and do not imply free access to themselves.

How to disassemble a Philips blender

Before proceeding with the disassembly of the device, carefully study the instructions supplied with it. Sometimes it indicates how to disassemble a Bosch blender, Philips, Scarlett, Polaris, etc. Prepare the necessary tools for work:

- Screwdrivers of various types and thickness;

- Pliers;

- A knife or a hard, thin metal plate that replaces it;

- Magnet for removing small parts from the case.

Parsing the device:

- We unscrew all the screws available for this, remembering their location.

- We remove the released body parts.

- We carefully study the elements remaining in the same place. It is possible that they are connected via latches.

- Having found the latches, gently squeeze out with a suitable tool.

As a rule, after this, the disassembly of the case is completed, and its mechanism hidden inside is provided for subsequent actions to replace components and assemblies.

To be honest, we don't understand very well the purpose of disassembling a blender ourselves. Since replacing the engine due to its cost is not a financially profitable operation, as well as smaller and less important parts. You will still have to buy them in a branded service center. You will not find them on free sale. The only motivation for parsing a failed blender can only be the user's natural curiosity or his desire to use the operating parts in the future. But already in devices for other purposes.

How to disassemble a blender - see the instructions in the video.

What parts can fail

Features of blender repair directly depend on which component is out of order. Some parts can be repaired, and some must be replaced.

Filters

Modern kitchen blenders have a filter in the lid. Additionally, you can use a mesh filter by placing it in the bowl.

