Laying the foundation for stove heating

The need and purpose of the foundation was discussed above. Installation of a stove is possible only if the foundation is ready for it, and the process of its creation takes some time. When laying the foundation, you must follow some rules that will help create a reliable foundation for the stove.

The foundation can only be made on dense soils. Semi-rocky or rocky soils are perfect. If the soil is loose, then it must be carefully compacted in such a way that its final thickness does not exceed 20 cm. When laying the foundation on loose soil, it is also necessary to compact it so that the base of the foundation can deepen. When planning and arranging the foundation, it is necessary to do it with a small margin so that the stove does not stand "back to back". In addition, an increase in the area of the foundation will reduce the load on it.

The distance from the foundation to the walls of the house should be at least 5 cm, and the free space can be covered with sand. In addition, in no case should the foundations of the building and the stove be combined, otherwise, in the future, deformations may occur not only of the stove, but of the whole house.

How does a heating stove work on two floors

For a complete understanding of how the oven works in a two-story house, you can pay attention to the photo. If the house is made of brickwork, then the stove can be installed on steel beams, which were originally built into the walls of the building.

When installing beams, it is necessary to use spacers that will soften the effect of weight on the walls and thereby prevent their deformation. The space between the beams is filled with ordinary mortar, but it is clay mortar that is used to reliably cement the furnaces.

When installing stoves for heating a cottage, it is necessary to observe the independence of the systems: each stove of a two-story cottage must be able to work separately from the other. If desired, a fireplace can also be built into the erected structure, which will add an additional portion of comfort. If you choose a heating and cooking option as the main stove located on the ground floor, then this design will provide the house with everything you need.

Stove heating of a two-story house

Today, advice on stove heating is given to us by Yuri Mikhailovich Kishulko, a hereditary stove-maker. Yuri Mikhailovich's father, a self-taught stove-maker from the Vitebsk region, has been improving his skills all his life. From early childhood, the son helped his father, absorbing the wisdom of the furnace business. Today, Yuri Mikhailovich is a virtuoso and a true enthusiast of his craft, easily laying out sophisticated stoves that can heat a two-story house, and fireplaces in small living rooms.

When placing stoves in a room, one should strive to ensure that they are located mainly near the internal capital walls. It is not recommended to install stoves near external walls, as this complicates and increases the cost of the work on the construction of chimneys. The stove, if possible, should be open and free to heat the room. For heating the kitchen, living rooms and utility rooms, the stoves should be grouped into a so-called heating unit. In this case, the chimneys are combined into one brick riser.

Compact stoves and hearths up to 700 kg can be installed directly on a solid floor. If this is not enough, the floors are reinforced with additional beams. Furnaces weighing more than 700 kg are placed on the foundation. The foundation is buried in the ground by at least 0.5 - 0.6 m for one-story furnaces without packing pipes and at least 1 m for two-story furnaces and root pipes. The foundation of the furnace must not be tied up with the masonry (foundation) of the building wall, since different shrinkage is possible.

If you have two floors ...

The designs of the bases for the furnaces of the upper floors are chosen depending on the structures of the walls of the building, the relative position of the main walls and the orientation of the furnaces themselves. The simplest solution is to install an upper deck oven on a lower deck oven, however, when repairing a first floor oven, it becomes difficult to maintain the upper oven. For a more even distribution of the load on the lower furnace, a reinforced concrete slab is laid on it (at the level of the floor slab). Sometimes in the array of the lower furnace (in the corners), when laying the racks made of square, round or profiled steel, the lower ends of the racks are embedded in a solid foundation. A solid platform of channels and corners is made from above, on which the upper furnace is installed.

