Lubrication and installation

Maintaining a bicycle fork requires first of all the cleaning and lubrication of its components. The range of products used for these purposes is wide. The best option depends on the type of bike, the model of the mechanism, and the riding conditions. Specialized oils are the most effective, but also expensive. It is unprofitable for those who ride a bicycle rarely, therefore many amateurs, wishing to save money, use cheaper means such as "Litola" or "Uniola", "Solidola". They have their own negative side properties that should be taken into account (for example, "Litol" has a bad effect on aluminum).

Lubrication of the spring fork begins with the spring. The lubricant is applied quite thickly (excess will come out through the oil seals). It is also used to machine rings, glass, cups and bearings.

To install the fork mechanism:

- A ring is put on the junction between it and the steering column, clamp it with a key and lightly hit it with a hammer to put it in place. As soon as the sound becomes resonant, the beats stop.

- Lubricate the stopper (use "Buksol", "Litol", more expensive specially created compounds).

- Carefully install the bearing with the balls upward, after placing a sealing washer under it. The bearing is also slightly lubricated.

- Insert the rod into the glass and then carry out all the actions as during disassembly, but in the reverse order.

Some bikers find it advisable to go over even completely new bike forks with their own hands. Allegedly, this will contribute to their better tuning and a longer service time. In fact, high-quality mechanisms do not need this, and the degree of strength of any front elements is determined only in riding conditions.

Put the ring on the joint of the fork with the steering column

Put the ring on the joint of the fork with the steering column Lubricate the stopper

Lubricate the stopper Lubricate the bearing, insert the stem into the glass and repeat all removal work in the reverse order

Lubricate the bearing, insert the stem into the glass and repeat all removal work in the reverse order

