Step-by-step instructions for making a stove

Step 1. In our example, a simple 250 liter thick-walled barrel is used - ideal for making an oven. Cut off the top of the barrel, but do not discard.

The top of the barrel is cut off

Step 2. Make a kind of pancake cover out of the upper part for oxygen supply. Fit it to the size of the barrel - as a result, when installing between it and the walls, there should be 2 mm around the entire circumference. Weld the neck of the lid. In its center, make a hole for installing a pipe through which air will be supplied. Also weld 4 channels, as in the photo below.

"Pancake" for air supply Another photo of the element

Step 3. Slightly stepping back from the upper edge, cut another hole in the wall of the barrel - for mounting the chimney. In our example, a pipe with a diameter of 140 mm will serve as a chimney.

Chimney installation hole

Step 4. Start making the cover. Make it out of 4mm sheet metal and weld a sealing ring on the bottom to match the diameter of the barrel. In the center of the lid, make a hole for the pipe that was welded to the pancake.

Lid for the oven In the middle of the lid there is a hole for the air duct from the "pancake"

Step 5. Make simple legs at the bottom of the barrel to keep the structure stable. The legs should be metal, as well as all other elements.

Making stove legs Legs must be metal

Step 6. Place the stove in the right place and start creating the chimney. In our example, it is of the prefabricated type. First of all, make a clamp by means of which the chimney will be attached to the body.

A clamp that will allow you to attach the chimney to the stove

Step 7. Make guides in the chimney, thanks to which it will easily be fixed on the body.

Chimney guides

Step 8. Dock the barrel to the pipe, without fail laying all the joints with asbestos cloth. Put a clamp over the fabric, tighten it.

Asbestos cloth Tighten the clamp over the cloth Finished joint between pipe and barrel

Step 9. That's it, the structure is assembled, you can check its performance. Load sawdust or wood inside.

Stove loaded with fuel

Step 10. Pour used oil over the fuel, then install the cap. As for the "pancake", do not use it yet. After the fuel has ignited, remove the cap and put on a "pancake". It takes about 10 minutes to fully warm up such a structure, in the future the firewood will burn for a long time. Although how much combustion will last depends largely on the quality of the fuel.

Photo of the finished oven for the garage

Video - Homemade potbelly stove for a garage

If you wish, you can modify the design described above, although it will already perfectly cope with its functions. For example, to increase efficiency, you can increase the surface and thereby improve heat transfer. To this end, weld metal plates on the sides of the case.

In addition, you can make a grate with an ash pan: cut out a circle from a sheet of metal along the inner diameter of the body, drill holes with a diameter of 60-80 cm and install from below. After that, the ash will be poured down through the holes - to where the ash pan is equipped. It is believed that the fuel will burn faster because of this, keep this in mind and make sure that the ash pan is sealed as much as possible.

Types of modern wood-burning stoves for heating a private house

Modern wood-burning stoves are of various types: devices differ in power, according to the principle of operation, in appearance. Such appliances also often have additional functions that make the stove a complete replacement for a stove and a water heating boiler. Most often, for country houses, they choose an ordinary wood-burning model with an electrical connection.

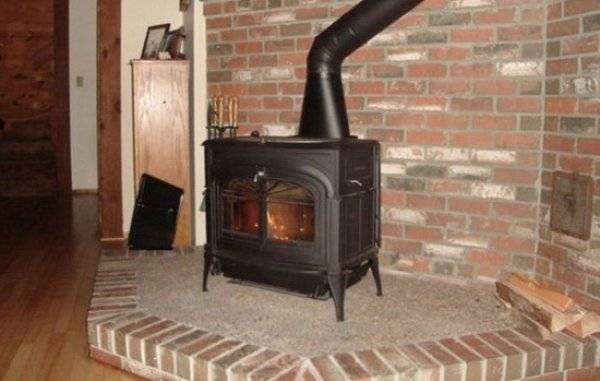

Classic wood burning stove

An ordinary stove, for which firewood is used, is the most common option for heating a country house. The device is not afraid of the absence of a gas pipeline or any problems with electricity, and its reliability and long service life compare favorably with other types of devices.

Photo 1. A classic wood-burning stove made of bricks and equipped with a place for cooking and storing firewood.

There are several types of devices that differ in the material of manufacture.