In brick buildings, it is widely used to install products on rails or steel beams of various profiles embedded in brickwork to a depth of at least 38 cm (one and a half bricks). To prevent the brick from collapsing, the embedding is carried out using gaskets. The space between the beams is filled with lightweight concrete or masonry. When laying out the ovens themselves, it is better to use an earthen solution, it, when heated and cooled, will work in unison with the brick, which means that your oven will remain intact and functional for many years. The brick is laid in the form of a vault. The beams are fastened with ties. If you have a summer cottage, the most practical way to heat the second floor is to install a small hood or shield that is heated from a stove located on the first floor. Sometimes the flap can be interlocked with a small fireplace (if the height of the chimney allows). If stove heating is the main in your house, then you need an option with stoves on the first and second floors, which can be heated separately. Based on this, a house project is made, rooms are tied, etc.

Consider in detail a two-tier thick-walled heating stove with heat transfer on the first floor - 3.7 kW and on the second - 2.7 kW, its dimensions are 64x115 cm. a larger oven with a built-in oven.

Refractory bricks (chamotte) are not produced in Belarus. Only imported bricks from neighboring countries are on sale. The average price for it is 2000 rubles per piece. Tiles for facing furnaces in Belarus are produced by the only enterprise KUP "Volkovyskstroy-materials". Ceramic tiles are intended for cladding and masonry of front surfaces of heating household stoves, kitchen stoves and fireplaces.

The design of the tiles is strong, durable, and is securely fixed in brickwork. Tiles are sold in ready-made sets, their cost starts from 800 thousand Belarusian rubles for the simplest version.

Heating scheme of a two-story cottage by means of a stove

Heating scheme for a two-story cottage by means of a stove.

Image 1 shows what a stove should look like when equipped in a two-story house. If the house has brickwork, the stoves can be installed on rails or steel beams, which should be built into the brickwork. In the process of sealing such beams, it is imperative to use special gaskets that will help prevent destruction. Between the beams, lightweight concrete will have to be poured, and it is preferable to seal the furnaces themselves using clay, this is due to the fact that the clay interacts perfectly with the brick.

It is important to remember that both ovens should be built so that they can be put into operation separately. The heating of a two-story house will be not only a stove, but also a fireplace, if it is built into the overall structure

The stove heating that the house will be equipped with will become more functional if the stove laid out on the ground floor is used for cooking, and for this it will only need to be installed in the kitchen space

The heating of a two-story house will be not only a stove, but also a fireplace, if it is built into the overall structure.The stove heating, which the house will be equipped with, will become more functional if the stove laid out on the ground floor is used for cooking, and for this it will only need to be installed in the kitchen space.

Double deck oven with fireplace and hob

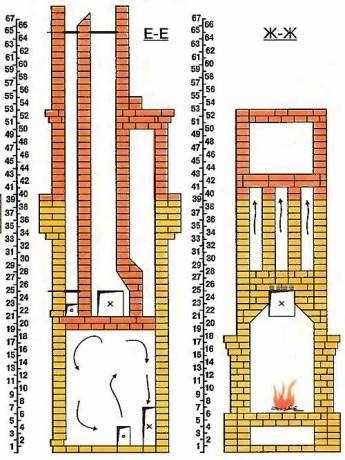

Functional model with one firebox and open fireplace on the first floor and two decorative fireplaces on the second. The stove insert and the fireplace are located on different sides and can work at the same time. Consolidation of gas streams begins above the fireplace damper. The design of the fireplace insert is simplified, there is no smoke tooth. There is a hob on the side, no oven.

