We install slopes in a wooden house

To make high-quality exterior slopes for windows, the material must be very resistant to moisture. For interior furnishings, the requirements can be omitted and any material desired can be selected. Window frames can be finished with plastic, wood or clapboard. Slopes from the lining are considered universal of the listed materials, since the material is perfect for decorating a house both from the inside and outside.

For exterior decoration, a moisture-resistant material is used.

For exterior decoration, a moisture-resistant material is used.

To install window slopes you will need:

- wood panels;

- corners;

- a set of self-tapping screws;

- polyurethane foam;

- screwdriver.

Front of work:

- If the walls in the house do not differ in evenness, it is necessary to install a crate, the slats for which must be selected in proportion to the thickness of the panel for finishing. When preparing the bars, consider not only the dimensions of the slopes, but also the installation technique. The lathing should be attached with self-tapping screws around the perimeter of the window frame using a screwdriver or drill. Thoroughly fill the vacated space with a material with a thermal insulation function. If the walls in the house are even and beautiful, the first step along the crate can be safely skipped and immediately go to the slopes of the window frame.

For interior finishing work, lining is most often used.

- Next, we fasten the lining with a screwdriver to the screws. For vertical installation, we fix the slopes on the windows from the outside or from the inside according to the area of the frame, where the grooves should lie. Using the fasteners, fix the panel to the body. When installing horizontally, start work from the bottom side, having previously mounted the starter strip on the frame. We fix the slopes of the windows first in the openings of the strip, then with each other.

When the lining is installed horizontally, the installation starts from the bottom side

- We supply the installed slopes with corners that will help hide minor errors and defects, as well as contribute to high tightness.

What materials are most often used for mounting slopes?

Slopes on windows are not simply installed to hide all traces of installation, they are also used to isolate extraneous noise from the street, as well as for thermal insulation and anti-fogging of windows. The basic rule is correct installation, otherwise about 40% of the heat will go through the window. Slopes are not just a beautiful attribute of the interior, but also the protection of polyurethane foam, which is used in the installation of windows. Without a slope, the foam will crack, absorb moisture and collapse, due to this, the insulation will deteriorate every year.

Plastic window without slopes

Plastic window without slopes

The variety of materials for window cladding is large, but the main ones are distinguished:

- Plastic.

- Drywall.

- Plaster.

- Sandwich panels.

Increasingly, during the repair, plastic is used on the slopes, for plastic windows, working with your own hands. It is not only easy to clean and care for, plastic has other features, but all this can only be seen in a comparison of materials. Below are the advantages of the materials:

| Plaster: | Plastic: | Drywall: |

|---|---|---|

| Easy to close up windows. | Installation is carried out very quickly. | Durability when using GVL. |

| The design is very cheap. |

It is easy to wash the surface of the plastic slope. |

It is possible to insulate the window opening with cotton wool or foam, thereby increasing the thermal insulation properties. |

| You can change the color of the window opening with paint. | The material does not fade in the sun. | |

| They can serve for about 20 years or more. | ||

| With the right choice of color, it will turn out to achieve harmony with the window itself. | ||

| Good insulating qualities. |

As for the plaster, it has more disadvantages.Over time, such material will lose its color due to sunlight. After a few years, restoration will be required, because plastering is not durable, cracks appear, and sometimes the plaster simply leaves the walls in pieces. The thickness of the plaster will be large, since several layers are applied to the window opening, and the technology is long-lasting, because each layer dries out. After plastering, primer and paint treatment is carried out. This material does not imply the use of a heat insulator, due to which the windows will fog up.

Plasterboard slopes on the windows

Plasterboard slopes on the windows

The disadvantage of drywall is that not all types of gypsum boards can be installed in wet rooms, and during work it is necessary to use paint and a primer. You can also trim the window using the following materials:

- Tiles.

- Metal or metal profile.

- Siding.

Some people create a wooden slope, but it is better to use the material inside the house and process it with additional means to prevent mold and mildew. In general, there are many materials for finishing windows, some are used as external cladding material, and some as external.