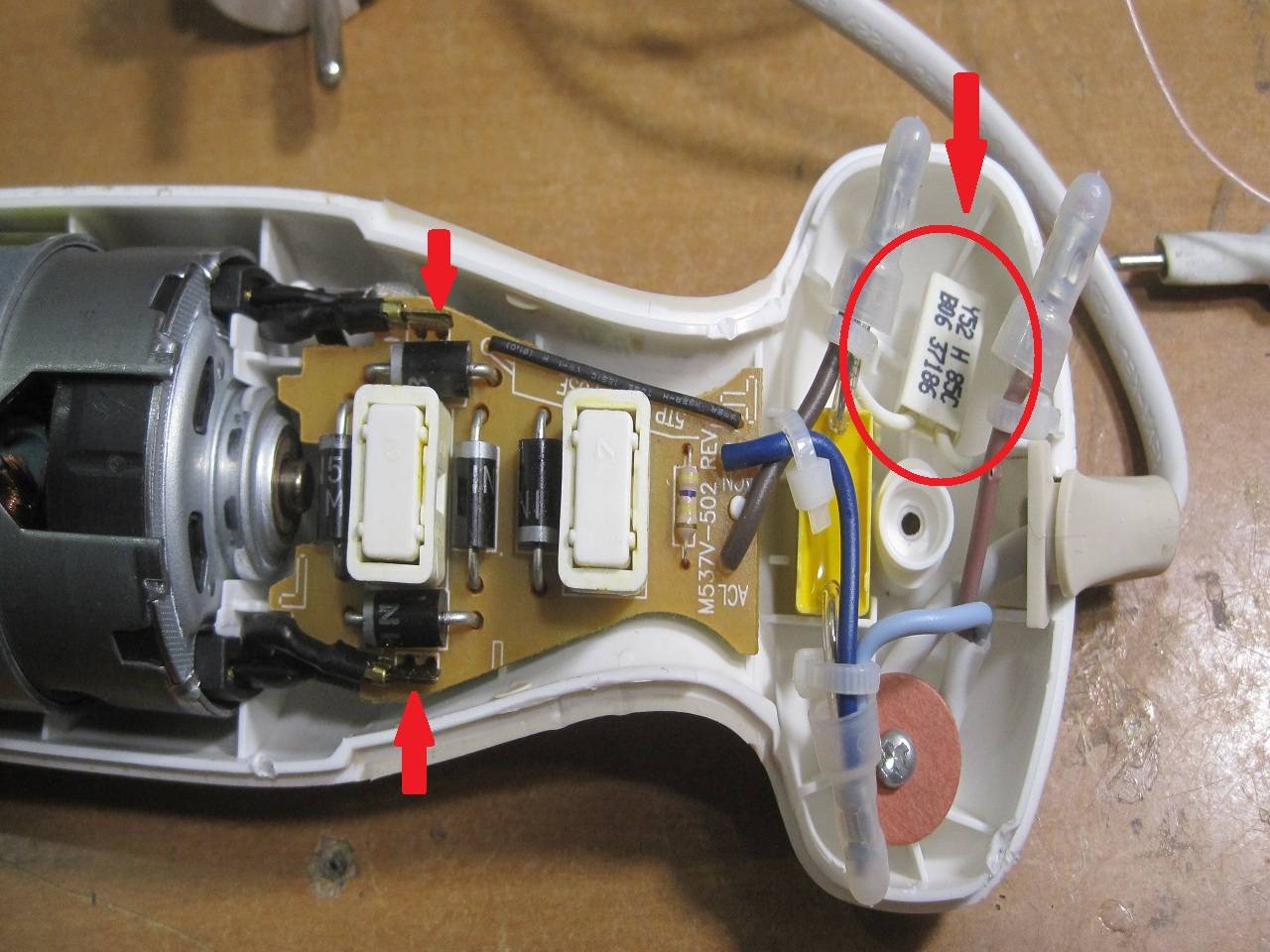

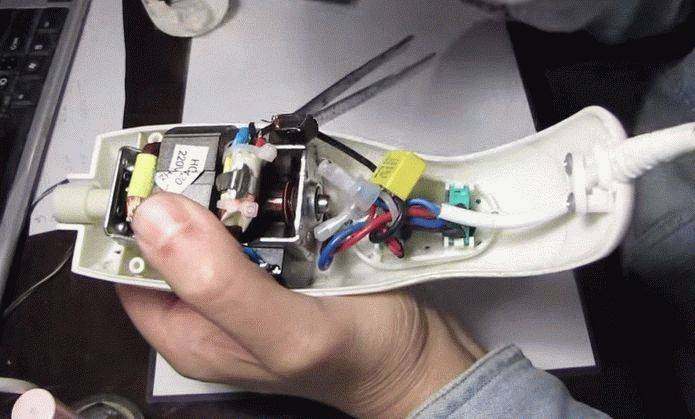

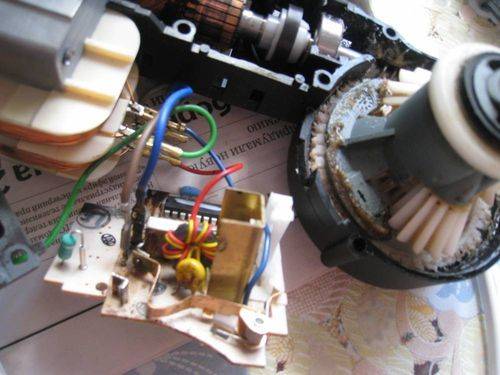

Diode bridge

Budget blender models have one rotation speed, and the electric motor is powered directly through the diode bridge. A malfunction of a part leads to the fact that the engine slows down or does not start. To use the device in normal mode, you will need to perform diagnostics and, if necessary, repair or replace the diode bridge.

Transformer

The role of a transformer in a kitchen blender is to control the level of voltage that is transmitted to the electric motor.

Generator

The generator is one of the key internal components and works in conjunction with other mechanisms, including the engine. It is possible to detect a malfunction of the generator only when disassembling and diagnosing the equipment.

Key transistor

The key mode of operation of the transistor is one of the simplest and most common. Most of the time, the blender transistor is in two states: cutoff and saturation. Failure of the transistor results in the lack of response of the device after switching on.

Rectifier output diodes

To check the performance of the rectifier output diodes, a standard dialing procedure is carried out. In many types of blenders, the motor is connected through a diode, therefore the possibility of operating the device depends on the correct operation of the component.

Varicaps

Varicaps are semiconductor diodes. They change the capacitance in proportion to the magnitude of the applied reverse voltage.

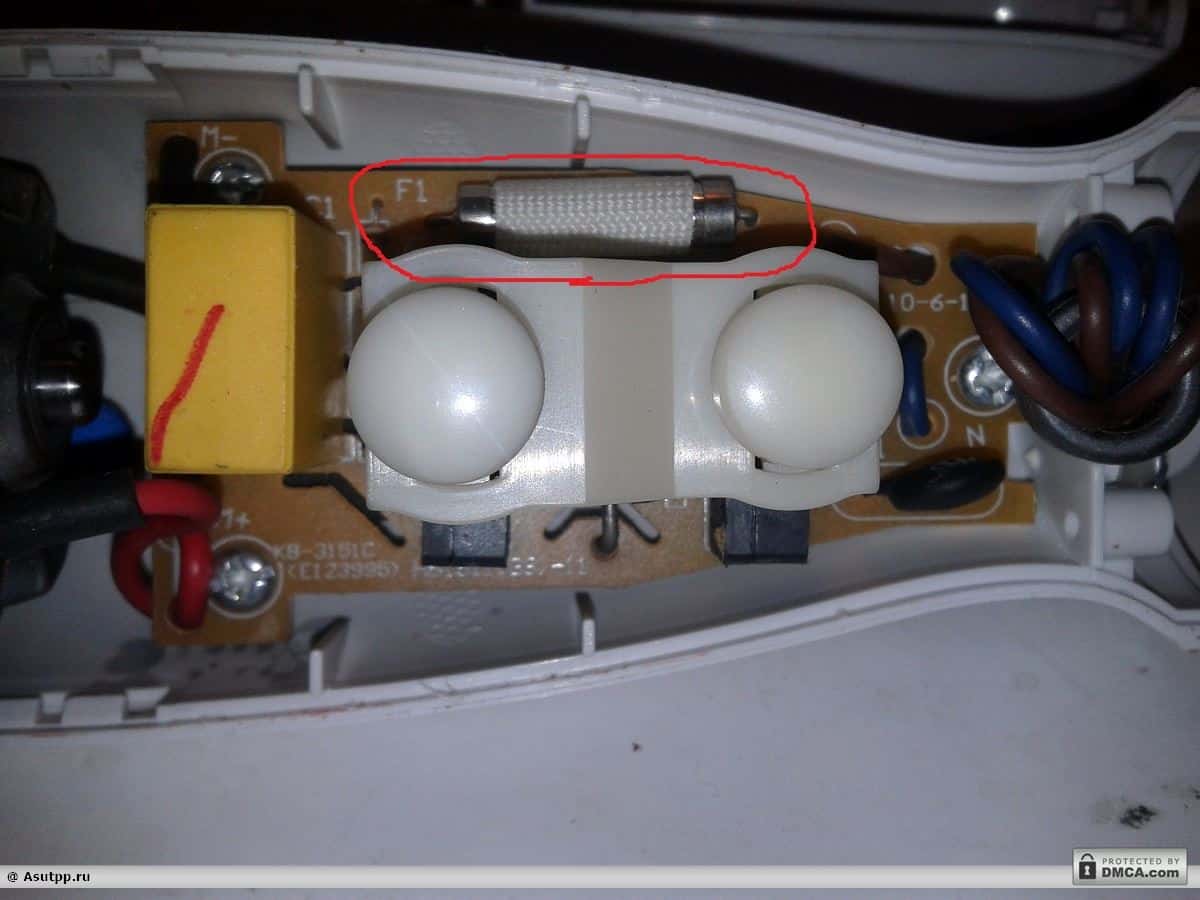

Circuit breakers

Continuous use of the blender may cause the fuse to blow. In this case, it is not allowed to use the device until repair or replacement. Otherwise, you can provoke new breakdowns.