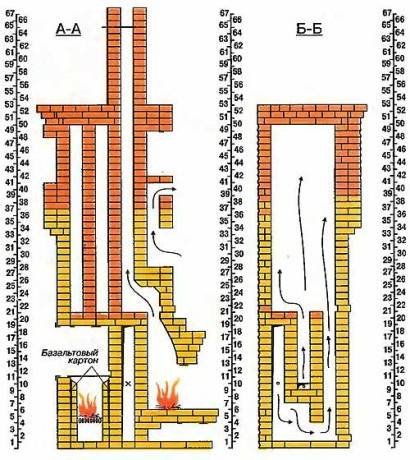

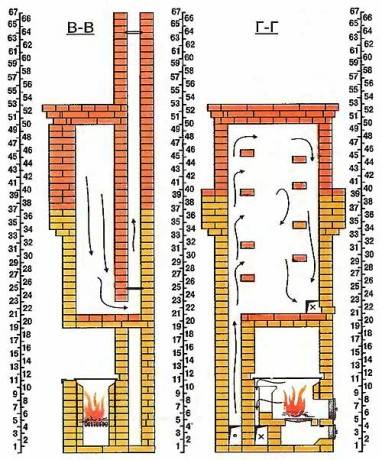

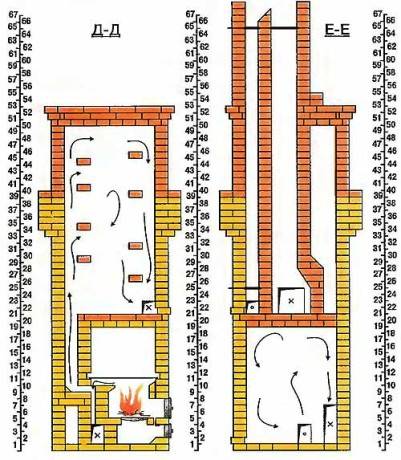

Cross-section of a two-level stove with a fireplace

Diagram of a two-tier model

Laying principle and gas movement

The author of the order used modern techniques to increase efficiency and simplify operation. When using a furnace door with glass, it is recommended to leave a through gap in front of the grate in the hearth of the furnace. This trick prevents the formation of soot on the door.

Masonry order from 1 to 15 rows

Ordinal scheme from 16 to 26 rows

Wall masonry from 27 to 42 rows

For construction, 1000 pieces of fireclay bricks are required (highlighted in yellow in the diagram) and 1100 pieces of single solid red bricks. The choice of refractory bricks for the construction of the walls of the furnace and fireplace is justified by the wishes of the customer.

Important! Any ready-made ordering of the stove for 2 floors requires revision, taking into account the features of a particular house, its area, and the height of the ceilings. Consult an experienced stove-maker before purchasing materials.

If necessary, he will make constructive changes to the circuit and give practical advice.

Consult an experienced stove-maker before purchasing materials. If necessary, he will make constructive changes to the circuit and give practical advice.

The choice of heat carrier and method of transporting heat energy

The most rational solution in two-story houses, in which there are a large number of rooms and there is an overlap between floors, is the implementation of water heating. With a complex building configuration, in the overwhelming majority of cases, there is no alternative to such heating. The system is a looped structure of pipes through which the coolant flows, and heat transfer is carried out by means of radiators or air heaters.

Also, heating with a warm floor can be arranged as an additional or only source of heat. Its principle of operation is similar to heating with radiators.

The choice of coolant is extremely important

The choice of coolant is extremely important

The use of underfloor heating that runs on electricity in the premises of the entire house is a theoretically feasible option. However, this raises a number of problems in its implementation. First, from an economic point of view, heating organized in this way is not always profitable. Secondly, there is a possibility that it is not technically possible to carry out the task of air heating.

Warm floor

Warm floor

Air can be used as a coolant in multi-level buildings. In this case, it is necessary to solve the problem of its transportation. To implement such a project, it becomes necessary to create a system of channels in the space of the building, as well as equip them with fans to pump the air flow. Only in this way can heating organized to ensure the delivery of heat to remote rooms and rooms located on the second floor.

Devices

The list of devices and materials necessary for the construction of this furnace is given in table. 2. Its design does not differ in any special complexity, but requires from the performer a sufficiently high qualification and accuracy

Particular attention should be paid to the quality of the masonry not only of the firebox and the outer walls of the stove, but also of the inner channels of the chimneys, since the communication of the stove's smoke flows with each other, which is not provided for by the design, can lead to its inoperability.