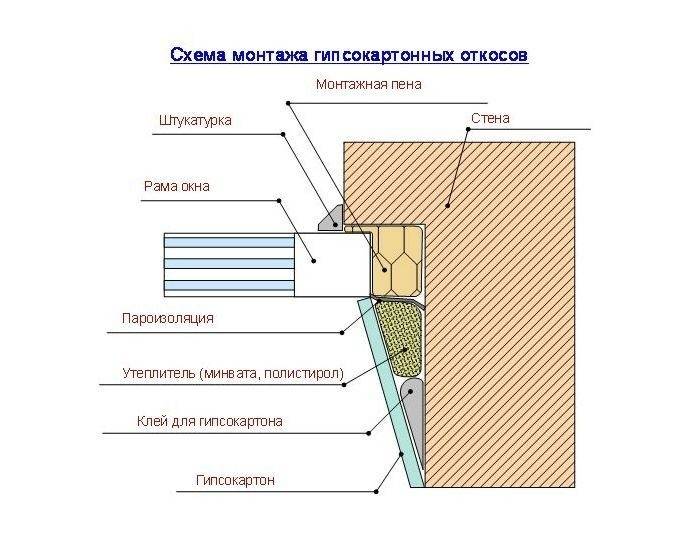

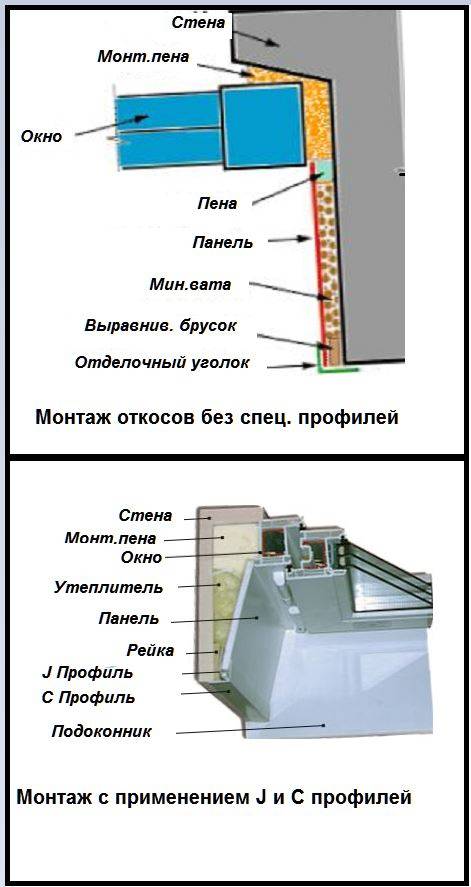

Dismantling an old wooden window creates large holes in the opening, even after installing a new PVC window. In this case, it will blow from the windows and you will need to fill up the holes. In addition, additional sound insulation and thermal insulation will allow you to get insulation if the frame method of decorating the slope is used. In this case, a heater is placed in the frame and closed with trim.

Insulation of the slope with mineral wool

Insulation of the slope with mineral wool

Among the available and modern insulation materials and methods, there are:

- Filling cavities with mineral wool when installing window sills and slopes on plastic windows.

- Smear the junction of the window and the wall with foam in order to exclude freezing.

- Put on the trim on the slope, and also install the ebb if the installation is carried out from the street.

In addition to cotton wool, you can use other materials:

- Penoplex.

- Expanded polystyrene.

- Sandwich panel.

- Izover.

The choice of insulation depends on the width of the gaps and the features of the window opening, as well as the junction of the walls with the PVC frame. If the gap is up to 50 mm, and the surface is smooth, then expanded polystyrene or isover up to 3 cm are used. For unevenness, mineral wool is suitable, it will also do if the defects are very strong after the old window has been removed. Having familiarized yourself with the materials used for windows, as well as insulation, it is necessary to understand the method of installing slopes on plastic windows with your own hands.

Metal slopes. Installation of metal slopes and ebbs

Metal slopes

Finishing with a metal slope - a set of works on the installation of auxiliary elements designed to extend the service life of the entire structure and improve its functionality. Slopes also close the holes between the frames and partitions of the house. The installation of such slopes, depending on the type, is referred to as the exterior or interior decoration of the apartment.

In winter, the slope does not let the cold pass and retains heat, creating a comfortable microclimate in the house. Such a detail of the opening insulates the seams and closes microcracks, improving the sealing of the apartment.