Classic Russian brick stove - a universal choice

A great example of a multifunctional device. With its help, the house was heated, and food was prepared, and water was heated for household and personal needs. She often served as a sleeping place, her ability to keep warm for a long time made the winter cold fearless.

Modern Russian brick ovens represent various improved versions of the historical prototype. They are even more functional. Such ovens are easier to maintain, they evenly warm up the room, thanks to the long burning system. It is possible to install an oven and hob, as well as a heat exchanger for water heating.

Classic metal stove

Compares favorably with a brick device in its compactness and ease of installation. Despite their small size, such devices are designed to heat a fairly large space due to a long burning system. For manufacturing, steel or cast iron is usually used, combined options are not uncommon.

Photo 2. Wood-burning metal stove with installed thermal glass and a place for cooking.

It is possible to connect a water circuit to devices of this type, add additional functions, for example, a hob. By installing a door made of thermal glass, it is possible to manufacture an analogue of a home fireplace, which creates a special comfort.

The device of a conventional wood-burning stove includes two chambers - the main firebox and a chamber for burning the gases released during combustion. For efficiency, such devices are often used to heat the room not by the burning of wood in the firebox itself, but by the process of their smoldering. For this, a system is equipped that blocks the air access to the combustion chamber at the right time.

Combined electric wood stove

To increase the efficiency of heating equipment, as well as to cover large areas, a variant of combined devices has been developed - wood stoves equipped with one or more heating elements and requiring connection to the mains.

Reference. It is often advantageous to equip such electrical devices with a water circuit to maintain heat throughout the house.

The principle of operation of such equipment at the first stage of operation does not differ from the operation of a conventional wood-burning stove: firewood is put into the firebox, after they burn out, an electric heating system is connected, most often these are two electric heaters installed on the sides of the combustion chamber, which turn on as soon as the temperature begins to fall below a certain mark.

This method allows you to effectively extend the life of the heat from one firewood load, more expensive models can also be equipped with an automatic fuel filling device, which removes the need to directly monitor the operation of the stove. In the event of a power outage, such a device can be equally effectively used to heat rooms in the mode of a conventional wood-burning stove.

Which heat transfer material is better, which stove to choose for the villagers. Photo

In order to choose the right equipment for heating a country house, you need to take into account a number of important factors.

Photo 3. Classic brick wood-fired stove.With the help of it, you can not only heat the room, but also prepare food.

It is necessary to calculate the area of the heated room. An ordinary brick wood-burning stove can take up a lot of space, while it will qualitatively heat only a small room in terms of area.

The material for the manufacture is essential. Classic brick is reliable, keeps warm for a long time and gives the house an atmosphere of coziness, and a metal device will warm up the room faster and take up less space

In the case of choosing cast iron, the walls of the combustion chamber will be protected from oxidation by combustion products, and the device itself will retain heat much longer. A stainless steel heating device warms up faster and cools more quickly, but this material is lighter and stronger than brittle cast iron, which can crack when it cools quickly, and, unlike it, must be repaired.

Photo 4. Cast-iron wood-burning stove. Equipped with thermal glass, which will allow you to enjoy the flame.

Most often, a combination of steel and cast iron is used for manufacturing. The cast iron doors and walls of the combustion chamber are protected from deformation due to high temperatures, and the stainless steel housing helps to avoid sudden temperature changes.

Photo 5. Stainless steel wood-burning stove. Such a device heats up and cools down the fastest.

If high-quality heating of the house is a priority, you should stop at a compact metal heater connected to the water circuit. It can be installed in a separate room, where it will not interfere with your home.

If the device will be used both for cooking and as a piece of furniture, it is better to choose brick models equipped with an oven and a cast iron hob. Heat-resistant glass doors are installed on the combustion chambers of such models, which allows them to be used as a fireplace.

When selecting heating equipment for a large house, you should pay attention to electric-wood stoves with an additional connection to the water circuit. For a small country house, where the owners come for a short time, a compact wood-burning stove made of metal is quite suitable, which will successfully cope with the task of quickly heating a small room

For villagers who need a better and more regular heating of the premises, additional functions for cooking, independence from power outages, the best option would be a brick wood-burning stove of long burning, which retains heat for a long time due to the body and is able to work completely autonomously.

