Replacing the Bearing in a Top Loader Machine

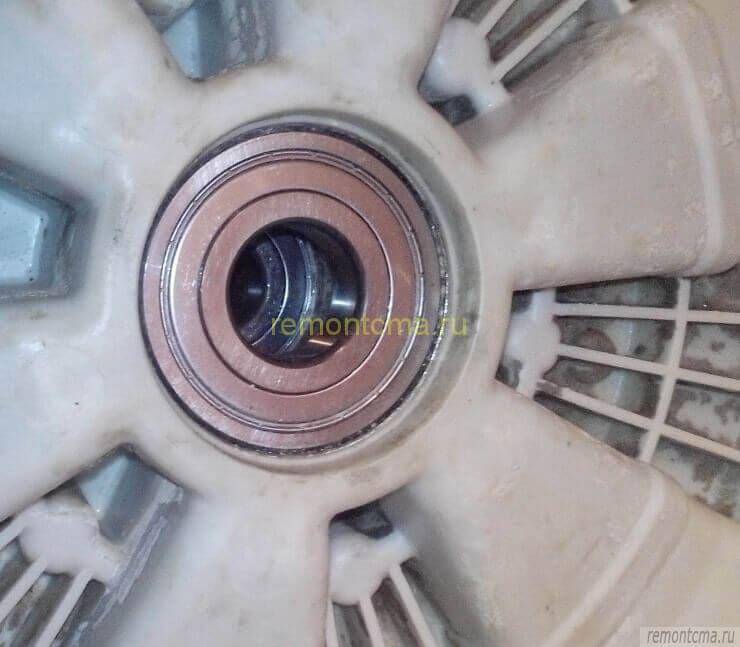

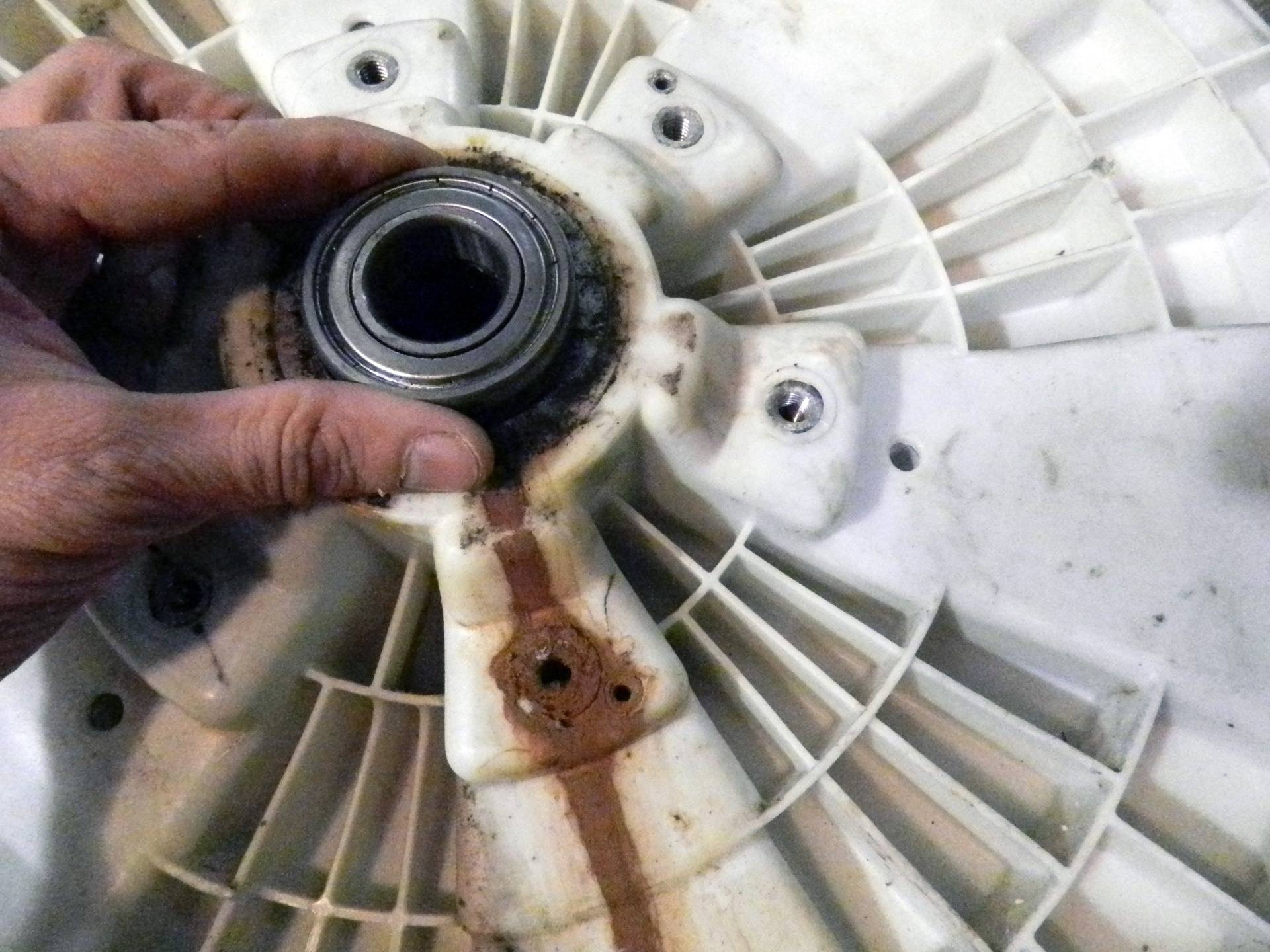

Separately, it should be said about top-loading washing machines. Where are the metal rings in these models? The bearings are installed on both sides of the tank; the shafts of the drum supports (flanges) are inserted into them. The bearings themselves rarely fail, usually the flanges are the first to withstand the load: the places of their attachments burst, and the shafts damage the place where the bearing is installed.

