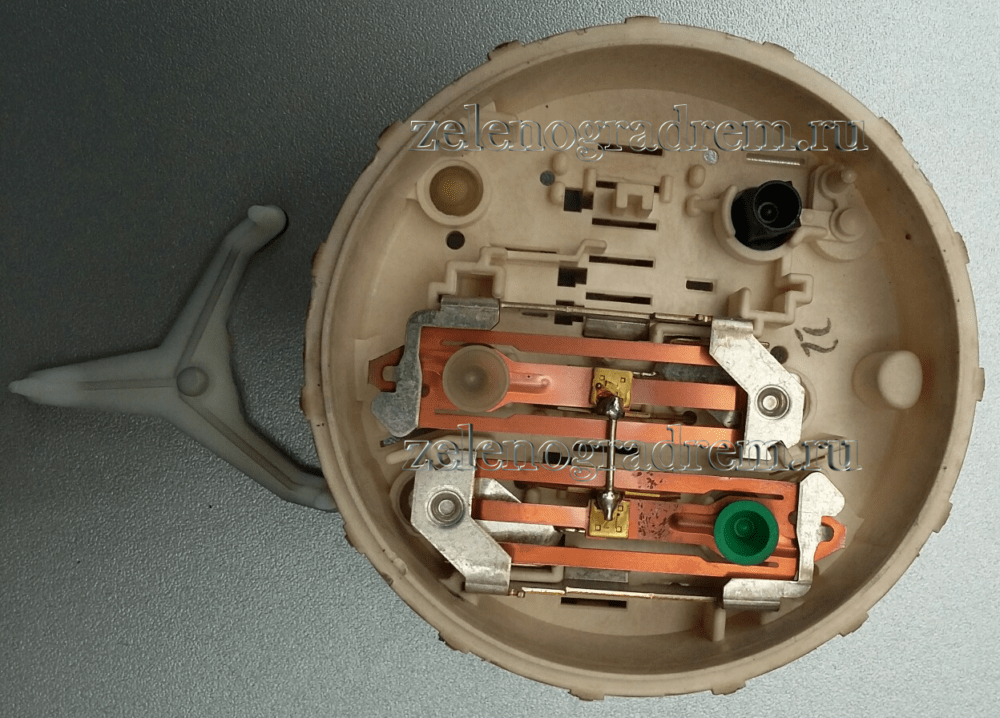

Before opening the pressure switch

After detecting a malfunction in the system, it is necessary to understand whether the pressure switch was really the cause of this. Carefully inspect the filling system, examine the hose and connection of the water intake sensor, its transition chamber. The inspected elements should not contain:

- scuffs, tears;

- plaque from detergents.

If you find dried detergent on the parts, be sure to rinse the accessories and try again to start the machine. Perhaps these measures will help restore the pressure switch to work.

Next, it is worth checking the stability of the connection of the supply wiring to the sensor. Perhaps a wire is frayed or bent. If a defect was found, eliminate it and check the washing machine for operation.

And, finally, it is necessary to view the contacts of the pressure switch, if they are dirty, they should be cleaned. Then start checking the water intake sensor. For diagnostics, you will need a tube with a diameter similar to the permanent sensor hose. One end of the tube will have to be put on the inlet of the device, slightly blow into the free second hole. When the sensor is working properly, it makes a clicking sound. If after such a check no problems were found, it is necessary to disassemble the pressure switch.

Hardware check of the sensor

Before trying to check the pressure switch on a Bosch Maxx 4 (or Samsung) washing machine using a tester or improvised means, you should weigh the rationale for this action. If the washing machine is under warranty, unauthorized interference with the operation of the unit will become a reason for refusing warranty service by the seller or manufacturer.

Sequencing:

- Unplug the power cord from the socket.

- Dismantle the top panel by removing the two small screws located on the back side and sliding the panel back and up.

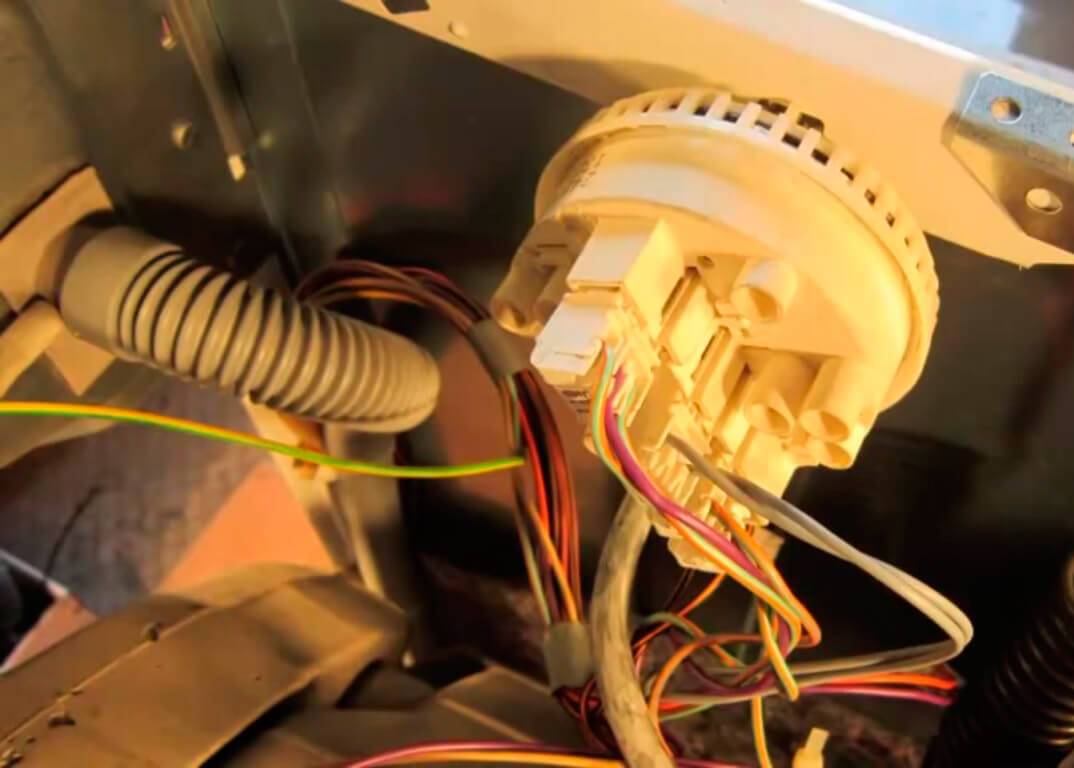

- Find the sensor cantilevered to one of the walls of the case.