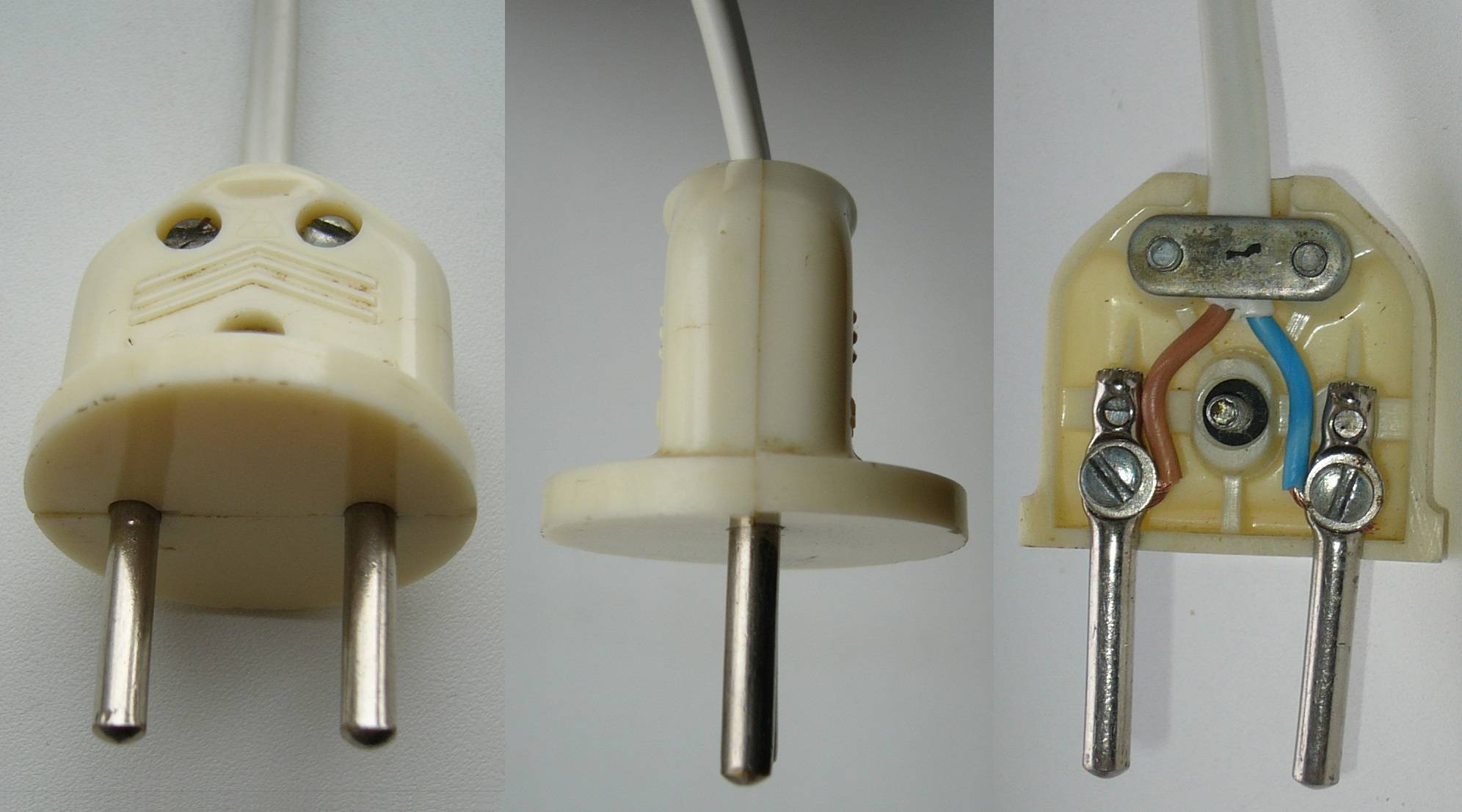

How to assemble a grounding plug

To correctly assemble a variety with a grounding contact, you need to follow the step-by-step instructions. Including, you will need to do the following:

- Disconnect the appliance from the mains. Disassembling a plug inserted into an outlet is inconvenient and dangerous.

- Remove the defective plug. In this case, it is necessary to inspect the traces of the influence of the current in order to understand the reason for the incorrect operation. In most situations, replacement is performed due to overheating of the case and loss of mechanical characteristics.

- Unscrew the screw and disassemble the housing for replacement. An ordinary screwdriver is suitable for these purposes.

- Strip the wires. First you need to cut the insulating layer and strip it 2-3 cm.

- Solder the wires. For convenience, the ends of the wires are twisted into rings.

- Secure the cord with the clip. After fixing the power cord, it remains to assemble the case and check the operation.