This is especially important given that polyurethane foam degrades quite easily and quickly. By the way, the same functions are performed by internal slopes, which are moisture resistant if the room is ventilated or there is a battery in the window sill niche

Nowadays, steel slopes are especially popular for windows and doors in private houses, as well as on the basement floors of offices and high-rise buildings.

Dimensions and construction

Since the slopes are made individually, measuring each window or doorway, the parameters of the product are very different. The same applies to the level of complexity of the design.However, the metal slope is always solid and exactly fits the measurements, therefore, high protection of the seams from water and the sun is guaranteed.

Slopes of the following types may differ in unusual design:

- For ventilated or siding facades. In this case, the slopes will have protruding elements and shelves for fasteners.

- For a brick facade. The slope will be in a Z shape.

Slopes for different facade windows, for example, can have a width of 2-60 cm. The length varies from 10 to 300 cm. The standard length indicators are 125 cm, 200 cm and 300 cm. The thickness of the metal varies from 0.4 to 0.8 mm.

Advantages / Disadvantages

Metal slopes are very popular in the market because the plates do not crack like plaster, do not swell like drywall and do not fade like plastic. If the bulk of the materials is suitable only for creating internal slopes, then with metal it is also possible to manufacture external slopes. The main advantages of steel slopes include the following characteristics of the product and the material itself:

- High quality sealing. Good metal-based slopes protect the installation seams from natural precipitation, as well as the very inner part of the walls from dampness and mold.

- Long operational period. It is enough to invest finances in the installation of window slopes once, and you can enjoy their quality for several decades in a row.

- High strength. Slopes on windows or doors made of metal perfectly overcome the negative influence of the external environment, be it high humidity, ultraviolet exposure, strong winds or temperature drops.

- Simple rules of use and care. In order for the metal slope to retain its beautiful appearance and familiar shine, it is enough to occasionally wipe it with a damp cloth. Unlike other materials, metal does not need to be tinted regularly.

- Home decoration. Laconic and stylish slopes for doors and windows complement the overall design of the apartment and become a decorative frame for each opening, because they have a special volumetric shape. Currently, there are different colors for steel slopes, so you can choose a part for any interior. The most common ones are white slopes for plastic windows and doors and brown ones for frames that imitate wood.

Materials and technologies

Plastic windows in a house made of timber or logs have been used for a long time and everywhere, therefore there are practically no restrictions for them in the choice of materials for slopes.

It is noteworthy that in this case, wood trim also looks normal, while the opposite option - plastic slopes with wooden windows - is much less common.

For the manufacture of slopes, several types of materials can be used, including those that are specially designed only for this purpose. Let's consider each of them according to three criteria: cost, practicality and complexity of installation.

Plastic

The production of plastic windows is not limited only to double-glazed windows and frames. The main products are usually accompanied by an extensive list of related parts, among which there are specialized panels for window decoration.

Whether or not such materials are used to install slopes in a log or log house depends on the artistic taste of the customer, but we immediately emphasize that from the point of view of installation, this approach is the simplest solution.

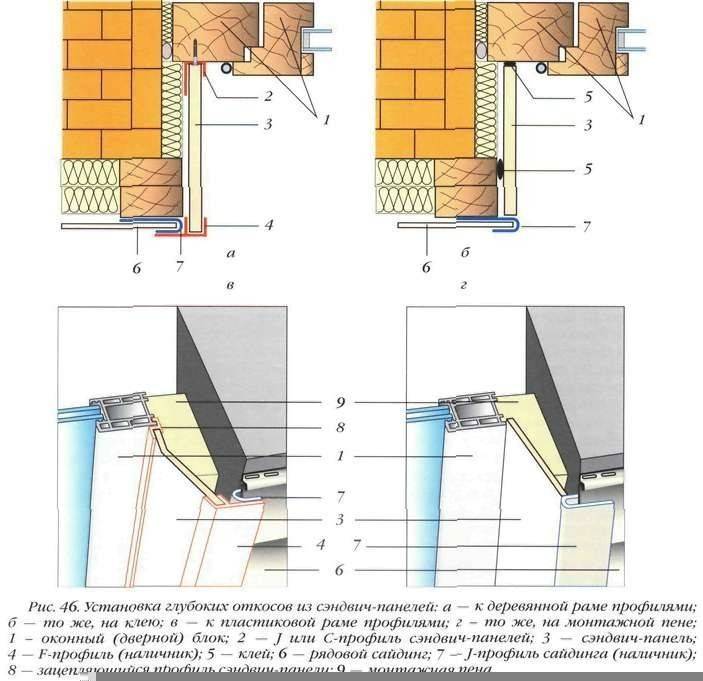

Two types of plastic slopes are poured:

- regular profile;

- sandwich panel.