DIY blender repair

Housewives are often faced with a situation where the blender has stopped and the knife is not spinning. It happens that the knife is spinning, the engine and the speed switch are in good order, but when loading products, the device runs “idle” without grinding them. In many cases, repairs can be done by hand. Let's figure out how to do this.

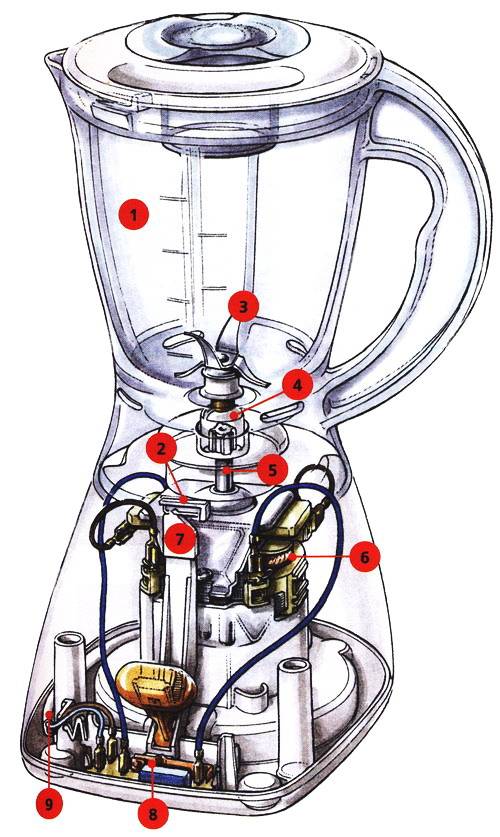

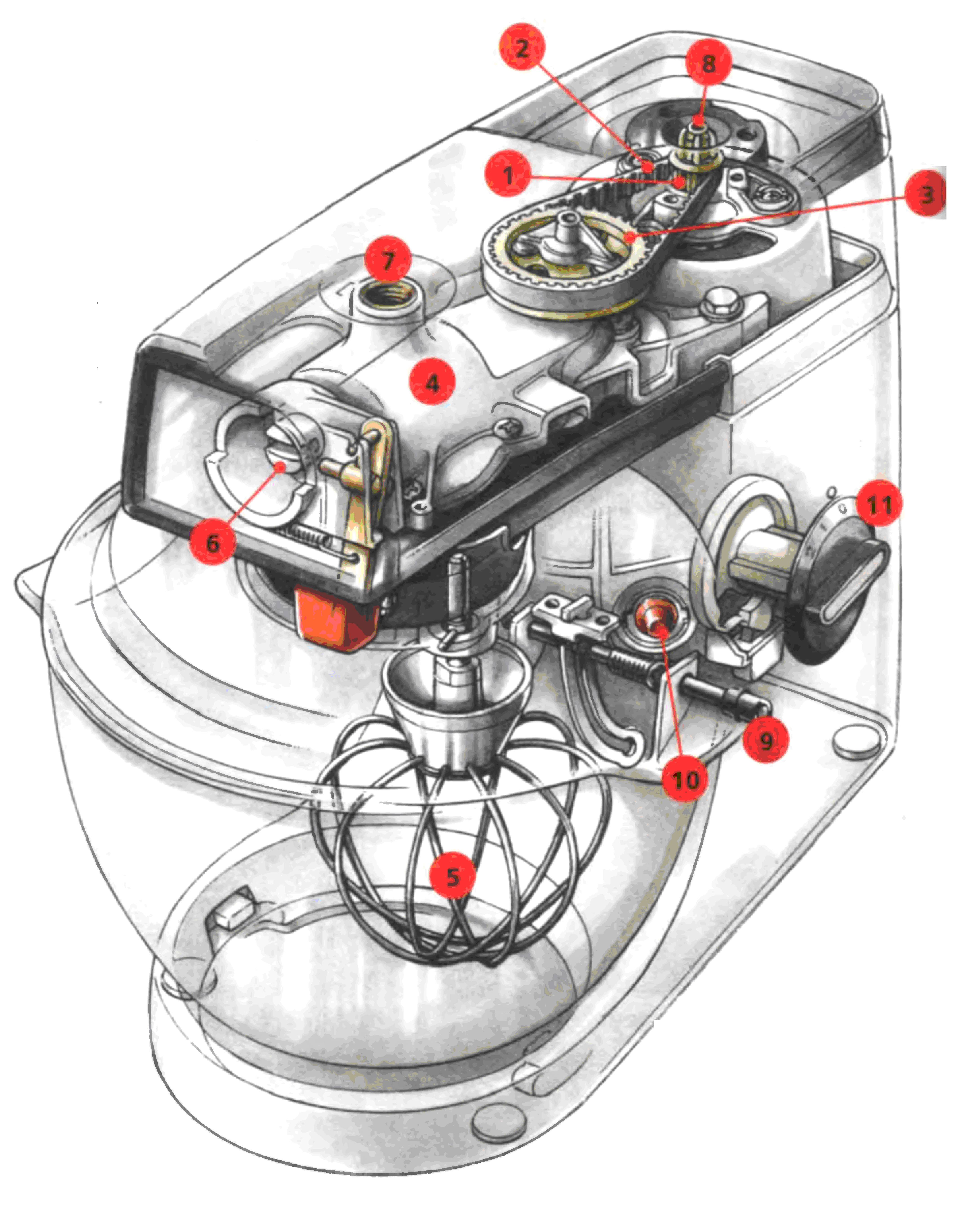

Stationary blender device diagram

(KMU: make a screen of the 1st picture with the name of the parts)

Before disassembling a blender for repair, you should carefully read the technical documentation. Disassembly instructions may be supplied with Bosch, Philips, Scarlett, Polaris models. It is best to follow the manufacturer's recommendations. Otherwise, there is a great risk of permanently breaking the device.