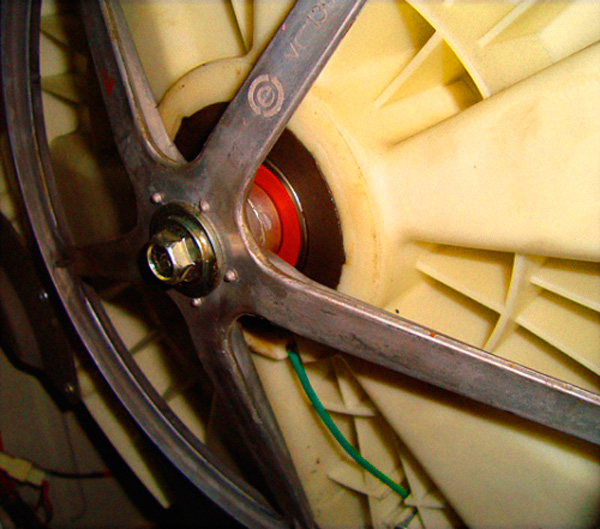

In the photo - a set for replacing the drum supports for a washing machine top loading

In the photo - a set for replacing the drum supports for a washing machine top loading

It is easier to change flanges and bearings on a top-loading machine than on a conventional machine. The side panels are removed first, and then the shaft of the smaller flange is removed from the bearing. Further, the replacement procedure will not differ much from that described above (taking into account the design features of the machine).

We repeat once again that replacing a bearing on a washing machine yourself is a complex process that requires special skills. Start repairing only if you are firmly confident in your abilities. We hope our article will help you.

Features of disassembling the tank and replacing bearings

We begin to disassemble the tank of the LG washing machine. First of all, we disconnect the fasteners (screws or latches) that hold the two halves of the structure together. Dividing the tank into two parts, we expose the drum pulley and its fastener, which we need to unscrew.

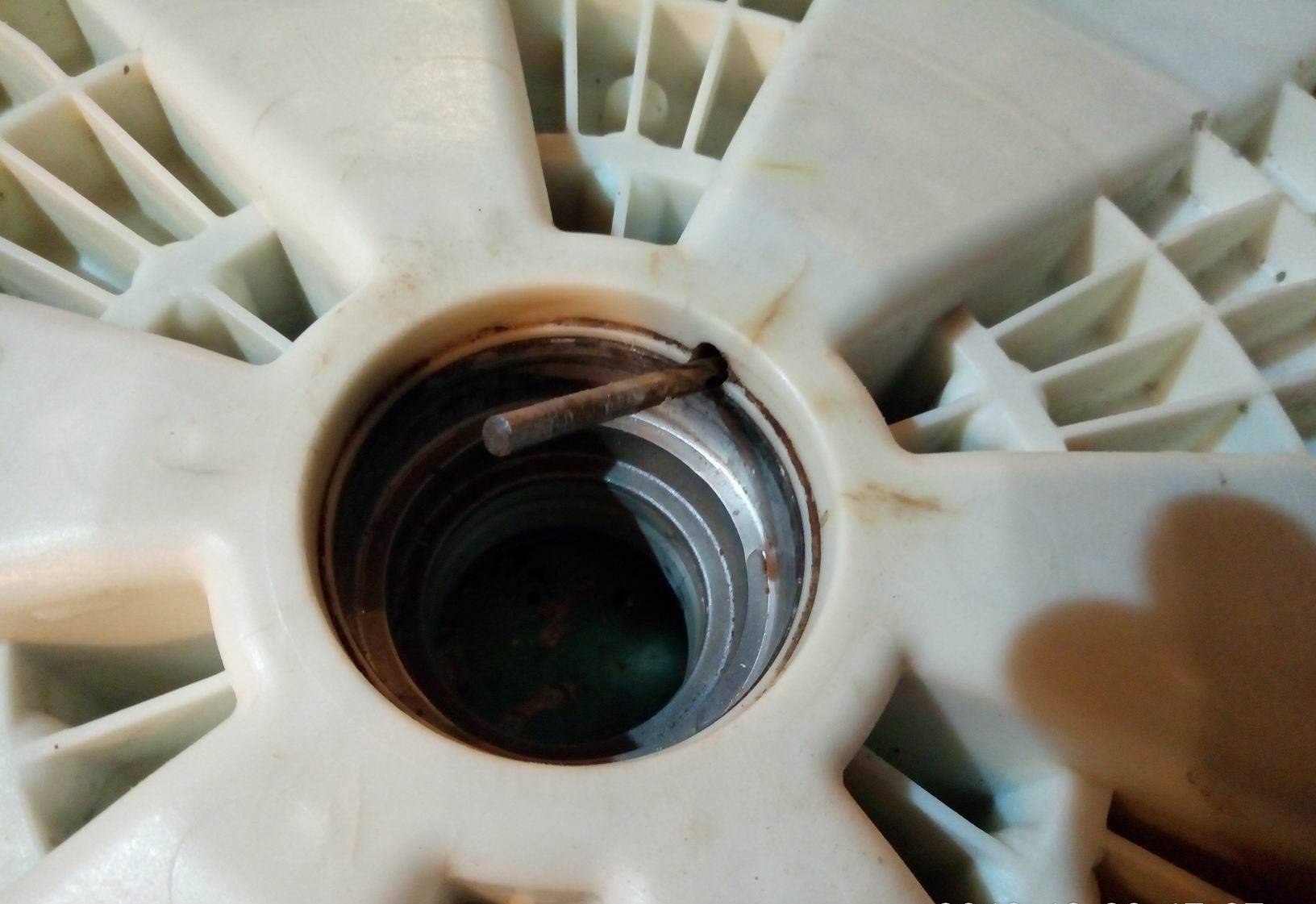

Having unscrewed the fastener holding the drum pulley, we carefully pull out the pulley, and screw the bolt into place. This little trick will subsequently help knock out the drum without affecting the shaft. Next, we rest the metal pin on the bolt screwed in by us and start hitting it with a hammer - our task is to knock out the shaft little by little. In no case should you hammer on the stud with significant effort, this can ultimately result in expensive repairs!

Having unscrewed the fastener holding the drum pulley, we carefully pull out the pulley, and screw the bolt into place. This little trick will subsequently help knock out the drum without affecting the shaft. Next, we rest the metal pin on the bolt screwed in by us and start hitting it with a hammer - our task is to knock out the shaft little by little. In no case should you hammer on the stud with significant effort, this can ultimately result in expensive repairs!