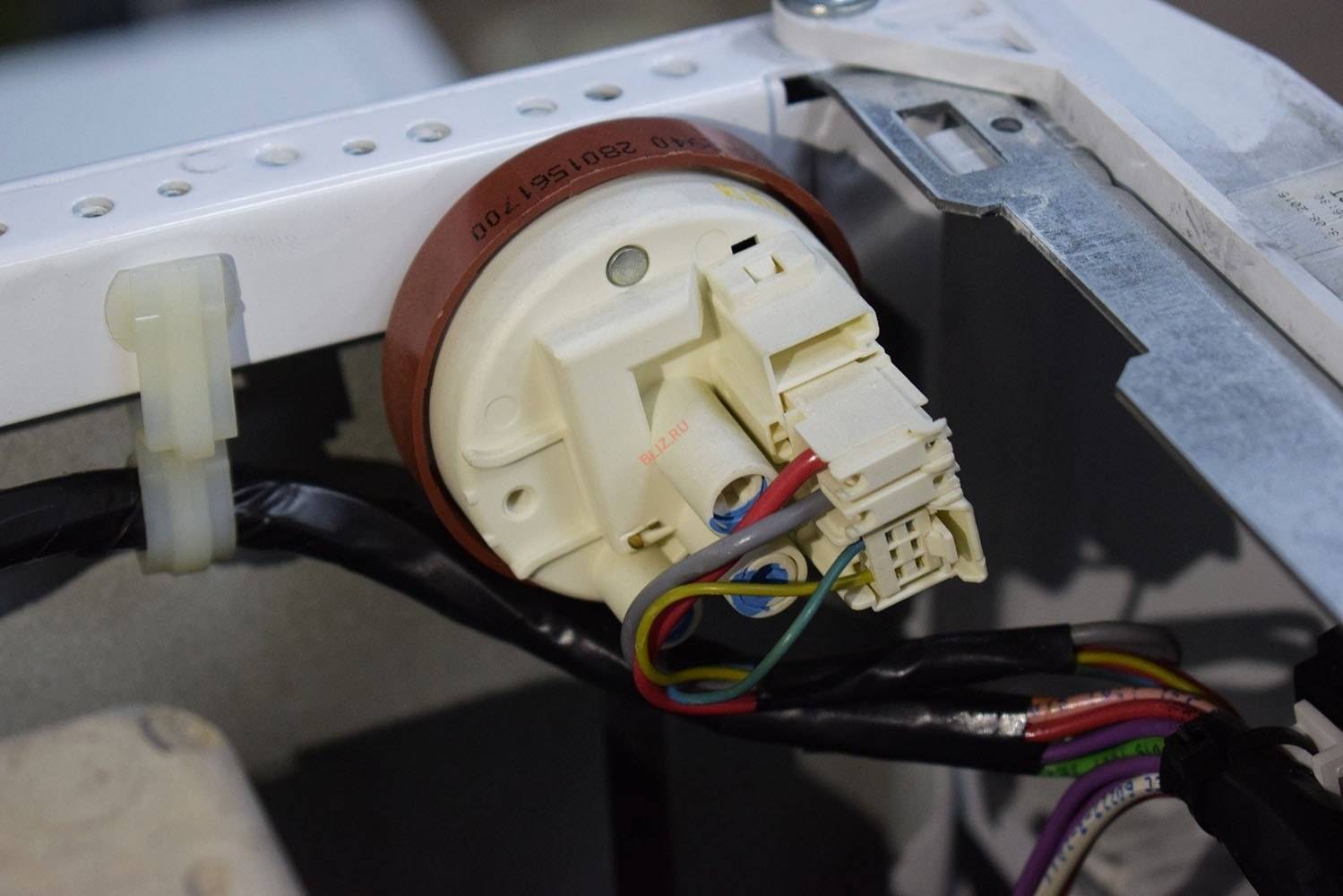

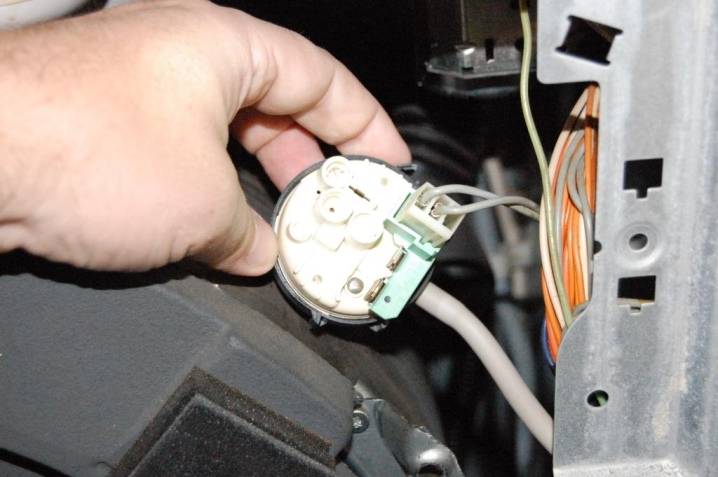

- Remove the connector, release the fastener (screw), pull out the sensor hanging on the tube from the machine.

- Using pliers, open the clamp on the inlet pipe and remove the device.

