Paint and roller

It is necessary to understand whether a particular roller is suitable for working with purchased paint or not. The essence of the problem lies in the composition of the water-based paint. In the domestic building materials market, as a rule, several varieties of such a coloring composition are common:

- silicone;

- silicate;

- mineral;

- acrylic.

Acrylic water-based paint is perhaps the most commonly used. It contains a large number of acrylic resins and latex. The treated surface is almost 100% moisture resistant and is not even afraid of direct impact. This coating can be washed without any damage to the surface.

The silicone paint contains many complex synthetic compounds. With their help, the paint easily copes with filling small cracks in the surface with a depth of no more than 2 mm. Most often, this paint is applied to coatings that are very often in contact with water. The only drawback of such a coloring composition is its high cost.

Mineral water-dispersion paint contains cements or calcium hydroxide form. This type of water emulsion is ideal for application on walls and ceilings of technical premises, where the scale can be really huge, and there is no point in buying expensive material. The downside of this coating is its quick wear.

Silicate water-based paint contains colored glass as a key component. Such a coating is most often used for facade work and painting the outer contour of the building. This paint can withstand almost any weather conditions throughout its entire service life. Next, you need to decide on the roller. Most often, on the building materials market, you can find rollers made of pile, polyamide, foam rubber or velor.

Foam rubber products are mainly used for working with glue and varnish. And for working with water-based paint, foam rubber is certainly not suitable - it very quickly becomes saturated with the coloring composition and stops absorbing it, which results in stains and splashes. And the foam rollers have to be constantly changed, even when working with adhesive.

Lint rollers work better with water-based paint. Nowadays, it is practically impossible to find natural pile in stores, but with synthetic pile the situation is much better - on the shelves it is easy to find rollers with small, medium and long pile. Of course, the choice here should be made based on your own needs - rollers with long pile absorb a lot of paint, but it is much more difficult for a beginner to work with them.

Therefore, if you choose a roller with a nap, then it is better to stay on a model with a fine or medium nap coating.

Velor products are known for their excellent resistance to aggressive media of water-based paint, solvent or varnish. There are no pronounced drawbacks in velor rollers, and therefore they are often used to work on large industrial sites, where the use of a spray gun is excluded for some reason. Polyamide rollers are made from raw materials similar in properties to textiles.

The peculiarity of the production of such products lies in the fact that the pillow at the assembly stage is repeatedly stitched with a strong polymer thread - this significantly increases the strength of the product and its service life. For the general consumer, the polyamide roller comes first. This is especially true where you have to work with acrylic water-based paint.

In the domestic construction markets, you can most often find replaceable rollers of three serial standard sizes:

- up to 100 mm;

- 100-150 mm;

- over 150 mm.

Of course, the choice of the appropriate attachment is only a matter for the buyers. It all depends on what size the drum handle is and what needs to be painted. Generally, a long-handled tool is convenient when working in tall rooms. The standard size of the drum is selected both taking into account the tool and with an emphasis on the task at hand.

No one argues that work can be done faster with a 300 mm drum, but we add here the height of the walls of 4-5 meters, a telescopic handle and paint saturation of the drum - and the optimism of novice builders immediately disappears, as their hands will simply start to get tired faster. ...

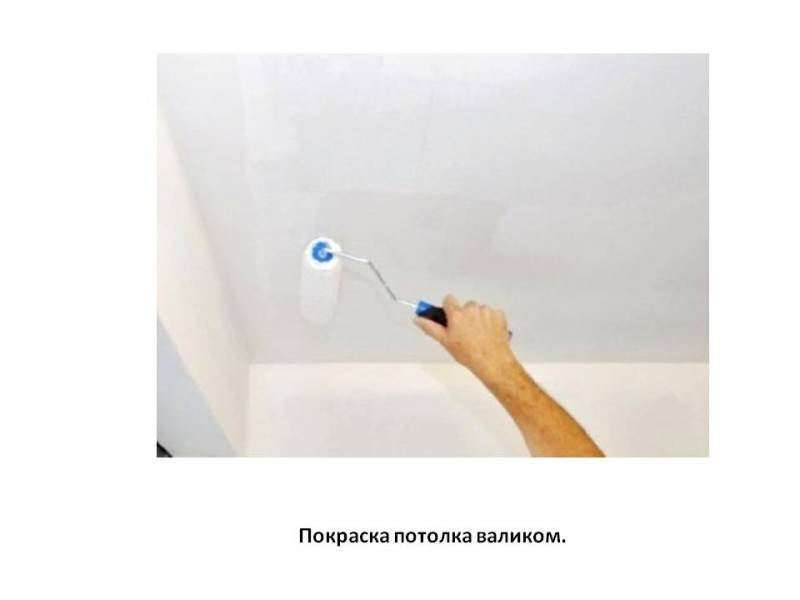

What roller to paint the ceiling

It is quite important to choose the right roller for painting the ceiling with water-based paint. Many people recommend testing the product before the purchase, so it is possible to prevent the purchase of a low-quality product.

