The basics

First you need to measure your balcony and write down all the results. You will need this to calculate the amount of consumables. Next, you need to decide on the type of finish. The balcony can be finished with siding, plastic, trolley, drywall, it is even possible to paste over with wallpaper. It is necessary to decide what to cover the floors, how to repair the ceilings. At this stage, you need to calculate the budget for repairs, and based on it, you need to choose the material. It is also recommended to draw a plan of the balcony based on calculations of the length, height and width of the balcony. Have you decided on the material? Now you need to buy everything and do not forget to make an allowance for a possible mistake, and purchase materials with a small margin. So that in case of problems you do not need to go to the store and buy in addition.

Pros and cons of using laminate to decorate a balcony

To use laminate flooring in the decoration of the balcony, one main condition must be fulfilled - it must be glazed. The fact is that this material is afraid of moisture and cannot get wet. The main advantages of using it include:

- Impeccable aesthetic qualities and a rich variety of textures and colors. If laid correctly, the laminate on the balcony cannot be distinguished from real parquet;

- Resistant to UV fading;

- Easy to install on the balcony. Laying laminate flooring does not require any special skills. It is a pleasure to work with it thanks to the special thorn-in-groove connection;

- Laminate is resistant to the appearance of fungi, mold and the development of various other microorganisms on it;

- Affordable price. The cost of a laminate for a balcony is relatively low, along with other facing materials.

- Easy interchangeability of one element. Unlike linoleum, the laminate does not have to be changed entirely in cases of local damage;

- Wear resistance. If used correctly, the laminate will last up to 10-15 years.

With such advantages, laminate flooring is still not without its disadvantages. Minuses:

- Deformation due to moisture. Cellulose, which is part of this material, when wet, tends to swell and deform the joints of the laminate. The protective film, of course, protects it from moisture, but only with short-term exposure;

- Reaction to temperature extremes. Laminate flooring expands at high temperatures and shrinks at low temperatures. This must be taken into account when performing installation work. If the temperature on the balcony is unstable all year round, a small gap should be left between the boards and the perimeter;

- High demands on surface quality. Laminate flooring requires a flat surface and the smoother its plane, the more ideal the coating will be.

Which laminate is right

The choice of the optimal covering for the balcony depends on the purpose of the room. For most domestic apartments, the balcony is a warehouse for small household items, a place for drying clothes, a room for smoking, repairing household appliances, etc. In rare cases, a loggia or a balcony with a larger area can be equipped in a separate recreation room.

The laminate for finishing the balcony must be treated with several types of protective equipment even at the stage of production at the factory

When choosing a finish, you should pay attention to the class. This is a parameter responsible for the strength of products, resistance to physical damage, moisture, open fire, UV rays.

For a balcony, it is better to choose class 31-33. This so-called "Production" laminate, which has the best protective properties, can be used in industrial premises.It is slightly more expensive than the standard 21-23 class, which is used in living rooms, but its general characteristics will allow the panels to be used for 10-15 years.

| Scope of EN 685 | Load degree | Laminate class |

| Living spaces | Easy | 21 |

| Living spaces | Average | 22 |

| Living spaces | High | 23 |

| Public spaces | Easy | 31 |

| Public spaces | Average | 32 |

| Public spaces | High | 33 |

It is advisable to purchase a more expensive coating for several reasons:

- a balcony or loggia has a small total area: 1-2 sq.m., which will not affect the price too much;

- operating features require a more durable coating that should last a long time;

- industrial laminate comes with different patterns, patterns, color palette - you will not be able to spoil the design of the balcony.

Methods for attaching laminate to the wall

Before proceeding with the laying of the coating, the wall surface is leveled vertically, all significant irregularities are eliminated. Smoothing of irregularities and leveling is performed by installing the lathing, plastering, sheathing with sheet materials.

When installing the lamellas of the lower row, a gap of 1–2 cm is left above the floor, otherwise stresses may appear in the finished plane during thermal expansion. The indentation after the completion of the installation is closed with a skirting board. The joints of the finished plane with adjacent sections on the side and ceiling are masked with corners or moldings.