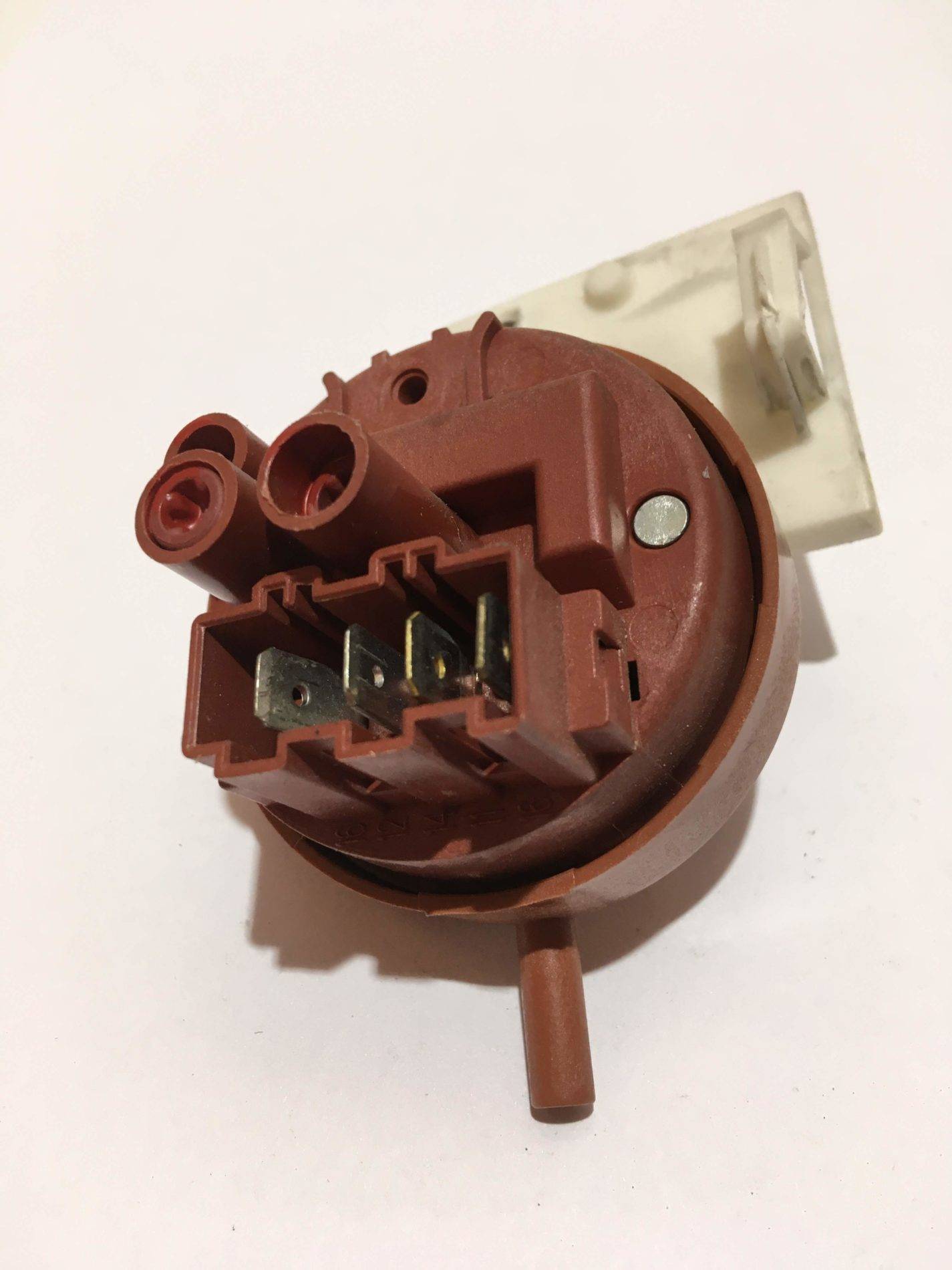

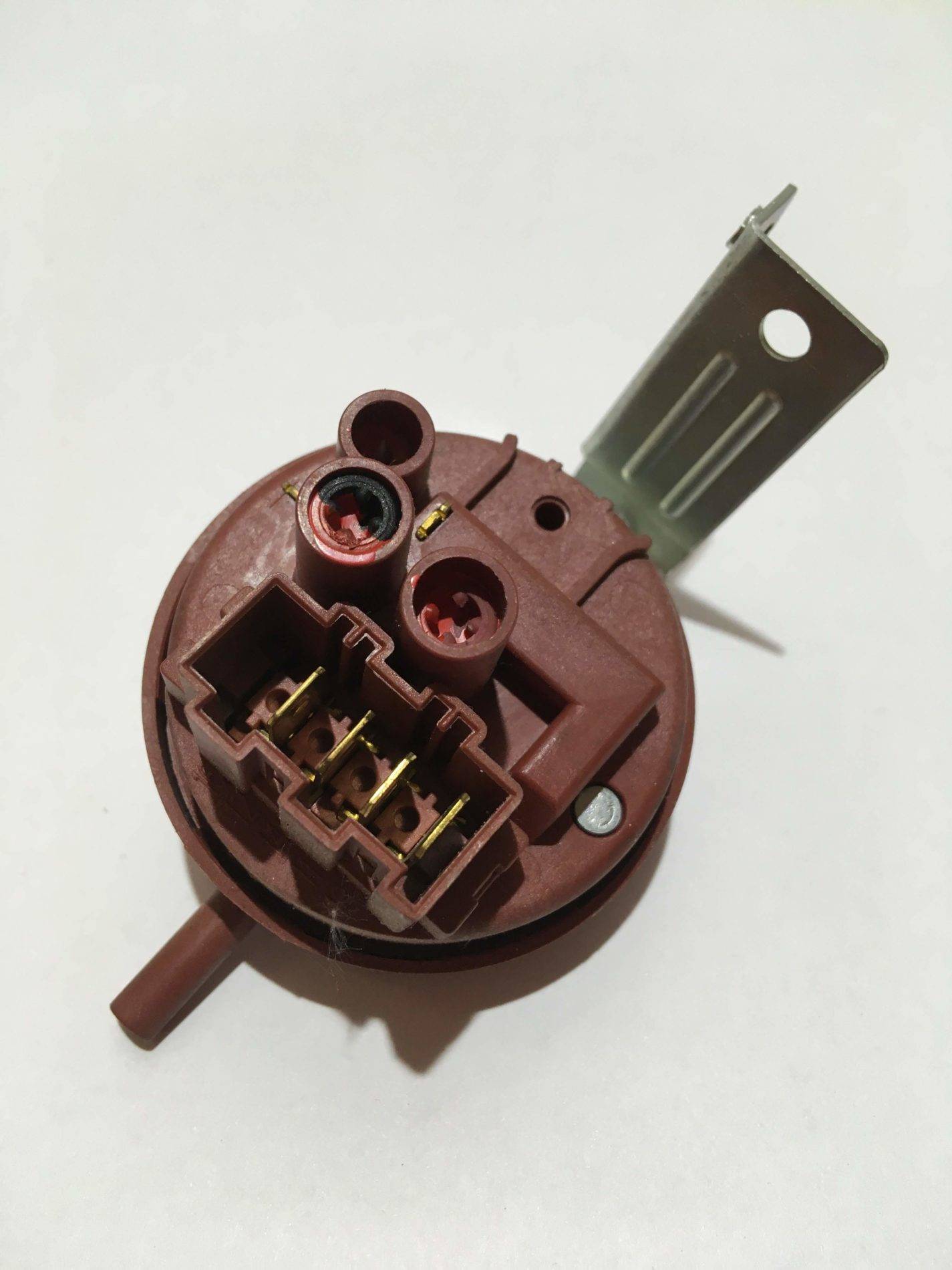

Water level switch

Before checking the adjustment of the device with tools, the overall performance of the sensor can be assessed. To do this, you need a piece of tubing that is identical to the rubber tube of the relay. Having pulled the device out of the machine, you need to connect it to a short tube, blow strongly into it and determine if the switch inside the device clicks in response to a change in pressure. If not, the sensor is faulty.

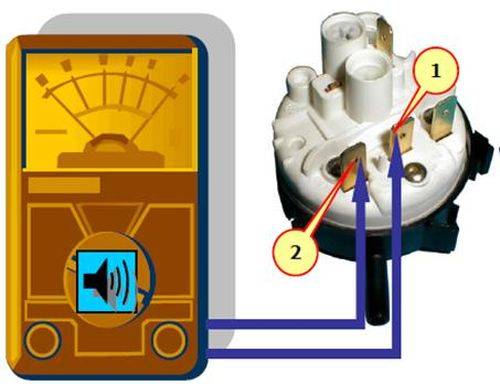

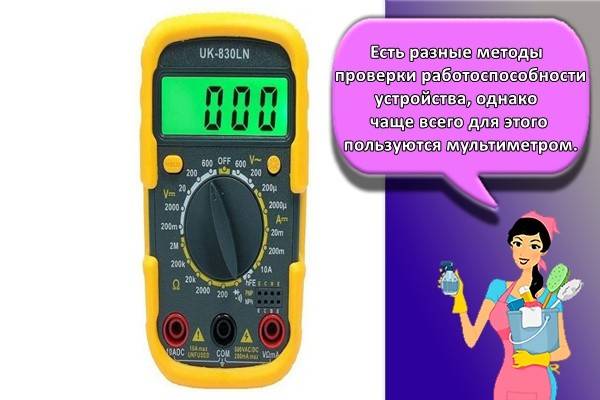

To check the pressure switch of an Ariston, Samsung, LG or Bosch washing machine using a multimeter, you need:

- prepare the device for testing resistance;

- place the probes of the multimeter on the contacts corresponding to the electrical circuit of the sensor;

- pressurize the air tube until a certain relay contact is activated.

If, when the contact is triggered, the resistance value has not changed, then the sensor must be replaced.

Checking pressure switches

Replacing the sensor

It is not possible to repair the pressure switch in all cases, so the best solution would be to purchase a new one and replace it. Replacing the sensor is expected to be of the same type and model of the washing unit. Before purchasing a new node, it is recommended to do the following:

- Clearly rewrite the name of the worn out pressure switch, rechecking each symbol or letter.

- Inform the model to the seller in order to exclude the possibility of an error.

Ideally, it would be the purchase of a labeled relay, in accordance with the number written on the body of the sensor.

To install, just use the following algorithm:

- Install the tube originally removed from the used pressure switch in the same place, but only on a different sensor.

- All electrical wires must be connected to the sensor.

3. The pressure switch is installed in the designated place using the bolts.

- The upper cover of the washing unit is re-installed in its intended place, and you do not need to forget about fixing it to the bolts.

- Now you can connect the machine to the electrical network.

- Loading laundry into the drum is the next operation.

- Set the recommended mode for washing and start the mechanism.

After the repair has been carried out, it is strongly recommended to be nearby to observe how the unit is functioning, so you can conclude whether everything was done correctly. In the absence of comments and other failures, there is reason to believe that everything is fine.

How to check the sensor

To make sure that the sensor is working, you need to check it. There are several helpful guidelines to help you check the health of a part.

Where is

Before proceeding with dismantling, you should understand the location of the product. Many washer owners mistakenly believe that the part is located inside the drum, but this is not the case. Most manufacturers install a level switch on the top of the drain box, which is installed near the side wall. This arrangement is considered very convenient, as it simplifies the removal of the product from the structure.

However, on some models, the sensor can be installed in other places. For example, in modern models of Samsung or Ariston washers, the part is installed on the right near the front wall. In Bosch machines, the relay is placed in the central part of the left side wall.

How to dismantle

It is quite easy to dismantle the pressure switch on your own. However, despite this, you need to familiarize yourself with how to do it correctly. The dismantling process is carried out in several sequential stages:

Removing the top cover. To get rid of it, you will have to unscrew the two bolts that are located on the back wall. Then the top cover is gently pushed back and removed.

Detachment of the part. The relay is connected to wires leading to the control unit and a hose

Before removing the product, you must carefully disconnect the wiring with the hose.

Removing the pressure switch. It is connected to the wall with fixing bolts that must be unscrewed.

Checking with a multimeter

There are different methods of checking the device's operability, but most often they use a multimeter for this.

It is pre-set in resistance mode, after which the probes are connected to the contacts of the removed part. After connecting the probes, the values on the tester display should change. If the numbers have not changed, then the relay is faulty and it will have to be completely replaced with a new one.