Undoubtedly, cost comes first. As a rule, budget models are not able to provide high-quality painting, in addition, the operational life will be much lower.

It is best to do the following:

first of all, it is recommended to squeeze the roller and check it for deformation, if the tool is deformed, then it is better not to purchase it;

it is important to understand that if there is a seam on the fur coat, then the composition will fall on the surface of poor quality, as there will be traces;

when choosing a fur coat with a long pile, you should first tug on it a little, if after these actions there is a pile in your hand, then you should think about the quality of the product.

If you adhere to these simple recommendations, you can avoid buying low quality products.

How to choose a roller for painting the ceiling by type of construction

Today on sale you can find a large number of tools designed to apply a paint and varnish composition to the surface of the ceiling. Since it is quite easy to get lost in this abundance, it is worth understanding what options exist.

If we consider the design features according to the principle of operation, then in this case it is possible to distinguish the following models:

- A familiar submersible model.

- With a piston system that supplies paint. In this case, the pen is a kind of reservoir that can hold up to 500 ml of paint and varnish composition.

- Automatic paint supply. Such devices are expensive, but the payback comes from the high level of performance.

Thanks to this variety, you can choose a tool on a budget.

What kind of roller is needed for painting a ceiling like a fur coat

If we consider the finished product by the type of coating, then it is worth highlighting the following models:

- fur is a universal option suitable for all compositions;

- foam rubber - great for painting, but a limited number of paints and varnishes;

- velor - used mainly for varnish, the tool is intended mainly for professionals;

- threads or fabric is a great option for paints of any kind;

- models with a smooth surface - as practice shows, these options are intended only for smooth surfaces that have passed a preliminary preparation process.

The best option is a fur coat.

How to choose the size of the drum on the roller for painting the ceiling

When choosing a roller for applying paint, you should pay special attention to the size of the drum. Today the drum is found in 3 variations:

- Short - dimensions vary from 8 to 10 cm, diameter is about 10-15 mm. This option is great for places that are difficult to reach and for small areas.

- Medium - 15-20 cm, diameter 20 to 90 mm. An excellent option for painting the ceiling surface.

- Long - from 25 cm, diameter more than 80 mm.These models have reinforced fasteners, high quality nozzle material.

When you need to paint a small area, the choice of model is not so fundamental.

Important! Long rollers are considered professional.

What is the best roller handle size for painting the ceiling?

When you plan to paint the surface of the ceiling, you should choose the right tool for applying paint. As practice shows, the most popular tool for carrying out these works is the roller. On the market of goods and services on sale, you can find a large number of products that differ not only in the skin, pile length, material, drum size, but also the length of the handle.

As a rule, the length of the handle starts from 70 cm.Thanks to the presence of the telescopic base, it is possible to extend the handle up to 4 m

It is important to understand that not every product can be equipped with a long handle. That is why it is recommended to first take into account at what height the work will be carried out and on this basis choose a roller of suitable dimensions for work

Features of water-based paint

Since in most cases, water-based paints are used for processing the ceiling, it is worth considering their features in order to know how to work with them. The material is really very good - it does not smell, lends itself to wet cleaning and is easily applied to the surface of the ceiling, as a result giving it a rather attractive look.

In short, the main advantages of water-based compositions can be summarized as follows:

- Environmental friendliness of the composition - the paint does not contain synthetic and toxic impurities;

- The paint has no characteristic odor;

- After application, the paint forms a uniform coating, i.e. we can talk about the high visual qualities of the material.

Water-based paints are classified, depending on the main component, into the following types:

- Acrylic;

- Silicate;

- Silicone;

- Mineral.

Each option has its own characteristics. For example, after curing, acrylic paints are almost impossible to wash off - they contain adhesive and latex components that improve adhesion to the ceiling surface and ensure its water resistance.