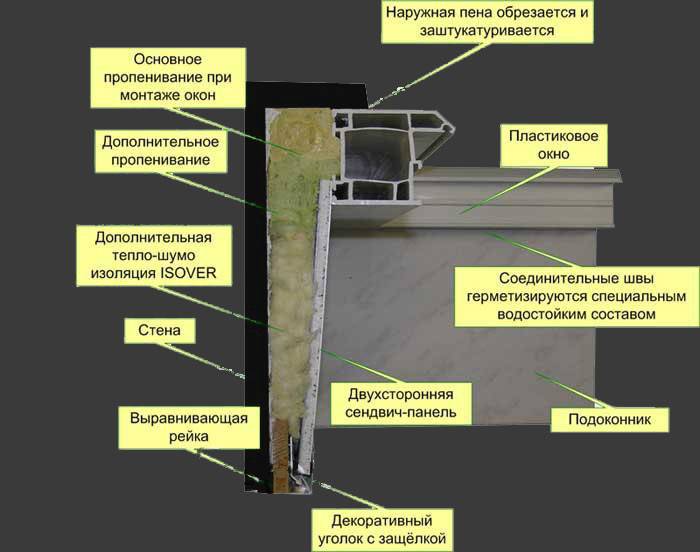

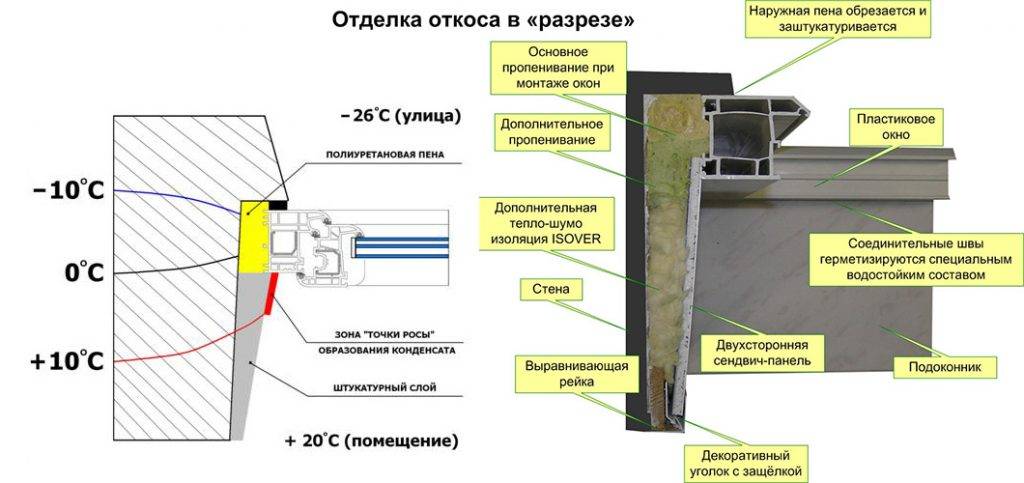

Warm slope in section

The first option is the most inexpensive and is most often used to make slopes for bulk orders (for example, in public buildings).

In the second case, the slope provides additional thermal insulation, which is always welcome in houses where energy efficiency has the highest priority (especially important for windows in baths and saunas).

From the point of view of the complexity of installation, both options are the same and allow self-installation without purchasing expensive equipment.