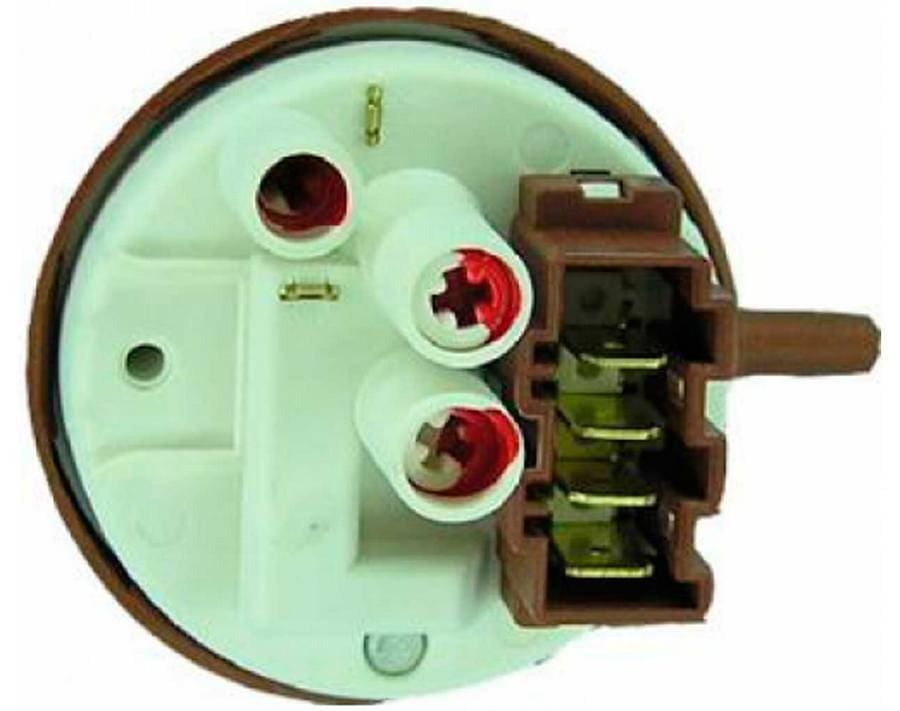

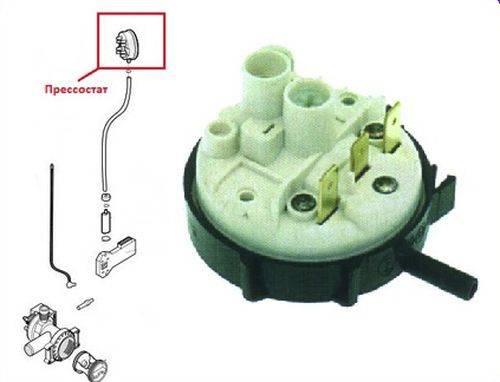

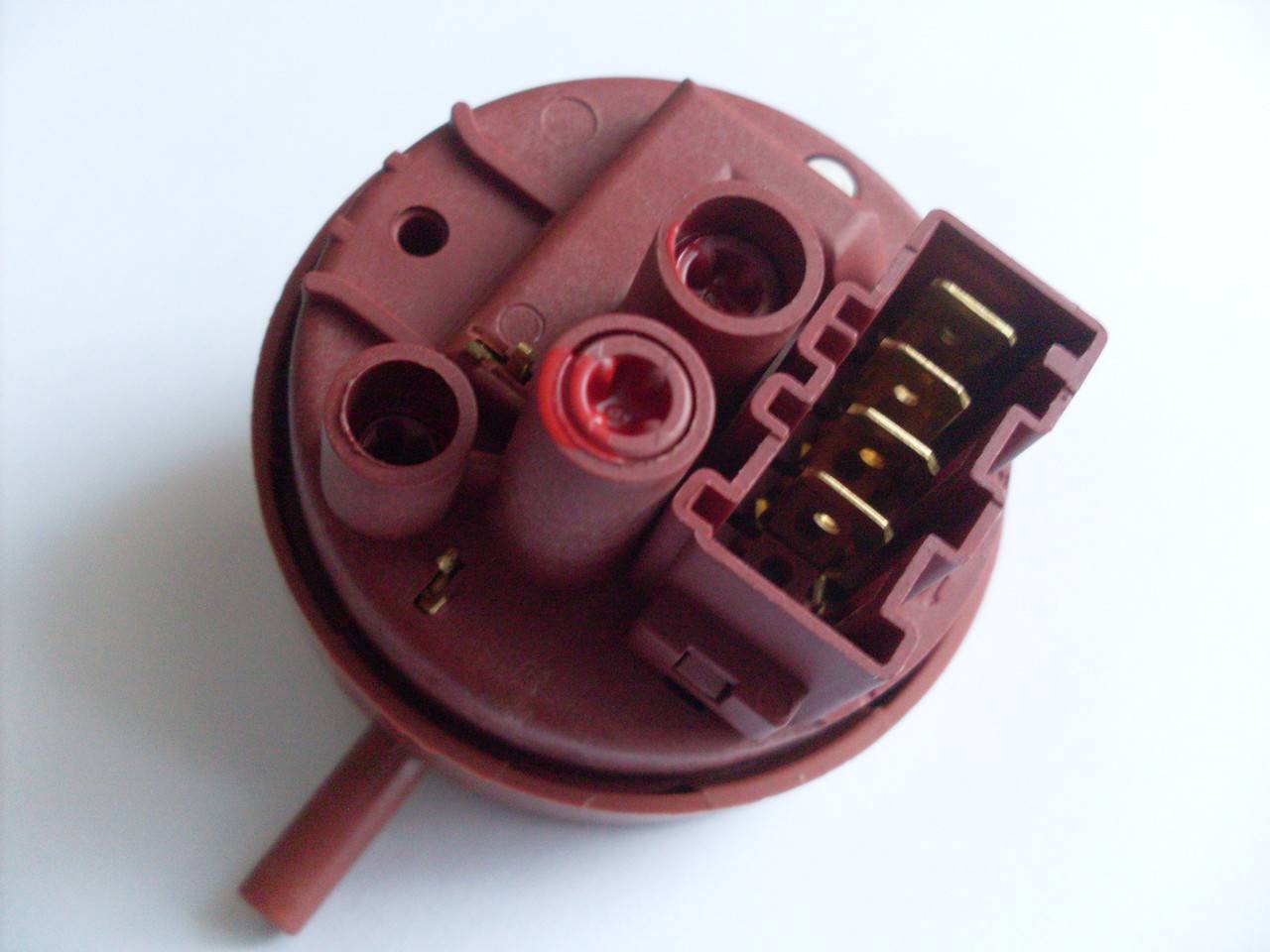

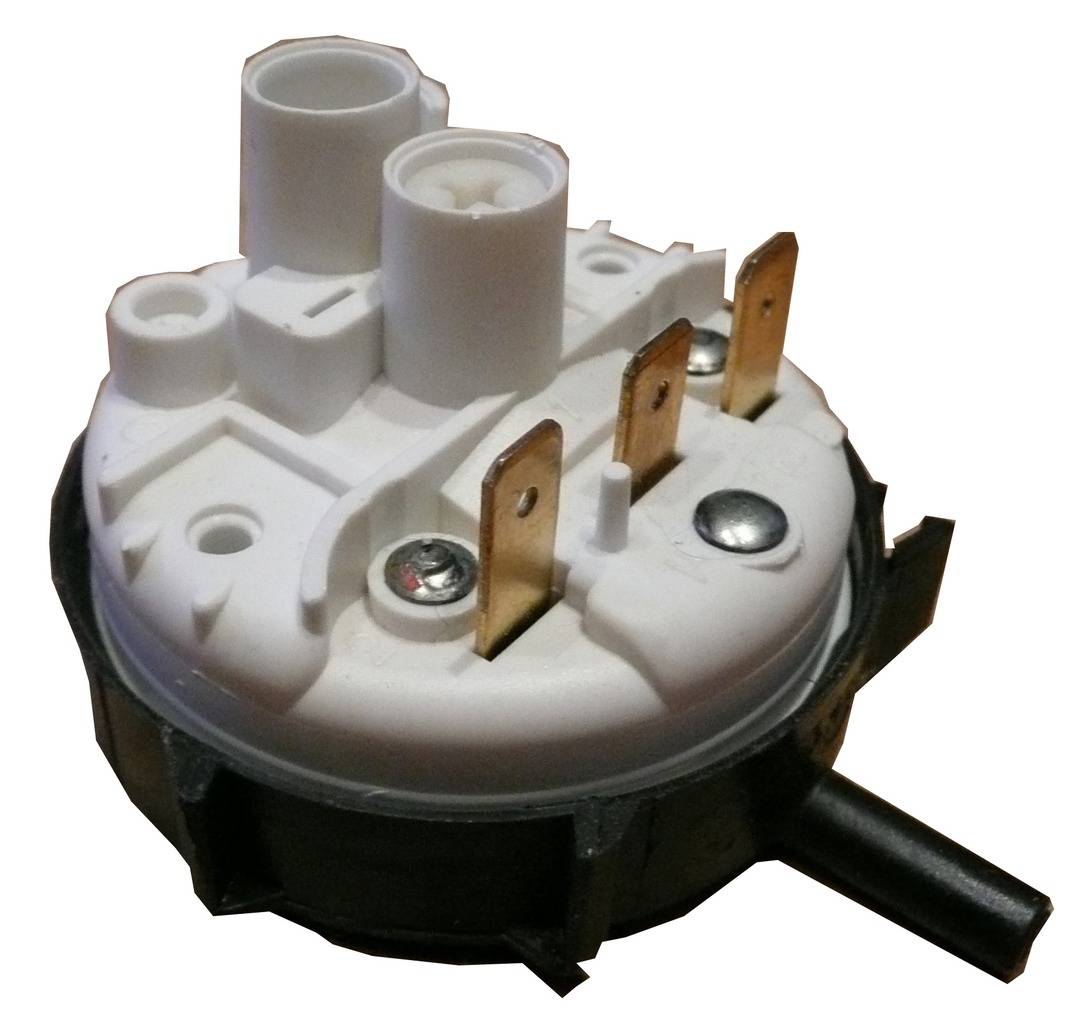

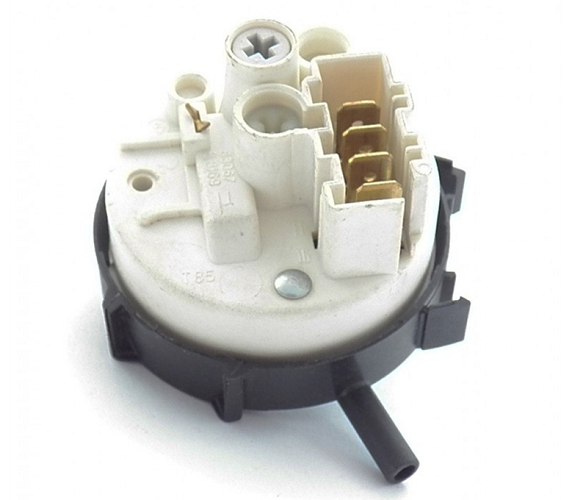

The principle of operation and the choice of relay for the washing machine

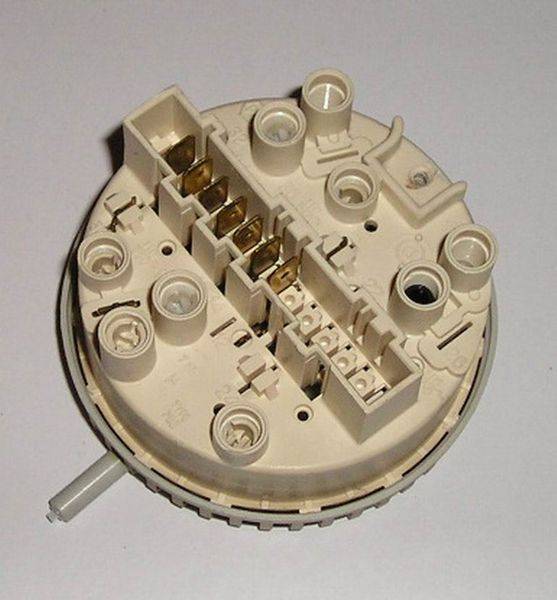

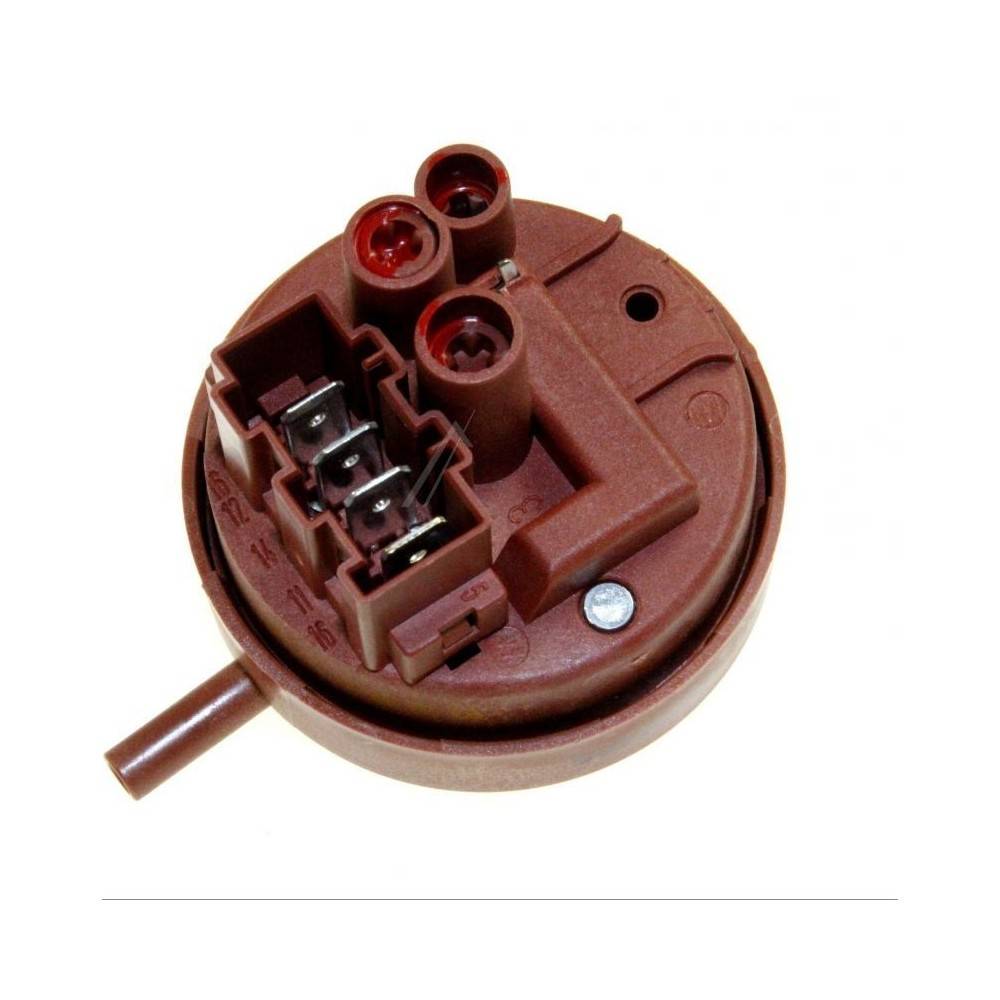

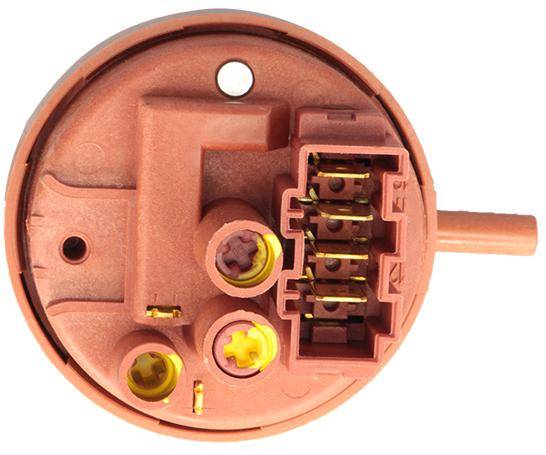

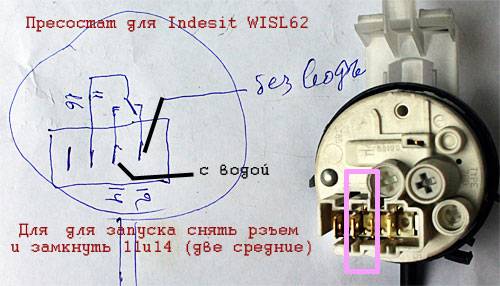