Operations with different tools

Painting the ceiling with water-based paint is a process that each master does in his own way, so the result can be very different. The work uses brushes, rollers or spray guns.

Brush painting

For many, this kind of work is greetings from the Soviet past, but in this case, a decent result can not be expected, since all the divorces and smears will be present. Another disadvantage of the method is the overconsumption of paint, which willingly leaves the brush, splashing on the floor and the master. Uneven coloration is the reason why some layers contain more water-based emulsion.

This method is applicable in summer cottages, for utility rooms, in workshops or garages, but it must be borne in mind that this work will steal at least three times more time, and it will take money for water-based paint, because you need to keep within 20 minutes.

Roller painting

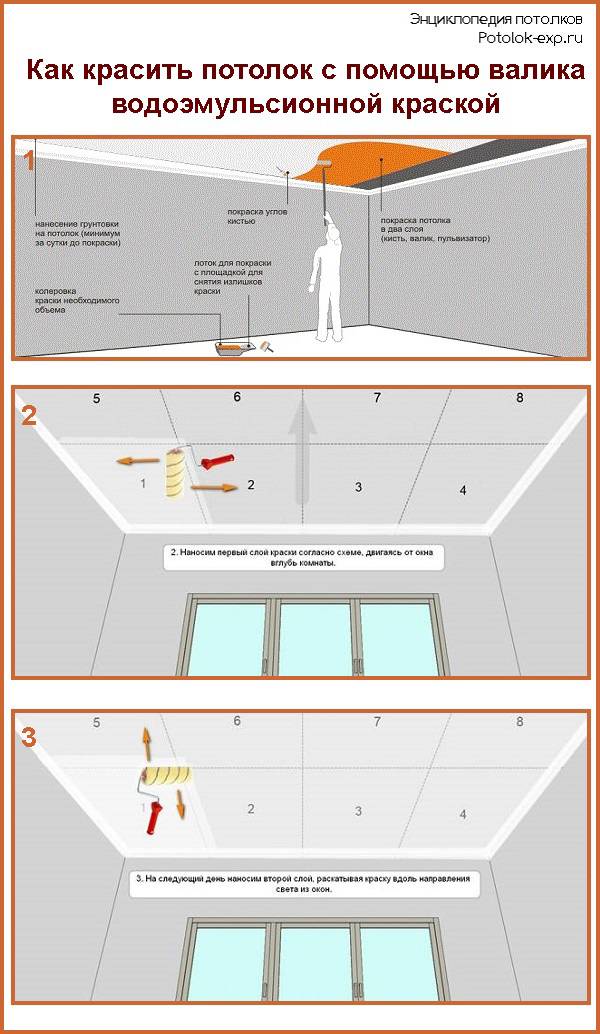

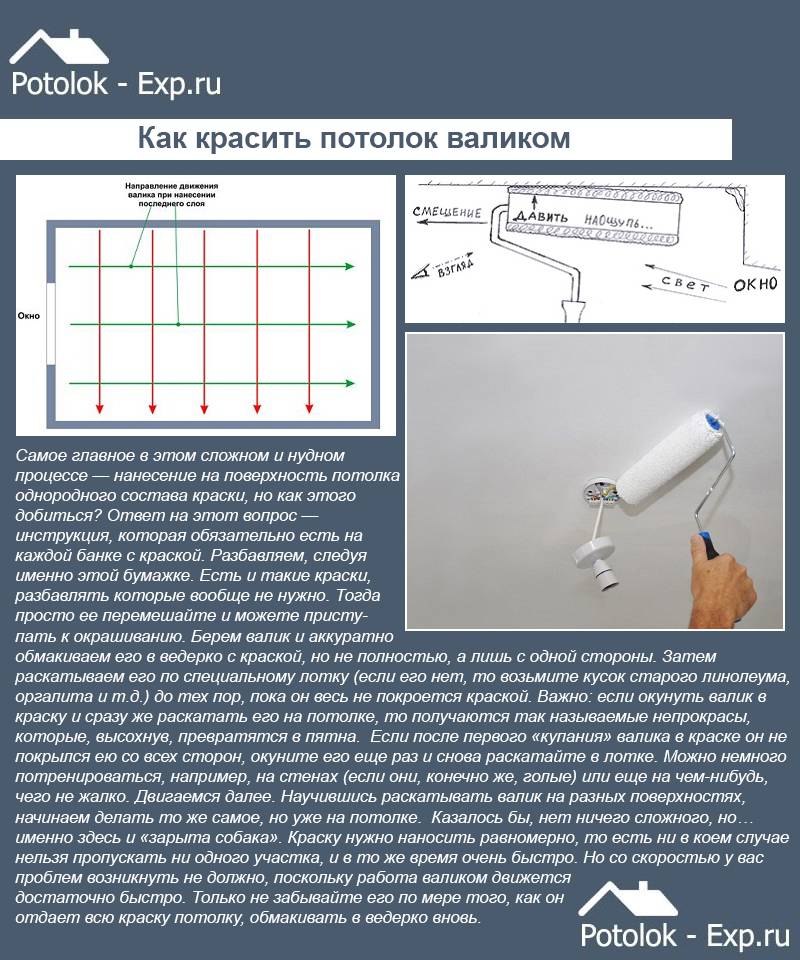

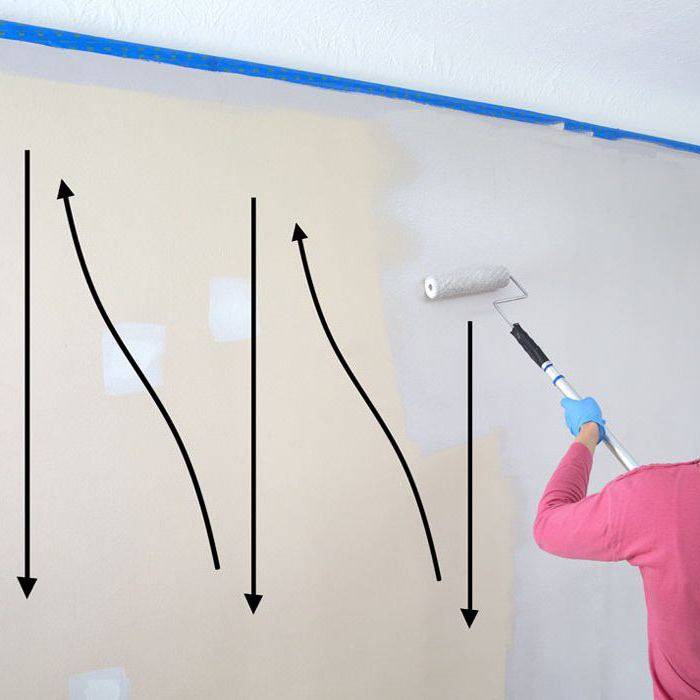

This option, on the contrary, makes it possible to get a ceiling without streaks and other defects. They act when stained in this way, which has already become traditional:

- The joint of the walls and ceiling around the perimeter of the room is sealed with masking tape. All surfaces are protected from water-based paint with plastic wrap.

- Prepare the composition for work: stir or dilute with water, following the manufacturer's instructions. Experienced craftsmen advise to dilute the paint for the first layer a little thinner. Mix the composition with a mixer nozzle. Grains that appear on the surface of the paint are removed by filtering the mixture through a triple layer of gauze.