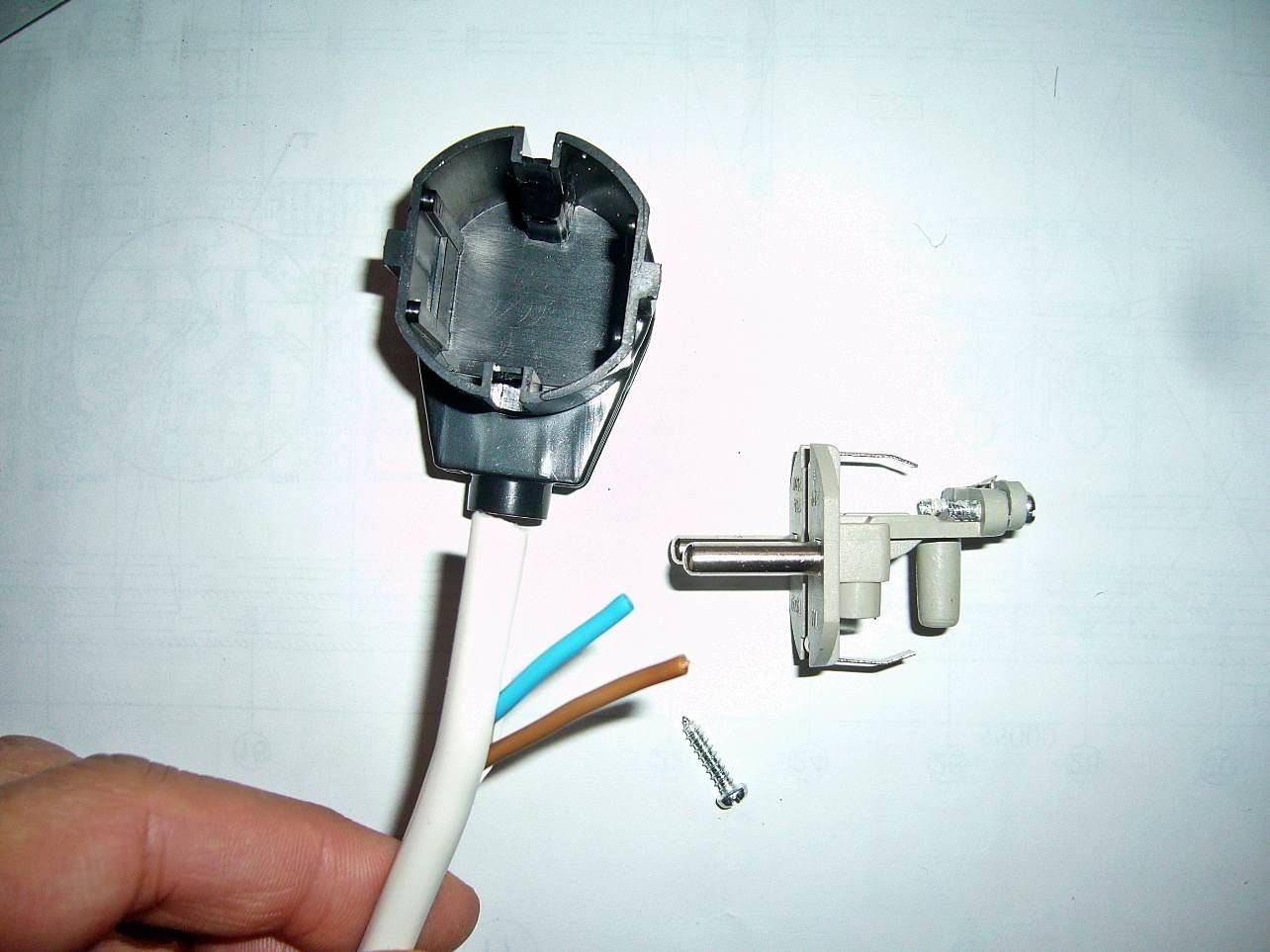

Change a broken Euro plug

If your electrical plug has melted or one of the pins is broken, the replacement technology is as follows:

Cut off the Euro plug that needs to be changed and remove the outer sheath of the cord (about 5 cm from the end).

We clean all 3 cores by 15-20 mm. We talked about how to properly remove the insulation in the corresponding article.

We twist the wires and cut them so that 10 mm of bare wire remains, which is enough to change the plug with our own hands.

For better contact with pliers, bend the copper ends as shown in the photo below.

And now the most important thing is connecting the wires. As a rule, the cord for connecting a washing machine, refrigerator or other household appliances has 3 contacts: blue - zero, yellow-green - ground, the rest - phase

To correctly change the plug with your own hands, "ground" must be connected to the central contact, the remaining two to the pins, here the polarity is not important.

Next, you need to clamp the cable (exactly it) with a plastic jumper, which will fix it in the seat.

Lastly, the body of the euro plug is assembled, which is fastened with one screw.

Replacement video tutorial:

How do you need to change the Euro plug with your own hands?

In this way, you can independently change the plug on the wire. As you can see, the instructions are quite simple, especially since each step of the replacement was considered in detail in the photo examples.

Non-separable electrical plug device

The design of non-separable electrical power plugs of all types is the same. The pins are installed at a distance of 19 mm into the plastic strip and the conductors are pressed into them. There are two protrusions on the bar that serve to bypass the wire. Bypassing is necessary to prevent the cord from breaking if a significant force is applied to it. For example, removing the plug from the electrical outlet by the wire, which is strictly not allowed.

The pins and wire are filled with molten plastic. Thus, a sealed waterproof plug body is formed with the power cord securely fixed in it.

The device is a collapsible three-pole electrical plug

In the recent past, only collapsible plugs were used to connect electrical appliances to the electrical network. And now a large number of them are still in operation. A collapsible fork is indispensable if you need to replace a failed cast. A collapsible fork is good because it allows you to use it repeatedly. It can be easily removed from an unnecessary electrical appliance and installed on a different cord during repairs.

The device of a collapsible electric plug C1-b

In front of you is a C1-b plug, disassembled into its component parts, designed for connecting electrical appliances with a power of up to 1200 watts to the electrical network.

It consists of two body halves, two brass pins, a cord clamp and fasteners.

Detachable electric plug C6

Consider the device of a collapsible plug with a grounding contact of the C6 type, designed to connect electrical appliances with a power of up to 2200 W. On the brass pins of the plug, threaded contact pads are pressed for screwing the wires. The pins themselves are fixed at the base of the plug.

The housing has a ground contact in the form of a threaded brass strip to secure the grounding conductor. There is a strap for fixing the wire with a plastic gasket.

Replacing the plugs

A plug is an electrical connector with which the plug connection is provided. With its help, it is possible to quickly connect and disconnect an electrical device using different plug contacts.

A plug is an electrical connector with which the plug connection is provided. With its help, it is possible to quickly connect and disconnect an electrical device using different plug contacts.

To replace the plug structure, you will need the following tools: Phillips and flat small screwdrivers, a stripper, a craft knife, and a new fork. The replacement technology is as follows:

- Unscrew the screw, whose task was to ensure a reliable connection of the halves of the mechanism, and disassemble it.

- Using a stripper, remove about 5 cm of the upper sheath of the cable. If the plug is equipped with a fuse, you need to select it correctly, for example, a red three-amp with a power of 720 to 3000 watts.