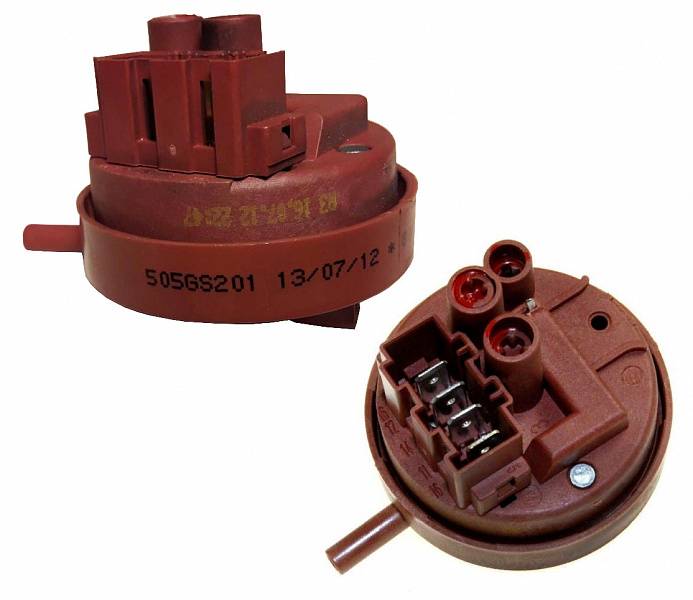

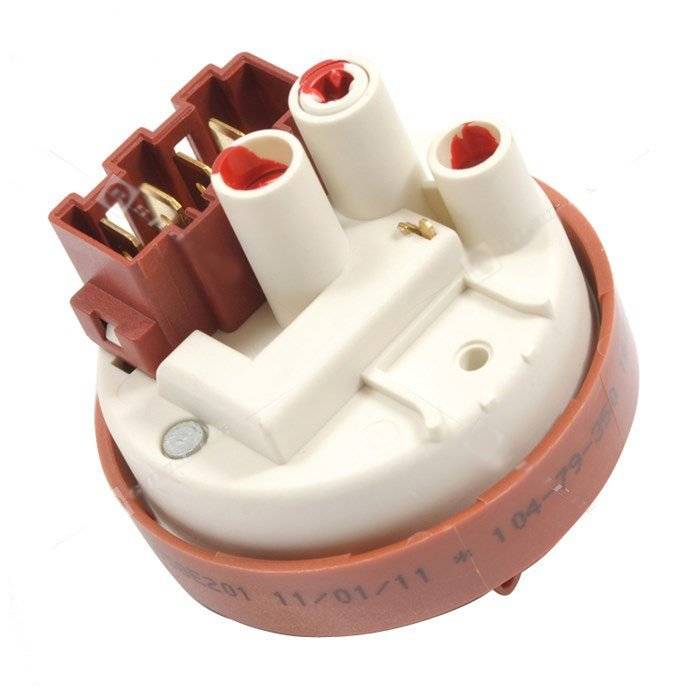

The pressure switch is made in the form of a round tablet. It is located under the top cover of the washing machine. A tube extends from the body of the part to the tank. The more water is taken by the machine, the higher the pressure in the tube rises. As a result, one of the contacts closes and the module sends a signal to turn off the inlet valve.