Having knocked out the shaft with the sleeve, we must carefully examine them for damage. To better understand how much the shaft is worn out, you need to hook a bearing onto it and turn it around. If there is some play between the bearing and the shaft, the shaft must be replaced. You can read more about disassembling a washing machine tank in the article How to disassemble a washing machine tank?

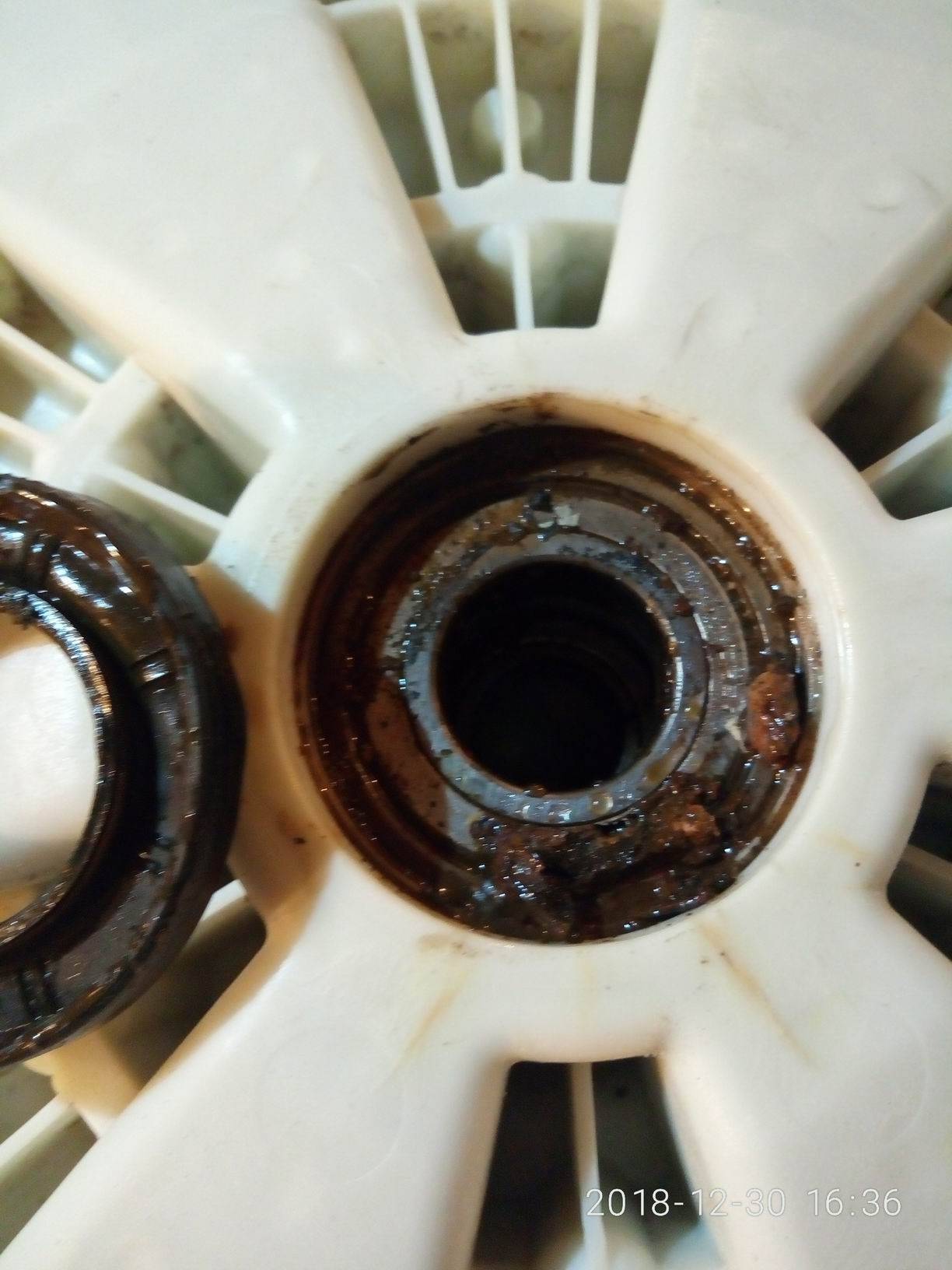

We proceed to replace the oil seals and bearings. We take the back of the drum and take out the oil seal from the hole in the middle of it. This is easy to do, you need to take a flat screwdriver and just pry it out of the hole. With old bearings it is more difficult - they will have to be carefully knocked out. We take our hairpin, we rest it on one edge of the bearing, then on the other, and with uniform blows of a hammer we knock it out of the hole.

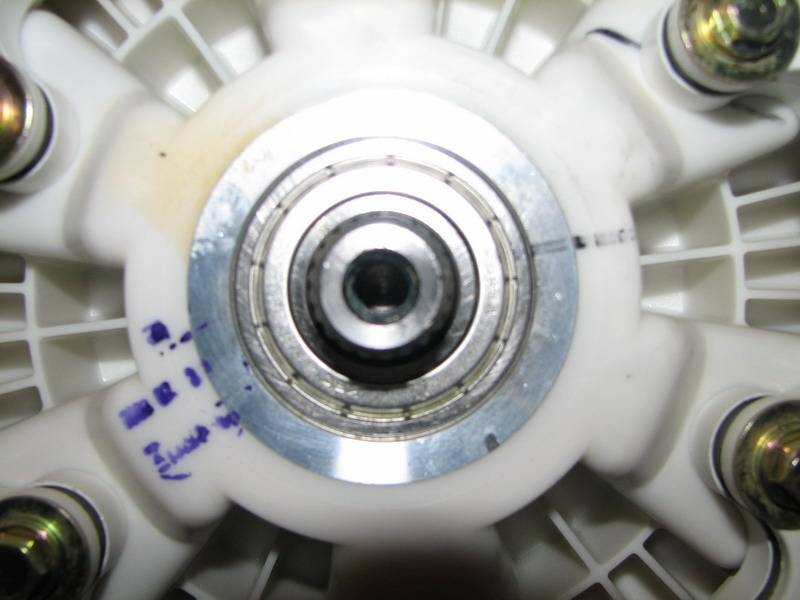

After removing the bearings from the drum, we clean the hole from chips and oil. The new bearing should only be “planted” in a very clean place. Carefully drive the new bearings into the hole until the end. Next, we lubricate the oil seals and put them in place - the replacement is done. We do all the above steps in reverse order to assemble an automatic LG washing machine.

