How to glue decorative gypsum stone

Gypsum stone has such advantages as maximum similarity with natural stone, ease of maintenance, hardness, environmental friendliness, resistance to moisture and temperature extremes.

Important details when working with plaster:

- The cement-sand mortar is applied with a wide spatula, and the residues are removed with a narrow,

- Tile adhesive requires the use of a notched trowel,

- The mastic is applied with a silicone spatula,

- It is more convenient to apply PVA glue with a sponge or a brush with a short nap.

To the question of how to glue a decorative gypsum stone, the masters answer - first you need to prepare the tools:

- cement mortar,

- special glue,

- reinforcing mesh,

- electric drill,

- acrylic primer,

- hydrophobic solution,

- dowels,

- building level.

How to properly glue a decorative stone

Gluing works are carried out only in weather from +5 to +35 degrees, so that the glued material does not peel off. Gluing is done from top to bottom so that the stone does not get dirty with glue.

We cut decorative stone

- The surface must be cleaned of grease, paint, oils and dirt, and it must also be coated with a primer.

- Next, the glue is prepared. Dilute two thirds of the package in five liters of water and mix thoroughly.

- Then pour out the remnants of the glue and knead. The mass turns out to be thick and retains its capacity for three hours.

- This solution is applied to the surface in a thin layer.

- A notched trowel creates waves, and a flat layer of glue is applied to the stone in a layer of 1 cm.

- A rim of glue is formed along the edges.

- Next, the material is applied to the surface and pressed with a rotational movement so that the remnants of the glue come out.

- If tiles are to be joined without seams, they must be joined tightly.

- The resulting rows are leveled using the building level and fixed with dowels.

If the work is carried out in rooms with high humidity, for example, in a sauna or swimming pool, it is necessary to pre-treat with a hydrophobic solution.

The adhesive solution is again prepared and applied with a smooth trowel in a layer of 2 mm, after which it is spread with a notched trowel.

In the resulting adhesive layer, a reinforcing mesh is embedded and then ironed with a spatula. It is necessary to apply the reinforcing composition gradually, and when the work is completed, do not forget to wash the tools and hands from the glue.

Cladding technology

Regardless of the type of surface on which the tiles are applied (brick, concrete, etc.), the laying is carried out according to a single scenario. First, it is necessary to knead the glue to a homogeneous structure if dry cement compositions are used. After that, the material is evenly applied to the wall, covering an area at a time not exceeding one square meter. If a sealant or liquid nails are used, then in the first case the glue is distributed in waves, in the second - drop by drop.

After that, you need to glue the first tile by pressing on the stone. It is not recommended to exert excessive effort at this stage. A small amount of glue should come out of the tile. There are several guidelines to follow when laying tiles:

- with a seamless method of laying, the procedure must be started from the bottom row (otherwise, from any angle);

- if a stone of the same size is used, then it must be laid so that the final drawing is uniform;

- cut edges are attached so that they remain invisible to the eyes;

- if laying is carried out from the middle of the wall, then a guide rail is previously attached to the surface;

- Use a rubber mallet to level the decorative tiles.

To form seams, it is necessary to leave equal gaps between the tiles. The rows of stones should run parallel to each other

At the end of the procedure, excess glue is removed, and the seams are rubbed with a specialized compound, the type of which is indicated on the package. It is recommended to apply such a product using a pastry bag.

At the end of the procedure, a protective layer should be applied to the tiles. This procedure extends the life of the decorative material. A protective layer is necessary in cases where the artificial stone is laid in rooms with high humidity and houses with children and animals.

Advantages and disadvantages of stone finishing

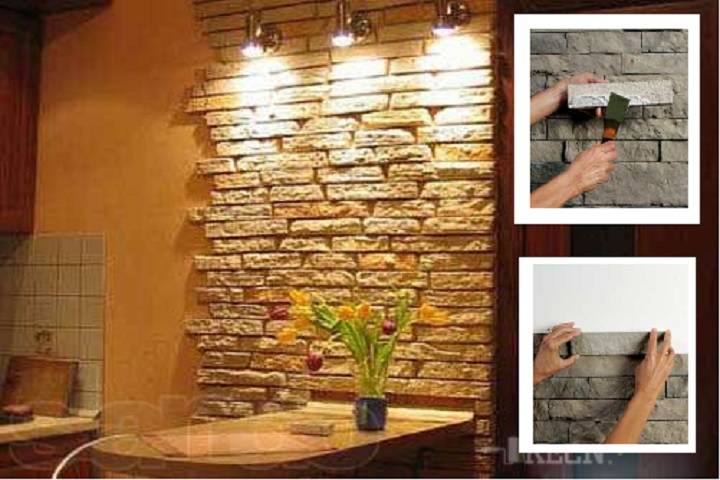

Designing a room with natural or decorative (artificial) stone or in combination with other finishing materials, designers use in decorating:

- individual elements: columns, arches, fireplaces, stoves, countertops;

- bathrooms, showers;

- kitchens;

- hotels;

- offices;

- saunas, baths.