The correct sensor can be selected by the serial number or model of the CMA. The series numbers are indicated on the pressure switch itself, so it's easier for you to dismantle it and go to the store. There, show the part to the consultant and he will suggest a suitable replacement.

Signs of a breakdown of the pressure sensor are failures in the water filling and draining system:

- The fluid is drawn up until an overflow or leak occurs.

- Waste fluid does not leave the tank.

- The wash cycle runs normally, but does not go into rinsing.

- The display shows a malfunction code.

- The cycle starts even though the water has not reached a certain level.

All these "quirks" are associated with the incorrect operation of the pressure switch. To carry out additional diagnostics and replacement, the element must be dismantled.

How to replace a relay?

All you need is a screwdriver and a short tube. Disconnect the machine from the mains by pulling out the plug from the socket. Close the water inlet valve. Remove the screws securing the top cover. Slide the panel back and away from the case.

At the side wall, you will see a pressure gauge. How to remove a part:

- In some CM models, the pressure switch is bolted. Others have snaps. In the first case, remove the fixing screw. In the second, turn the part clockwise to release the latches.

- Disconnect the wiring chips.

Disconnect the hose. Check it for blockage. It is often clogged with debris that comes from the mains. Therefore, the relay may give incorrect readings.

Run diagnostics before replacing the level sensor. Reconnect the pressure tube with a hose of the same diameter. Blow lightly into it. When the contacts are closed, clicks should be heard. If nothing is heard, then the contacts are not working and the part is broken.

Another way to check for serviceability is with a multimeter. Set its toggle switch to resistance measurement mode. Connect the test leads to the relay contacts. Blow into the tube and observe the reading on the screen. If nothing has changed, the sensor is faulty.

Prepare a new pressure switch. Reinstall it, fasten the fixing bolts. Connect the wires. Replace the hose, secure it with a hose clamp.

Without replacing the lid, start a short wash. Is the water drawn in and out normally? This means that the repair of the SM was carried out correctly.

During operation, it is recommended to clean the inlet hose and filter from debris and rust. Install cleaning filters so that fine debris from the water supply does not clog pipes, hoses and other equipment parts. The video shows the stages of work:

Badly

1

Interesting

Super

What is a pressure switch?

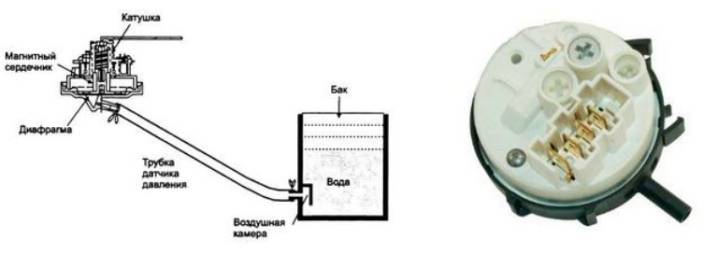

The main task of this unit is to determine the amount of water collected in the tank by the pressure of its column. The liquid is supplied to the sensor by a tube connected to the lower point of the washing container. Contact groups are used to transmit information signals to the electronic control unit of the machine.

The more washing modes or other functions the machine offers, the more complex its pressure switch will look. Each group of contacts is triggered when a certain amount of liquid is poured into the tank. But in the general case, the node looks like a flat, round, pill-shaped structure, to which a wiring harness fits on one side, and a fluid supply tube on the other.

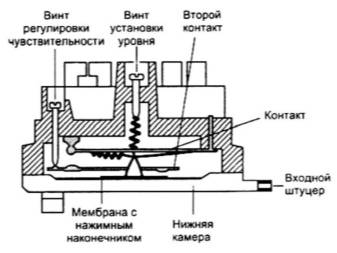

Description

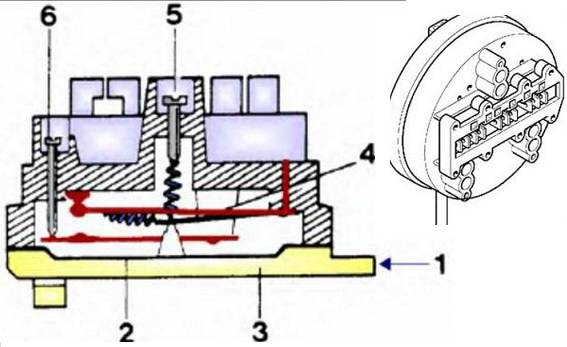

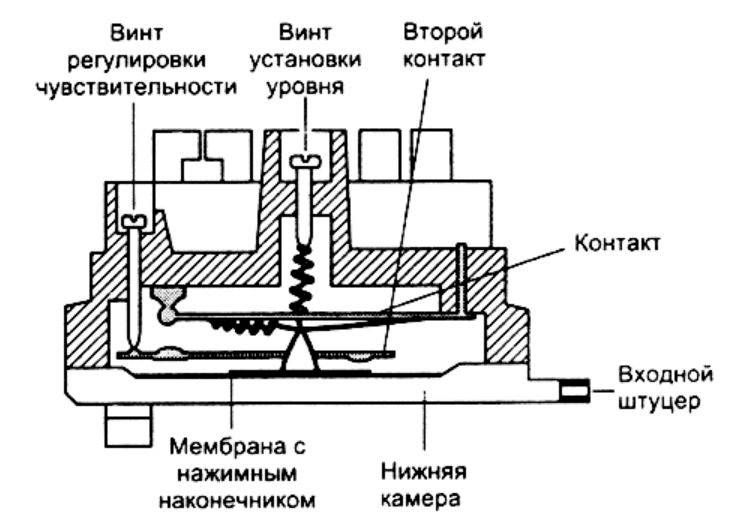

The washing machine pressure switch is a device that controls the volume of water in the tank. The main task of the device is to determine the amount of liquid by the pressure of its column. The relay has the form of a disk, inside which there is an air chamber with wires and a tube. The complexity of the pressure switch design depends on the number of washing modes that the machine is characterized by.

For this reason, a pressure switch from one unit will not necessarily function in another. The sensor is made of high quality plastic, usually it looks like a round part. We need a mechanism for the correct functioning of the washing machine and high quality washing. This simple mechanical assembly consists of the following elements:

- frame;

- inductor;

- magnetic core;

- a diaphragm that changes shape under the influence of water pressure and displaces the core;

- contact group.