What should not be done when replacing bearings?

Every stage of work on replacing bearings of an LG washing machine, including assembling and disassembling the machine itself, can be accompanied by oversights, which in turn can lead to problems with the repair. Experts have identified a number of typical mistakes that beginners make when they first take on the repair of a washing machine. And so what they do:

- Tear off the wires of the door lock sensor when removing the front wall of the washing machine.

- They tear the cuff of the washing machine hatch, trying to pull it out, while previously forgetting to remove the clamp.

- Damage to the pulley if an unsuccessful attempt to remove it from the axle.

- Tear off the "stuck" bolts, acting on them too hard and not trying to pre-lubricate or heat them.

- They cut off the wires of the temperature sensor, heating element.

- Tear off the filler pipe together with the hose.

- Pressing the bearings out of the drum damages it. The replacement of the bearings ends with the replacement of the drum.

Summing up, we note that it is quite possible to change bearings and oil seals on an automatic LG washing machine without the help of a specialist. But at the same time, keep in mind that, without experience in such a matter, you run the risk of running into even more expensive repairs. As they say, one wrong step and ...!

Solving common problems

In order for the repair of the device to be successful, it is necessary to correctly identify the causes of the breakdown. To do this, it is worth analyzing the symptoms of malfunctions:

- If the heating element breaks down, an error code appears on the monitor. If there is no such signal, the operation of the heating element can be assessed by other criteria - the quality of the wash, the dissolution of the detergent powder. To accurately determine the operation of an element, it is worth measuring the voltage. This is done on contacts.

- If the pressure switch breaks down, the water often drains itself. It is recruited and released immediately. The indicator does not signal that the tank is full. Therefore, water is continuously poured and drained from the device. Dealing with a violation is easy. For this, the pressure switch is replaced.

- If the bearings are broken, the unit generates unusual noises during operation. Sometimes the unit rumbles so hard that the sounds of a breakdown can be heard even in neighboring apartments. To identify a violation, it is worth spinning the drum in different directions. If a squeak and knock appears, you can suspect a bearing failure.

- A sudden shutdown of the device indicates the localization of the breakdown in the terminals. It can also indicate damage to the wires. The control module itself rarely breaks. Much more often the wires directed to the sensors burn out and close.

- The equipment of this manufacturer often breaks down the drain pumps. This is due to a poor design. The drain is often clogged. As a result, the blockage prevents the water from draining completely. In this situation, the “OE” code appears on the monitor.

- Sometimes the filler valve collar breaks. If it is broken, water enters the tank even when the unit is off. If the murmur of water appears after the device is turned off, a breakdown of the filler valve can be suspected.

Bearings break down quite often in LG technology. To cope with such a defect, it is necessary to properly disassemble the device. This must be done carefully, strictly following the instructions. It is advisable to photograph this process. Thanks to this, it will be possible to correctly assemble the unit.

Share link:

Replacing bearings in a LG direct drive washing machine. LG Direct Drive Washing Machine Bearing Replacement

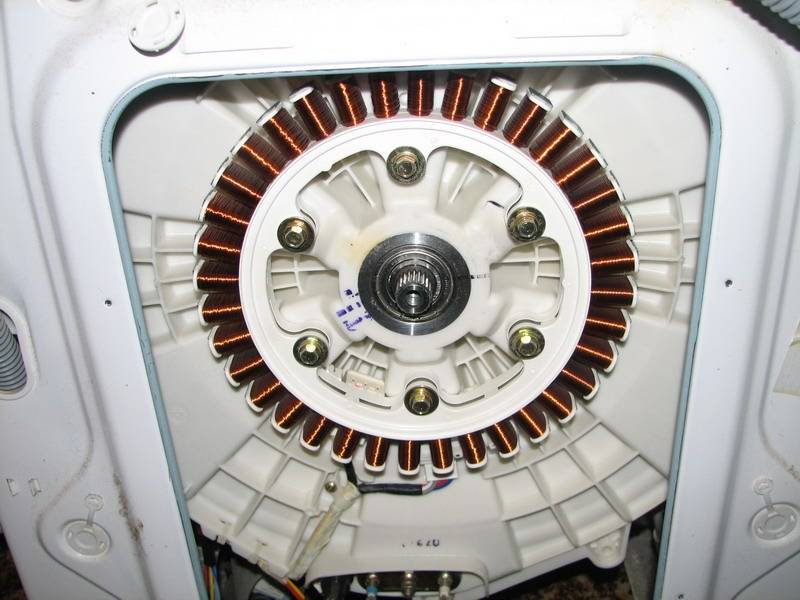

This article will describe the process of replacing the tank bearings of an LG direct drive washing machine.

Direct Drive, or Direct Drive, is a relatively new technology used by the Korean brand LG. Thanks to her, washing machines run quieter, since they do not have a belt, the engine is located at the back of the washing machine tank, and not at the bottom, as on other brands.

LG washing machine with direct drive. The engine is mounted at the back.

Disassembling the washing machine

First, remove the back wall and top cover. The top cover is fastened with two screws on the back, by unscrewing which the cover must be moved back.

After pulling out the powder tray, remove the control panel, it is fastened with two screws, which will become visible when you pull out the tray and several latches from above. Disconnect the control panel power wires.

In most cases, the power wires can only be connected one way, but take a photo or write down the locations of the wires just in case.

Now you can remove the front wall itself, for this:

- unscrew the two screws under the control panel

- three or four screws on the bottom, under the bottom panel that snaps off

- remove the O-ring from the drum cuff, it is convenient to do this with a flat screwdriver

- slide the wall up and then towards you.

Inside, the power wires for locking the hatch fit to the front wall, they are also disconnected.