- With a large brush, paint over the joints of the ceiling with the walls and places that are hard to reach for the roller (for example, heating pipes).The brush is dipped into the container by a third, be sure to squeeze it against the edge to remove excess that will not allow you to get a thin layer. Correct the "picture" with a small tool.

- The water emulsion is poured into a cuvette, then moistened (rolled) in the roller along its entire length (width) until the entire surface is evenly covered with paint. Apply a water-based emulsion from the corner.

- The width of the strip is maximum 50 cm, the overlap is 5-10 cm. The handle of the roller is held at an angle of 45 ° to provide better control over the contact of the pile of the instrument with the surface. The quality of the work is checked by directing the light of a flashlight to the site. Or they simply change the viewing angle.

- The nodules that appear are removed with a worked-out (already without paint) roller. Overlap marks - W-shaped movements. The finished surface is left for 12 hours so that the layer is completely dry.

Working with a spray gun

Painting the ceiling with water-based paint using this device is the most enjoyable operation, because it not only guarantees a flawless appearance of the ceiling, but also goes quickly, easily, without much effort. The process itself looks like this:

- First of all, water-based paint is diluted with water, since the composition for the roller and brush is too thick for this tool. Then the paint is filtered without fail, this is required by the nozzle, which is clogged even with small particles.

- Before starting to paint the ceiling, regulate the flow of the mixture. To do this, select another surface as a target, which is "watered" for about 20-30 seconds. Having stabilized the flow, they proceed to painting the ceiling.