- About 12-15 mm of the braid is removed from the ends of the wire. The wires are twisted with your fingers to make the end neat and smooth. The plug is disconnected and the cable is inserted into it. The end of the latter is securely fixed with a plastic clip.

Adaptation of non-standard 3-pole plugs

Sometimes electrical appliances are brought from foreign countries equipped with plugs that cannot be inserted into the outlet, although the product can be connected to an existing power grid for its eclectic characteristics.If the wiring is with a grounding conductor, then the way out is to connect the plug through an adapter - adapter, but you still need to find it, or cut a non-standard plug and replace it with a collapsible C6. If there is no ground wire in the outlet or the device does not require the first class of protection, you can modify the plug yourself.

The issue of finalizing adapters for connecting cell phones, office equipment, laptops is especially relevant, since the pins go directly from the adapter body, and it is not possible to replace them with a collapsible plug.

Adaptation of three-pole electrical plug IEC 60906-1

I came across a polarized plug of the SEV 1011 or IEC 60906-1 standard, I will not say for sure, since they are almost the same. The distance between the pins of the plug was 19 mm, the diameter of the pins was 4 mm, as in C5 forks. But unlike the C5, there was an additional grounding pin, which did not allow inserting the plug into the outlet.

I clamped the fork in a vice and carefully, so as not to damage the necessary pins, cut the interfering pin with a hacksaw for metal.

Without a grounding prong, the plug fits easily into any electrical outlet

Adaptation of British electrical plug BS 1363

When creating a home computer network, I had to modify the Huba plug. I got the hub by accident and was lying around, since it was impossible to connect it to the 220 V supply network due to the non-standard British plug BS 1363.

As you can see in the photo, there are three pins in the BS 1363 plug of the hub adapter and they have a flat shape. Two pins located on one horizontal line are for supplying the supply voltage, and the third, vertical, is for grounding and correct connection of the plug.

When measured, the width of the pin was found to be 6.5 mm. The distance between the inner planes of the pins is 16 mm, which corresponds to the distance between the pins of the C5 plug, an analogue of the European plug CEE 7/16. Thus, if you reduce the width of the flat pins of the BS 1363 plug from the outside by 2.5 mm, then it will fit into any outlet designed for C5 or C6 plugs. The only thing left to do is to remove the third pin and excess metal from the pins.

The vertical pin, it turned out to be completely plastic, was clamped in a vice, and cut down with a hacksaw for metal. The horizontal pins were in turn also clamped in a vice and sawed off with a file, to a width of 4 mm.

In the photo you can see the place where there was a vertical pin and a left fitted in width. Sharp corners formed on the pin after filing must be blunt with fine sandpaper.

After removing the extra pin and reducing the width of the remaining pins, the British plug BS 1363 became adapted to connect to sockets designed to connect C5 plugs. Therefore, it was easy to connect the Hub to the mains.

Malfunctioning electrical plugs

Plugs are designed simply and with the correct connection of the cord and the observance of the rules of their operation, they flawlessly perform the function assigned to them until the end of the life of the appliance. But still, refusals do happen.

Malfunctioning molded electrical plugs

The need to replace the cast forks may arise in the following cases. Poor-quality crimping of the conductor in the pin at the factory, chafing of the cord at the point where it exits from the plug body and due to a malfunction of the socket. More often, the cord is frayed with electrical appliances with C5 plugs, which are intensively moved during operation, this is a hairdryer, mixer, soldering iron and many others.

With a close examination, it is sometimes possible to visually detect the place of damage by a sharp bend of the cord when it is bent or swelling of the insulation. If the inspection failed to reveal a defect, then you need to ring the wires with a tester. This requires reaching the opposite ends of the wire, which is not always possible.You can use a thin sewing needle, pierce the insulation in the place where one conductor first passes and ring the pin-needle chain. If the wire is intact, ring the second conductor. To avoid accidental contact of the wire at the point of breakage during the dialing, you can slightly tug the wire and plug in opposite directions.

You can also check the integrity of the wire with a phase indicator

Attention! It is required to work very carefully so as not to get an electric shock. Touching a needle plugged into the lead with your bare hand while plugged into a power outlet may result in electric shock! It is necessary to pierce the insulation, insert the plug into the outlet so that there is a phase on the tested wire

They will touch the needle with the phase indicator, if there is no glow in the indicator, the wire is broken. The second conductor is also checked. The insertion and removal of the needle is carried out with the plug unplugged.

In the case of the integrity of the wires, the fault must be looked for elsewhere. Since the needle is thin, after removing it, the hole will tighten; it is not necessary to isolate the puncture site.