Your washing machine should now look something like this:

Disassembled LG washing machine. Front view

Remove the rotor, disconnect the stator power wires

Disconnect the power wires of the heating element of the washing machine

The heating element is located at the bottom of the tank

Remove the pipes:

- the tank-drain pump connection is at the bottom right

- the dispenser-tank connection is at the top, under the detergent dispenser

Remove the shock absorbers, they are located on the left and right under the tank

Remove the tank from the springs and pull out

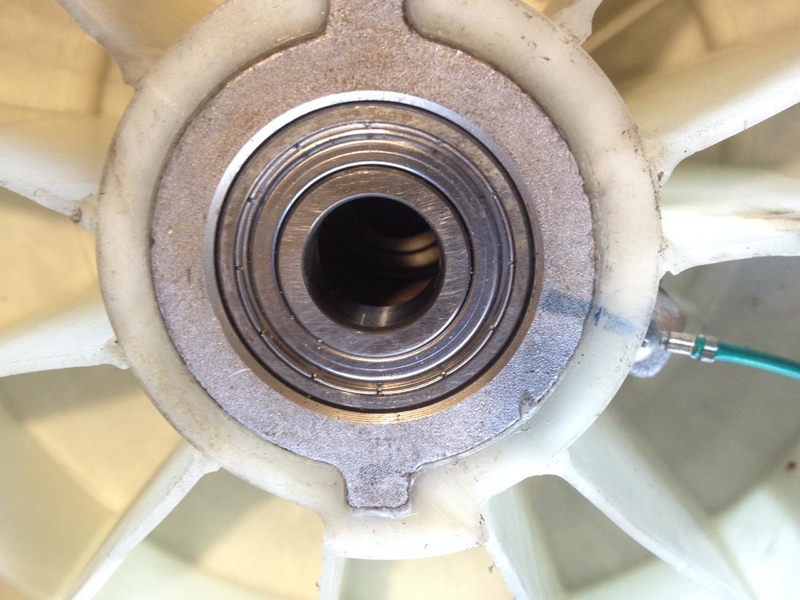

Dismantling and installing bearings

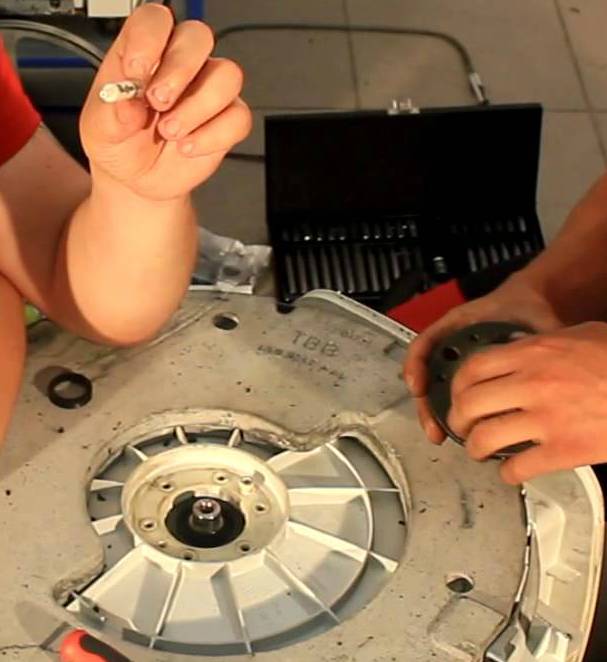

Now you need to unscrew the screws on the tank, cut the tank in half, pull out the oil seal and knock out the bearings.

De-scale the tank, thoroughly clean the place for the new bearings. It is advisable to lubricate the rubber of the seal between the halves of the tank with silicone sealant. If the elastic is disconnected, then the place of its connection should be at the top.

To make the new bearings sit better, the installation site can be warmed up with a hairdryer. Lubricate the oil seal with special grease.

Build and check

Reassemble the tank and washing machine in reverse order. After assembly, carefully check all connections, especially the clamps.

Replacing bearings at a service center

As you can see, replacing bearings is one of the most difficult types of repairs that should be entrusted to professionals. All our masters have extensive experience, in most cases we have the opportunity to replace bearings at the customer's home, without taking the washing machine to the workshop.

All work is done with you. During the work, we use only Swedish SKF brand bearings, which will be demonstrated to you before installation. After completing the work, all old spare parts - bearings and an oil seal will remain with you.

We give a guarantee for the replacement of bearings - from 6 months to 1 year. You can order repairs on the website, in the Repair of washing machines section, or by phone 8 (917) 420-49-39.

Features of the design of washing machines LG

This manufacturer produces quality direct drive washing machines. The use of technology helps to increase the resource of the motor. The same applies to moving elements. But sometimes the parts of the unit break.

The company's automatic machines include a large number of electromechanical components. During washing, all parts experience increased loads for a long time. They wear out under the influence of sudden temperature fluctuations. Also, water containing aggressive components leads to negative consequences. Masters claim that cars of this brand begin to break down after about 5 years of active use. Almost all breakdowns can be eliminated at home using improvised devices.

LG appliances can be standard or direct drive. In the first situation, the drum rotates under the influence of the drive belt, in the second - this happens after the start of the electric motor. The motor in such a unit does not contain small brushes that wear out quickly. To identify a breakdown, the device must be carefully examined.

Typically, the following parts of washing machines break down:

- tubular electric heater;

- bearings and oil seals;

- terminals and contacts;

- pressure switch;

- electric lock;

- drain pump;

- inlet valve;

- speed sensor;

- water pump;

- filling valve;

- contact wear;

- seals;

- hoses;

- drying system;

- steam treatment system.

Removing the tank-drum assembly

To change bearings, you will have to remove the plastic tub and drum from the body of the direct drive washing machine. The equipment must be disconnected from the network, as well as from the water supply and sewerage system.Disconnect the drain and inlet hoses from the back wall of the washer. The further algorithm of actions will be as follows:

- drain the water remaining in the nozzles of the machine. This can be done by unscrewing the trash filter. It is located at the bottom, behind the basement panel of the case. Remove the plug and collect the liquid in a container;

- remove the powder receptacle;

- remove the upper case cover by unscrewing the two bolts fixing it;

- unscrew the screws holding the control panel. It is not necessary to disconnect the wires, it is better to carefully remove the panel and hang it on a special hook on the side wall of the case;

- open the hatch door, bend the sealing collar, pry out the clamp that fixes it. Remove the holder ring from the machine;

- unscrew the screws along the perimeter of the front wall, remove the front panel;

- remove the upper metal bar, remove the counterweights;

- using pliers, unclip the clamp of the branch pipe connected to the dispenser. Remove the tube, pull out the detergent hopper;