- They try to keep the nozzle perpendicular to the processed plane, the distance from it to the tool is about 50 cm. The rate and speed of staining are controlled, the ideal is 1 m2 in 5 seconds.

- Painting is carried out in squares: movement in one direction alternates with a transverse direction, then proceed to the next section. Delays are avoided, because the consequence of such a slip will be a thicker layer of water emulsion. Underpainting in this case is much better, since it will subsequently be reliably hidden by the second layer. The optimal number is 3.

Painting the ceiling with water-based paint is a task that is very difficult to call super difficult, and a decent result will provide a premature acquaintance with the features of work and potential mistakes that are easy to avoid.

The following video will tell you how this work is going on:

How to choose the right roller

Water-based paints differ in their composition, but the basis for all is water, which also serves as a thinner. In each case, the components provide a different viscosity (ductility) of the mixture, which affects the choice of tool.

To choose a roller for an aqueous emulsion, you need to pay attention to several basic parameters:

- Fur coat material. For these purposes, foam rubber, natural or artificial fur, acrylic, velor and other varieties can be used.

- Fixture size. There are variations in the length of the nozzle, each suitable for a specific task. The width of the pillow is also important.

- The possibility of replacing the components. The parts of the tool can be separated, which allows you to change the fur coat if it becomes unusable or another material is needed.

- Fastening. The bracket can be fixed from one or both sides, which affects the functionality of the roller.

Modern rollers are equipped with a convenient fur coat attachment system, which makes it easy to change the nozzle

Modern rollers are equipped with a convenient fur coat attachment system, which makes it easy to change the nozzle

Evaluation of all parameters will allow you to paint the surface with high quality and without flaws.

Material for fur coat

Paint rollers are usually divided into three main types, depending on the material:

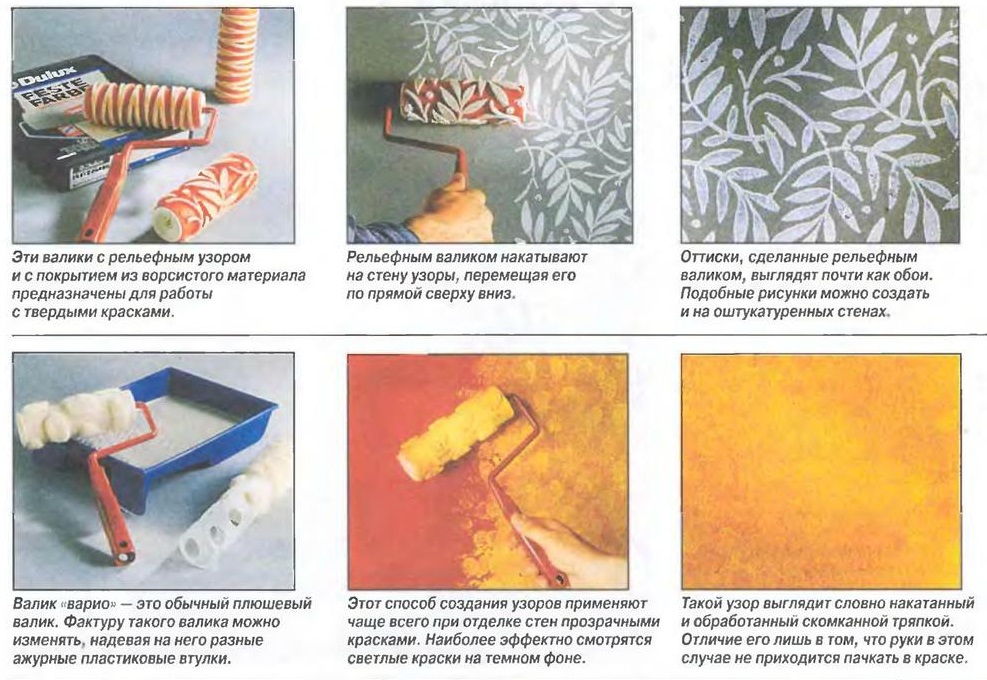

- Plastic. These fixtures do not belong to direct application tools, they are used to give the surface a certain texture.

