Preventive measures

- Change the lubricant twice a year.

- Every six months a routine inspection of the brushes.

- Thorough cleaning every time after use.

- Lubricate the back of the drill or chisel before work to reduce the load on the firing pin.

If the hammer drill stops working normally or there is a breakdown, read the instructions and inspect it carefully. Before you start repairing yourself, really assess your capabilities. If you are sure - try to fix it yourself, otherwise, if in doubt, it is better to contact a specialist. And remember that already repaired mechanisms are not subject to warranty obligations and service centers are reluctant to take them for repairs.

Mechanical malfunctions of air conditioners

Mechanical malfunctions of the air conditioner can occur:

- in the outdoor block of the split system, where the compressor and the fan for blowing the condenser are located;

- in the cooling circuit, where there are mechanical connections in the refrigerant circuit;

- in indoor units where fans are located to provide heat exchange between the evaporator and the air in the room.

Most often, such malfunctions occur in the outdoor unit, which is actively exposed to atmospheric phenomena, and it is also possible physical impact from the ingress of foreign objects, for example, icicles, large debris such as broken branches, plastic bags, etc.

Cooling circuit malfunctions are most often associated with improper installation and poor quality of the materials used. For the same reasons, mechanical failures can occur in the internal block of the split system.

The most dangerous types of mechanical failures of an air conditioner are associated with a split-system compressor, since they can provoke a whole cascade of malfunctions, the elimination of which will require significant costs. Their value can reach 50% or more of the cost of a new air conditioner.

Mechanical faults can be diagnosed by the electronic air conditioner control system. High-class split systems, a significant part of middle-class air conditioners and even individual products of the budget segment are equipped with such self-diagnostics.

Really good air conditioners not only reveal faults, but also do not allow using the unit until they are eliminated. In other cases, all hope is placed on the owner that he will identify the malfunction in time and take measures to eliminate it. The signs of mechanical problems are:

- Extraneous noise during the operation of the fans of the outdoor and indoor units.

- Long running time of the unit without interruption (conventional air conditioner) or deterioration of air cooling (inverter air conditioner).

- Freezing of evaporators and condenser.

- Condensation (water) flowing out through the indoor unit in addition to the drainage system.

There may be other external signs of mechanical malfunctions, so if the user notices that the air conditioner has begun to work differently than usual, you should immediately contact the service department to eliminate the malfunctions, and most importantly, the reasons why they occurred:

- Natural wear and tear;

- Ingress of foreign objects into the mechanical components of the air conditioner;

- Lack of lubricant or poor quality;

- Loss of a critical volume of freon due to natural evaporation or depressurization of the cooling circuit;

- Clogged air filter system;

- Air conditioner drainage clogged.

Malfunctions due to normal wear and tear usually occur among "veterans" of climate technology, but mainly occur due to non-compliance with the maintenance schedule. Breakdowns of air conditioners associated with mechanics, if they are not eliminated in time, always end in the failure of the compressor, which is very sensitive to violations of the operating mode.

Each mechanical failure causes a violation of the optimal temperature regime of the refrigerant circulation, as a result of which liquid freon can enter the compressor, causing its complete failure. Elimination of most mechanical faults requires little time and cost, provided that you contact the service center in time, otherwise a penny breakdown can lead to thousands of costs.

Room air conditioner malfunctions

| Malfunction | Cause | Elimination |

|---|---|---|

| The air conditioner does not work | No electricity in the circuit Damaged cord (broken wire) Defective switch |

Check plugs or automatic fuse Replace the cord Replace the temperature switch |

| The air conditioner starts to work and immediately burns out the plugs or knocks out the automatic fuse | Low-power tubes or automatic fuse The air conditioner is turned on too early after stopping The current is too high for this circuit |

Replace the automatic fuse or plugs with more powerful ones if the wiring allows Wait five minutes and turn it back on Disconnect other electrical appliances from the circuit. Check the gauge of the wiring, whether the wire is large enough, install a new circuit for the air conditioner |

| The compressor is running but the fan is not | The fan blades are blocked by something Seized fan motor bearings Blown out fan motor Open in the wiring circuit to the fan |