TABLE 1

CHARACTERISTICS OF TWO-STOREY HEATING OVEN WITH SINGLE FUEL

Furnace dimensions in plan: fuel section ……………………………………. 890 × 1150 mm flap of the 1st floor ………………………………………… 770 × 1020 mm flap of the Nth floor ………………………………………. 770 × 950 mm Furnace height * ………………………………………………………………………………………………………………………… 7150 mm Heat transfer surface ……… ……………………………………………………… .. 5500 kcal / hour Total daily heat transfer ……………………………………………………… .. ~ 132000 kcal Amount of fuel burned per day (dry wood) ………………… ………………………… 59 kg Heat transfer time after one furnace ………………………………………………………………………………………… 24 hours 3.4 m. It can be changed by decreasing or increasing the number of rows in the masonry from 26 to 46 and from 60 to 82 rows.

TABLE 2 LIST OF INSTRUMENTS AND MATERIALS

Solid red brick (selected) ……………………………………………………… .1900 pcs. Refractory bricks ……………………………………………………………………………………… 170 pcs. Red clay ………………………………………………………………………………………………… .2,1 m3 Refractory clay ………… ………………………………………………………………………………… 0.2 m3 Sand ……………………………………… ………………………………………………………………………… 2,3 m3 Furnace door 350 × 350 mm ………………………………… ………………………………………………1 PC. Blowing door 135 × 120 mm ……………………………………………………………………. 1 pc. Cleaning doors 135 × 120 mm ………………………………………………………………………. 5 pcs. Furnace valves 130 × 260 mm …………………………………………………………………………. 2 pcs. Pre-furnace sheet 500 × 700 mm ……………………………………………………………………… 1 pc. Grate 400 × 400 mm …………………………………………………………………. 1 pc.

1. 2. 3. 4. 5. 6. 7.

Heating a two-story cottage with a stove is quite simple, and such a system will not require any special treatment. The only condition that must be observed when using any stove is regular heating. Stove heating of a two-story house is very convenient to use, but the price for this ease will be the complexity of the installation, therefore, before erecting a stove heating system, it is necessary to draw up an accurate and specific scheme for performing the work.

Stove heating can work autonomously, and in this case there will be no interruptions in fuel supply. True, you must always take into account the fact that the stove occupies a rather large area, and you need to think about this in advance. In addition, being an excellent decorative element of the house, the operating temperature of the stove is practically uncontrollable, which leads to an uneven distribution of heat energy.

Dimensions (edit)

The dimensions of the firebox are designed for a single load of approximately 50 kg of dry logs 50 cm long and up to 10 cm thick. Moreover, the logs are placed vertically in the firebox. From the firebox, gases rise up the first ascending chimney. At a height of about 3.2 m from the floor level, part of the gases is separated into the smoke circuits of the heating panel of the first floor, and the other rises to the top of the stove and enters the smoke circuits of the second floor. Special heat exchange nozzles (outlets) - bricks protruding from the masonry into the channel - are made in the lowering channels of the smoke circulation of the heating shields of both floors and in the last lifting channel of the first floor. They increase the heat-absorbing surface in the smoke circulation and the heating rate of the furnace masonry. The last lifting smoke ducts on both floors (see rows from 60 to 88 in Fig. 1 and 2) have a cross section of 120 × 190 mm and end in the upper part of the furnace with a common chamber (rows 89 and 90 in Fig. 2).In this chamber, adjusting bricks are installed, with the help of which the corresponding amounts of flue gases are distributed to the smoke circuits of each floor. These adjusting bricks rest on special projections 1.5-2 cm wide, made when laying out the channels in the 88th row. Adjustment of the distribution of flue gases is done once during the first test furnaces, moving the bricks and achieving uniform heating of the furnace masonry on the lower and upper floors. After the final installation of the adjusting bricks, the side windows of the chamber are tightly closed and covered with clay. The chimney is a top-mounted chimney, built directly above the furnace. The overlap of the pipe channel and the regulation of the draft is carried out by two sequentially installed valves. In places of possible accumulation of soot and ash settling in the chimneys, cleaning holes were made, closed with cleaning doors.