- Foam rubber.This option is considered one of the most popular, due to the low price and availability. With obvious advantages, it is this variety that has the most disadvantages, especially the rapid loss of its original form stands out. This tool is great for applying varnish, primer, adhesives and oil-based paints. When working with a water-based emulsion (regardless of its viscosity), many problems arise. Firstly, the foam rubber absorbs the coloring composition well. This leads to the fact that when working with the ceiling, most of the mortar falls on the floor, and when painting the walls, drips that are difficult to remove are formed. Secondly, such a roll promotes the appearance of bubbles, which impart irregularity to the surface.

Foam paint roller is one of the cheapest and requires some experience.

Foam paint roller is one of the cheapest and requires some experience.

-

Hairy. This category includes materials whose fur coat has different lengths:

- Short pile. This is the best option for bases that have been thoroughly prepared. If the walls or ceiling have a rough structure, then the lack of paint on the instrument will have to be compensated for by frequent dipping into a container with the composition.

- Average. This size is considered universal, since in this case the paint is absorbed in the required volume and evenly distributed over the surface.

- Long. A large amount of composition and structure of the pile contribute to obtaining a thick layer and good texture of the coating.

Fur coat pile length

Fur coat pile length

The disadvantage of this tool is hair loss. If the problem is permanent, then the coat needs to be replaced.

Width and size of the cylinder

The size of the working surface of the roller affects the time and characteristics of the process. The range of the cylinder width can vary from 5 to 30 cm, and the diameter - from 4 to 11 cm. The size gradation is as follows:

- Mini. The width of the tool is no more than 10 cm, and the diameter is up to 3 cm. They are used for work in hard-to-reach places, well suited for small areas.

- Average. Width - up to 15–18 cm with a diameter of up to 6 cm. The standard size that is used for work on prepared surfaces, including painting wallpaper.

- Big ones. More than 18 cm wide and over 6 cm in diameter. This is a specialized tool that requires certain skills to work with. Not suitable for low viscosity water emulsion.

Different roller widths help you to complete any task, from painting corners to façade work

Different roller widths help you to complete any task, from painting corners to façade work

There are also corner rolls, which have a small cylinder with a diameter of 5 to 12 cm.

Bracket attachment

The fixing of the bracket affects the order of work. There are two options:

Fastening on one side. This is a classic variation that allows you to change hands. Ideal for painting walls. The design can be collapsible or non-collapsible.

Tool with two-sided fixation. Allows you to quickly paint the ceiling and obtain surfaces of excellent quality

This is ensured by a uniform load, which is important when working at heights.

Roller selection

To understand which roller is better to paint the ceiling with water-based paint, they need to be compared with each other.

| View | Characteristic |

|---|---|

|

Fur |

Are popular. Working with them is a pleasure, since the material saves paint, that is, the entire volume that it has absorbed is transferred to the surface. With the help of them, you can create a perfectly even coating without further ado. They have a high price tag. Suitable for water-based, latex paint. With this tool, you don't have to ask the question of how to paint the ceiling with a roller without streaks.

Disadvantage: Lint can remain on walls or ceilings. |

|

Thread |

Convenient to use, best in quality. It is difficult to work with them, as they are capable of splattering the dye. |

|

Velor |

Suitable for: acrylic, lining, water-dispersion, water-based, latex paints. They are not afraid of solvents, wear-resistant.

Disadvantage: it is costly, the velor material pulls a lot of paint over itself, because of this it is often necessary to dip it into the emulsion. |

|

Foam |

Has a low price. After applying the enamel to the wall, small bubbles form that cannot be hidden. The foam material excessively absorbs paint, which drips during painting, forming a streak. The material is not durable. Suitable for varnished materials and adhesives. If you have a question about which roller to paint the ceiling with acrylic paint, then a foam tool will help solve this problem. Not suitable for embossed structure. |

Types of water-based paint

Before painting the ceiling with ceiling paint, you need to familiarize yourself with the variety of water-based formulations. They are used much more often than acrylic or oil ones.

Water-based paints are less toxic and smelly and do not need to be diluted with solvents such as acetone or white spirit. To achieve the required consistency and follow the recommendations on how to properly paint the ceiling with a roller, you need to add plain water to the coloring composition.

The water-based coating is resistant to vapors and moisture; conventional detergents are used to remove dirt from it.

There are the following types of such paints:

- Silicate... For their manufacture, the so-called "liquid glass" is used. They should not be used in rooms with high humidity, but they are suitable for painting the ceiling surface in living rooms.

- Mineral... They are made on the basis of lime or cement. Such compositions are used for facade work.