- disconnect the pressure switch union;

- disconnect the drain pipe from the washing machine tank. It is fastened with a clamp;

- remove the back wall of the machine by removing all screws;

- take a photo of the wiring diagram, this will help with reassembly;

- unscrew the main screw of the direct drive. To do this, you will have to fix the motor;

- to remove the central bolt, hold the tank, preventing it from rotating, throw in the key with your free hand and unscrew the fasteners;

- remove the motor cover;

- reset the electric motor chips, disconnect the wiring;

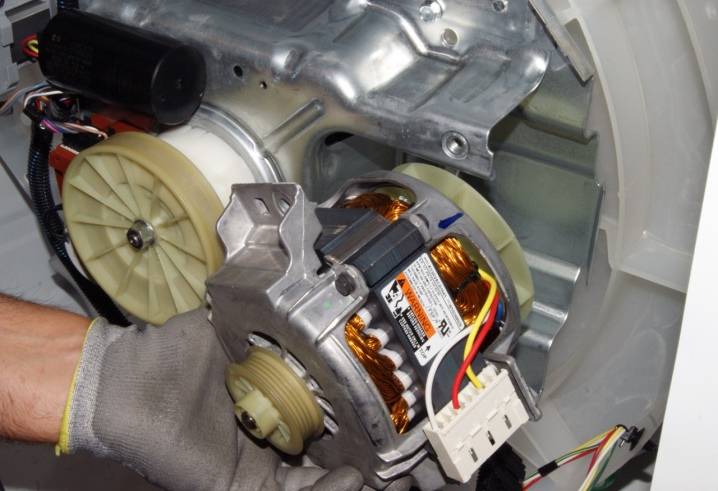

- remove the engine by unscrewing the screws holding it;

- disconnect the contacts from the heating element, pull out the tubular heater;

- remove the shock absorbing elements. To remove the damper bushing, push down on its latches from the inside and pull towards you.

Now, nothing prevents the extraction of the node. All parts and wires connected to the main tank of the machine have been removed or disconnected. You can raise the tank by removing it from the springs, pull it out of the body and place it on a flat, hard surface.

How to replace a bearing with your own hands

Replacing the bearing yourself is not so difficult:

- First, place the drum on a high surface. Place the bolts to be removed around its perimeter.

- Remove the front section and pull out the broken element. If difficulties arise after applying the lubricant, the part should be knocked out. To do this, it is recommended to place a block on the shaft and hit it with a hammer.

- It is also recommended to remove the second fragment of the tank. Dirt and scale inside should be thoroughly cleaned with a brush. It is best to use a wire for this purpose.

- Pull out the oil seal, take grease and fill the bearing seating areas with it. Pull out the part with a hammer and a punch. This is done through the top. In order to pull out the outer bearing, the tank must be turned over.

- The seat should be carefully cleaned. Any items that are broken must be disposed of.

- Take replacement parts and treat them with soap.

- Install the bearing in a special place and hammer in with a hammer.

- Insert the outer bearing in the same way.

- Lubricate the oil seal and apply soap to the edges. Press on the element with your fingers to push it in.

To prevent problems with repairs and maintain the functions of the unit, it is worth avoiding common mistakes that beginners make:

- When removing the front fragment of the unit, the wires of the hatch blocking sensor are often torn off.

- When trying to pull out the cuff, the part breaks, because inexperienced craftsmen forget to remove the clamp.

- Excessive impact on the attached screws without heating or lubrication will cause them to break.

- There is a risk of breaking the wires of the temperature sensor.

- The filler pipe is removed with a hose.

- There is a danger of damage to the drum, which makes it necessary to change it.

What to look for when repairing?

When performing self-repair of LG washing machines, you need to be very careful and careful.

It is recommended to pay attention to the following nuances

Be sure to pay attention to the seats where new parts will be installed.

If there is dirt or rust in it, it is imperative to get rid of them.

Before starting repair work, it is imperative to disconnect the equipment from the network and disconnect all hoses.

Take a closer look at the front of the LG washing machine, since at this moment many inexperienced craftsmen tear off the wires of the door lock sensor.

Trying to get to the cuff can tear the part as people often forget to remove the clamps - be careful.

You should be more careful with the stuck screws in the device of a branded washing machine.

If you act on them with excessive zeal, without using grease (all the same WD-40) or heating, then this may result in the failure of parts.

Care must be taken with the thermal sensor as well. Novice craftsmen often tear his wires out of carelessness and inattention.

Carefully remove the filler pipe - in many cases, inexperienced DIYers tear off this part along with the hose.

The utmost care must be taken when working with the drum of the washing machine.

If you accidentally damage this important component, then later it will only have to be changed to a new one, which will take more time and money.

Care must also be taken with regard to small details, so as not to damage or lose them.

How to replace bearings in LG washing machine, see below.

Replacing the bearing on the Indesit washing machine.

Hello everyone, I have a problem again. The other day the washing machine broke down, the bearing buzzed, and the prices for new cous-bites, and even the crisis has crept up, well, without hesitation, I flooded it into the garage for an operation, I think it's business - change the bearings, races and that's it)))! But it was not there, the autopsy showed that the drum was not collapsible, and I walked home to my favorite Internet with lowered hands, maybe I think I’ll find something smart, and I found it! In short, I sawed the drum in half, changed the bearing, drilled a bunch of holes in the old one the seam of the drum, pulled both halves of it with self-tapping screws and warmed it up with a hairdryer while pulling the screws together so that the gaps between the two sawn parts were minimal and left it to start twisted. The next day he unrolled the whole thing, sanded it and put it on sanitary silicone. While my drum was drying, I was cleaning the tena, the first night he spent the night with me in Calgone and acetic acid, the second in lemon, well, he seemed to be cleaned, though not completely. Today I tested everything and put everything together, and there was even the first wash, albeit without linen, until everything is nishtyak, it does not leak, and then the war will show the plan))! During the repair, there were many difficulties and jambs on my part, I even had to solder in a pair plastic drum in places, but I will not talk about it, if anyone is going to do the same poronography I will tell you. And I will throw off another photo, otherwise in my set of words, you will not immediately figure it out. By the way, the typewriter is 4 years old.

Contacting the service center is practical! Need proof?