Clamp fastening

Kleimer is a galvanized metal bracket with three fastening holes used for concealed fastening. The kleimer is pushed onto the groove wall and fixed to the base with nails, screws or staples using a stapler. The lamella is attracted and is fixed on one side with a groove-tenon connection, and on the other with a cleat. A similar installation method is permissible if the listed types of fasteners for cleats can be driven into the base.

Fastening with screws, staples or nails

The fastening principle is similar to that used for clapboard cladding. As with cleats, the base must be suitable for screwing in or driving in fasteners. The installation itself is faster, but the fastening is rigid, deformation of the lamella is possible.

Laminate through the groove wall is attracted to the wall with self-tapping screws or nailed with staples or nails. Before fixing the laminate to the wall with self-tapping screws, it is recommended to drill a hole in the wall 1 mm less than the diameter of the fastener to prevent delamination of the material. For better fastening, it is allowed to coat the back side with glue.

Fastening with glue or liquid nails

Due to the high labor intensity, fastening to glue is used less often than previous methods. For vinyl laminate, this is the only possible installation method, all others can damage the finishing material.

The adhesive version of the installation of the coating requires a perfectly flat base and high qualification of the installer. Aligning the wall with a crate is not suitable, since the contact surface area when glued will turn out to be too small, the lamellas will not be able to hold onto.

For the glue method, it is preferable to choose a thinner material in order to lighten the load on the lower rows. Since the coating does not bear a mechanical load, the use of lamellas with lock connection in in this case, it is not at all necessary, which allows you to save on the cost of the material.