I took the photos while repairing a failed hair dryer. As it turned out, one of the conductors was rubbed inside the plug, in its flexible place. I had to cut the cord at the exit from the plug and connect the wires to a new collapsible plug in the way described below.

Also, the plug may fail due to poor contact in the outlet into which it was inserted. If the pin does not make contact with the contacts in the socket, then a lot of heat is generated, the pin heats up and melts or even charred the plug body where it touches it. As a result, the pin will begin to swing, which is unacceptable. The plug has to be replaced.

To check the reliability of the contact of the pins of the plug with the socket, after the end of the operation of the electrical appliance, remove the plug from the socket and immediately touch the pins with your hand. If they are slightly warm, then this is normal, but if they are very hot, then it is necessary to repair or replace the outlet.

Malfunctions of collapsible plugs

Collapsible plugs suffer the same malfunctions as non-collapsible plugs, but in addition, collapsible plugs often fail due to poor contact between the conductors of the cord with the pins. The reason is a violation of the tightness of the wires to the pins due to the absence of a spring washer. Over time, from temperature changes, a gap forms, the contact is broken and heat energy is released. A spring washer selects this clearance to ensure long-term, reliable fork performance.

With poor contacts in the plug, its pins get very hot and melt the body up to charring. A fork with a charred body must not be used and must be replaced. If the case is not damaged, then you should disassemble the plug, strip the wire and the place of its contact with the pin with sandpaper until it shines. If the wire is badly burned, then it is necessary to cut off the damaged part to the length of the insulation brittleness and connect using the below recommended technology. The screws and washers also need to be replaced. As a rule, they are highly oxidized, and it is impossible to descale them.

Which fork is better - collapsible or cast?

A molded plug is more reliable, its main advantage is the tightness of the contacts that connect to the pins. The cast model uses spot welding, solder and crimping. Another advantage of the model is its tightness.

But there are annoying drawbacks: it cannot be disassembled in order to eliminate the cause of the breakdown. If the cord gets frayed at the base due to prolonged use, then the only way out is to cut off the molded plug to replace it with a collapsible model. It is possible to completely change the cord with a plug to a new one, but for this you have to disassemble the device.

However, if such a replacement does not frighten, it is better to purchase a cast product, especially since, due to the increased reliability, such a fork fails much less often than collapsible analogs.

Types of electrical plugs

At present, in Russia, all electrical appliances are produced with cords at the end with non-separable plugs of two types of type C in accordance with GOST 7396.1-89. On the body of each plug, a marking is usually applied, which indicates its technical characteristics - the value of the maximum permissible current and the permissible voltage of the supply network. This does not mean that this is such a strength, but only indicates that the plug is designed to transfer current up to the specified value.

C5 (analogous to European electrical plugs CEE 7/16) - with round pins with a diameter of 4 mm, converging slightly to the free ends, the pins are insulated for a length of 10 mm from the body, without a grounding contact. The C5 plug is designed for a load current of up to 6 A (with a supply voltage of 220 V, it can withstand a power of 1300 W).

C6 (analogue of European plugs CEE 7/17) - with round pins with a diameter of 4.8 mm, there are three-pole with a grounding contact and two-pole without a grounding contact. The C6 plug is designed for a load current of up to 10 A (with a supply voltage of 220 V, it can withstand a power of 2200 W).

There are still many devices in operation, with cords equipped with collapsible plugs of the type C1-b with round pins with a diameter of 4 mm without a grounding contact and designed for a load current of up to 6 A (with a supply voltage of 220 V, it can withstand a power of 1300 W).

Dismantling the suspension fork

Replacing the entire mechanism does not require disassembly. But to repair a bicycle fork, lubricate the inner surface, replace faulty elements, you need to get inside it. The general process of disassembling parts with a shock absorber is approximately the same for different models:

- the bolts on the bottom of the "pants" are unscrewed with a hex wrench;

- unscrew the Preload (this is the bolt that regulates the compression of the spring and is responsible for the shock absorber travel);

- “pants” are removed from the fork's “legs” (if you can see that there is dirt under the oil seals, then they too), the old oil is drained;

- the rods of the "legs" are cleaned of old grease, dirt, the travel stops and stops are removed from them;

- unscrew the adjustments located at the top of the "pants" (so as not to spoil the edges of the nut, it is advisable to use a key-head with a cut-off edge);

- take out, clean from dirt, remnants of old grease, foot stocks, elastomers, springs.