Clean the fan to let the blades rotate freely Lubricate bearings or replace motor Replace fan motor Connect the wires at the break or tighten the terminals |

| The fan is running but the compressor is not | Defective thermostat Overload protection defective Condensation radiator for example down Compressor motor burned out |

Check thermostat and replace if faulty Check and replace if necessary overload protection device Clean the radiator Replace engine |

| The air conditioner works, but does not cool properly | Room air conditioner too low The evaporator freezes due to too low outdoor temperature Clogged filter Air leaking in the window The room temperature is too high The fan cover does not close and air flows in Defective thermostat Landing on the blade shaft is loose and insufficient air is supplied Partial refrigerant leakage has occurred in the system |

Buy a more powerful conditioner Do not use the air conditioner at this time Clean the filter Seal all cracks Insulate walls, ceiling, floor and blinds on windows Loosen the cover and lubricate the hinge Replace thermostat Tighten the attachment of the blades to the shaft Invite a technician to repair the leak and recharge the refrigerant circulation system |

| Compressor switches on and off with very short cycle times | The thermostat is set to an insufficient low temperature Mains voltage too low The thermostat sensor on the radiator is out of place The air conditioner is turned on too early after it is turned off. |

Set the thermostat to a lower temperature Check the mains voltage. Contact your electrical company Put the sensor in the right place Turn off the air conditioner, turn it on again after waiting five minutes |

| Water drips into the room | Drain pipe to condenser blocked The air conditioner is installed with a slope towards the room |

Clean the drain Tilt the air conditioner slightly outward |

What can be done if the climatic device does not turn on?

If such techniques do not bring a positive result, then you still have to seek help from the employees of the service center, since we can talk about a rather serious breakdown, the elimination of which will require experience and special repair equipment.

It will not be superfluous to check the batteries in the remote control, as in hot weather they tend to sit down much faster.

And for what other reasons can HVAC equipment fail? In some cases, the ineffective operation of the air conditioner may be associated with the presence of other electrical appliances nearby: a stove, toaster, kettle, etc. And in this case, it is quite simple to exclude self-repair of split systems - we eliminate such an unsafe neighborhood and allocate a separate power source for climate technology.

Also, quite often there are malfunctions that manifest themselves in a completely opposite effect: during operation, the air conditioner creates strong drafts. Dealing with this problem is extremely simple.

Many models of modern split systems can independently eliminate the problem with drafts using a very useful function - auto-oscillation of blinds. Being in a horizontal position, the blinds very quickly neutralize drafts, while maintaining a fresh breeze that is pleasant for the body and safe for health in the room.

To avoid all these minor malfunctions, repair and maintenance of split systems should be carried out in a timely and competent manner. And doing it yourself will not be difficult, since it is very simple to do.

Causes of compressor malfunctions

Many, even fairly experienced drivers, are delusional, believing that the compressor is the most reliable unit of the car air conditioner and that there is simply nothing to service there. Sooner or later, such beliefs lead to the appearance of symptoms in the operation of the compressor that were not there before. For example, hum when the air conditioner is turned on. Since it is not always possible to determine the source of the appearance of extraneous noise due to the operation of the engine, if the owner of the car is inactive, the compressor quickly becomes faulty, which may require expensive repairs or a complete replacement of this unit.

The second most common compressor malfunction is clutch failure. If, when you turn on the air conditioner, you do not hear a characteristic click, which means that the clutch is engaged with the pulley, this is precisely what indicates a malfunction in this compressor unit. The magnetic clutch may break due to overheating of the compressor (for example, when the vehicle is stationary for a long time in a high ambient temperature), as a result of which the coil wiring is melted. There may also be a manufacturing defect in the clutch itself, which manifests itself in the formation of an unacceptably large gap between the pulley and the pressure plate.

If the car is old, then the reason for the loss of performance of the clutch may be its elementary wear. In this case, the repair of the air conditioning compressor of the car is carried out by replacing the clutch, which is carried out in almost the same sequence as the installation of a new bearing.