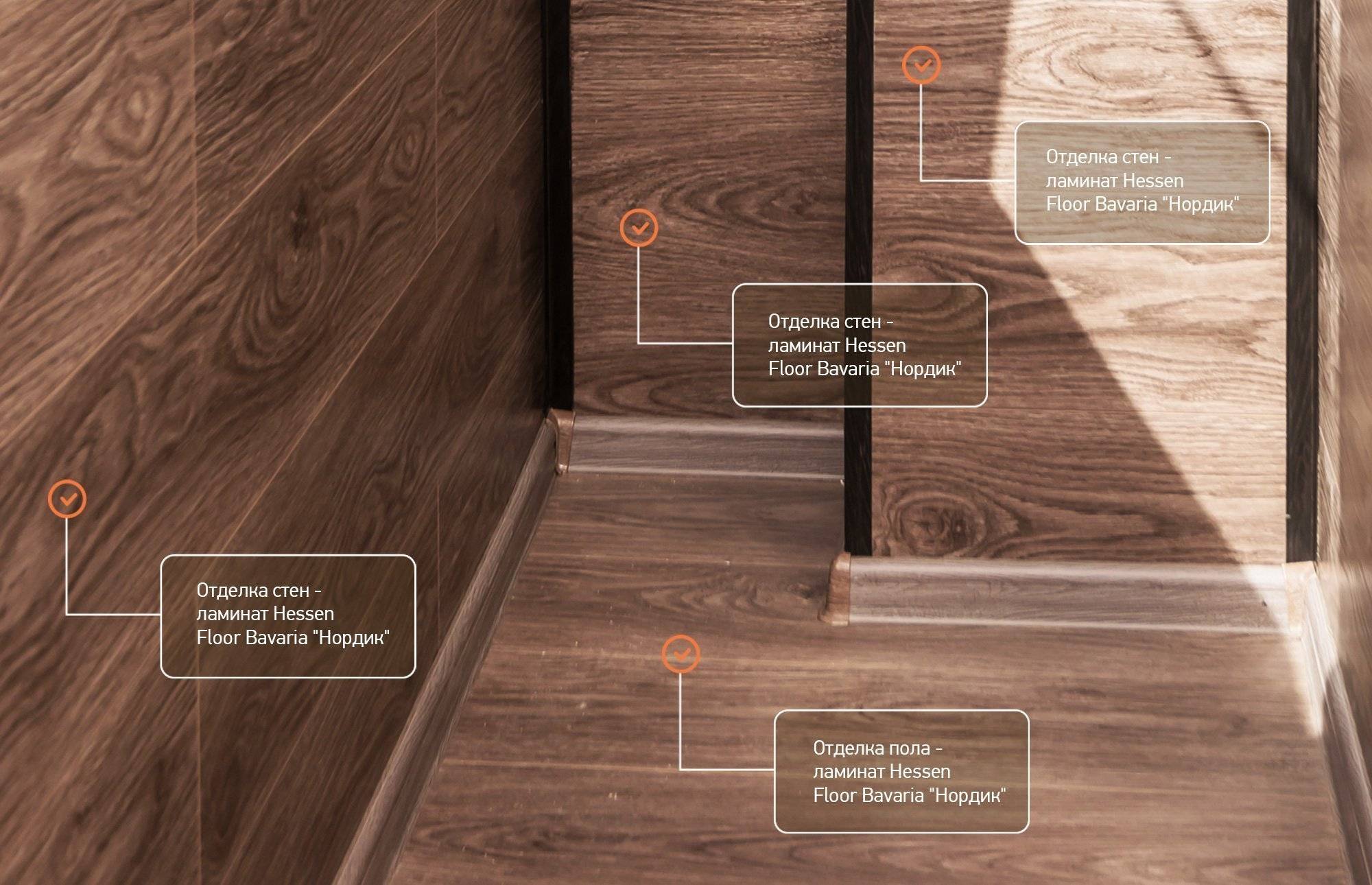

Laminate in the decoration of the walls of the balcony

Finishing the walls of the balcony with laminate is a very profitable and practical solution for the improvement of this room. This work can be done in several ways, depending on the type and method of installation of the coating.

How to fix the laminate to the balcony wall? The adhesive laminate is attached to a metal sheathing covered with plasterboard. The joints formed between the sheets of drywall must be glued with adhesive tape and treated with putty.Then the resulting surface is primed, and laminate panels are fixed on it with a special glue.

Balcony cladding with laminate adhesive on leveled walls

The click-type laminate, which has reliable and durable locking elements in its design, is attached to the lathing, which can be made of metal or wood. The frame is attached to the surface to be finished using dowels, and the lathing elements are connected using self-tapping screws. In this case, the width of the cells of the frame for fixing the panels should be no more than 40 cm. Fixing the panels to the frame can be done with glue (liquid nails) or small nails. It is very convenient to use a construction stapler and clamps for this purpose - galvanized staples created for fastening this material.

They can be of two types:

- With serrated protrusions (hammered into the cut end of the laminate board and mounted on the crate or wall using self-tapping screws).

- With flat projections (pressing the protruding part of the click lock of the panel and not preventing it from joining other boards).

In order to sheathe the balcony with sheet pile laminate, a lathing is also made of wood or galvanized profile. It is attached to it with nails or staples.

Plastic paneling

Plastic panels

Plastic panels are a convenient and practical type of finish. They are easy to cut, bend, and have high strength. Taking care of them is also quite simple. To panel the ceiling and walls of the balcony, you will need wooden battens and a ceiling profile. The slats are attached to the insulated surface with a pitch of 50-70 cm, placing them strictly vertically. The ceiling profile is mounted along its length, fixing it with 4-6 mm dowel nails.

Plastic paneling

For a corner connection, the ends of the profile are cut at an angle of 45 degrees; it is more convenient to cut the ends using a special device with grooves - a miter box. The racks of the crate must be installed in each corner of the balcony: if this is not done, the panels will sag in the corners, and the entire finish may be deformed.

Plastic panels. Balcony finishing

For the inner cladding of the balcony, it is recommended to use plastic panels with a width of 10 to 20 cm and a thickness of 1 cm, as well as guides and two-sided corner profiles. The guides are screwed to the crate with screws 20 mm long and with a wide head, placing them in the corners of the room and along the perimeter of the openings.

Frame for panels

Fastening panels

Fastening panels

Now the panels are cut to length, applied with the groove up to the surface and, bending in an arc, insert both ends into the guide profiles. Having straightened the panel, the next one is installed, then both boards are tightly shifted and fixed with screws.