Where to place a brick oven. Key recommendations

As noted earlier, the choice of a particular place for a heater depends on many factors of an individual nature. Therefore, you can choose the correct location of the stove in the house using universal recommendations.

- First of all, the structure must be located so that during operation it gives off maximum thermal energy from the entire surface.

- If only one room will be heated with the help of a future stove, then it is recommended to put the structure close to the walls due to the fact that the thermal energy in this case will come only in 2 directions out of 4.

- In other cases, it is advisable to install the heating device at a certain distance from the wall surface.

- Also note that the width of this gap must be at least 150 millimeters, otherwise heat transfer will deteriorate significantly.

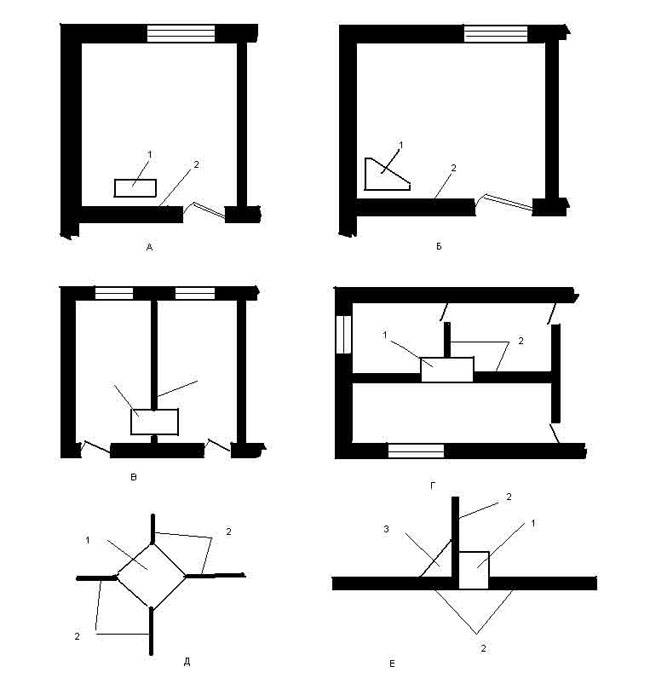

- The image below (more specifically - a, b) clearly demonstrates a couple of options for open placement of heating devices in the presence of a recommended air gap (it is also called a retreat).As you can see, the stove is located in the corner of the room or in the middle of the wall.

- If two adjacent rooms are heated at once with the help of a stove structure, then the ideal (and also the most effective) option is to locate the device in the internal partition between the rooms (as shown in the same image, point c).

- There may be a more serious option. If the heater will simultaneously heat three adjacent rooms (and this is also possible), then it should be placed in an internal partition that separates these rooms, but as shown in the image (subparagraph d). Here in 2 rooms there will be one side of the structure, and in the remaining third - two at once.

- Image e shows another option for heating a pair of adjacent rooms with one stove. This option differs in that the combustion chamber is located on the veranda. This is ideal for small country or garden houses.

- One important point: when planning the placement of the stove between adjacent rooms, it is required to take into account the fact that the chimney should be erected above the partitions only when their thickness is at least 250 millimeters (that is, 1 brick).

Note! Today, many owners of private houses prefer to have a stove in at least one of the rooms. Of course, gas or electric heating has a lot of obvious advantages, but still they can hardly be considered autonomous (unlike stove)

If you follow some rules, as well as adhere to the above recommendations regarding the placement of the stove structure, then you can ensure yourself the most comfortable microclimate for the winter.

Advantages and disadvantages

Long burning stoves certainly have many positive aspects, but it should be noted that they also have enough disadvantages. And the choice of just this type of heating directly depends on whether you can come to terms with certain nuances or not. That is why you should study all the pros and cons of gas-generating furnaces, which are presented in the table for convenience.

Advantages:

- saving materials for the furnace, models of such furnaces use furnace materials much more efficiently than other more traditional counterparts;

- the efficiency of gas-generating furnaces reaches a maximum value of 85%;

- compact size and the ability to select a model that will harmoniously fit into any interior;

- easy control, switching the active mode of operation to the smoldering mode is carried out by adjusting the incoming air, and fueling is necessary after 5 or more hours;

- the possibility of using various types of fuel, both solid (wood, coal, wood waste, pellets) and liquid.