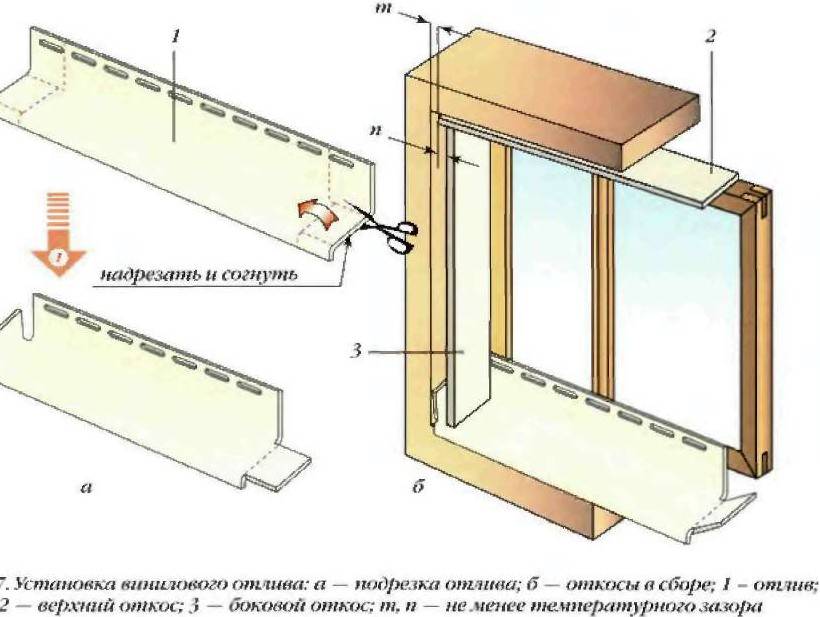

The installation sequence for plastic slopes consists of five simple steps:

- installation of an equalizing rail and a locking latch;

- determination of the exact dimensions for each panel;

- cutting the material with a mounting knife or hacksaw;

- installation of insulation (or application of polyurethane foam);

- panel assembly.

It is important to take into account that the arrangement of the slopes should be carried out only after the window sill has been installed.

Please note that only internal slopes are made of plastic, since when installed outside, such panels quickly collapse

Wood

It can be a solid board made of stable and properly dried wood or a type-setting composition of lining.

Note that wooden slopes are most often straight and can be used for both interior and exterior decoration of windows.

The cost of such a solution is quite high, but as a result, the windows will acquire a more respectable look than when using plastic structures.

From a technical point of view, the assembly of a wooden slope is difficult only in those cases when it is type-set, and for its installation it is necessary to pre-install the guides.

Fixing the strips to the guides is carried out using clamps.

Why do we need slopes?