- Acrylic-latex... In addition to the coloring pigment and water, they contain low-toxic resins, due to which the coating acquires a gloss or dullness, which depends on the type of composition.

How to paint a ceiling with a roller

Painting is carried out in several stages:

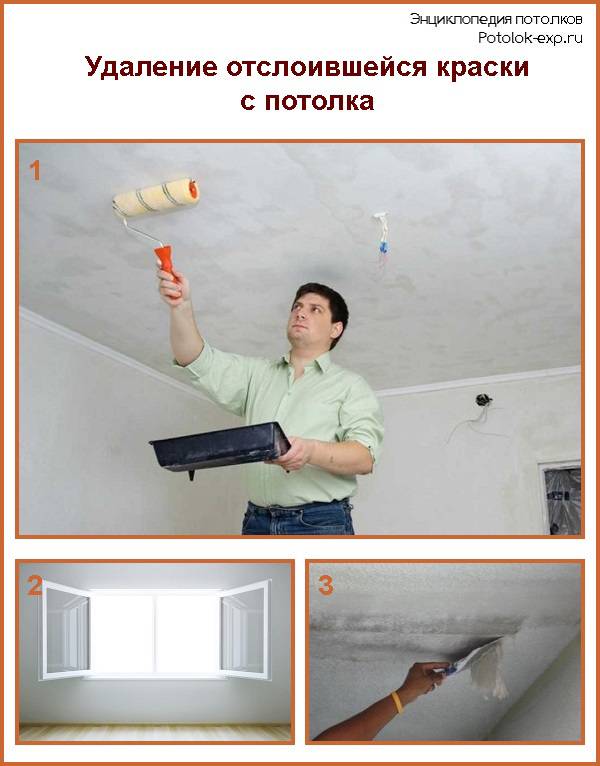

- Surface preparation.

After you have taken out all the furniture from the room and covered the one that cannot be taken out with plastic wrap, you can start preparing the surface for painting.

- First you need to clean it from the old whitewash.

- If there are seams on the ceiling, it is necessary to free them from the old putty with a spatula and carefully seal them with fresh compound.

- Sand the surface with sandpaper and remove all dust.

After cleaning and processing the seams, a primer mixture is applied

The primer should be applied starting from one of the corners and moving along the perimeter, proceed to the treatment of the entire surface of the ceiling, paying special attention to the corners and hard-to-reach places. This is done for so that the plaster adheres tightly and does not crumble

Figure 2. Painting the ceiling in stripes.

Next, using a special compound and a spatula, it is necessary to plaster the ceiling to obtain a perfectly flat surface. After finishing the putty, you should walk with fine sandpaper over the entire surface, destroying all irregularities and defects.

- Coloring.

The choice of paint must be taken very responsibly, because the process and quality of staining, appearance, durability of the finish, as well as the serviceability of the tool will depend on this. If the paint is not thinned enough, then the roller will have to work in difficult conditions, and it will quickly deteriorate. For example, a foam covering begins to flake and tear.

The most suitable for painting the ceiling is water-based paint. It ensures the application of an even and uniform layer, dries quite quickly, is non-toxic, does not have an unpleasant odor, and is easily washed off from hands and used tools.

After completing all the preparatory work, you can directly start painting the ceiling with a roller.

- Use a brush to paint over all the corners and other hard-to-reach areas.

- Then pour paint into the tray, dip the roller and roll it on the wringing net several times.

- After the roller is saturated with paint on all sides, start painting by rolling it over the surface of the ceiling.

- Apply stripes 50 centimeters wide to ensure the paint is applied correctly and evenly.

- The new strip must necessarily fall on the previous one by at least 10 centimeters to avoid the presence of gaps.

- When painting, do not tear the roller off the surface, and as the paint is consumed, increase the pressure.

- When the roller runs out of ink, dip it back into the tray.

Figure 3. Painting the ceiling in a perpendicular way.

And so continue until the end of the painting.

After you have applied the first coat of paint, you need to wait until it is completely dry, and then apply the second coat in the same way. However, keep in mind that the joints of the first layer should never coincide with the joints of the new one.