The main advantage of natural material over artificial is durability. But in terms of safety parameters, color variety, ease of gluing, efficiency, surface load, transportation, the ability to make tiles yourself - choose a synthetic artificial stone.

But this finishing material has small drawbacks:

- the quality of a flat surface on the back side;

- you need to ask for a product certificate;

- has a long service life, but not eternal, like its natural counterpart;

- may fade under the influence of sunlight - additional processing is necessary.

How to apply a decorative stone wall covering

Before finishing, completely clean the wall from the past coating, dirt, because the strength of the finished finish depends on this. Then apply a primer to the surface. For greater strength, some use a reinforcing mesh.

The finished mixture is applied in equal parts to a small section of the wall and hands create the necessary shape, imitating a stone.

In addition, you can use tools like a scarpel, trojan horse or bushard, special stencils. After drying, the surface is sanded and painted if necessary. To give additional volume, the convex areas are painted with a lighter color, and the recesses with a darker one.

Can finishing material be attached to a paper surface?

- Classic paper canvases will get wet if you apply glue to them. As a result, it will not be possible to properly fix the stone. Most likely, the finishing material will fall off the wall even before the glue dries (read here how and how to apply glue to the wallpaper).

- Vinyl wallpaper won't get wet, but still won't fit. There will be insufficient adhesion between their surface and the plate. Therefore, the finish will quickly begin to lag behind the wall.

When carrying out finishing work, specialists always remove the coating from the wall, be it old paint or wallpaper. Otherwise, the plates will not fix correctly, and in the future they may come off under their own weight.

Therefore, it is highly discouraged to attach a decorative stone to the wallpaper. But there is one exception. If, after combining the wallpaper and the artificial finish, no more than two cm of the wallpaper sheet remains under the decorative slab, it will still be fixed normally. When you need to dock wallpaper with a decorative stone, you can use one of the following two methods:

When you need to dock wallpaper with a decorative stone, you can use one of the following two methods:

-

First way:

- First, mark the line from which the decorative finish will begin.

- Next, wallpaper sheets are glued, while they should go beyond the line by 1-2 cm.

- The last step is to attach a stone that will cover several centimeters of the paper web. In this case, the seam between the stone decor and the wallpaper will not be visible.

-

Second way:

- You can first attach some of the tiles and mark the borders of the decorative finish with a pencil. Set aside the remaining styling elements around the edges.

- Now wallpaper is glued that will go beyond the designated border.

- Using a knife, the sheets are cut along the indicated line.

- Once the glue is dry, you can attach the decorative tiles around the edges. They will overlap the wallpaper by a couple of centimeters, but that's okay.

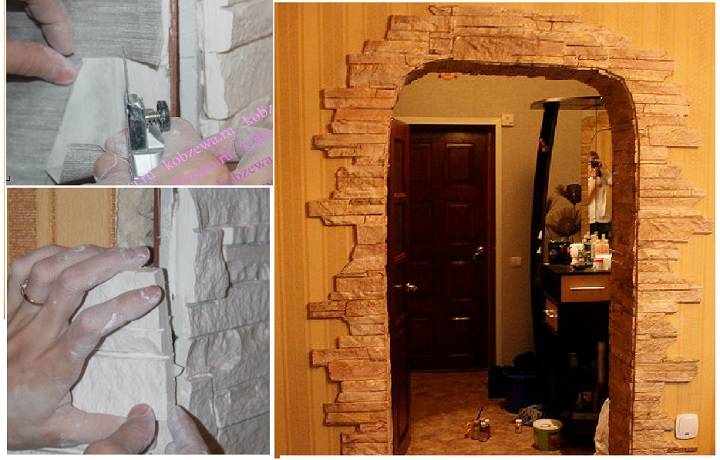

Step 3. Facing the corners

For facing the inner and outer corners, you can purchase special corner tiles that are more expensive than usual, but significantly simplify the workflow. If the budget is limited, you will have to adjust the stone yourself using a grinder or a hacksaw. There are 2 options here - to overlap the stone or grind the edges at an angle of 45 degrees.