Disadvantages:

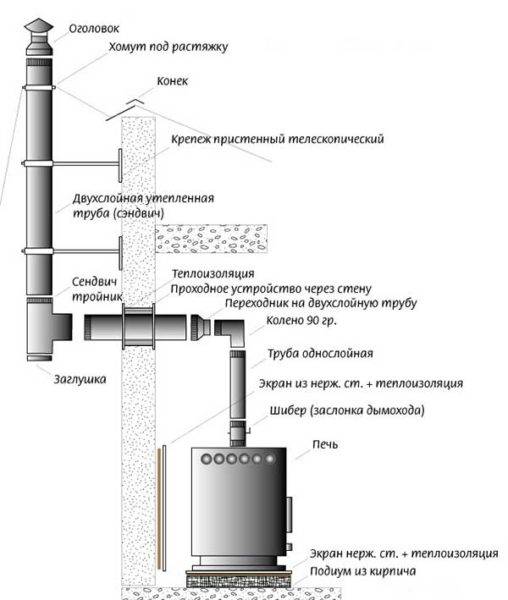

- the complexity of building a chimney, a chimney for such a stove must be built based on strict rules and regulations;

- incompatibility with multi-pass curved chimneys, this is due to the intensive production of condensate, which requires a strong draft to drain;

- a large amount of emitted combustion products, due to which the chimney will have to be cleaned more often;

- the smoldering mode is not activated instantly, in order to enable economical long-term combustion, you must first warm up the house to the required temperature;

- lack of versatility, each model of a gas-generating furnace is designed for a specific type of fuel: solid or liquid.

6 Water use

Arrangement of a wood-burning stove for water heating of a house is a good alternative for classic air systems, since the liquid has many advantages. As you know, water has an excellent specific heat, especially when compared with dry air, so it is able to receive and transfer impressive amounts of heat. The heated heat carrier is easily transported to the most remote sections of the pipeline through pipelines with small dimensions.

Water is the most harmless source of thermal energy, while it is non-toxic and does not increase the risk of fires. Moreover, this type of coolant is always available, and sometimes completely free. Wood heating can also be used for hot water supply, as well as for powering the coil in the bathroom.

Among the disadvantages of water heating, one should single out the high freezing point, which is equal to 0 degrees Celsius. Freezing, the coolant begins to expand in size, damaging important components and devices of the heating system. Together with air, water can trigger corrosive processes in ferrous metals. And if it has increased rigidity and contains a lot of calcium and magnesium salts, this leads to the appearance of scale on the inner surface of the line, radiators and other important parts of the system, which negatively affects the final quality of work.

DIY iron summer cottage stove - step by step instructions

The simplest version of an iron stove is a well-known potbelly stove, which is absolutely undemanding to fuel. Refined factory options can be made of steel and cast iron, have a decorative finish and a glass door, installed on bent legs

But for self-production, something else is important: simplicity, reliability, straight lines of construction

Table 2. Characteristics of Butakov's popular iron furnaces.

| Model | High school student | Student | Engineer | Assistant professor | Professor |

|---|---|---|---|---|---|

| Room volume, cubic meters m | 100 | 150 | 250 | 500 | 1000 |

| power, kWt | 6 | 9 | 15 | 25 | 40 |

| Dimensions, cm | 37*66*78 | 37*66*78 | 44*76*89 | 57*97*115 | 67*111*125 |

| Weight, kg | 55 | 77 | 113 | 182 | 235 |

| Chimney diameter, mm | 120 | 120 | 120 | 150 | 200 |

| Min. chimney height from the grate, m | 5 | 5 | 5 | 6 | 8 |

Loginov's potbelly stove is successful for self-production. It differs from an ordinary stove by the presence of two shelves at the top of the firebox, which more than double the path of the burnt gases, increase the efficiency and heat output.

Step 1. Cut out the material. Having drawn a diagram of a potbelly stove on paper, estimate all the dimensions. The best option: 80 * 45 * 45 cm.In addition to the box itself, you will need to place a grate and two reflector shelves inside. It is better to make all elements removable. Cutting can be done with a grinder, and the chamfer from the edges can be removed with a grinding wheel.