- The washing machine was restored to work on the same day.

- You can call the technician to repair the washing machine until 23.00 on any day, weekends and holidays.

- You will receive full diagnostics for free.

- You will be offered original spare parts, no doubt about it.

- Doing work from home doesn't take long.

- You have a guarantee in accordance with GOST for everything that has been done and installed.

- You save money with a flexible pricing policy that provides benefits and discounts.

You should not take on painstaking troublesome work if you are not sure of success. Trust the experience of the master, and you will not have to regret your decision. Call us!

Parsing the car

To disassemble the device, first of all, it is worth disconnecting it from the power source and blocking the hoses.It is recommended to install the unit so as to gain access to each of its parts. All disassembly procedures are worth photographing. This will help to properly assemble the device after the repair is completed.

Removing the top cover

First you need to unscrew the lower fixing screws that are located on the back wall. They should be slightly moved back - by 3-4 centimeters. Then remove from the stops, fold back and set the cover aside.

Detergent drawer

To remove this part of the device, you need to press it with your finger on the latch located in the center. Then the tray can be pulled out. The side bolts can then be seen. They should be unscrewed with a Phillips screwdriver.

Disconnecting the wires

To disconnect the wires, you need to unscrew the plastic holders. Then it will be possible to pull out and disconnect the wires. To do this, you need to find and squeeze the latches. Then disconnect the connectors one by one.

How to remove the clamp

The next step is to open the door. The clamp spring should be hooked. This is done with a screwdriver. It is located under the rubber band of the drum. The clamp should be removed, and the cuff should be inserted under the drum.

Service panel cover

To remove the service panel, it is worth squeezing out the clips that go on top. Then lift and slightly tilt the panel towards you. It is recommended to unfasten the wires and pull them out through a special hole. Then remove the control panel from the device.

Cuff

The hoses connected to the cuff can be disconnected with a flat screwdriver. The collar is fixed to the tank with the same clamp as on the hatch. Therefore, the spring should be hooked. This is done with a flat screwdriver. As a result, you will be able to get the retaining clip. The cuff can then be removed from the drum and set aside.

Disconnecting the tank hoses

To make the tank lighter, it is worth detaching the heavy counterweights. Then you need to unscrew the screw fasteners of the counterweight located on top and remove it. You can do the same for the lower counterweight.

Heating element

To remove the heating element, it is recommended to detach the batteries and cut the tie with wire cutters. Then you can unscrew the grounding pins.

Disconnecting all items associated with the tank

It is imperative to remove all parts attached to the tank. The clamps of the nozzles can be loosened with a Phillips screwdriver. Also, remove the screws securing the pressure take-off chamber.

Stator

This part should also be removed after unscrewing the screws. It is recommended to tilt the element downwards. This will help remove the wires from it.

Shock absorbers

These fragments are fixed on pins. To remove them, you need to put on a key and squeeze the locking tendrils. Then pull the part towards you with pliers. It is recommended to disconnect it and lower it down. Then remove the front shock absorber. This is done by means of a spanner key. Use pliers to remove the pin.

Tank

To remove the tank, it is recommended to remove the side springs that fix this structural element. Use a flat screwdriver to flip the plug, lift and pull the spring out of the hole located on the frame. Carefully lower the drum down and remove the spring. Do the same for the second side.

When and why should you change?

LG washing machines have long conquered the market. This applies to a wide variety of models. Devices with a capacity of 5 to 8 kg are especially popular today. They are chosen by many consumers who want to buy high-quality, reliable and durable household appliances. However, even the owners of such devices may encounter certain malfunctions and shortcomings in their work. There can be many reasons for this - it all depends on the specific problem that has arisen.

Due to it, unhindered rotation is carried out. If you use this household appliance too often or do it without observing all the necessary rules, the specified part may wear out a lot. The first signs of a problem can be noticed immediately.When a drum spins in vehicles with a faulty bearing, it makes noise, creaks or hums.

Replace the damaged part as soon as possible.

It is risky to drag out for time, because after a while the drum will stop spinning altogether, which in the future will provoke a breakdown of such an important part as an electric motor. For this reason, it is very important to always keep under control the operation of such household appliances.

In order for the bearing in the design of the LG washing machine to last as long as possible, it is recommended to select models with a direct drive and place them on a perfectly flat surface. It is advisable to adjust the equipment according to the level.

How much does it cost to replace bearings in a washing machine - price overview

The cost of repairs associated with replacing bearings depends on a number of factors:

- region and location of the service center or repair shop;

- manufacturer's brand;

- features of a particular model, if any;

- availability of a warranty period after the repair has been completed;

- urgency of work.

On average, the work of replacing bearings, performed by professional craftsmen, takes from one to three hours, depending on the model of the washing machine and the design of the tank (collapsible / non-collapsible). The cost of replacing a bearing in a washing machine in different regions of our country is:

- in Moscow - from 1,000 rubles;

- in St. Petersburg - from 1 100 rubles;

- in Krasnodar - from 1,800 rubles;

- in the city of Vorkuta - from 1,800 rubles;

- in Novosibirsk - from 2,000 rubles.

Although the work associated with replacing the bearing belongs to the category of quite difficult. Nevertheless, many users try to do it on their own, since on the Internet you can find many stories that suggest how to do it correctly. One of these videos is shown below.

Replacing the bearings on the drum of the Indesit washing machine. Replacing the bearings of the indesite washing machine

When choosing bearings for a washing machine in a store, take worn-out parts with you first so as not to miss. If you buy online, make sure that the selected bearing really fits your Indesit. Prices can also be found on the Internet or by phone.

It is important that you need to buy not only the bearing itself, but the whole set: two bearings and two oil seals, they need to be changed together, otherwise the replacement will need to be repeated soon

Tools for disassembling washing machine Indesit

Replacing the bearing of an indesite washing machine with your own hands is not so difficult. The main thing is to get the bearings themselves, while you will have to disassemble the entire machine. Please be patient with the following tools:

- Phillips and flathead screwdrivers;

- socket and open-end wrenches;

- hammer;

- bit;

- hacksaw;

- pliers;

- WD-40 lubricant;

- glue and finally replacement parts.

Dismantling the washing machine

First of all, disconnect the equipment from the power supply, turn off the water, drain the water and turn off all communications.