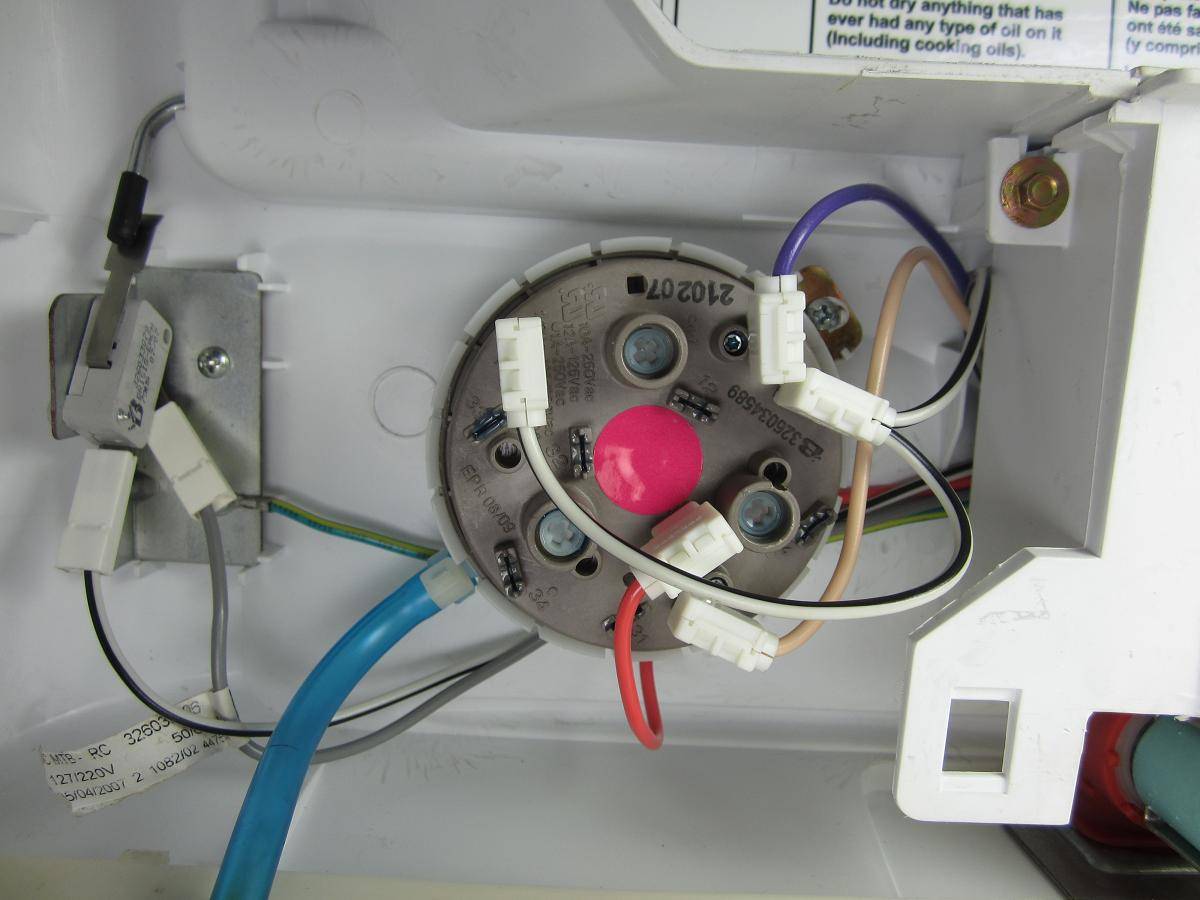

An electronic liquid level sensor can be found in the following parts of the unit.

- Under the top cover in classic washing machines, where there is a front door for loading things.

- In the lower part under the tub in the technique, which is characterized by the vertical type of loading the laundry.

- In the area of the rear part of the case, slightly below the linen container, the pressure switch is located in those machines that have plastic drums.

Inspection instructions

It is not worth going into the machine without reason. Before diagnosing a pressure switch in an LG washing machine, it is worth checking for certain signs of a faulty water level switch. The breakdown is not without consequences, so the unit will let the owner know about the problem with the following signals:

- the drum rotates or the heater is turned on without water in the machine;

- there is an insufficient or excessive set of the tank;

- in rinsing mode, the water is pumped out and refilled;

- there is a burning smell;

- the fuse on the heating element is triggered;

- the laundry does not spin.

Even one present "symptom" is a signal for diagnostics of the pressure switch. But you cannot blame only the level switch for problems, since other faulty parts can also lead to similar troubles. To eliminate an error, we take out the sensor and check it for operability.

- We unscrew the two screws on the back of the case that hold the top panel.

- Press on the cover away from you and remove it.

- We find a rounded black or white plastic box near the side wall - this is the pressure switch.

- Disconnect the connected wiring and pipes from the sensor.

- We loosen the fixing bolts and pull out the body with a long tube that goes into the tank.

Having taken out the sensor, we begin the inspection. First of all, we assess the condition of the tube visually: there should be no damage or blockages, and the outer lamellas on the connectors can only be clean and not oxidized. If problems, corrosion, oxidation or contamination are visible, the relay is carefully cleaned and washed. Then we proceed to direct verification:

- we find a hose or tube commensurate with the opening of the pressure switch fitting;

- we put the tube on the fitting;

- we bring the block to the ear, and the end of the hose to the mouth;

- we blow into the hose and listen for a click. There are usually two or three clicks, but in some models, a single actuation of the contact is allowed. The main thing is that there is no silence, which signals a faulty pressure switch.

There is another way - connect an ohmmeter or multimeter to the sensor terminals. If you close and open the contacts, the device should record a sharp change in resistance. In order not to make a mistake when connecting to the connectors, it is recommended that you first study the wiring diagram in the factory instructions.

How to check the pressure switch?

They independently check the serviceability of the pressure switch by removing it from the washing machine.

Part removal procedure

- Disconnect the apparatus from the mains by unplugging the power cord.

- Remove the top cover by first unscrewing the mounting bolts located on the back of the machine and slightly sliding the cover.

- Find a water sensor (usually located on the upper side of the sidewall).

- Disconnect the air compression hose after removing the fastening clamp.

- Without removing the sensor, try to blow through the hose. If it is clogged, it is difficult or impossible to do this. In this case, the sensor did not work because overpressure did not flow into it. The compression tube is cleaned with an elastic wire. Visible damage to the hose is a reason for replacement: excess air comes out of the tube, and the pressure switch membrane does not work.

- If the reason is not in the tube, continue to remove the pressure switch.

- Disconnect the electrical connector. An unreliable (floating) contact at the connector is the reason for the incorrect operation of the washing machine.

- Remove the sensor by unscrewing the mount at the wall of the machine.

Principle of operation

To find out where this sensor is located in the washing machine, you will have to remove the top cover of the unit.The pressure switch outwardly resembles a flat corrugated washer, to which wiring is connected from both sides, and at the end there is a plastic tube. There are washing machines with an oval sensor that has only two contacts - for wires and a tube.

The sensor is essentially a pneumatic relay, which is triggered by air pressure created in a tube connected to the washing machine tank. The water flowing into the drum creates a certain pressure, the air begins to press harder on the relay membrane, which closes or opens the contacts, allowing the current to pass through the wiring and transmit the necessary command to the control unit.

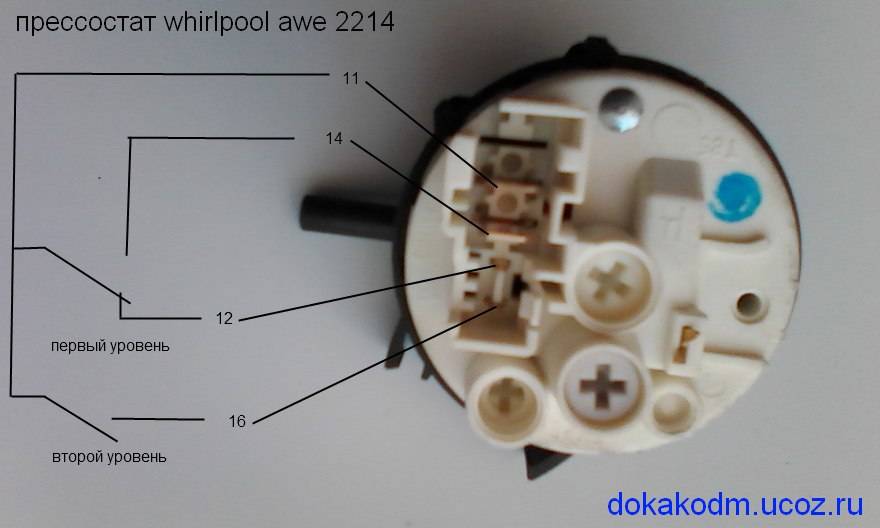

If there is no signal at the beginning of the operation, or the conduction is broken in the circuit, the control unit stops the program by sending an alarm signal to the display panel. For example:

- LG gives PE signal;

- SMA Ariston and Indesit signal with codes F04 and F05, respectively;

- Bosch CMA will report a problem to you with code F26;

- Electrolux for this case has several versions - E11 - E 12; E21 - E22;

- Kandy - F03.

If the water control sensor starts to work incorrectly, in the future, certain malfunctions may appear:

- water will be overflowed in the tank, the device will constantly collect and drain liquid;

- there will be an insufficient amount of water for washing, which will worsen the quality of the washing machine;

- water after washing will not drain completely, after spinning the laundry will remain damp;

- the program will start without water, after which the water heating element will overheat and fail.

The principle of operation of the pressure switch

When a certain water level in the tank is reached (depending on the washing mode), one of the switches is triggered. The water level sensor in the automatic washing machine gives a command to close the water supply valves. After this command, the flow of water into the tank stops, and the machine starts washing. If the washing mode is changed, the pressure sensor can command to add water to the tank, and then turn off the water supply again.

You can find out where the pressure switch of the LG, Samsung, Indesit or Bosch Maxx 4 washing machine is located by dismantling the top panel of the unit. The pressure switch looks like a flat plastic (monochrome or multi-colored) corrugated washer, to which wires with connectors fit from both planes, and a plastic tube from the end.