When using the first option for the outer corners, the open ends must be filed and tinted, otherwise they will stand out too much.

In the inner corners, both ends are closed, so processing is not necessary.

The second option is more suitable for plaster products, which are convenient to cut with a miter box.

So, first, the required number of fragments is determined, they are cut from a certain side, the sections are processed with a file.

Next, the stones are smeared with glue and alternately attached to the walls on both sides of the corner, carefully combining the joints. When the vertical of the corner is laid out, you can expand the masonry to the walls.

How to glue decorative stone at the corners. Preparation for finishing

First you need to calculate the amount of material. If the stone will cover the entire area of the walls in the hallway, subtract the area of the openings and add 10%. If the decor will be located around openings, niches, in separate fragments on open walls, draw an approximate sketch of the finish and measure each section. Then add up the area and add 10-15% for pruning. When buying material, it should be remembered that the amount of an angular stone is counted in linear meters, and the amount of a regular stone is in square ones.

Artificial stone in the hallway

Additionally you will need:

- hacksaw or grinder (depending on the type of stone);

Bulgarian

- simple spatula 7-9 cm;

Putty knife

- notched trowel 15-17 cm;

Notched trowel

- level;

Kapro professional cast level

- long ruler;

- pencil;

- paint brushes;

- varnish;

- file;

- acrylic primer.

Acrylic wall primer

You can attach an artificial stone to liquid nails, cement or gypsum-based glue. The consumption of glue is necessarily indicated on the packaging, so when buying, you should know the exact area of the finish and take it with a small margin.

Liquid Nails

If gypsum stone is used, a special miter box with high sides is required for cutting.

Plastic miter box

When everything you need is purchased, you should start preparing the surface.

Step 1. Removing the cover

Dismantling the cover

If the stone will cover the walls of the hallway solid, the old covering is removed completely to the base. If separate areas are intended for decoration, you need to dismantle the coating very carefully.

On the wallpaper, the borders of the finish are marked with a pencil and carefully trimmed with a clerical knife, leaving a margin for stones 1-2 cm wide.Glue from the wallpaper is soaked with water and removed with a spatula, the walls are thoroughly washed

Also remove the paint, if it is peeling or cracked, peel off the loose plaster.

Step 2. Aligning the walls

Putty

Laying the stone should be carried out on a flat, smooth surface - this will facilitate the work process and increase the strength of the decorative coating. Therefore, all small cracks, gaps, grooves are rubbed with putty, and if there are drops of more than 5 mm, it is better to plaster the entire area

Particular attention should be paid to doorways: deep cracks can form along the perimeter of the box, for the sealing of which it is recommended to use a cement solution

Step 3. Priming

Padding

Dry walls must be lightly sanded to smooth out irregularities in the putty areas, and then wiped with a cloth to remove dust. After that, the surface is treated with an acrylic primer 1-2 times. If there are wallpapers around the perimeter of the treated areas, the primer should be applied so as to capture the edge 1 cm wide - what will be hidden under the cladding.

Rusting

In most cases, the decorative stone is placed under the jointing. This implies a certain distance of the tiles from each other. These seams, in the process of pressing down the stone, can be filled with glue. Therefore, it should be carefully eliminated. After that, these seams are filled with special jointing. If the grouting mixture consists of the same adhesive, then it makes no sense to remove the remnants of the adhesive from the joints. When the mastic has completely hardened, it can be tinted in a different color, which will enhance the expressiveness of the decorative stone. As for the width of the seam, everything here will depend on the tile you choose. The seam can be millimeter wide or several centimeters wide. For example, when a brick is placed under the jointing, the standard joint width is 1.2 cm. If the process of gluing the tiles was carried out correctly, then there may be enough glue to form the seam, which has come out into the seams. To arrange it, you should wait a little so that the mixture hardens slightly. Shaping can be done using a special wooden spatula, which must have a certain shape and the appropriate thickness for the seam.

Sewing seams

Sewing seams

If the squeezed out glue is not enough for a beautiful seam formation, then an additional mixture should be prepared. To apply it, you will need a special bag from which it will be convenient to squeeze the mixture into the seam. So, there is less risk that you will stain the tiles. When the seams are dry and the mixture has a crumbly character, the surface of the stone can be cleaned from the remnants of glue that could get on it. This can be done with a dry brush, but never with a wet and hard brush. This can cause irreparable harm to the decorative stone.