How to Connect a Plug - Grounded

Another article in the "ELECTRIC" heading - I propose to talk about connecting an electrical plug to a regular cable, we will consider the option with grounding, because personally I think this option is the only correct one for use. Where do we need such knowledge? Usually large electrical appliances go without plugs - such as water heaters, some household appliances (ovens), and some lighting fixtures. In general, you need to know how it connects, and it's quite simple ...

CONTENTS OF THE ARTICLE

- About power

- What tools will be needed

- Now the process itself

- Video version

About power

First, guys, let's talk about maximum power. Why am I starting this conversation but everything is simple - many are trying to connect a plug to an induction hob! Guys, this can be dangerous - the surface consumes about 7 KW and not all plugs can withstand it, especially if you have a regular 16A plug, for "induction" you need a 40A plug or a direct connection - read this article, the usual from such a load will simply melt !

This simple example shows us first you need to estimate the power of your electrical appliance. If there is an oven, then there is a consumption of about 2.8 KW, if a water heater (I mean a storage type) there is 1.5 - 2, KW, a 16A plug is enough for them. In general, the maximum voltage should be written on the package, here is a photo.

What tools will be needed

You need to take a screwdriver, preferably a Phillips screwdriver.

A knife (you can use a plastic penknife) to cut and strip the cable.

Now the process itself

We bought the desired option, we also have a 3 X 2.5 mm flat cable (we will connect it).

We unscrew the case, usually it is held on one bolt, either from the side (like mine), or from below.

We see the contact group - "phase" and "zero" are connected to the main fasteners, the contact in the middle is ground.

Now we strip the cable. We need to achieve three separate strands with stripped wires at the end, about 1 cm, no longer needed. We look at the photo.

Now the blue and brown wire (there may be variations - red and blue), we connect to the main contacts.

The remaining yellow (sometimes green-yellow or white) is connected to a grounded connector.

All contacts need to be stretched well so that the wires sit well.

After that, we put everything in the case, collect it. Then we tighten it with a bolt.

That's all the fork is assembled. As you can see, nothing complicated.

Now video version

VIDEO

I will end on this, read our construction site.

.