Versions of execution of pressostats

The water level sensor is, in fact, a pneumatic relay triggered by the air pressure filling the tube connected to the machine's tank. Depending on the pressure created by the water flowing into the drum, the air pressure on the inner membrane of the relay increases. The membrane, in turn, closes and opens certain contacts, passing current through the connected wires and launching the corresponding command in the electronic control unit.

The lack of a "response" of the relay to the operation that has begun or the lack of conductivity in the control circuit in electronically controlled units turns on the stopping of the washing program and an error signal appears on the dashboard indicator.

Water level sensor

Pressostat error codes depending on the manufacturer and equipment model:

- LG - PE;

- Ariston (Indesit) - F04 (F05);

- Electrolux - E11-E12; E21-E22;

- Bosch (Maxx 4) - F26 (F19);

- Samsung - E7 (E2; E3).

The principle of operation of the water level switch of the washing machine is based on the effect of pressure on a special membrane (diaphragm). During the collection of water into the tank of the washing unit, water fills the compression chamber and through a special tube pressure is injected into the sensor housing, which corresponds to the level of the collected water.

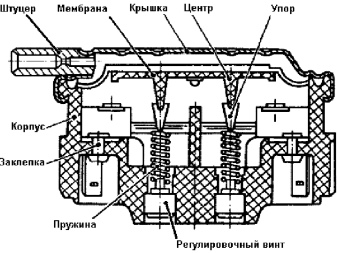

Dual chamber pressure sensors are specially designed for washing machines with small and large loads. At low load, one membrane is triggered and water is supplied in a minimum amount.With a large drum load, the second membrane is activated, the contacts close and the control processor gives a command to supply the maximum amount of water.

As a rule, the membrane installed inside the sensor is made of rubber or elastic polymer and is designed for multiple on and off cycles. The principle of operation of the pressure switch combined the sequential effects of air pressure on the mechanical part, above which the electrical contacts are located, and a direct electrical impulse to the control processor of the washing unit.

Checking the pressure switch

If you have the slightest doubt about the correct operation of the pressure switch, you must immediately replace it with a new one. But before that, you need to gain confidence that it is in the sensor. It is quite simple to check the pressure switch of a washing machine:

- It is necessary to dismantle the top panel. You can remove it by unscrewing the special bolts and sliding it in the opposite direction from you. On most models, the sensor is located at the top of the side wall.

- Experts recommend simply unscrewing the pressure switch. It is fixed, as a rule, with several screws, which are quite easy to unscrew.

- Then disconnect the tube and contacts from the sensor. The hose is secured with special clamps, they will either have to be carefully disassembled, or cut off and then replaced with new ones.

Carefully study the dismantled pressure switch: there should be no damage or formations on the body. Check the tubing and the condition of the insulating material of the wiring equally carefully. If necessary, clear blockages and repair minor damage. Clean the sensor contacts.

Now let's start checking the device itself. Usually, a ten centimeter hose is used for this, identical in diameter to the one already removed. After connecting the tube to the pressure switch inlet, blow strongly into it.

At this moment, clicks should be heard from the sensor. Their number depends on the blowing force.

This small device is essential for the entire system. When it fails, it deprives you of the ability to wash, and can lead to various breakdowns. Replacing the pressure switch in an automatic washing machine is a troublesome but not complicated process.

Pay attention to the behavior of your machine, and you can spot the malfunction in time

After some time from the moment of operation of the washing machine, any of its elements may lose their functionality. For example, a violation of water intake, expressed in underfilling or overflow of liquid, will tell you that there are problems with the sensor that controls its intake. It does not always need to be replaced, sometimes it is enough to adjust the pressure switch of the washing machine for it to work normally. By completing these steps yourself, you will not spend extra money on a new element and extend the life of the existing sensor.

Malfunction symptoms

Sometimes it is quite difficult to determine the malfunction of a product, especially for people who do not understand technology. It is recommended that you familiarize yourself with the common symptoms that indicate a malfunction of the pressure switch.

Stops collecting water in the tank

People who have their own washing machine are often faced with the fact that liquid ceases to accumulate in the tank. There are several reasons for this problem:

- Problems with the valve responsible for the supply of water. Liquid enters the system under tap pressure. The flow is opened using a special built-in valve, which starts to work after a signal from the control module. If it is defective, the liquid will not start flowing.

- Failure of the control module. Due to a malfunction of this part, a signal does not come to the valve, and it does not start to draw water.

- Breakdown of the blocker. He is responsible for locking the hatch door. If the blocker malfunctions, the machine will not start working.

However, the most common cause is considered to be a malfunction of the pressure switch. If this product does not work, the machine will not be able to evaluate and will not begin to fill the tank.

Repeated repetition of water supply and drain cycles

Modern washing machines are equipped with an automatic liquid intake system. Not only valves, but also a level switch are responsible for the flow of water. All these parts function with special commands from the control unit.

The control unit perceives this as a failure to comply with the command, and therefore it re-sends a signal for a sop of water. This leads to the fact that the cycles of feeding and draining are repeated many times. Repetition of the cycles can increase the washing time dramatically.

Reducing the quality of rinsing and washing

Sometimes, after using the washing machine for a long time, the rinsing and washing performance of the laundry will gradually deteriorate. Many attribute this to the use of unsuitable powders. However, there are other reasons why things start to wash worse.

A common cause of deterioration in wash performance is a level switch failure. Due to the breakdown of this part, the washer cannot determine how much water is in the tank, and because of this, it often does not fill up completely. This leads to the fact that the collected liquid is not enough to properly wash and rinse the washed items.

Remains of water after the end of the wash

There are times when, after the completion of work, some water remains inside the drum. This can happen due to the fact that the pressure switch has failed and has ceased to function normally. If it does not work correctly, the control unit of the device will not receive a signal to clean the tank. This will prevent the pumps from starting to pump out excess water.

However, there are other reasons for this problem:

- Clogged pump filter. Obstruction of fluid from the tank sometimes appears due to a clogged filter. It will have to be cleaned in order for the drain to start working.

- Blockage inside the nozzle. During the draining process, the waste liquid passes through the pipe. Experts advise you to clean it once a month so that it does not get clogged.

How to check the pressure switch yourself: 5 steps

Before replacing this element of the washer, you need to make sure that malfunctions occur due to the water sensor. Sometimes difficulties are attributed to it, for which another mechanism is actually responsible. To check, you need to remove the pressure switch from the unit and test its functioning.

The procedure for checking the water level sensor in the washing machine:

- Unscrew the two bolts behind the vehicle and pressurize the top cover. In the surveyed space, the sensor will be placed on the side wall. It is necessary to separate the hose and connector with wires.

- Unscrew the screws holding the pressure switch and dismantle the block.

- Clean the tube if contamination is found. Examine the surface of the item to be tested. If there are signs of oxidation on the connectors or other signs of damage to the element, it will have to be replaced with a new one. Dirt and corrosive changes must be removed.

- Attach a hose to the fitting. Put the block to your ear, the hose to your mouth and blow into it. If the contact of the fixture works correctly, a clicking sound will be heard.

- Check the reliability of the contacts by connecting the device to an ohmmeter. Closing and opening will change the readings of the device.

Be sure to read:

The spin class in washing machines - which is better, what does the washing class mean

This type of sensor is considered quite reliable, since its operation is based on the mechanical movement of the membrane under the influence of air pressure. Nevertheless, the likelihood of its breakdown cannot be ruled out. If this happens, then the consequences can be very serious, up to the burnout of the heating element.And this will already entail substantial cash costs.

1. De-energize the washing machine by unplugging it from the socket. Carry out further actions only after completing this item.

2. You need to get to the level sensor itself. Since the relay is located at the top of the machine body, you need to completely remove its top cover. For this, the bolts holding the cover to the body are unscrewed. The cover slides in and out.

3. Having found the sensor, unscrew the bolts holding it, and then remove the sensor itself.

4. The tube and all wires are disconnected from the sensor body. The tube is secured with a clamp that can be unscrewed. If the electrical wires are held on the chip, then to disconnect them, simply pull the chip out of the socket to disconnect them.

5. The tube is checked for blockage. If there is a blockage, the tube is flushed until it is removed.

6. A visual inspection of the sensor is carried out. If any broken elements are found, then the sensor must be replaced. The cleanliness of the contacts is also checked.

7. The pressure switch of the washing machine is being checked. To do this, you need to take a piece of tube, the diameter of which corresponds to the diameter of the removed hose. A removed hose can also be used if it is not dirty inside. One end of the tube must be connected to the sensor, and blown into the other end. Moreover, do not blow strongly, in order to avoid damage to the membrane.

The cost of the pressure sensor is low, therefore, if you suspect a malfunction, it is recommended to purchase a replacement and install it on the machine.