Stoves on two floors

The main task of the stove-maker when erecting a two-story stove is to distribute heat in such a way that, taking into account the characteristics of the room, it will not be too hot on the first floor and not too cold on the second. When calculating the stove, you need to remember that warm air rises, which means less heat is needed to heat the second floor than for the first. Based on this, on the first floor, you should not get carried away with the large length of canals, but it is better to save them for the second floor. If the room on the second floor is not large, then a hood that accumulates heat after passing through the channels of the first floor will be quite enough for heating.

Double-deck ovens should not be equipped with horizontal channels, as this significantly slows down the speed of gas movement, and therefore contributes to increased soot formation. With an excessive length of the flue channels, the temperature of the gases at the outlet from the chimney may drop below 100ᴼC, which will inevitably lead to the formation of condensate.

The stove of the second floor must fully rely on the stove of the first floor; it is strictly forbidden to place the stove of the second floor on the beams of wooden floors, since the wooden house eventually sits down and will tear the masonry at the junction of the stoves. Two-storey brick ovens must be equipped with a forward stroke valve to facilitate ignition after a long break between fireboxes. In the event that the design does not allow making a forward stroke valve, you can pre-ignite the stove through the last cleaning door.

Is it possible oven heating in a multi-apartment home? Yes, furnace designs allow even large buildings to be heated if they are no more than two stories high. There are several options for arranging heating of two-story buildings, and, despite the new, appeared types of equipment, stove heating does not give up its positions. The stove can be used as a hob, as a fireplace, and as a conventional solid fuel boiler, if equipped with an additional water circuit.

Air heating

In this category, we include all heating methods without the mediation of a heat carrier - water, oil, antifreeze and any others. Air heating in the room is carried out by direct contact with the heating element.

Buleryan

The stove is a firebox, which is surrounded by thick pipes with open up and down ends. The pipes heat up and provide convective mixing of the air in the room.

Their orientation in different directions speeds up the process. If it is necessary to heat several isolated rooms from buleryan, air ducts are wired with natural or forced circulation.

Advantages:

- Existing furnaces provide almost complete combustion of fuel due to the fact that they provide long-term smoldering with a limited supply of oxygen. This provides an efficiency unattainable for traditional stoves.

- Buleryan does not take up much space and does not require its own premises. A stove for heating two floors may well fit in a living room or dining room. There will be no soot and odors.

- Air duct routing will cost less than water heating system routing. Although, taking into account the necessary thermal insulation, and not much.

Disadvantages:

- It is almost impossible to lay air ducts after finishing the final renovation so as not to spoil the aesthetics of the room. The heating plan for a two-story house - both the heat source and the wiring - will have to be thought out in advance.

- Any stove heating of a two-story house is associated with the need to store stocks of firewood, coal, pellets or peat briquettes.

In the photo there is a buleryan stove in the living room.

Brick oven

An ordinary Russian stove usually has very impressive dimensions. It occupies up to a third of the area of the house and is quite capable of heating several rooms. It is clear, however, that two-story heating stoves are somewhat more complex designs.

In general, there are almost no standards in the field of designing brick ovens. The specific implementation depends on the size of the room, the location of the stove, the imagination of the stove-maker, or, as an option, the order of a ready-made solution invented by someone else found on the Internet.

A typical heating stove on two floors is a firebox located below and a bell or duct chimney making several turns on the second floor.

Execution options can be varied. For example, it is enough to put a cast-iron stove on the firebox, laying an asbestos cord under it to isolate the room from combustion products - and you will get a heating and cooking stove on two floors.

The stove can stand in the middle of the room or in the corner; finally, if you wish, you can even organize water heating of a two-story house with natural circulation, simply by placing a coil in the firebox.

Dignity:

In the absence of gas, stove heating is the cheapest heating method. A brick oven pleases owners with a large thermal inertia: it is usually heated once a day for 2-3 hours, while the rest of the time it gives off the accumulated heat.

Disadvantages:

- Again, you will need a supply of fuel, which will take up a fair amount of space in the yard.

- Folding the stove so that condensation does not appear through the masonry, so that the stove does not crack and does not smoke into the room is an art that is gradually being lost.