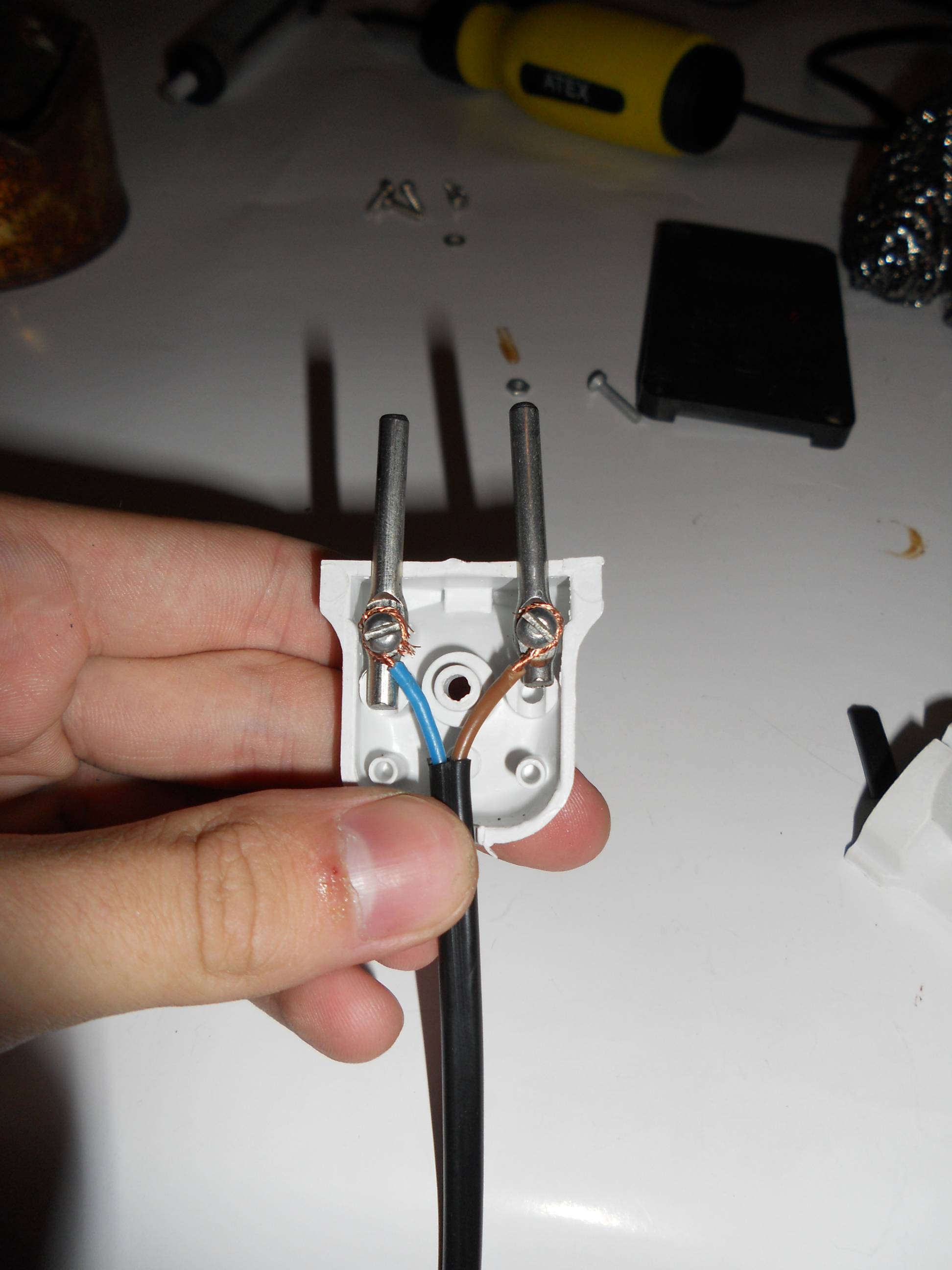

Repair of a collapsible electric plug

- Match the pin sizes of the plug to the size of the power outlet. Due to the disproportionate pins, the plug may not fit into the "two holes". Conversely, the diameter of the pins is small, so that the plug falls out of the socket. Select the correct socket and plug in size.

- Unscrew the nut with the screw connecting the halves of the plug.

- Separate the two halves of the plug.

- Inside the frame, unscrew the metal bracket, which is held by two bolts. The bracket is used to hold the cable in the plug.

- Remove some of the PVC wrapping from the ends of the cables.

- Twist the ends in the form of "rings", you can also tin the ends with a soldering iron.

- Unscrew the screws on the pins. To this place is the installation of the "ring" of the wire.

- Fasten the “rings” with screws. Installation of "rings" must be reliable. Poor fastening of the wires provokes heating, and even melting of the plug frame.

- Install the pins with the cables attached to them into the special bosom of the half of the plug frame.

- Fasten the halves together with a mounting screw and nut.

Can you disassemble?

Before you fix the plug for the outlet, you need to understand whether it can be disassembled or not.

Collapsible forks are of several types. Unfortunately, there is no single world standard for such devices, and this causes a lot of problems. For example, you bought a device abroad, you are trying to turn it on, but the pins are not included, because the distance between them is greater or less than that on which the holes at the outlet are located. Or there is an additional rod of an incomprehensible shape, which has nowhere to stick.

You can use an adapter, but most often in such cases, the plug is removed:

- unscrews;

- trimmed.

To fix the electrical plug in this situation, a new one is put in place of the old one, which is suitable specifically for your outlet. Such an operation usually does not affect the operation of the device in any way.

How to change correctly

The procedure for replacing the plug depends on the specific type. Having found out the model and design features, you need to study the corresponding instructions.

C1-b

Before replacing the C1-b model, you need to properly prepare the ends of the wires. First, cut the cord at an interval of no more than 5 cm from the beginning of the plug body. If, as a result of a poor-quality connection, the plug overheats, then the insulation next to the case will become rigid and will need to be replaced. Rings are formed at the ends of the wires, and then spring-type growers and washers with a flat surface are mounted on the screws. This structure is connected with screws.

It is important to tighten the screws into the pins to the limit, after which you can connect the wire to the next pin. Installation is carried out using protrusions in the housing, placing them in special recesses

A bar is applied to the wire and fixed to the case with fixing screws. If the insulation is thin, it is recommended to fix a rubber or alternative tube on top to prevent abrasion.In the end, it remains to fasten the parts of the case and tighten the screw.

C6

The preparation of wires when replacing the C6 plug is performed by analogy with the previous model. To replace a part, you also need to dismantle and then assemble a new body. If the basic configuration does not include grower forks, you will need to buy them separately. The yellow wire can only be connected to the grounding element. As a rule, it is located between the contact pads of the pins. In the two-pole version of the wire, the grounding element is not assumed, so the place for it inside the case will be free.

C5 or C6 by extension

Situations often occur when the power plug is faulty, and there is an urgent need to use an electrical appliance. To fix the problem, you can take any other faulty device and use its mains plug. The wire on the old appliance is cut, leaving it as long as possible. A 15 cm cord is enough for extension. The sheath of the cords is carefully cut to a length of 10 cm and the wires are removed, while leaving the sheath in place.