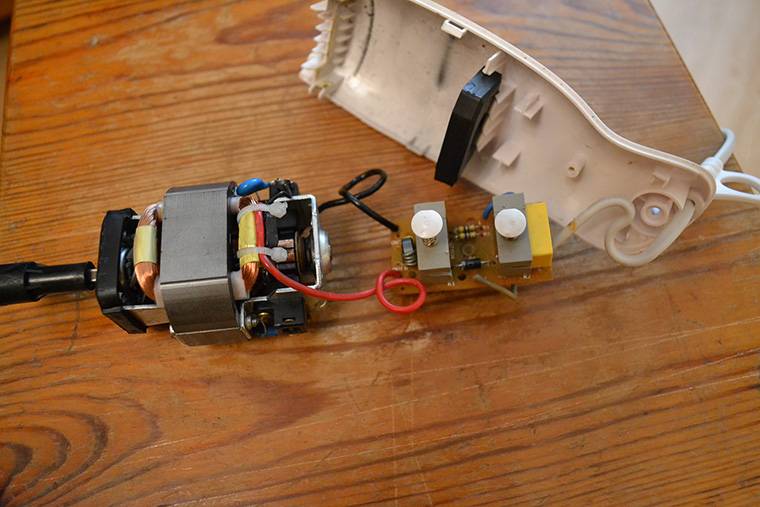

Blender Braun

For disassembly and repair, you will need the following tools:

- flat thin screwdriver (if such a screwdriver is not available, it can be replaced with a narrow knife);

- long screwdriver;

- pliers;

- a magnet to reach small parts if you cannot remove them with tools;

- superglue or any other reliable adhesive with which you can restore the integrity of the seams if they are damaged.

Disassembly Polaris

DIY blender disassembly procedure:

- Remove all screws, remembering or noting where they are located.

- Remove as many items as possible.

- Parts that could not be removed must be carefully inspected. They can be clip-on. In this case, they can be removed by squeezing the latches.

- When the body is disassembled, you can start checking the performance of parts and repairing.

Philips disassembly

The most common models of Scarlett ("Scarlet"), Vitek ("Vitek"), Polaris ("Polaris"), Philips ("Philips"), Bosch ("Bosch") are usually disassembled, so they can be repaired by hand, replaced nozzles. Let's consider in what cases self-repair is possible.

- Replacing the knife. If the knife is dull, it can only be replaced, because it cannot be sharpened. New knives are sold in specialized and hardware stores. To replace, remove the old part by wrapping a towel around it and unscrewing it. After that, insert a new knife (it may differ in appearance from the old one), secure.

Old and new knives

- Speed regulator. In stationary models, it can be difficult to check the switch, because the function of blocking switching on without a bowl is often provided. By the way, the problem of stopping the operation of the device is also associated with blocking. If you suspect a malfunction of the speed switch, it must be evaporated, each position must be checked in full, and repaired.

Speed regulator

- Stopping work. If the device does not turn on, the first thing to do is check and, if necessary, replace the cord. If it turns on and buzzes, but does not work, then disable the lock. Inoperability when the blocking is released most often indicates a burnout of the electric motor winding. It can be replaced, but this is an expensive repair, so more often than not it is more profitable to just buy a new blender.

Philips model repair

Video: disassembling and repairing a blender ↑

So that you have to disassemble, check and repair blenders with your own hands as rarely as possible, you should adhere to simple rules of safe operation. Check the reliability of attachments before starting work, do not turn on the device without a bowl, do not overload, handle the wire carefully (make sure it does not bend or twist). The main thing is to follow the instructions for use. These simple measures are quite enough for the equipment to serve for many years without repairs.

Rack structures on the ceiling are used to decorate various premises, both residential and public. The kitchen is no exception. The popularity of this material.

We mount a rack ceiling with our own hands: a master class with video instructions

Someone becomes an adherent of this style at first sight, someone is annoyed by its excessive cloying and "mimicry", but completely indifferent shabby.

Do-it-yourself shabby chic in the kitchen: 21 interior design photos + video

The financial costs of arranging a kitchen and a bathroom often account for the lion's share of the cost of repairing an entire apartment or private house. No wonder, after all.

Using a blender helps when preparing a large number of dishes. Improper operation, external damage, or third-party factors can damage the equipment. The blender repair features depend on the type of malfunction and the design of the device.

Elimination of minor breakdowns

Next, you will learn how to repair a blender with your own hands and that this only requires initial information from the field of electrical engineering and electronics, some tools and desire.

Info: there are models of hand blender with molded plastic body, which cannot be disassembled or repaired.

Blender Knife Repair

It is unlikely that you will be able to sharpen a knife for a blender or chopper yourself if you do not have special tools and proper experience. Moreover, if these are knives in a dicing attachment, but everyone can replace a dull knife:

It is unlikely that you will be able to sharpen a knife for a blender or chopper yourself if you do not have special tools and proper experience. Moreover, if these are knives in a dicing attachment, but everyone can replace a dull knife:

- check that the device is not plugged into the outlet;

- remove the bowl from the stationary blender;

- on some models, the knife is fastened with nuts, remove them using a wrench;

- grasp the knife with a cloth;

- unscrew, considering that the thread is left-hand.

Check the contents of your blender for a spare knife. If not, buy a new one based on your model.

A rare case when you need to disassemble the bowl to remove the knife. The actions are the same, but it is worth replacing the oil seal at the same time.