Drawing of Loginov's stove

Drawing of Loginov's stove

Step 2. First, the side and back walls are welded together, pointwise. They are knocked with a hammer for leveling, placed on the bottom, which is also welded, now along the entire seam for the rigidity of the parallelepiped. The grate can be made from a sheet of steel with a thickness of at least 4 mm, in which longitudinal holes can be cut. 4 pieces of reinforcement are welded along the inner walls, on which the grate will lie. In the same way, the upper reflectors are installed, but always with an offset - the lower one is closer to the front wall, the upper one - to the back.

Prices for popular models of welding machines

Welders

Side and back walls are tacked first

Side and back walls are tacked first

Step 3. To hang the door, the hinges are first welded onto it, and then onto the front wall. The firebox door is larger than the blower door. The easiest way to make the gate valves is to use bolt-on strips that go behind the hooks welded to the front wall. The front wall is welded last, after the top sheet with a hole for the chimney.

Door version

Door version

Step 4. The box is ready. For convenience, legs are welded from below from pieces of a metal corner. A piece of pipe is welded to the opening of the chimney, onto which the rest of the pipe is then put on. In this segment, you need to make a gate, that is, a damper, by adjusting which you can turn an ordinary potbelly stove into a long-burning furnace. The principle is simple: if you close the gate and close the doors of the furnace and the blower, the air will flow very slowly, and the wood will smolder and not burn.

Having laid a lot of wood, you can stretch one firebox for 8 - 10 hours - just enough to sleep comfortably. Two coaxial holes are drilled in the pipe, a hairpin is inserted into the bottom, the outer end is bent 90 degrees. Inside the pipe segment, an iron round is welded to the hairpin, slightly less than the diameter of the pipe. By turning the pin around the axis, you can adjust the width of the open chimney duct.

The gate allows you to make the combustion slow

The gate allows you to make the combustion slow

Step 5. The height of the vertical pipe is about 1.2 - 1.5 meters. Next comes the inclined part with a length of one and a half to two meters. It is called boar and is also involved in heating the room, because hot gases heat it up a lot. It is better to bring it out through the wall, overlaying it with glass wool or mineral wool at the exit.

Competently organized chimney

Competently organized chimney

Places the finished potbelly stove on a steel sheet. A screen is sometimes hung on the sides. It has a dual role: it protects against contact with hot walls; heating itself, it serves as a plane, giving off a lot of heat into the room. With these simple measures, you can bring a simple iron stove into a piece of engineering.

Why choose a wood-burning stove

If we exclude gas and electricity, the first - due to the complexity of installing a separate pipeline, the second - as an expensive energy carrier for heating, there are not so many types of fuel left for a summer cottage. Bituminous coal has a high heat capacity and gives a long-lasting and persistent heat. But its cost in regions that are far from coal-mining areas negates its advantages. Nowadays, wood pellets and briquetted fuels have gained popularity. The calorific value of these materials is higher than that of firewood, but it is also more difficult to get them, and the price is higher.

At the same time, firewood is a renewable material that grows in abundance in most of the territory of Russia. In wooded regions, it is the cheapest type of fuel. The wood-burning stove is also convenient in that, if necessary, you can burn in it not only conditioned firewood, but also wood waste - old boards and wood products not covered with varnish and paint. It may not be the main source of fuel, but such disposal can still be beneficial.

Firewood continues to be the most affordable fuel

Firewood continues to be the most affordable fuel

Types of stove heaters

There are a lot of stoves for a summer residence, into which you can load firewood. But according to the material from which the oven is made, they are divided into two types.

Table 1. Efficiency of different types of furnaces.

| Furnace type | Efficiency |

|---|---|

| Dutch oven | 45 — 55 % |

| "Swede" | 50 — 60 % |

| Iron potbelly stove | 60 — 70 % |

| Long burning oven | 80 — 90 % |

Brick stoves

Such structures are erected from refractory bricks - red, which is not afraid of temperature and does not crack from heating. Hollow bricks are used to relieve the load on the foundation. The furnace can have different shapes and configurations, not only its dimensions depend on this, but also the efficiency and the degree of fuel combustion. The well-known Russian stove is also made of bricks, and then coated and whitewashed. But for a modern dacha, it is not suitable: it is too large and heavy, difficult to build, in addition, it must be constantly heated. After complete cooling, it will heat up the room only after a few hours.