Compressor breakdown can be caused by clogging or depressurization. In the latter case, the problem can be eliminated by simply tightening the connections, if this is the reason for the depressurization. To clean the compressor, it is necessary to disassemble it, rinse it thoroughly and replace the repair kit.If you have never disassembled an air conditioner compressor, it is better to entrust this operation to professionals, especially if the housing parts have been damaged. Probably, the compressor inoperability is caused by the blockage of the main pipes. It is difficult to diagnose such a malfunction, but you can clean or replace the tubes yourself.

The reason for the noise when turning on and operating the air conditioner may be the lack of operating pressure on the discharge line. If the readings of the pressure gauges indicate exactly this, the compressor may also be the culprit - due to natural wear and tear, due to the filling of too much freon or due to its leaks. In such cases, troubleshooting of the compressor is performed, which makes it possible to clarify the nature of the malfunction and begin repair work.

Leakage is another common cause of compressor breakdowns. Usually, this result is caused either by a weakening of the fastening of the main pipeline, or damage to the stuffing box. In the latter case, it is unlikely that it will be possible to replace it on your own - it is much more difficult than replacing the bearing. However, you can reduce the cost of repairing an auto-air conditioner compressor if you remove it yourself and bring it to the workshop in this form. As practice shows, one month of driving on a leaked oil seal is enough for the compressor shaft (or rather, its outer part) to be completely covered with corrosion. So, most likely, it will need to be removed and resurfaced.

Piston seizure is the most serious compressor failure. Here, one replacement is not enough, since a broken piston usually damages both the cylinder walls and the valves. In such cases, the best option for restoring the compressor and the entire air conditioning system is to completely replace it with a new unit.

Typical malfunctions and their causes

For all household air conditioners, regardless of brand and cost, there are five types of problems:

- Decreased operating efficiency (low cooling capacity, poor heating)

- Strong draft

- Leaks

- Failure of the device (lack of response to remote control commands)

- Unpleasant odor coming from the device

To understand whether it is possible to repair air conditioners with our own hands, it is necessary to identify the source of the problem. Violation of operating standards and technical malfunctions are the main reasons for the failure of devices. They are the primary sources of all types of air conditioner breakdowns.

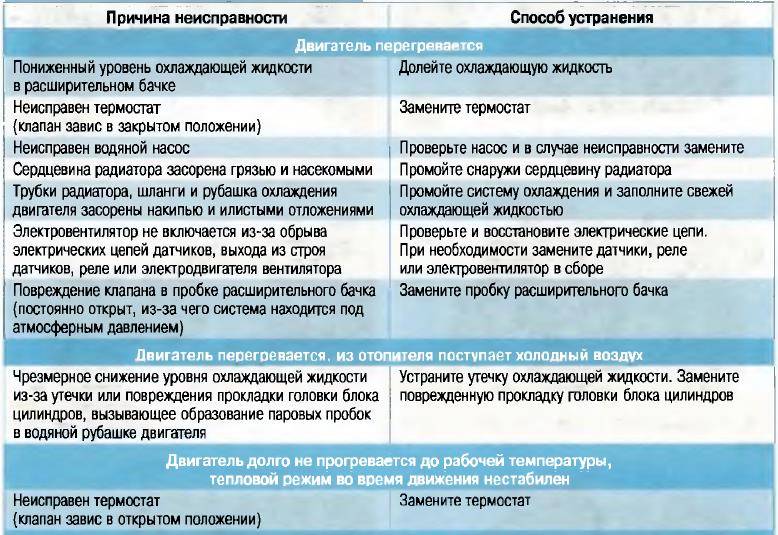

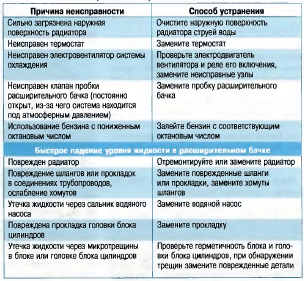

Decreased work efficiency

The most common category of malfunctions. Unsatisfactory operation of the air conditioner is caused by one of the following factors:

- Leakage of refrigerant (freon). It is caused by the depressurization of the cooling system of the device, it is solved by eliminating damage and refueling freon.

- Damage to the heat pump. Occurs due to a factory defect or natural wear and tear of the unit. It involves the repair of an air conditioning compressor or the replacement of its individual parts (fan, sensor, valves, evaporator).