The last panel is cut in width, a little silicone is squeezed into the grooves of the guides, the cut board is inserted and lifted up until it stops. Holding the panel in this position, insert the missing fragment and tightly join the edges. The sections above and below the openings are sheathed last, then platbands, ceiling moldings, plinths are attached.

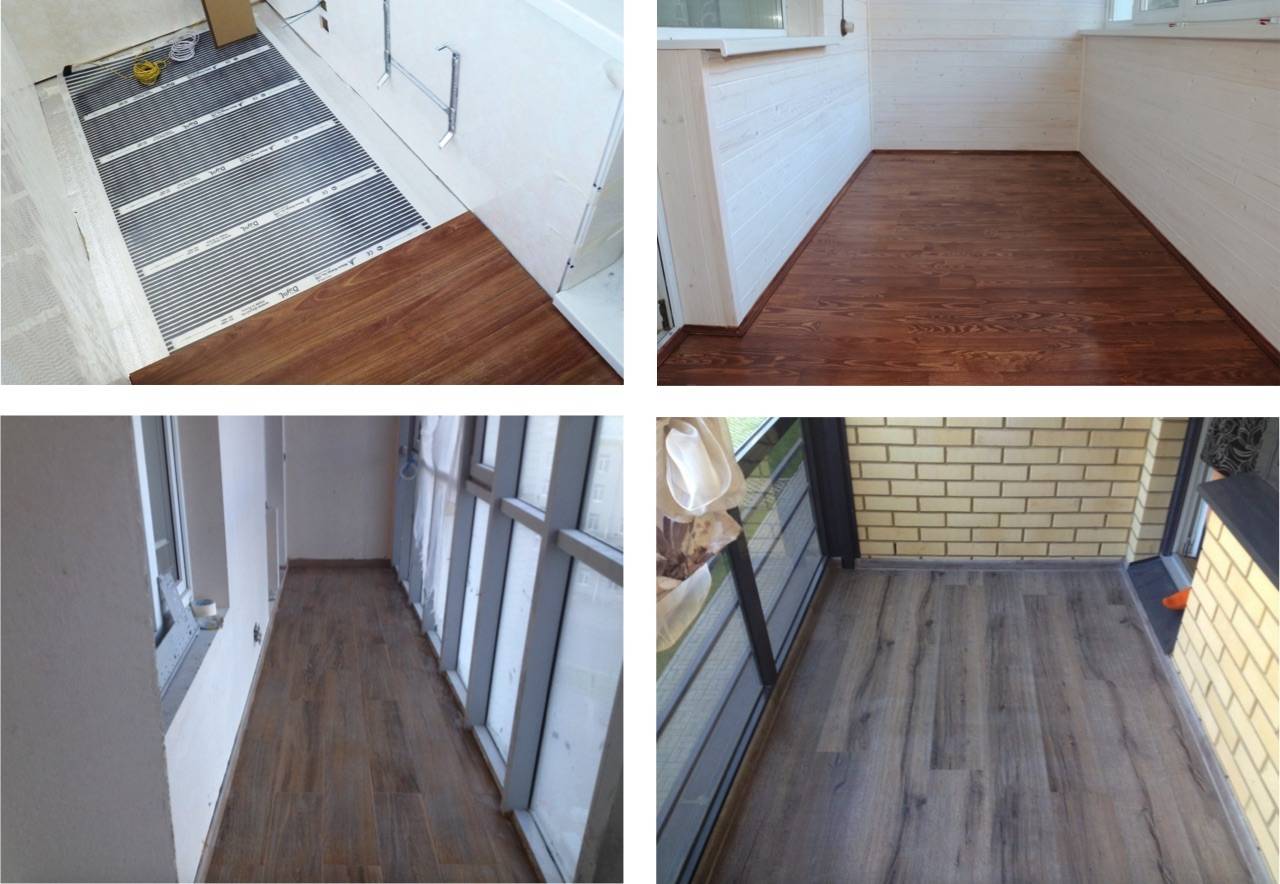

Laying laminate

It is possible to start laying the laminated coating only on the balcony, where two or three-chamber double-glazed windows have already been installed and the walls are insulated.