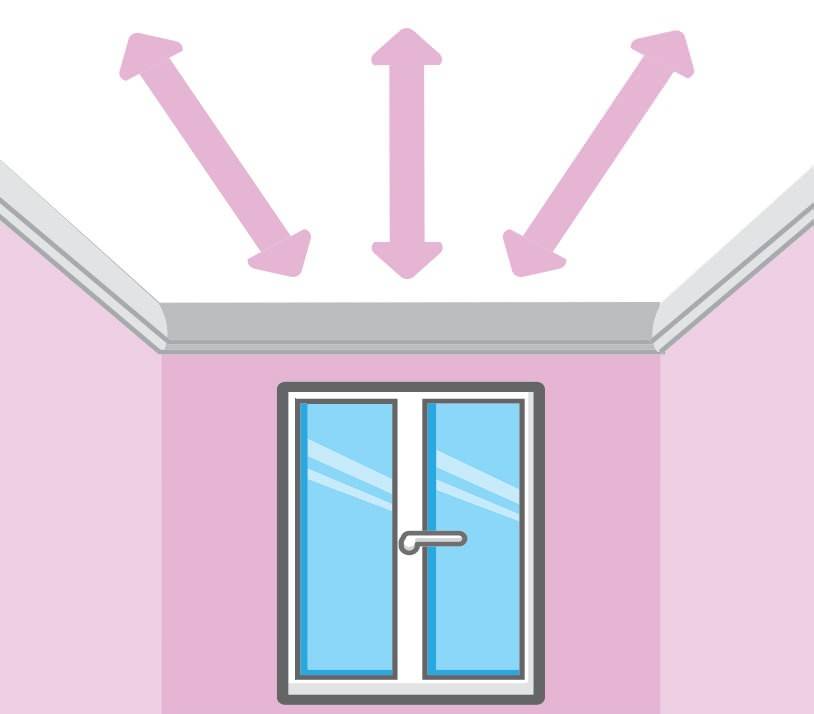

There are two ways to paint a ceiling surface correctly:

- Stripes, from one side to the other and vice versa. This method allows you to paint the surface perfectly without leaving any gaps. Figure 2.

- First, paint the surface horizontally, and apply the second layer vertically. Figure 3.

After finishing painting work, you need to thoroughly clean the tool and send it to storage.

Otherwise, the tool will deteriorate and you will never be able to use it.

If the work was carried out using water-based paint, it is necessary to wash the tool in water and, so as not to cause its deformation, without wringing it, hang it to dry.

When varnishes or acrylic paints were used to paint the surface, a special composition will be needed. The cleaning procedure must be performed immediately after completion of work.

How to choose and prepare paint

There are different water-based formulations. Each of them has features that will need to be taken into account when choosing a paint:

- Acrylic. Such a water emulsion is good in that it allows you to get a smooth surface, hiding small defects, such as small bumps or cracks. It serves for a long time and has a low consumption when painting. Acrylic paints are suitable only for dry rooms, but they are resistant to wet cleaning. The disadvantage of acrylic is the high price, as well as the impossibility of painting a poorly dried surface.

- Silicates. This coating is resistant to moisture and is suitable for outdoor work, for whitewashing the ceiling on balconies and verandas.

- Mineral water emulsions. Such compositions adhere without problems to any surface, but they are also easily washed off, therefore wet cleaning is not available for a surface painted with a mineral emulsion. These paints are the cheapest.

- Silicone. Such paints are attractive because they allow you to get a smooth ceiling even without careful preparation. Silicone emulsion can mask gaps up to 2 mm. It is suitable for ceilings in bathrooms and other damp rooms. The disadvantage is the high cost.

Taking as a basis the characteristics of the listed compositions, you can choose exactly the one that is most appropriate for painting the ceiling in a particular room. You can choose matte, semi-matte, glossy or semi-glossy water emulsions by color. There is an instruction on the container with paint, which describes the order of work. Some paints need to be diluted with water, others just need to be stirred.

If the emulsion is diluted with water, this happens gradually. After adding water, everything is mixed, and then the resulting composition is tested on a small area of the surface.

Removing stains

It is also necessary to remove all noticed stains from the surface of the floor slab.

The cleaning method directly depends on the type of pollution:

- Fat... To remove the greasy stain, you will need a piece of rags and a 5% aqueous solution of soda ash.Pressing the wet cloth against the contaminated area, you must wait for it to disappear. Upon completion, I wash off the solution with clean water.

- Mold... Biological formations are well removed by ordinary "Whiteness" diluted with water. Having smeared the spots of mold and mildew, you must wait until the solution is completely dry.

- Rust... You can remove such a stain with an aqueous solution of copper sulfate. Another option is to paint over the rusty area with white oil paint.