And it is not at all a repair case - this is not a collapsible bowl. Then you just need to throw it away and buy a new one, but here it is worth considering the price issue. Is it better to buy a new blender?

Cleaning required

Important! Do not put metal objects such as spoons, forks and knives into the blender.

Any cleaning should be started by disconnecting the device from the mains:

carefully remove the bowl from the main body;

unscrew and remove the ring nut, which is located under the blade holder;

gently release the knife from the stuck object;

check the integrity of the knife (most likely it needs to be replaced with a new one);

rinse all parts with warm water using a non-aggressive detergent;

dry thoroughly and collect;

check the work.

Features of disassembling blenders from different companies

In everyday life, the models Brown, Polaris, Redmond, Philips, Scarlet, Bosch are widely used. Some of them are disposable and non-repairable. Disassembly is not provided.

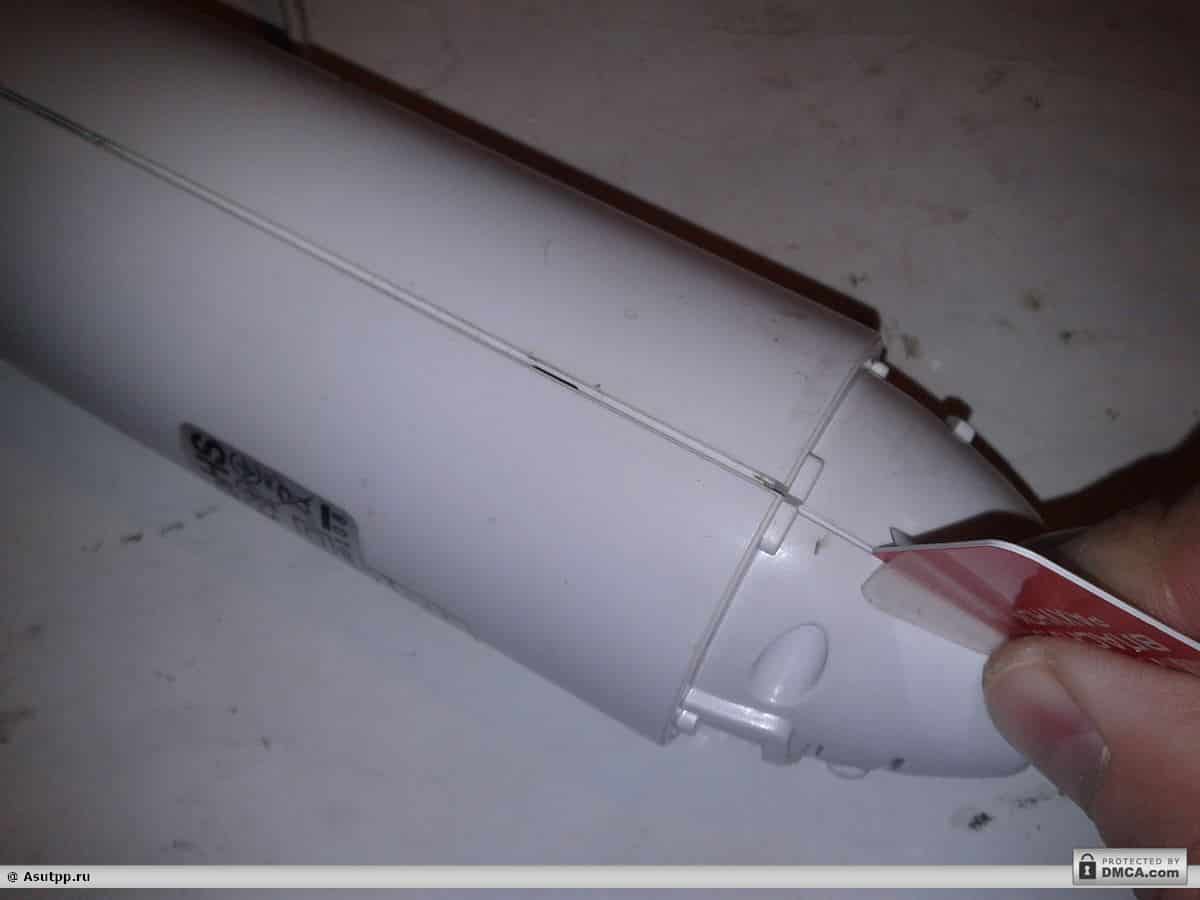

Brown's technique is disassembled as follows:

Use pliers to remove the cartridge (nozzle holder).

A thin screwdriver is pushed into the seam between the body and the outer shell. Lightly hit the screwdriver with a hammer, thus knocking out the weld. This action is continued until the engine begins to move freely inside the housing.

Everything is done with great care so as not to destroy the clips.Do not use a thick screwdriver, it may damage the outer shell of the case.

Press down on the clips and remove the engine

Usually the control board is pulled out with the motor. If it does not give in, it is pulled up with pliers by the lower edge.

Inside there are lid fastening latches. They are bent along the arrows.

Use a screwdriver to pry off the speed control cover.

Bend back the power cord fasteners located inside.

Polaris models are collapsible and non-collapsible (for example, PHB-0713AL), the parts of which are glued or soldered.

The elements of collapsible blenders are separated as follows:

- unscrew the screws;

- with a blade or a thin knife unfasten latches, plugs;

- carefully disconnect the elements.

The glued parts are cut, but such a blender will not be able to return to its original appearance during assembly.

In the Redmond technique, all fasteners are clamps. Disconnect them carefully, otherwise, during assembly, discontinuities will appear at the joints.

Popular Randmond models are disassembled as follows:

- remove the upper metal ring by bending back the internal latches;

- with a slight effort, remove the adjustment knob, holding the plastic rotation axis and the spring;

- unscrew 4 screws;

- pry off and remove the bottom ring, carefully pull off the metal protective casing;

- the glue seam is processed with a knife around the circumference of the body and the cylindrical part is removed;

- take out the guide sleeve;

- the motor is pulled out of the housing together with the board.