Glazed balcony ready for laminate installation

When is the best time to lay laminate

It is not advisable to lay the laminate on the loggia in winter, especially at temperatures below 10 degrees and humidity above 70%. Ideally, the temperature should be above 5 degrees. If these conditions are not met, the surface of the laminate may become cloudy, flake off or stand on end.

Preparing the surface for laying

Pay particular attention to the surface on which you will be installing the new floor covering. It should be even, well-dried and clean.

For this:

- Remove all objects and things from the balcony;

- Remove the old coating down to the slab using a chisel and hammer;

- Take out excess trash;

- If there are cracks, holes and irregularities, they must be removed with a new screed or grout;

- Check the leveled sub-floor with a building level.

Cooking the floor surface

Required set of tools

To sheathe a balcony with laminate, you will need these tools:

- Marker and tape measure;

- Building level;

- Spacer wedges;

- Circular saw and hammer;

- Clamp;

- Metal bracket or bar;

- Protective glasses.

Metal shackle and hammer

How and what to cut laminate flooring

As we already said, before starting installation, you must leave the laminate on the balcony for two days, after which you can cut it into pieces of the desired size, following the step-by-step instructions:

- Draw a line on the board with a ruler and marker.

- Take another laminate board and lay it flat along the line of the future cut, securing it with a clamp. This is to prevent the saw from going to the side. Check that everything is securely fastened.

- Wear safety glasses.

- Saw the board off with a circular saw or jigsaw.

- Check if this board is the right size by placing it on the installation site.

You can cut laminate with a regular saw

Main job

Finishing a balcony with laminate is quite simple and does not require much effort. You can easily cope with this work yourself without the help of specialists. Laminated panels are easily fastened to each other with locks formed when the tenon of one board is inserted into the groove of another, and are fitted with a hammer and a metal bracket.

Two types of locks

Start laying the laminate on the loggia from the side opposite to the exit. Lay the boards perpendicular to the window, then the joints will be almost invisible. Pre-install wedges at the threshold and wall, as well as at the jambs and pipes. The first row must be laid with a gap from the wall from 5 mm to 1 cm, otherwise the laminate will deform over time, as it can expand or contract after a while. Take a hammer and a metal bracket and gently tap the end of the first board so that the tenon of the second board fits into its groove. First, adjust the last board in the row to the desired size.

Wedges for laying laminate

The rest of the rows are assembled by analogy with the first and are additionally connected along the longitudinal edge. To do this, one board is inserted into the groove of the other at an angle of approximately 40 degrees. When lowering the board, a characteristic click will be heard. Use a clamp to connect the last plank to the wall.

We collect laminate

When finished, remove the spacer wedges and close the gaps with a skirting board by nailing it to the wall. Do not forget to fit the sills that will complement the look of your new loggia. By the way, these details will also protect the laminate from moisture and make it static.

Video instruction

These are all the main stages of the work that must be carried out in order to independently lay the laminate on the balcony or loggia. Rest assured, laminate flooring is the best and optimal flooring solution in these areas. Ease of installation, ease of maintenance and long service life will meet all your expectations.

Laying laminate flooring

After finishing the walls, you can start installing the floor covering. But the first question that will arise for you is how to properly lay the laminate on the loggia or balcony. The first step is to prepare the floor.

Preparing the surface for laying

As in the case with other rooms, the surface for installing the laminate must be flat.

If this rule is not critical for wall decoration, then it is very important for floors. Surface preparation for installation consists in performing several actions:

- take out all objects from the balcony: tables, chairs, cabinets;

- dismantle the old coating to the plate itself;

- clean the floor about dust and debris;

- if it is wet, then be sure to dry it;

- if there are deep cracks or holes on the slab, seal them up with a cement-sand screed;

- check the resulting surface with a building level.

How to cut a laminate

Instruments

To install the laminate on the balcony floor, prepare a set of tools:

- marker and tape measure;

- level;

- spacer wedges;

- circular saw and hammer;

- clamp;

- metal staples or bar;

- protective glasses.

How to cut laminate flooring and how to do it correctly?

Professionals know that a lot depends on the correct cut of the laminate elements. But not everyone knows how to do it correctly. By following our tips and instructions, you will learn how to accurately cut the desired piece of laminate to cover your floor.