If you are not afraid of experiments, you can try to do this work yourself; but in the absence of any experience, it is better to be prepared for a variety of surprises.

Gas convectors

Another way in which, with a minimal investment of time and money, air heating of a private two-story house with your own hands can be performed is the installation of gas convectors.

Each device is a closed burner with air intake from the street and exhaust of combustion products there through a coaxial pipe. The heat exchanger heats the air in the room. The devices can operate on both main gas and bottled gas.

Advantages:

- Full autonomy of heating of each of the premises of the house.

- Low project cost. The price of each convector is 4-8 thousand rubles. Considering that you do not need a boiler and wiring from it, this will mean tangible savings.

Disadvantages:

- Main gas, alas, is not everywhere.

- Installation of convectors is possible only on the outer wall of the house.

- Drilling wide holes for a coaxial pipe in, for example, reinforced concrete is still a pleasure.

- see here.

Construction stages

Foundation for double deck oven

The first thing to start with is the markup for laying the groundwork

It is important to remember that the dimensions of the foundations in any case should be larger than the base itself. To equip the structure, you will need the following:

- plywood for formwork construction;

- sand and cement;

- fittings;

- crushed stone;

- waterproofing sheet (preferably made of roofing material).

Stages of work:

- Prepare a place for the foundation, cut out part of the floor boards if necessary.

- Make sure that the future structure will not rest against the supporting beams of the ceiling, otherwise you will have to change the top scheme.

- The pit is pulled out, taking into account the work plan.

- Crushed stone with sand is poured to the bottom, the composition is compacted.

- The formwork frame is equipped so that the concrete does not flow out of the walls.

- Reinforcing mesh is being installed. The fittings for a two-story oven are made stronger than for a conventional one.

- A concrete solution is poured and left to dry for several days.

Masonry scheme

After the foundation is ready, you can start laying the foundation. The ordering is carried out strictly according to the scheme and includes the following stages:

- The order of laying the first row on the waterproofing sheet is noted.

- The solution is mixed for work.

Next, the rows are built:

| Row number | Execution of works |

| 1 | Spreading out without using a clay mixture to understand the further scheme of actions |

| 2 | Blower pry using wire |

| 3 | Formation of the combustion chamber |

| 4 | Laying of asbestos strips along the side openings of the furnace chamber for further installation of the grate |

| 5 | Installation of a combustion door, similar to the blower |

| 7—10 | Standard laying pattern |

| 11 | Hob mount, metal corners installation |

| 12—16 | Formation of the cooking chamber |

| 17—19 | Laying out lines in solid brick rows, forming a place for a chimney |

| 20—22 | Installation of corners, fixing the doors for the cleaning chamber |

| 23—24 | Raising the sides of the drying chamber |

| 25—30 | Bookmark goes unchanged, valves are formed |

| 31—38 | Formation of chimney ducts, expansion of masonry and bringing to the ceiling |

The following steps relate to the construction site on the second floor:

- From row 1 to row 26, the standard work scheme is used.

- The 27th stage ends with the formation of the valve. And until 31, everything goes according to plan.

- The beginning of the chimney is considered to be 31 and 32 rows.

How does stove heating of a two-story house work?

Any stove has a lot of weight, so it should be placed next to the main internal walls, which will make it possible to balance its work. If the total estimated weight of the stove is no more than 700 kilograms, then it can be installed directly on the floor, but only on condition that it initially has high strength. If the total weight of the stove comes out too large, then it becomes necessary to lay the foundation. The foundation must be laid to a depth of at least one meter.

In the event that the stove heating in the house is the main one, then a separate stove must be installed on each floor. In general, it will be best to design and calculate the stove masonry even before the house is built. The stove installed on the second floor should be located directly above the stove, which is located on the floor below. This is done to reduce the load on the floor between floors. In addition, reinforced concrete slabs are often used to provide greater reliability and rigidity.