Philips models are disassembled according to the following instructions:

- from the side where the speed control knob is located, disconnect the decorative cover by prying it with a knife or screwdriver - it is attached with double-sided tape;

- the next cover, fixed with self-tapping screws, is dismantled with a screwdriver;

- the plastic gear is removed by hand;

- on the reverse side, unfasten the protective cover, for this, press the latch buttons with a screwdriver and bend the ear with a knife;

- followed by a glued shaped cover that protects the motor - it is disconnected with a knife.

At the final stage, the motor and control board are removed.

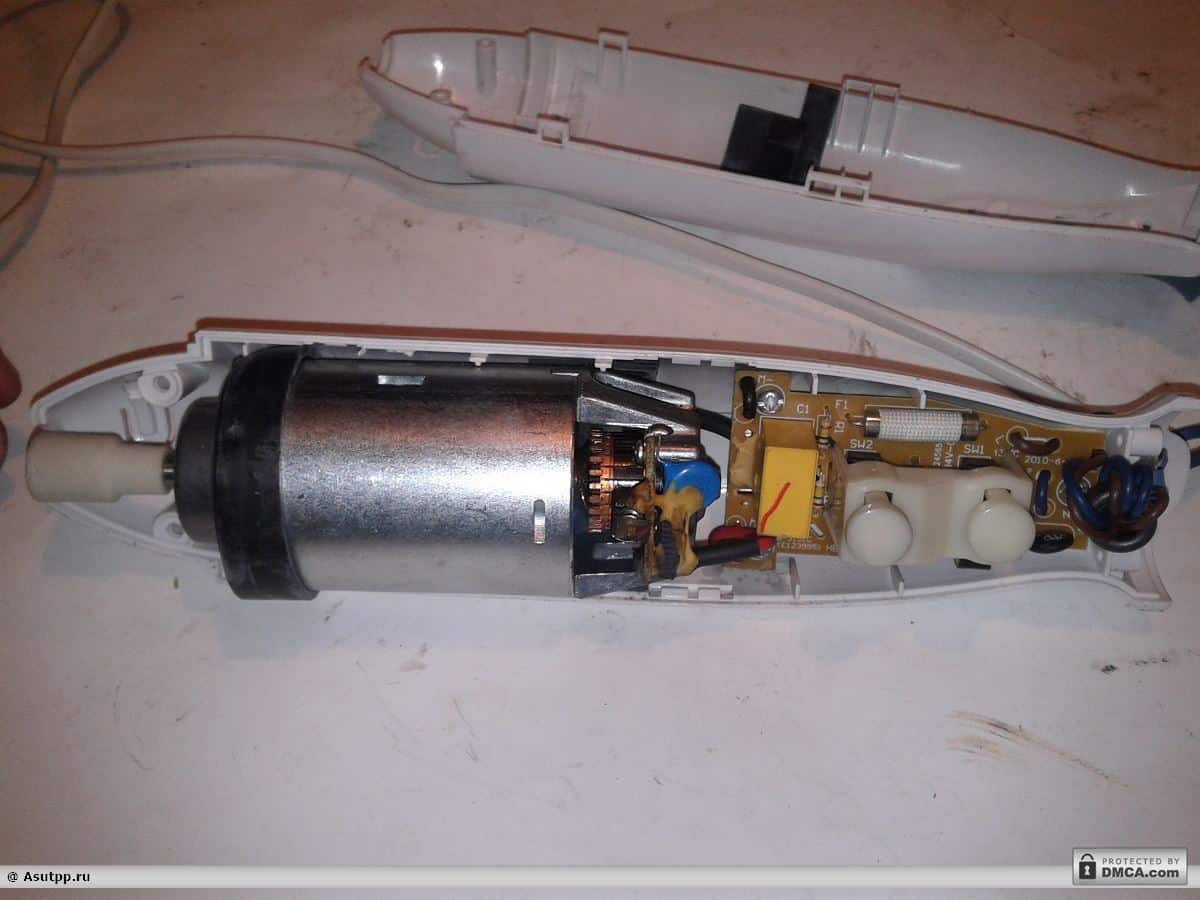

Scarlet submersible models are disassembled in the following sequence:

- pry off the speed controller cap with a screwdriver and remove it from the rod;

- unscrew the 4 screws that secure the cover;

- pull out the connecting sleeve that covers the engine;

- remove the motor and board.

The engine is the most vulnerable part of these devices.

Parts of Bosch stationary blenders are dismantled using a wrench and pliers.

Disassembly of submersible varieties has features:

- fastenings on the outer surface - fragile plastic latches;

- internal parts can be fastened with bolts, self-tapping screws, screws.

The blender has stopped and the knife is not spinning

You have decided to grind the minced meat, and the blender simply does not turn on! Don't panic right away! This trouble can be solved even easier than if the device worked, but did everything badly.

First, press the button and listen. Is there a quiet hum? It means that the engine is running, but it cannot turn the knife. Disconnect the bowl and with your fingers or a small screwdriver, squeeze the button that blocks the inclusion of the blender. If everything starts working, then the defect has been identified.

If the device does not start even with the interlock disabled, then the matter is in the engine, more precisely, in its windings. One or two of them burned down. In this case the engine must be replaced. If you can manage to buy it at a reasonable price, then you are in luck. But more often than not, its cost is comparable to the cost of a new, not expensive device, therefore it is not economically justified to repair such a blender. Easier to buy a new one!

If, when the button is pressed, you do not hear the operation of the engine, in order to make repairs, it is necessary to examine the power supply circuit:

- Make sure the electrical outlet is working first.To do this, take any household appliance that works for sure and plug it into the tested outlet. If it works, then the socket is working, and you should continue checking.