- First take measurements and mark them on the laminate plank with a marker.

- Take a ruler and draw a straight line where you want to cut the board.

- Prepare a second laminate board and place it along the future cut to prevent the saw from moving to the side. Make sure the board is securely fastened.

- Take care of your eyes and wear glasses.

- Use a jigsaw or circular saw to cut the laminate flooring along the marked line.

- Attach the cut piece to the place of laying, check if the dimensions are the same.

Check the evenness of the screed

Installation of laminate

Further finishing of the balcony will not cause difficulties. This work does not require special knowledge. If this is your first time styling, practice in small sections first to understand how the snaps work on the material. Snapping is usually tricky, but you can use a hammer or metal brace to secure it in place.

Laminate locks

Installation of laminate sheets begins from the opposite side from the exit to the balcony. To make the seams less visible, many prefer a perpendicular laminate in relation to the window.

Spacer wedges are installed at the very threshold, walls, jambs and pipes. For laying the first row, leave a gap of 1 cm from the wall, this will help to avoid deformation of the material during expansion.

Using a hammer, place the thorn of the second board into the groove of the first. When laying the last board, you must first adjust its size.

Strut wedges

All other rows are assembled, like the first, only they are additionally connected to each other along the longitudinal edge. To do this, insert the next board into the groove of the previous panel at an angle of 40 degrees. After lowering the panel, a characteristic sound will be heard, which means a good connection. You will need a clamp to secure the last panel.

Assembling laminate boards

When the last board is laid, the spacer wedges can be removed. The gaps between the wall and the floor are closed with plinths, nailing them to the wall. The entrance to the balcony is made out by arranging a sill in this place. Finishing details - plinths and sills, in addition to the aesthetic function, also perform a protective one. They prevent moisture from entering the laminate.

average rating

ratings more than 0

Share link

Wall decoration

Buy wall laminate for a balcony, most likely, will not work. The fact is that this material, for its intended purpose, is used only as a floor covering.

Mounting on the wall is a modern design solution aimed at giving the room a certain uniqueness, chic and color. Certainly, a wide range of color shades, imitating natural wood materials to a greater extent, guarantees wide popularity of laminated panels. For more information on the basics of laying laminate on vertical surfaces, see this video:

Installation methods

To properly fix the panels on the wall, you can use 2 methods. The first is to adhere the laminate to the surface. To do this, carefully prepare the base: align and prime it.If this is not done, the subsequent installation will be complicated by the fact that the connecting seams may protrude, and in the whole structure it will not look aesthetically pleasing.

For uneven walls of the loggia, the optimal solution would be to prepare for the facing system - lathing. The advantage of this method is that there is no need for leveling and priming the surface, which requires additional time and money. The lathing can be made of low-cost wooden beams. This allows us to speak of a low cost of work.

The walls under the laminate must be flat, otherwise the structure may "lead"

In addition, inside it, you can place not only electrical wiring, but also a heater, which will simultaneously play the role of a sound insulator.

After the sub-cladding system is assembled, and the electrical cable and insulation are fixed inside, you can proceed to fixing the laminate to the wall. This can be done using clamps used to fasten MDF panels.

In this case, it is recommended to take into account the property of the material, to absorb moisture, therefore it is not recommended to use it in rooms with high humidity: bathrooms and showers. In all other cases, the installation of laminated boards on the walls is allowed. For more information on another method of installing laminate on walls, see this video:

Self-laying laminate flooring on the balcony is not so difficult. In addition, this requires a small amount of material. But the result will not keep you waiting, after the installation of the skirting boards is completed, and the coating takes on its final appearance, you can enjoy with pleasure the interior view of the room, which has been transformed for the better.

Mounting Features

There are several mounting methods:

- on glue to drywall

- on a wooden crate

- on a metal crate

Glue mounting

This method of fastening can be called the simplest. It is carried out on a plasterboard surface. But it has many disadvantages and nuances that you need to know about.