Form making

The appearance of the decorative stone depends on the form. To obtain variety, you can prepare several different templates at once, the samples from which will alternate during installation. Tray modules with a minimum of ten cells are usually used.

Large shapes will speed up the stone making process if you need a lot of it. In terms of materials, they usually use silicone or plastic. Unfortunately, the service life of such molds is limited by a certain number of fillings.

Polyurethane is a more expensive option.

These molds can be reused as many times as necessary, while the form will retain its original appearance. Any stone you like is suitable as a sample for the matrix.

Some people use molds made from planks.

Moreover, the more irregularities and roughness on their surfaces, the better. The composition after pouring will repeat these defects, which will give it the resemblance to a wild stone. A sample is not needed with this technique.

Installation instructions

You need to glue the decorative stone on the wall according to the instructions, which will be given below. In addition, this process requires compliance with certain rules.

You need to know that the drywall (work surface) on which you will glue this finishing material should have a temperature slightly less than +25 oС. If the surface is hotter, then it will be necessary to wet the back of the material with water. This should be done 20-30 minutes before styling begins.

Water must also be moistened with that part of the wall that was previously prepared.Remember that the final result directly depends on the correctness of the preparatory work and compliance with the laying technology.

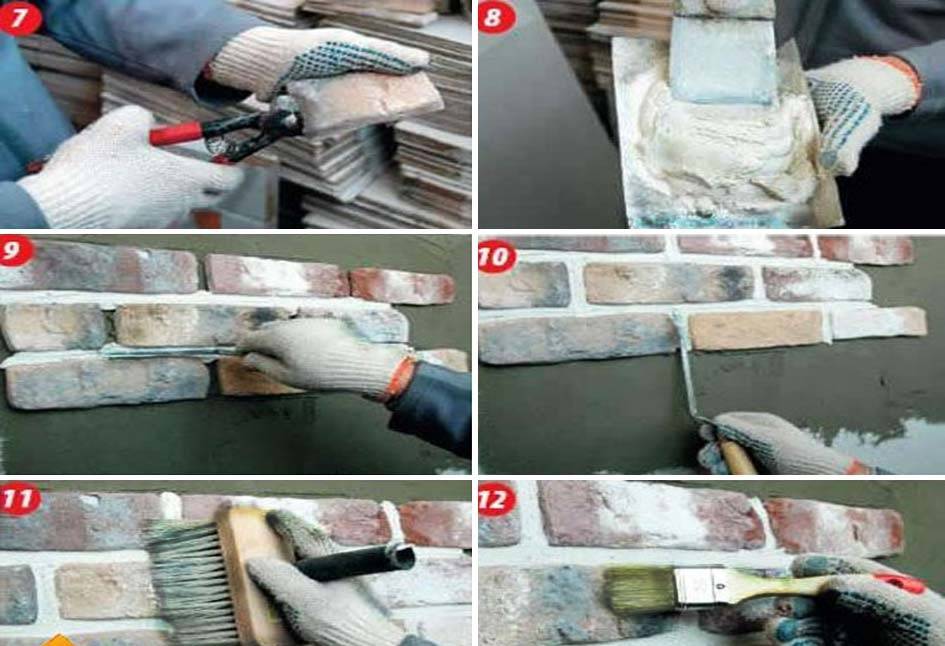

The step-by-step installation instructions are as follows:

Markup

- we put markings on the wall. It looks like horizontal lines going every 10-15 cm. Check the evenness of the lines according to the building level;

- leave a little space at the bottom for trimming. This must be done if the standard number of rows does not fit on the wall;

- we apply glue with a spatula to the back of the stone. If it is uneven, apply a 6 mm layer of glue. Apply the glue in an even layer, without gaps;

- then we press the elements tightly against the wall and hold for some time until the material adheres to the base at the desired level;

- when installing a pair of elements, use special plastic crosses. This will make it much easier to align the seams between the material;

- it is best to glue the stone from the corners of the room;

- then we do the styling horizontally;

If it is necessary to report incomplete elements, then the stone must be cut. For these purposes, a grinder with a metal or diamond disc or an ordinary hacksaw for metal is suitable.

After completing work on a certain area (after installing about 15 tiles), coat the glue that has come out in the seams with a wooden stick. When the solution starts to dry, wipe away excess with a dampened brush or cloth.