- The second step in checking is the electrical cord. Practice shows that it is often frayed, or breaks off from the inside. We disassemble the blender body. In modern household devices, manufacturers are very fond of using special screws, so it is required to stock up on various heads and nozzles before disassembling. You cannot do with a Phillips and flathead screwdriver. The cord inside the blender is attached to a special block using screws or soldering. Using a voltmeter, we check the cord for integrity. Its resistance should be almost zero. If there is no voltmeter, but take a new cord, replace the old one and plug it in. This will identify the breakdown.

- If there is a fuse in your blender circuit, it should also be tested. Remove it from the socket. If it fails, then the thread inside the body will be broken. It is not worth repairing the fuse by making a "bug". Usually such parts in the store cost a penny, and homemade products can lead to a fire. On the fuse body there will be all its technical parameters, write them down, and it is better to take the part itself with you to the store. The seller will help you find a similar one. By the way, the contacts of the fuse socket are a very convenient place to check the presence of voltage in the network.

- You put on a working fuse, and when you plugged in the blender, it immediately burned out again! This indicates that there is a short circuit inside the blender. The problem is either in the engine or in the control unit. We connect individual units to the electrical network and observe the result. Here it is worth putting a "bug", because a large current can pass through it. We connect the ammeter and check the voltage. In this case, it is worth doing everything quickly so that the overload protection circuit breaker does not work in your house. We substitute the displayed value in the formula for calculating the power and estimate this value. If it significantly exceeds the nominal value, then the source of the problem has been found.

- If after all these steps you understand that everything is in order with the power supply, you need to inspect the printed circuit boards. Capacitors often fail. Visually, this can be determined by their swelling. If the resistor burns out, it turns black. The connecting tracks on the board must not have breaks or delamination. If you find something similar, then the device does not work due to the fault of the electronic unit. If the motor has a short circuit, then the unit can hardly be repaired. It must be replaced with a new one.

If you decide to fix the blender yourself, here's the work order. If the device fails during the warranty period, the service center must repair it free of charge. It is better not to disassemble expensive blender models and try to repair it yourself, but you need to contact a specialized workshop. Today, the cost of an expensive blender can be considered 3000-3500 rubles.

Food processor supplement

The blender, which is an integral part of the combine, is in many ways similar to the stationary model. The device is built into the food processor and has many functions. If it is necessary to carry out repairs, it may be necessary to partially disassemble the combine.

Replacing the knife

In case of significant damage to the knife, it needs to be replaced. Most blender models are easy to purchase as they are sold as separate spare parts.

How to pull out

After purchasing a new knife, you must first remove the old one and replace it. The process involves the following actions:

- When disassembling the device, first unplug the blender and remove the bowl.

- In order not to hurt yourself on a sharp blade, take a clean towel and unscrew the knife from the motor spindle. Since the threaded connection is not standard, the knife must be unscrewed by turning it to the left.

- If the knife is fixed in the bowl with nuts, wrenches or pliers must be used to remove the part.

How to disassemble the bowl

There are models of devices in which, to install a new knife, you will need to first disassemble the bowl. As a rule, it is sufficient to remove it from the central mount.

It is important not to forget to change the oil seal for a new one.

If the bowl is not separable

In cases where the design features of the blender do not allow disassembling the bowl, the only way to solve the problem is to replace the bowl with the knife. You need to choose a bowl that is suitable in size and fix it in the correct position.

Speed regulator

On many blenders, a breakdown of the speed regulator often occurs. Due to incorrect operation, the speed can change during operation or be greatly reduced.

Withdrawal of a part

In stationary versions, there is often a problem with checking the switch due to the presence of a switch-on lock without a bowl. To remove the regulator from the case, you will need to unsolder it and check the condition of the internal components.

Dialing

The speed controller dial helps to find an open in an electrical circuit or a short circuit, which contributes to effective diagnosis and elimination of the problem. For continuity, a special multimeter device is used. It is allowed to ring only de-energized circuits to avoid injury and damage to the equipment. The procedure is performed according to the following instructions:

- Fix the probes in the multimeter connectors.

- The dialing mode is switched on on the device, after which the unit should appear on the display.

- Check the correct functioning of the multimeter by connecting the contacts of the probes. If the device is in good working order, it will emit a sound signal.

- The multimeter probes are applied to the contacts on the speed controller. If there are no faults, the buzzer will beep and the display will show a value close to zero.

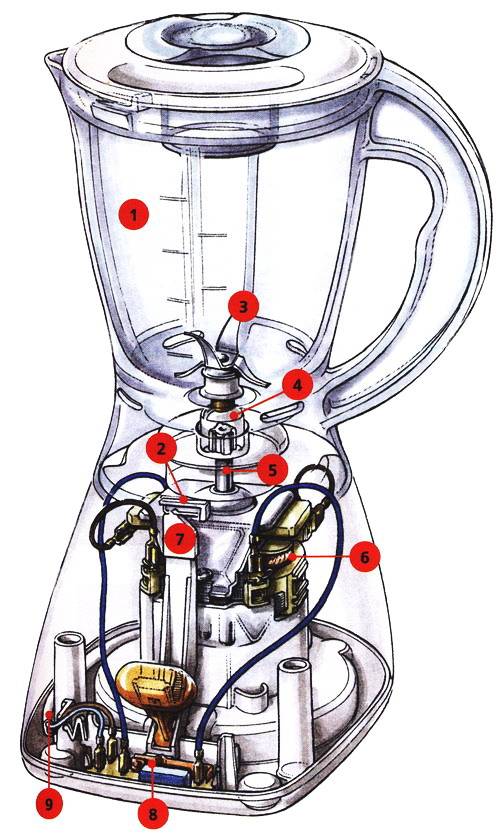

The principle of the stationary blender

Let's look at the device and how the blender works. Food is placed in the blender bowl. The device turns on and its knife starts to rotate very quickly. The shape of the knife is designed to make the products move in a closed path. The knife of the device is located at the bottom of the bowl and mates with the motor rotor. High speed and the right shape allow you to quickly chop the food. The blender blade is shaped like a propeller. This allows him to draw in products for cutting, and at the same time throw the already crushed mass onto the walls of the bowl.