- Clogged filters. It is the result of dust settling on the mesh of the external panel of the device, it is solved by flushing the filter, fan impeller and air duct cavities.

The stability of the mains voltage also has a significant effect on the efficiency of the air conditioner. The technician must be provided with uninterrupted power supply: repair the outlet or install a voltage stabilizer.

Draft

The problem occurs when software glitches or loose blinds. If the activation of the auto-oscillation mode of the curtains does not help, the position of the shutters must be adjusted. To do this, you will have to disassemble the device, so it is better to entrust such repair of air conditioners to a specialist.

Leaks

The malfunction is caused by blockages of the drainage system of the equipment with ice or debris. Ice plugs are typical for the cold season.In this case, cleaning the evaporator and refueling with freon will help.

Owners of equipment most often encounter blockages after repairing a home. The process of renovation of premises is inextricably linked with construction dust, which heavily clogs the device.

It is important for owners to remember that when the apartment renovation is completed, the air conditioner needs to be serviced. Deep cleaning will help to fully restore the functionality of the device and provide better air filtration in the room.

Device failure

In situations where the air conditioner has stopped turning on or responding to remote control commands, the problem is associated with three types of malfunctions:

- Low mains voltage. Use a multimeter to check the serviceability of the socket, plug and connection cable.

- Batteries. If all the elements of the power supply chain are normal, it is necessary to replace the batteries in the remote control.

- Software glitch. Repair work involves flashing the control board or replacing a broken part.

Electronics malfunctions are eliminated only by specialists from specialized service centers. Unauthorized intervention in the control system of the device is fraught with the occurrence of more serious malfunctions, the repair of which will cost much more than servicing the board.

Bad smell

The reason is the accumulation of microbes. Poor-quality ventilation, the repair of which involves antibacterial treatment of filters, cleaning the evaporator with a steam generator and flushing the duct channels, poses a threat to the health of the inhabitants of the room. That is why it is better to entrust the elimination of unpleasant odor to specialists.

Car air conditioner compressor device

The task of the compressor is to ensure the movement of freon in a closed loop. After the compressor, the freon enters the condenser, where, thanks to the blowing of air produced by the fan, it cools, condensing on the radiator tubes, changing its state of aggregation to liquid. Passing through the receiver, the refrigerant is cleaned of impurities and enters the thermostatic valve, the task of which is to inject freon into the evaporator in a metered dose. This is the unit that is directly responsible for cooling the passenger compartment. Here the refrigerant in the form of an aerosol is cooled even more, turning into a gaseous state. The working body of the evaporator is a radiator, or a system of pipes. When in contact with them, freon cools their surface, and the fan blows the cold back into the cabin.

The refrigerant moves on, being in a sufficiently cooled state, falling back into the compressor. Thus, the circle is closed, providing a continuous flow of cold air into the vehicle interior. The section from the compressor to the expansion valve is called the high pressure line, the area from the evaporator to the compressor is called the low pressure zone. The operating parameters of the air conditioner are monitored by sensors: in case of excessive pressure, which occurs, for example, when the car is in a traffic jam, the fan turns on at full power, helping the condenser to do its job - to convert the gas into liquid and thereby relieve the line. If this does not help, the emergency pressure sensor is triggered, turning off the air conditioner.

We have already mentioned that the compressor consumes a lot of energy, taking away about 5-15 horsepower from the power unit, and this power take-off on weak motors has a very noticeable effect on the dynamic characteristics. In addition, a running air conditioner causes an increase in fuel consumption (up to 1 liter per 100 km), which forces many drivers to drive with the air conditioning system off, despite the hellish heat. It is clear that open windows at low speeds are ineffective, and at high-speed driving this is a powerful source of drafts. So if you want to drive in comfort, you need to come to terms with the additional costs and reduced engine throttle response.

Repair of tubes and hoses

Timely diagnostics of the connecting hoses coming from the compressor and exposed to high pressure - a guarantee of long-term operation of both the compressor and the entire climate system. If the recommended frequency of checks is observed, the shelf life of the air conditioner compressor can be increased by one and a half to two times. The problem is that line hoses are prone to shocks and vibrations that are inevitable when driving on imperfect roads. Another risk factor is the close proximity of the hoses leading directly to the compressor with the exhaust manifold - a source of increased temperature. As a result, it is in these places that the drying out and cracking of the main pipelines most often occurs, which threatens to depressurize the system.