After all the tiles have been glued, give the glue time to crystallize. Usually this process takes about a day, but sometimes it can take a little longer. After that, we carry out the following manipulations:

- wipe the surface of the stone with a damp sponge;

- we clean and dry the seams;

- after that we fill the joints with grout of the desired color. For this, you can use a special syringe gun. Or you can get by with a regular plastic bag with one cut corner. The grout may differ in tone from the color of the tile. This will give the finish more elegance;

- slowly squeeze the grout into the joints, carefully filling them;

Grouting

- the seams must be filled completely. It is recommended to leave at least 5 mm from the back of the tile. This will help create relief, as well as the play of light and shadow on the wall;

- remove excess grout with a rag.

After that, finishing work can be considered completed.

Following the instructions above, you will cope with the task without any problems and will be able to correctly and efficiently glue the decorative brick to the plasterboard wall. The masonry technique is quite easy to perform and accessible to any person.

Such decorative masonry on the wall or part of it can give your home more comfort and warmth. Using a minimum of materials, you will achieve a completely different look for your home.

How to properly glue fiberglass on a plasterboard

Correct installation of plasterboard hatches

Areas of application of gypsum decorative stone

An artificial product is understood as an industrial product that imitates a wild, natural stone. The decorative material is created from plaster, quartz and colored cement with the addition of polyester resins. Both gypsum and cement stones can include fillers from natural marble chips, granite. Acrylic stone is also produced (for example, the Tristone brand), which has a rich color palette.

The material is suitable for various substrates: drywall, concrete, brick, wood, plastered surfaces, it is used for indoor and outdoor use. The most durable is the quartz finish. It easily withstands temperature extremes, is not susceptible to the development of mold, is suitable for damp rooms, and is frost-resistant.

The fields of application of decorative stone are varied:

- facing of stoves, fireplaces;

- finishing of bathrooms, showers, baths, saunas, swimming pools;

- installation of sinks, countertops, bar counters;

- production of window sills, sinks, sanitary products;

- creation of decorative elements and sculptures, moldings, baguettes.

Acrylic stone is often used for repairs in medical institutions, furniture making. A concrete-based material is popular in decorating the facades of buildings and structures; for interior decoration, it can also be used, especially in offices and premises with high traffic. Plaster stone is often used to decorate living rooms, kitchens, hallways, it gives a cozy look to the apartment. They can also frame mirrors, niches, headboards. Due to its low mass, gypsum stone is well suited for decorating partitions and ceilings.

What glue is used when working with decorative stone

The stone is glued to the following compositions:

- mastic,

- tile adhesive,

- cement-sand mortar.

We recommend the following options:

- KNAUF.

- Dauer Uniflex.

Cement-sand mortar is prepared in proportions of 3 parts of sand to 1 part of cement. The disadvantages are long hardening and non-plasticity.

Tile adhesives must be diluted according to the instructions on the package.

Usually this is no more than 10 liters per 25 kilograms of dry mix. The resulting composition reliably adheres to concrete, brick, is plastic, it is convenient to apply it, and then remove the excess.

But there is also one drawback - it does not fall into the cracks in the brick, thus, the engagement area decreases, which in the future can lead to the appearance of air bubbles.

The adhesive mastic is thick, has good adhesive qualities, and is suitable for working with both bricks and plaster. But applying it in a thin layer is difficult.

If the gypsum stone needs to be glued to the plastered wall, the cement-sand mixture should be discarded, since it does not adhere to the plaster and peels off.

For gypsum walls, PVA glue is the best choice. It is not only easy to apply, but also elastic, does not shrink, and quickly sets.

Apply the composition to the entire surface, and press the material tightly and hold for several seconds.

When asked what kind of glue is used when working with decorative stone, when it comes to wooden walls, the masters answer that there are several ways. If the wall is not covered with anything, it is treated with an antiseptic, and then PVA glue is used.

A wall treated with stain, paint or varnish must be sanded, then treated with an antiseptic, and then proceed to gluing.

VIDEO

Laying decorative stone on drywall

- Adhesive for decorative stone;

- Primer;

- Grout the desired color;

- Water repellent - as an alternative to waterproofing, but in this case, the walls will not only be able to resist moisture, but also breathe.

The most interesting thing is the finish. Some of the steps may seem too easy, but each step is important to create the perfect finish. Decorating country houses and apartments with decorative stones is becoming popular. The reason is the chic look of the interior, which is obtained after using this material. Moreover, working with a decorative stone is easy, similar to laying tiles.