Much better suited for a country house more compact options with a quick warm-up: "Dutch" and "Swedish". Both of these stoves do not require a rough construction, heat is emitted by the walls, inside which the chimney passes. The heat transfer of the furnace, the degree of fuel combustion and other factors depend on the number of bends and bends in the channel. Such stoves can be folded by any summer resident with their own hands, if you follow the instructions.

A brick oven can be laid out according to your project

A brick oven can be laid out according to your project

Metal ovens

The material for these products is cast iron or steel. Cast iron structures are good in that they have walls of greater thickness of the porous structure. When heated, they cool down more slowly, continuing to give off heat. Steel has its own advantage - they weigh less, since steel is stronger, and the walls of the furnace are made thinner. Such a stove, having extinguished, cools down quickly, but it heats up in a matter of minutes - that's what it is for a small house.

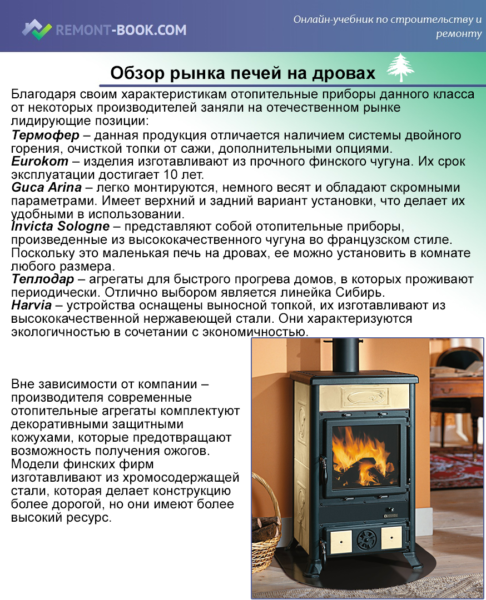

Market Review

Market Review

Steel stoves include a potbelly stove - the simplest cylindrical stove with one door and a chimney from a simple pipe. If you have materials, you can do it yourself using a home inverter welding machine. They put on dachas and constructions more complicated - stoves "Buleryan", Butakov. Their configuration allows the furnace to operate as a convector, pumping air through the pipelines heated by the flame. Such systems are characterized by a very high heating rate.

The main advantage of metal furnaces is a ready-made version, it is enough to take and buy. On the other hand, the price may be higher than when laying a brick oven yourself.

The iron stove is already ready for use.

The iron stove is already ready for use.

Advantages and disadvantages of stove heating at home

The popularity of wood-burning stoves is explained by the following advantages:

Low operating cost: In rural areas, it is possible to prepare a sufficient supply of fuel for a wood stove without much labor and any costs. Old trees or dried-up branches are cut off in significant quantities every year, utilities will be only too happy if someone can help dispose of this wood. But even if you have to buy firewood, peat or coal, the price for such fuel will most likely be lower than for gas and even more so for electricity.

Energy independence: By getting fuel from one or another centralized system, the homeowner becomes dependent on its operation. In the presence of a wood-burning stove, any surprises are excluded, if only you timely worried about the supply of fuel for it.

It is impossible not to take into account the fact that in some regions the gas mains have not yet been laid, but one cylinder with liquefied gas is enough for a maximum boiler operation day.

Additional functions: a wood-burning stove is usually used along the way for cooking, and the dishes in it turn out to be much tastier than those cooked on gas. This unit will be indispensable in the bath, because only firewood can provide the most useful, as they say, living warmth with a unique aroma.

The ability to make it yourself: the simplest option, both from bricks and from metal elements, can be made by anyone

If you have access to the Web, where all kinds of drawings, orders and recommendations are posted in large quantities, the task is even more simplified.

Reliability: with the correct positioning of the stove, it can be used to heat up to four adjacent rooms without resorting to a hot water heating device. At the same time, the house can be left unattended for a long time in winter, without fear that the frozen water will rupture pipes and radiators.

At the same time, the owner of the stove has to put up with some disadvantages:

- Lack of any automation: fuel supply, as well as control of the furnace, have to be done manually. The good news is that today the so-called. long-burning stoves, which can work for 10 - 12 hours on one tab of fuel.

- We'll have to set aside a room for storing fuel.

- Danger of fire: unlike a gas boiler, which behaves quite peacefully, a wood-burning stove sometimes "shoots" hot coals. Any of them, if left unchecked, can cause a fire.