The same result is possible with aging of various rubber products - gaskets and O-rings. Finally, loss of tightness is also possible on metal pipes, which are susceptible to corrosion.

Therefore, it is so important to regularly visually inspect the main pipelines (especially in the high pressure area) and in all places where refrigerant leaks are possible. The fact that such is the case will tell the oil stains

In such cases, immediate repair of the leaky elements (hoses, tubes, gaskets, O-rings) will be required, and if this is not possible, their complete replacement.

How to remove the air conditioner so that freon does not leak

During the time there is a problem - freon flows out of the device.

When buying a new split system, the required amount of freon is located in the sections of the outdoor unit. The twisted service valves in the outdoor unit keep the gas inside its elements. There is ordinary air in the indoor unit. During the installation period, these 2 blocks are hermetically united by tubes, only after this action the taps open and the freon acts on the indoor unit. A closed circuit is formed, according to which freon circulates throughout the system.

If freon is to be conserved, then “pumping” it back into the outdoor unit is considered the only option. All that needs to be done is to turn on the taps when the freon is in the outdoor unit.

Procedure:

- We turn off the taps and attach pressure gauges to them. This action must be performed as carefully as possible, when the pressure gauges are connected, freon is released under pressure. Gloves must be worn to avoid burns.

- This method requires a hex wrench. With it, you need to close the tap of the thin tube. You need to turn the tap clockwise, applying effort, turn it all the way. At this moment, the pressure level on the pressure gauge will drop. After 15-20 seconds, when the pressure level drops to zero, you need to tighten the tap of the already thick tube. The device turns off immediately after all actions.

This method is best used only in the most extreme cases (during the cold outside, when the unit cannot be turned on). It is necessary to tighten the two valves of the outdoor unit (the air conditioner is inoperative). So it will be possible to save not all the freon, but more than 50%.

Saving freon

Using the above methods, you can fix minor problems in the operation of the air conditioner yourself, while saving your money on calling a specialist. More serious breakdowns in this type of equipment are extremely rare. If you regularly carry out preventive maintenance of the device, the likelihood of breakdown is significantly reduced.

Diagnostics of air conditioner malfunctions

However, it is possible not only to clog the filters, but also to clog other internals of the air conditioner. They also require periodic cleaning, otherwise unpleasant problems arise, one of which is the leakage of drainage.

The drainage pipeline is not insured against the settling of debris, which leads to clogging of the pipes, as a result of which the liquid in the indoor unit of the air conditioner flows out, making puddles on the floor in the room. This is an extremely unpleasant phenomenon.

You can eliminate the leakage by thoroughly cleaning the drainage channel (remove foreign particles from it). In the winter period of the year, a leak may appear due to the clogging of the pipe with an ice plug. To eliminate this problem, the best solution is to clean the evaporator, or additionally fill the air conditioner with freon.

If the air conditioner refuses to work, does not show a reaction to the commands that are given to it by the remote control, then first check the voltage in the power outlet. If you need to change the voltage, use a special device - a multimeter.

Determination and diagnostics of air conditioner malfunctions.

If the multimeter shows that the voltage in the electrical network is normal for the device to work, then the cause of the malfunction is different. In order to carry out an accurate diagnosis, first pull out the plug and completely de-energize the climatic equipment.

After a minute, turn on the air conditioner. If nothing has changed, it may be necessary to replace the batteries in the remote control, which is not difficult to do on your own.

During operation, a large amount of air is passed through the air conditioner, which is not always of ideal quality. Therefore, quite often, after a rather short time after installation, a new air conditioner begins to emit unpleasant odors after being connected to the power grid.

The reasons may be different, but most often this smell arises from bacteria accumulated on the filter elements of the air conditioner. To get rid of this problem, you need to treat the equipment filters with special antibacterial agents. The need for additional processing with the help of a steam generator of evaporator radiators is not excluded.