At the next stage, the length of the conductors is adjusted so as to move the places of the future rings from the ends of the wires

It is important to take into account when fitting that only wires of the same color are allowed to be connected to each other. Insulation is removed from them to a length of about 15 mm and twisted

For strong contact, three turns of entanglement are enough.

The bonded wires are placed in the cut sheath of one of the cables. There is no need to insulate the connections, since due to the displacement of the twists, there is no risk of contact between the bare sections of the wires. Then it remains only to rewind the cable junction with electrical tape.

Cord plug repair

Before opening and replacing the Euro plug, it is recommended to make sure that it is damaged. For this purpose, the plug of the machine wire is removed from the socket, its body part and wire are inspected. Signs of carbon build-up, melting, or a burnt odor will confirm the need for repairs.

For work, you will need a sharp knife, screwdriver, pliers. The algorithm of actions is as follows:

- cut off the old element;

- remove the upper insulation by a few centimeters from the cord;

- we clean each wire;

- we twist and cut the inner cores so that one centimeter of uninsulated wire remains;

- bend the wire ends with pliers;

- we inspect each wire. A standard-made cord, as a rule, comes with three wires - blue or blue leads to zero, yellowish-green indicates grounding, a black, brown or pink wire is taken under the phase;

- the wires are connected to the new plug, with ground being brought out to the pin located in the center.

It remains to clamp the cord with a jumper made of plastic material so that it is securely fixed in the required seat. Then we re-check the clamps, assemble the plug body, tighten the main screw.

Electric plug and its own replacement

Home »Household appliances» Repair of appliances »Electrical plug and its self-replacement

An electrical plug is required to connect your equipment to the mains. Instructions for replacing the power plug are necessary for people who do not know which pin to connect to which conductor. Today, almost all household appliances will be connected to the mains using an electric plug. On the market for these products, you can find a wide range of products. Some products may be grounded.

If the plug is grounded, then instead of two conductors you will need to connect three conductors. In this article, we will tell you not only how to change the plug on the wire, but how to replace the old plug.

Replacing the old Euro plug

Replacing the electrical plug may be required when one of the pins is broken.The electrical plug has a simple replacement technology, which includes:

It is necessary to cut off the old Euro plug and remove the outer sheath from the cord. From the end, you need to cut about 5 cm from the cord.

You need to strip all the wires by 15 cm. This length will be enough to connect the wires to the plug.

Now you need to cut off all the wires so that the bare wires remain all 10 cm.This will be quite enough to change the plug with your own hands.

To improve contact, you need to bend the ends of the wires with pliers.

Replacing a broken Euro plug has the most important stage, which includes connecting the wires. Typically, all cords have three wires. The blue pin is zero, the yellow pin is ground and the brown pin is phase. In order to properly change the plug with your own hands, you will need to connect the ground to the center pin.

- In order for the electrical plug not to wobble, you will need to clamp the wire with a plastic jumper. It will securely fix your wire.

- Now you need to assemble the finished Euro plug body.

As you can see, the design of an electrical plug is quite simple. If your refrigerator does not turn off, then you should read about this problem. That is why you can easily carry out the replacement yourself. You can watch this process in the video below.

Old electrical plug and its replacement

The old plug has a simpler design. Here, the replacement technique will be slightly different. Here are the basic steps you will need to follow:

First you need to cut off the old electrical plug body and disassemble it.

As with the Euro plug, you need to strip the wires. The ends should be stripped 15 cm of the wire. The design in a conventional plug may differ, which is why it is necessary to strip the wires, as indicated in the photo below.

There is no ground here, so only two wires need to be connected.

When connecting, be sure to pay attention to the polarity

Now you can start assembling the plug body.

As you can see, the old electrical plug has a simple assembly design. You can see how to do this in the video below. If your washing machine is making noise, then you should read about this problem.

.

This is interesting: The electric kettle does not turn off when boiling: this is informative

Which fork is better, collapsible or cast?

A reasonable question arises, which fork is better? Cast, of course. Its main advantage is the absence of low-reliable detachable mechanical contacts of the current-carrying wire with the pins of the plug. The conductors are connected in one of the following ways: spot welded, soldered or crimped. In addition, the plug is sealed, which increases the safety of its use.

The only drawback is the impossibility of re-installation. If the wire is frayed at the point of entry into the plug, and this often happens with electrical appliances that have to be constantly moved during operation, for example an electric hairdryer, then you will have to cut the plug and throw it away, and mount a collapsible plug in its place. You can replace the entire cord with a new one with a molded plug, but then you will have to open the electrical appliance, which is not always possible.