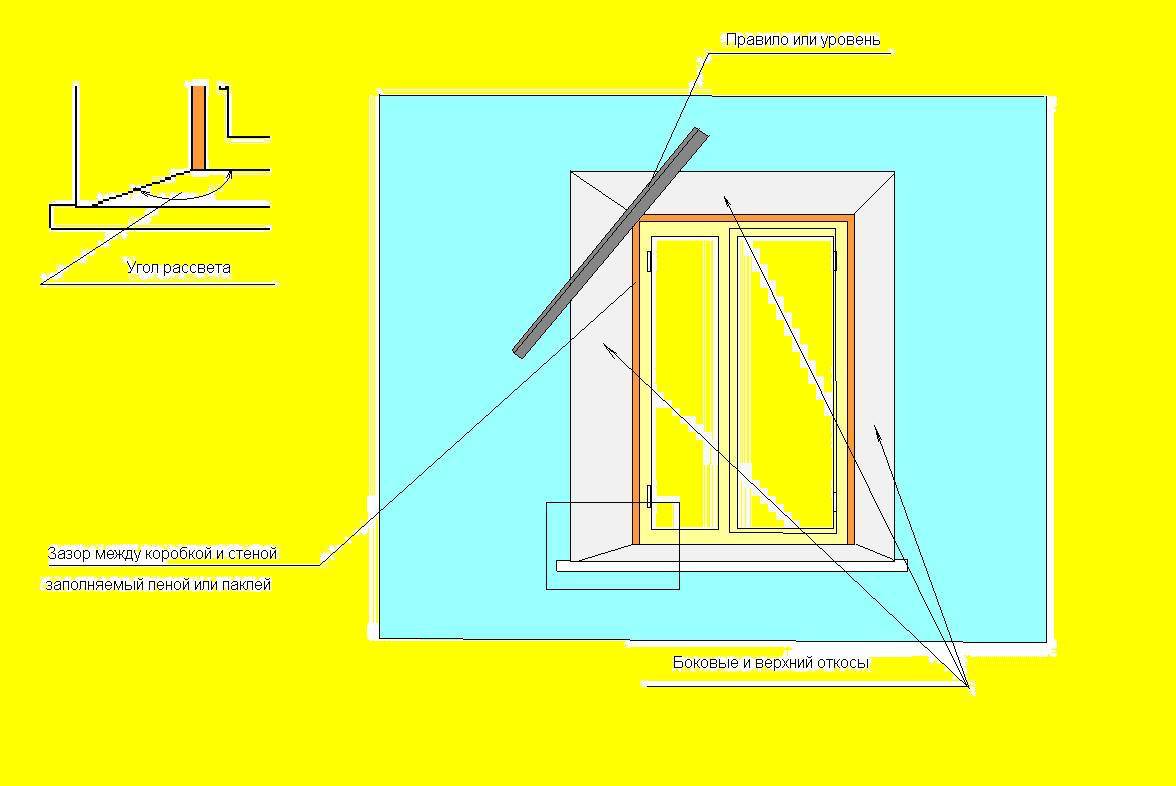

The basic technology for installing PVC windows assumes that they are not installed close to the casing, but with the creation of a small installation gap. After centering the window, the gap is filled with polyurethane foam, and waterproofing and slopes are installed to isolate it from the external and internal influences of the atmosphere.

In general, two goals should be highlighted that are achieved by installing slopes:

- decorative concealment of construction irregularities and communications;

- additional thermal insulation of the window.

The listed goals can be achieved both simultaneously and separately.

Plastic window in the finishing casing

For stone houses, the specified installation scheme is unchanged, but in wooden houses solutions are possible when there is no need to install slopes. A typical example of this approach is when plastic windows are installed in a reverse quarter-finish window, in which the casing frame, window sill and slopes are integral elements of one wooden structure.

In modern construction practice, it is customary to use a universal option, when the slope is not only a decorative panel, but also an additional protection of the window from freezing.

Traditionally, it is believed that the slope is an element of interior decoration. Indeed, if the window is mounted in compliance with all the rules for installing waterproofing, then the internal slopes will completely eliminate heat loss through the installation gap.

Outer slope

However, in cases where the window has a deep fit in the reverse quarter, it is not possible to close the installation gap with the help of the casing alone, and in such cases it is necessary to put an external slope.

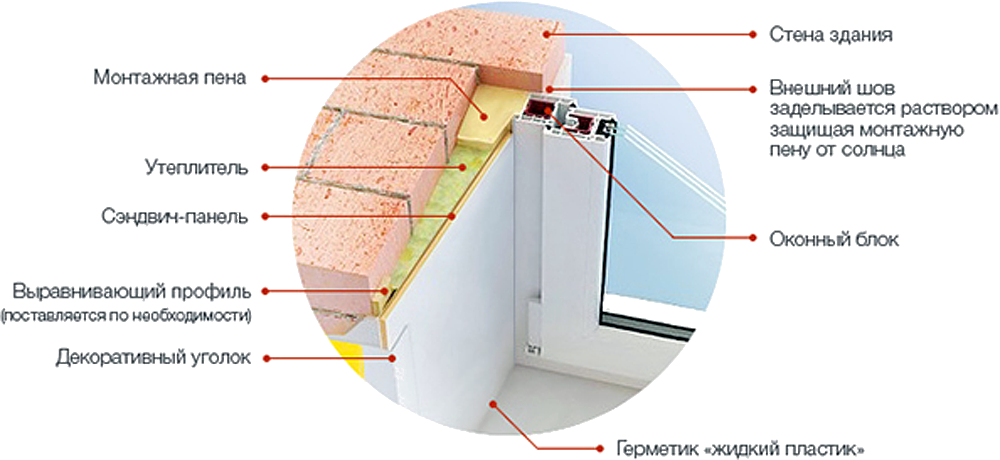

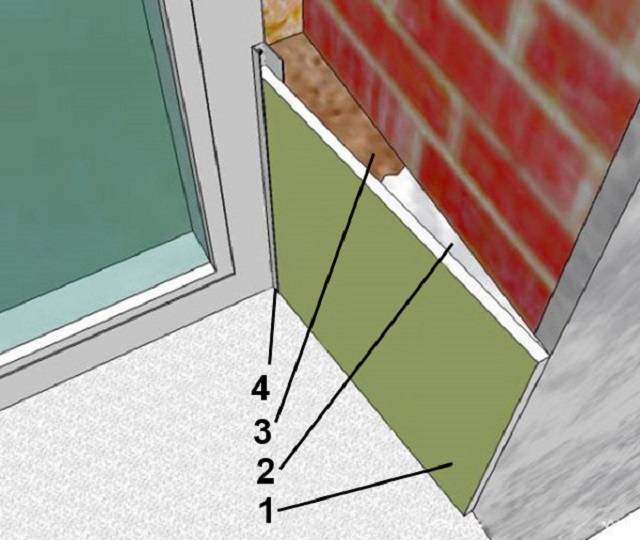

At first glance, the slope is just a panel covering the building cavity of the window. But from a technical point of view, this is far from such a simple construction, consisting of several elements:

- decorative and protective panel;

- internal filler that plays the role of thermal and sound protection;

- devices for fastening the outer edge of the slope;

- decorative corners for external finishing of butt areas.

Slope design in section

As an insulating filler, both polyurethane foam and mineral wool can be used.

In the given example, the filler serves as the basis for the decorative panel, but it must be borne in mind that for some models of slopes, it is necessary to arrange a more complex supporting structure.

Separately, we note that if the window opening is wide enough, then the window sill area can be used as an additional usable area, and elements of household infrastructure (sockets, network communicators, etc.) are introduced into decorative panels.

Types of wooden slopes and their properties

A slope is a part of the window opening both inside and outside the window structure. They are made from different types of wood, as well as from cork oak bark, and their function is mainly to disguise traces of installation of window frames, such as foam and unsightly joints. Qualitative and correctly selected, they can become a worthy interior decoration and a beautiful frame for windows.

Wooden slopes give the window nobility.

Wooden slopes give the window nobility.

In addition to the decorative function, the slopes for window openings function as a kind of window insulation, since they overlap the joints and cracks. So, let's look at the main functions that wooden window slopes carry:

- Provide protection against freezing. Wooden slopes are saved with poorly made thermal insulation when installing windows, since they close the gap that forms between the frame and the window opening. At the same time, the slopes significantly improve the thermal insulation of the room. Also, wooden slopes prevent the appearance of condensation on the window frame, because it is condensation that contributes to the occurrence of mold and rot.

- Protect from wind and drafts. The polyurethane foam used for sealing joints when installing windows loses its properties when exposed to ultraviolet radiation and water, which is why it quickly collapses. By installing the slopes, it is possible to prevent the destruction of the foam, which, in turn, will eliminate the appearance of drafts.

- They have high decorative properties. In addition to masking foam, chips and joints, wooden slopes look very impressive in the interior and add completeness to the window frame.

During the manufacture of slopes from wood, special glued shields are used, which are treated with special compounds to prevent exposure to the environment. For the manufacture of the slopes, it is recommended to use the same species of wood that was used for the manufacture of window frames - in this case, both the color and texture of the window block will completely match, and wooden windows with slopes will look solid.

Different types of wood, such as, for example, larch and pine, differ in the texture of the wood pattern, and even if the same varnish is used to decorate the window and slopes, the original color will still differ.

Different types of wood, such as, for example, larch and pine, differ in the texture of the wood pattern, and even if the same varnish is used to decorate the window and slopes, the original color will still differ.

As a rule, wooden slopes are not mounted on the same day as windows in a wooden house, this is done so that the foam for installation has time to dry out and become durable. At least 11-12 hours should elapse between the installation of windows and wooden slopes. But it is not recommended to hesitate with the installation of slopes, because the influence of the environment gradually destroys the polyurethane foam.

Design features

The device of slopes has its own characteristics. The fact is that it is necessary to take into account the main nuances that must be performed when working with your own hands:

The structure should be trimmed so that the edge of the frame closes quite a bit.

The location of the hinges and the opening flaps must be taken into account.

The foam is trimmed flush with the frame. If you remove more substance than required, then a skew of the structure may appear.

Also, any bulging residue will interfere with the finishing process.

Particular attention is paid to the assembly seam. The option that will be used for facing the window slopes depends on its thickness.

The sealing process is a very important point

All places must be well missed.

Sealing of window seams and joints will protect against blowing, freezing and leakage of windows

Sealing of window seams and joints will protect against blowing, freezing and leakage of windows

But how to finish the slopes, the location outside the room? The technology is almost completely consistent with the internal work.But the obligatory and most important rule will be the installation of an ebb tide.