The first thing to look for when choosing this method is that drywall reacts negatively to high humidity. Therefore, it is better to initially give preference to a special gyiscardboard impregnated with a mixture to reject moisture

Before finishing, the surface is carefully prepared - it should be perfectly smooth. Plasterboard on the wall can be glued. But in order to be sure of the durability of the fastening, it is still better to additionally attach it with self-tapping screws and dowels.

The easiest way to fix the laminate is with glue

The easiest way to fix the laminate is with glue

Laying on the floor involves leveling with plasterboard - this material is resistant to stress. Laminate is glued to the floor with pre-assembled strips of boards. Before connecting the locks, the grooves on the boards should be coated with glue or sealant - this will increase the moisture resistance.

After that, the glue must be applied to the base and the mounted strip must be laid. Carefully insert the board locks into the grooves and hit with a hammer. The floor is covered with a floating substrate, but nevertheless, the use of the glue method is preferable.

With the floor, everything is clear. But in order to glue the laminate on the walls, you will need to try. First, you should be careful when knocking down the boards, because there is a risk that the already glued material will collapse. To prevent this from happening, first assemble the board from the boards, and only then glue the structure to the wall. Of course, this is inconvenient, but it will save you from destroying other parts.

Installation on wooden lathing

In view of the difficulties described above with the adhesive installation method, it is more expedient to assemble the laminate on the lathing. It can be wooden or metal. The first option is more economical, the second is more expensive, but more durable.

How to make a crate from wooden bars? The length of the bars should correspond to the distance from the floor to the ceiling. Before installing the crate, it is better to treat the bars with an anti-fungus agent. Fastening takes place along the entire wall at a distance of 40 cm. On top of the vertical beams, horizontal slats are attached. It is on these slats that the laminate is installed.

Installation on a metal crate

Frame made of metal profiles

Frame made of metal profiles

Metal lathing is constructed according to the same principle as of wood, only zinc profiles are used. Lighthouses are extreme profiles - they will become a guideline for the installation of middle battens. But horizontal slats with a metal crate are also used from wood.

IMPORTANT. The methods discussed above are used only when sheathing with laminate, the boards of which are directed vertically

When laying horizontally, the finishing is done the other way around: the lower beams should be attached along the wall, the upper ones - along its height.

Installation of the material is done with clamps. One is placed on the top of the board, the second on the bottom. A clamp with notches is driven into the sawn-off board end, it is attached to the crate. The locking spike is clamped flat and thereby fixes the board.

When connecting the boards, apply glue or sealant to each groove of the panel - this will make the fastening more reliable and moisture resistant.

In this way, the entire surface is covered. If necessary, the board can be sawn. The edges of the last rows are closed with an aluminum corner. But before fixing it, the corner is also treated with glue or sealant.

What are the best materials to choose

For finishing work, a variety of materials can be used, providing an excellent result of the work. The following options are considered the most popular.

| Material | Specificity of its application |

| Wooden lining | Decorating balconies and loggias with clapboard is considered the best solution. This material is made from natural wood and also has a beautiful look. Photos of this design are very beautiful. The material is simple to work with, but not cheap. |

| Siding | Its installation involves not only improving the appearance of the balcony, but also additional work is being carried out related to the insulation of this room. The siding is available in numerous colors, and during the production process it is equipped with special fasteners that guarantee a simplified installation procedure. |

| Moisture resistant drywall | It is mounted on the crate, after which all the resulting joints are sealed. Such a covering can be covered with wallpaper, paint or other materials for decoration. This option will not require a large investment in the repair work for the loggias. |

| Plastic panels | They are a good choice for a balcony, however, they do not have the required vapor permeability indicator, so an airtight finish is obtained. They are produced in numerous colors, so with their help an interesting and bright design is obtained. |

SidingGypsum boardWood liningPlastic panels

The above materials are considered the most relevant and often used in the process of finishing balconies. Long-lasting and beautiful coatings are obtained from them. Anyone who does not have experience in this direction can perform all the work on their creation.

Most often, lining is chosen for loggias, which forms a beautiful coating. It is easy to work with, and in production conditions it is treated with special protective compounds that prevent possible rotting or the development of microorganisms. Photos of such a finish are widely presented in the selection, so you can be sure of the correct choice of cladding for the balcony surfaces.