Free the pump filter from water (below the hatch, under the front panel) - unscrew and pour out the water. Next, move the device to be repaired away from the wall for further work.

Repair of washing machines indesit ws84tx, wiun 81, wisl 85, wisl 83, w84tx, iwsc 5085, iwsb 5085 and other models, when replacing the bearing, is carried out in the same way.

We proceed directly to disassembling the device:

- We remove the top cover, for this we unscrew the two self-tapping screws from the back with a Phillips screwdriver.

- Remove the back panel, unscrew the bolts and remove the panel.

- Removing the front panel:

- we take out the tray for powder and detergents by pressing the central clamp, we remove the tray;

- unscrew all the screws on the control panel, two behind the tray and one on the opposite side;

- use a flat screwdriver to open the latches on the panel;

- do not touch the wires, place the panel on the top of the case;

- to open the hatch door, bend the rubber, pry the clamp with a screwdriver, remove it;

- we unscrew the two screws on the hatch, disconnect the wiring, remove the cuff inside the tank;

- unscrew the door bolts with glass and set aside;

- removing the front panel, unscrew the screws.

- We remove the parts to pull out the tank with the drum:

- remove the drive belt, pull it towards ourselves by scrolling the pulley;

- remove the pulley, fix its wheel and unscrew the central bolt, spray with WD-40 if necessary;

- We do not remove the heating element, but disconnect the wires from it and from the electric motor;

- we take out the motor, unscrew the three bolts and swing back and forth;

- disconnect the pipe through the bottom, put the washing machine on its side, loosen the clamp with pliers and disconnect it from the tank;

- unscrew the bolts that hold the shock absorbers at the bottom of the case;

- unfasten the cuvette, first remove the pipe, loosening the clamp, then the hoses, then unscrew the bolt and remove everything together, disconnect the pressure switch hose.

- We take out the tank by pulling it up a little.

- If the tank is welded, we make holes for future bolts and saw the tank with a hacksaw.

- We take out the drum by hitting on its sleeve.

- Remove the oil seal by tightening it with a screwdriver.

We proceed to replace the bearing indesite:

- Remove the bearing with a puller, if it is not there, then use a chisel and a hammer to knock out the bearing, lightly tapping on it.

- Clean and lubricate the new bearing area.

- Fit the part straight into the seat by tapping on the outside of the bearing. Also install the second part.

- Slide the pre-lubricated oil seal onto the bearing.

- Insert the drum into the tank, glue the two parts, tighten the bolts and proceed with the reassembly of the washing machine.

Do-it-yourself replacement of the bearing on the Indesit washing machine. Instructions for replacing bearings of an Indesit washing machine with a glued (welded) tank with your own hands:

- flat and curly screwdrivers,

- spanners,

- tubular wrenches or heads,

- hammer,

- pliers,

- bearings,

- oil seals.

- Remove the top cover. To do this, unscrew the two self-tapping screws from the back of the Indesite washing machine. After that, the cover must be shifted back a little. Lift up slightly and remove it. Then set it aside so that it does not get in the way during further disassembly. Some models have plastic clips that secure the front of the cover. In such cases, remove from the latches with light blows from yourself.

Remove the cover

- Next, unscrew the six self-tapping screws on the back wall. It should detach itself, freeing access to the motor. In principle, the engine will be removed at the end. But in any case, the wall had to be removed in order to disconnect the wiring and the strap from the tank so that it would not cling anywhere.

Removing the back cover

- In washing machines, the indesite tank is pulled out of the body through the top. To remove it, you must disconnect the front panel, powder receptacle, concrete weight, rubber cuffs and disconnect the water level sensor tube. This is for the top. From below, you need to disconnect all the wiring, the drain pipe that goes to the pump and connects it to the tank and turn off the shock absorbers that hold the tank so that it does not loosen much during the wash process. After all this is turned off and disconnected, it will be possible to remove the tank. Look

Washing machine device

- It is easy to remove the wiring from the heating element. To do this, pull the clamps down. Do not mix up the wires later during assembly. The yellow wire in washing machines is always yellow. The wire that plugs into the temperature sensor has a plastic connector. The remaining two wires are power wires. They can be interchanged as they are supplied with alternating current.

- Remove the power chip from the motor and the ground wire.

Remove the power chip

- To disconnect the shock absorbers and the branch pipe, you need to access the bottom of the washing machine. To do this, tilt the washing machine to the front or to the side.

- Using pliers, remove the clamp and disconnect the drain tube from the pump.Before that, it is recommended to unscrew the filter and drain the water from it. Unscrew the two nuts on the left and right sides. This will release the shock absorbers. Squeeze the shock absorbers and move them closer to the tank so that they do not interfere in the future. Make sure nothing is holding at the bottom of the tank.

- Reset the washing machine. Using a pipe wrench or a socket, unscrew the bolts from the weight located on the top of the machine. Then take it off.

We remove the load

- Unscrew the self-tapping screw from the back that holds the powder receptacle. Remove the detergent drawer. To do this, lift it slightly and pull it towards you. At the front, the powder receptacle is screwed on with three self-tapping screws. One at the bottom and two at the top. Before removing it, you need to unscrew the screws securing the control panel.

- Remove the powder receptacle and panel by lifting it up. Disconnect the wires from the panel.

- It is not necessary to remove the wires from the powder receptacle. Remove the rubber loop from the hook and disconnect the nipple. In some models, the branch pipe is not held on a hinge, but with a spring clamp.

- Remove the cuffs from the tank by disconnecting the clamp securing it and pulling towards you. Removable from the front using the same method.

Removing the cuff

- Detach the tube from the water level sensor. It is advisable to remove the pressure switch so as not to break it off when removing the tank. To do this, use a thin screwdriver to disconnect from the latches.

- Pull the tank out of the body. Further, all manipulations will be carried out only with the tank.

The removed tank

- Remove the springs and weight from it.

- Disconnect the motor.

- Drill holes around the perimeter at four centimeters intervals to fit the screws, as assembly will be done with screws. Where you can't drill, skip.

We cut the tank

The next step is to unscrew the pulley. To do this, you need a T40 star wrench. Remove it gradually by loosening it.

Replace the screw and knock the shaft out of the drum. Assemble in reverse order.