Therefore, finishing is done independently, if you have the skills to work with building material.

- Drywall is strong, but cannot withstand a huge load, so only light grades of stone are used.

- If the drywall is outside, in the open air, the decorative stone cladding will not last long, they are considering the possibility of completely replacing it every 3-4 months (at best), which is irrational.

- Moisture-resistant gypsum plasterboard must be primed without fail, after drying it is ready for further finishing.

If this is not the first repair and previously there was wallpaper, paint or whitewash on the drywall, everything is removed so that the adhesion of the stone and the surface is as strong as possible. Walls in need of plastering are being processed.A primer is applied on top, which brings the particles of the wall closer together, which leads to a better attachment of the finish. “Liquid nails are a safe and environmentally friendly material, but the cost per square of finish is high for medium to large jobs, so this cladding adhesive is rarely used.

The surface to be faced (brick, concrete, plaster) must first be primed with a hydrophobic primer to retain moisture in the glue in contact with them, and the seams of the brickwork must be rubbed with a leveling compound.

- hacksaw or tile cutter;

- building level;

- notched spatula; Types of tools for laying artificial stone

- roulette;

- pencil;

- building bucket for mortar;

- rags;

- crosses;

- wand.

Drywall fits these parameters and is an excellent base for artificial stone

Attention! There is a limitation on the type of drywall that is planned to be revetted with decorative stone - it should not be moisture resistant. Types of drywall suitable for facing with artificial stone The secret to quickly installing artificial stone is to pre-sort it. After opening the package, take a few minutes to sort by color and size, which will further reduce the time spent looking for a suitable fragment.

That is, how to glue, from top to bottom or vice versa, depends only on your preferences.

After opening the package, take a few minutes to sort by color and size, which will further reduce the time to find a suitable fragment. With a solid surface facing, direction does not play a special role. That is, how to glue, from top to bottom or vice versa, depends only on your preferences.

However, if decoration with an artificial stone is performed only on certain areas of the surface, then it is advisable to start from the widest part. Add 10-15% of the "safety interest" to the value obtained as a result of the calculations. This will prevent a shortage of material and eliminate the need to control its consumption too scrupulously. Quite often, it becomes necessary to trim fragments of artificial stone in order for them to fit more organically into the overall canvas. It is easy to carry out with a hacksaw or grinder, so feel free to experiment to achieve the best result.

However, try to place such fragments away from eye level. Alternatively, seam masking can be applied, where a small amount of adhesive is applied over the edge of the cut, hiding it. The choice of glue will depend on the base material of the decorative stone. Almost any glue is suitable for gypsum.

Silicone sealant is a good choice. If the stone is cement-based, choose tile adhesive. If the cladding will be fixed using a seamless method, then you will not need anything else.

Otherwise, it is necessary to purchase a composition for a beautiful design of the seams.

Types of decorative stone

Types of artificial stones

Types of artificial stones

The finishing material for the walls is different in its composition. Therefore, having studied the features of each of them, you can independently choose options for facing surfaces on the street and in the house. Artificial stone is made in several ways and is divided into the following types:

- Ceramic - requires high temperature annealing to create.

- Gypsum - ideal for interior cladding. You can make tiles at home. The appearance is difficult to distinguish from natural. Not used as an external element due to instability to cold.

- Concrete - concrete is the main component, so the cladding is heavy and not always appropriate as an interior decor. Resistant to frost and negative atmospheric manifestations.

- Acrylic - plastic in the molding process, manufacturing is allowed at home.

- Flexible - a modern cladding element in which sandstone is applied in a thin layer on a flexible surface.

Where the use of artificial stone is appropriate:

| A place: | Description: |

|---|---|

| Courtyard | A wide assortment makes it possible to decorate not only the outer walls of the house, but also paths, gazebos and fences. |

| Facade | Installation on a foundation creates additional protective properties against wind, rain and frost. The base is most susceptible to mechanical stress. |

| Fireplace | Furnishings of stoves and fireplaces have long been made, both natural and artificial materials. Even tiles for brick, which can withstand high temperatures, are suitable. |

| Arch | Interior portals without doors are arranged in random order. Wallpaper, plaster, painting goes well with the finishing material. |

| Front door and hallway | Facing work begins from the corner; tiles prepared in advance in shape are used for the opening. |

| Window | The room looks beautiful, in which not only the interior portals are decorated with stone. An apartment with clear zoning of space looks good. |