The blender bowl has a special shape that allows the movement of the processed products in a circle. The walls expand towards the top. In this regard, the resulting mass begins to fill the walls, freeing the center of the mold for not yet cut products. As soon as the amount of processed products on the wall reaches a critical weight, they fall back onto the knife and further chopping takes place. In practice, all this happens in a matter of moments.

We have described the process that can be observed with quality equipment. Cheaper models may not cope with the task at hand. Lack of power does not allow creating a continuous flow of processed products and the knife begins to cut the air. If you decide to chop the cabbage, add a little water. This will help the knives handle this vegetable.

If the blender does not cope with chopping food, this does not mean that it is broken, it may simply not have enough power. Then you should add some liquid and try to start the blender again. If this does not help, then perhaps you should do the repair yourself:

- sharpen or replace the knife;

- test the speed switch;

- make sure the engine is working properly;

- check how the bowl connects to the knife.

If you decide to repair the blender with your own hands without involving professionals, then you should start by checking the speed regulator. It's simple. It is necessary to press successively different speeds and determine by ear whether the speed of the rotor is changing. If the speed changes, then the regulator is working, and it is worth checking the blender knife.

Identifying and fixing faults

Basically, problems with the iron arise from faulty wiring, which is revealed when disassembling the back cover. Also, a fuse, heating element, thermal protection or steam spray mechanism may fail.

Power cord

If the equipment stops working, then it is necessary to check the condition of the power cord. This requires a multimeter. Using this device, you need to "ring" (touch) different parts of the power cord plugged into the outlet. If the LED lights up, then the fault lies elsewhere. But when the light is flashing, it indicates a problem with the cord. This malfunction can be of two types: the integrity of the wires is broken, or the latter do not fit tightly to the contacts. To eliminate the first problem, you need to find the bend and insulate.

Heating element

If at the first stages the malfunction is not detected, you should contact the heating element, which is hidden under the sole. Having disassembled the device, you need to check the resistance level of the heating element. Normally, this indicator does not exceed 250 ohms (the exact value must be specified in the passport). If the measuring device shows infinity, then this means that the heating element is out of order. In such cases, it is recommended to buy a new iron, since the replacement of the heating element is done together with the sole, which is comparable to the cost of the device.

Thermostat

Thermostat problems are of a different nature. Before disassembling the iron, you must scroll the part all the way. At this moment, a click should occur, indicating that the contacts are closed. The thermostat must be left in this position and proceed to further check the component.

From this part in the direction of the heating element there are two contacts that need to be "ringed". This procedure must be repeated, having previously unscrewed the thermostat all the way to the other side. In the first case, the multimeter should show the presence of voltage, in the second - the absence.

Thermostats fail due to acidification or contamination of the contacts. The wires must be cleaned with sandpaper and re-checked with a multimeter. During the procedure, you must not bend the plates strongly. If the thermostat is difficult to turn, then the part must be turned in one direction and the other several times (flat pliers may be required), and then rub the assembly with a pencil.

Fuse

In 50% of cases, an iron breakdown is caused by a blown fuse. This part is located under the body. Having disassembled the iron, you need to check the condition of the fuse with a multimeter. If the device does not respond, then this part must be removed and a new one must be soldered.

Steam spray system

A malfunction of this system is caused by the accumulation of scale on the iron parts. In this case, you will need to disassemble the device and clean the internal components.

Stuck or failure of the steam button

This malfunction occurs due to scale in the pump chamber. The latter is built into the iron handle, on top of which there is a steam supply button. To eliminate the malfunction, you need to disassemble this part, remove the pump (compact box) and push the ball, which has dropped down, back into the chamber.

Clogged steam outlet

The lack of steam is caused by the accumulation of scale in the iron reservoir. To fix this, stir a tablespoon of citric acid in a glass of water.Next, you need to fill a separate container with the resulting solution so that the liquid covers the sole by 1-1.5 centimeters. Then this tank with the iron is placed on the stove. After waiting for the mixture to boil, you need to turn off the heat, wait 20 minutes and repeat the procedure.

Oxidation

If at the first stage of the inspection of the iron no malfunction is detected, then you need to check the condition of the heating element. To do this, you need to remove the back cover, under which the terminals are hidden, connecting the electric cord and the heating element.

Device and principle of operation

All blenders are divided into several categories, which differ from each other in design and method of use, as well as in different attachments and functionality. To carry out repairs efficiently and correctly, you need to understand the design features.

Stationary

Stationary varieties outwardly resemble small food processors and are bowls with knives rotating inside. Typically, the knives are installed at the bottom of the bowl. The device is a desktop device and does not need to be supported during operation. This blender model is capable of grinding a large portion of food at a time.

The main disadvantage of stationary devices is the need to allocate a lot of storage space. In addition, some models do not chop vegetables well and grind them into crumbs or leave too large pieces. In terms of repair, stationary equipment is much easier to disassemble and repair than submersible equipment.

Manual (submersible)

Hand blenders are designed in the shape of a long handle with a cutting tip. The nozzle is lowered into a container with products, the device is turned on and held until the grinding process is completed. Due to their compact size, the submersible devices do not require much storage space in the kitchen. The ability to change attachments significantly expands the list of cooking.

This creates discomfort with prolonged cooking. Also, the device is not suitable for stirring a large portion of food.