The advantages of stove-type heating

Stove heating, which can be used to equip a two-story house, may also be the only possible solution, since a cottage located outside the city may be deprived of electricity or a gas pipeline. In addition, heating a two-story house with a stove is quite cheap, you only need to buy coal or firewood.

However, such heating also has some disadvantages, including the significant weight of the heating system, as well as its dimensions. Heating and all its advantages can be started to be used long after the start of heating, since the stoves are inertial: they heat up for a long time, but cool down just as long. With the heating of the house, the stove is capable of losing a lot of heat, which goes through the chimney. The efficiency of stove heating is low and amounts to only 25 percent, which means that before the stove starts its immediate duties, it will warm up the walls.

Features of the heating stove for two floors

It is important to know exactly what the weight of the future heating system will be. To build a reliable structure, it is necessary to fill the foundation

It must be deepened into the ground by at least 1 meter, and the overlap between the first and second floors must be very strong. A reinforced concrete slab can withstand such a weight. The installation of such structures should be carried out along the internal load-bearing walls.

A two-story stove can be of two types - a stove with one firebox or with two. The main firebox in such structures can only be on the ground floor, as well as all heavy extensions - a stove bench or a cooking stove. A fireplace can be installed on the second floor - sometimes false, but more often it is functional. A false design will increase the heat transfer of the heating system, and the existing one will allow the room to warm up faster. Such systems include two-channel chimneys.

Stove with one firebox

A heating system with one firebox can last less than two furnaces. This is due to the specifics of the construction of the system itself.

The top floor should always have vertical ducts. In order to separate the heating of the floors, dampers are installed.

Their function is to block the movement of flue gases. After that, the cooling gases in the chimneys of the second floor form condensate. thus, the masonry begins to gradually deteriorate. The design of a stove in the house with two fireboxes will be able to provide faster heating.

On average, the dimensions of the firebox of such a stove are designed for a single load of up to 50 kg of dry firewood. Usually, for stoves with one firebox, the logs are stacked vertically. This allows for faster heat dissipation. The gases rise up the first ascending chimney, then, at a height of about 3 meters, the gases are separated into the distribution chimneys of the first or second floor. Inwardly protruding bricks can be located inside the vertical channels. They allow you to increase the surface area that absorbs heat.

In those places where there can be accumulation of soot or deposition of ash, special openings for cleaning should be provided, but closed with doors. The heating system with one firebox has a big plus. You need to heat only on the first floor. No need to carry firewood upstairs and do the same thing twice.

Fireplace design

Such structures on the outside are very similar to a fireplace, but inside they have the same number of chimney channels as in the stove. Connecting a fireplace and stove is not a novelty. Such a hybrid design has been used in everyday life for a long time. Its main difference is that it is able to keep warm in the house for 18 or even 24 hours. Heat transfer in such furnaces can reach 5 kW, which is twice as much as in conventional units, and this figure saves on fuel. This result can be achieved by using fireclay bricks in masonry. On three sides of the firebox, there are smoke channels that allow you to evenly heat the surface.

Typically, a fireplace stove takes up much less space in the house. than the classic one, and visually such a design looks quite attractive.

But when choosing such a system in the house, it is important to understand that installation and material costs can be more expensive because of the firebox doors - which can be made using fireproof glass, or because of a design idea. Very often, a stove is located above the firebox, presented in this structure as a fireplace.

It is very convenient to bake here, but unfortunately, in such a design, the heating system is the main one, so the hob is not provided here.

Very often, a stove is located above the firebox, presented in this structure as a fireplace.It is very convenient to bake here, but unfortunately, in this design, the heating system is the main one, so the hob is not provided here.

Stove heating of this type for a two-story house, although it has advantages in heat accumulation compared to others, still does not give as much heat on the second floor as on the first. It is better not to build such a structure yourself, but to entrust it to professionals.

Stove heating for a two-story house located outside the city or in the countryside may be the only option. The high cost of electricity and frequent interruptions cannot provide inexpensive and efficient heating in a home. The use of natural gas is also not always possible, because access to it is not available everywhere, and using propane in cylinders for heating is not profitable and may be unsafe.