How to make a firewood stand from water pipes

Want a nice firewood rack by the fireplace? Perhaps you will like the design suggested by the author, which can be done in a couple of hours. The idea was taken from the catalog, there is, of course, a large selection, but the price does not suit everyone. And why waste money, when it is quite possible to make a stand for firewood with your own hands, from materials that you may not even need to buy. You can use leftover lumber and old water pipes, there are practically no costs, but look at what a beautiful fireplace stand, and even on wheels, is very convenient.

Materials:

- wooden blocks;

- plywood

- nails

- reinforced wheels

- screws

- black paint

- spray

¾ "water pipes:

- 4pcs "150 cm long

- 4 pieces "12 cm long

- 1 piece length 45cm

- 4 pcs turn signals 90 °

- 2 pcs T fittings,

- 4 pcs flange

Instruments:

- Sander

- a circular saw

- hammer

- drill

How to make a stand for firewood from water pipes, look at the step-by-step photos.

Firewood stand from pipes

The presented project is a firewood stand for a fireplace, an ideal gift for those who like industrial decor. According to Kirsten Dunn, the author of this project, such a rack, with all the necessary materials, can be assembled in just 2 hours. And if you make a small roof using the top bar, even just pulling on the tarp, you get a good option for an outdoor firewood stand. The presence of wheels makes it possible to easily move the rack around the house and, if necessary, roll it out into the street, that is, you will have a mobile firebox for the fireplace.

Materials (edit)

- boards and bars

- 4 - ½ Black steel pipe 60 cm

- 1 - ½ Black steel pipe 30 cm

- 4 - ½ Black steel pipe 15 cm

- 4 - Turn signals 90 °

- 2 - ½ "black steel tee

- 4 - Floor flange

- 4 rollers (optional)

Instruments:

- saw

- roulette

- electric drill

- rags

- disposable gloves

Step 1: Saw out the wood pieces

Cut seven pieces 36 cm long, two pieces 51 cm long and one piece 44 cm long.

Step 2: Sand the surfaces of all parts

Step 3: Dry dry all the pieces together, cut as needed to fit all the pieces tightly, here's how you should position the pieces together:

- A 44 cm segment, this will be the lower support beam in the middle of the five upper 36 cm pieces.

- The four remaining pieces (two 36 cm and two 51 cm) will hold the five top pieces.

Step 4. Using a straight edge draw a line through the middle of the top five boards. This will be the drilling mark. Make sure the bottom is under this line.

Step 5: drill holes

- Start pre-drilling along the line by making two holes in each board.

- Secure with 2½ ”screws.

- Turn the boards upside down and place a frame around the middle boards.

- Pre-drill and attach the shorter sides of the frame with four 2½ ”screws.

- Install the longer frame sections by pre-drilling a total of nine screw holes in each: two ends of each perpendicular frame member and one in each plank in the middle. This must be done so that the middle boards do not wobble.

Step 6: Coat with wood oil or varnish whichever you prefer.

Step 7: Screw on the casters. This is not necessary unless you intend to move the wood rack, just for convenience. The wheels are attached to the bottom of the stand, to do this, turn the stand over, mark the screw holes with a pencil. Make sure the casters are far enough away from the boards to roll freely. Drill the holes and fasten the wheels with the screws.

Step 8: Prepare the pipes. Plumbing or gas pipes are usually coated with grease, so wear disposable gloves. Remove plastic caps and any stickers from the pipes.Use a damp cloth and Barkeeper Friend to clean the pipes. Wipe cleaned pipes with a fresh, damp cloth

.Step 9: Collect the pipes. Simply connect all parts of the pipes to the turn signals and T-fittings, as well as the flanges separately from the wood base. The diagram in the photo on the right.

Step 10: That's it. All that is left is to load the rack with wood and enjoy the new firebox.

Written by Kirsten Dunn

Firewood trolley

If you have a wood-burning fireplace, you are most likely doing several things: collecting wood in the yard, putting it in a wheelbarrow, taking it to the house. Transfer the wood from the wheelbarrow to the inner rack and from it you throw them into the fireplace. This is very inefficient and annoying all the time. Therefore, half of the steps can be reduced by making a homemade firewood cart with your own hands. The wood-burning rack on wheels presented here contains design elements that make it presentable enough to fit in the living room; therefore, the cart is used to transport firewood and store it next to the fireplace. The stand is made of a square profile and painted "wood-like". It rolls well and makes the process of stoking the fireplace much easier.

The design of the wood cart will depend on the wheels you plan to use. You will also need the following items:

- 5 x 3/4 '' Square Pipes 1.2m

- 1 x 1.2m square tube

- 1 x bar 5 x 5 cm long meter

- 4 x 10cm nails and a few 5cm nails

Instruments:

- Hacksaw for metal

- Welding machine

- Angle grinder

- Sandpaper

- Hand saw for wood

- Metal plate

- Drill

Step 1: Cut the metal parts. In the manufacture of this structure, you will have to make many corner cuts. Most of the angles are 45 °, with the exception of the base of the two arcs that attach to the rectangular frame. I decided to first put together a base rectangle and attach the wheels before trying to figure out what angles are needed for the uprights. Once you've decided on the wheels, draw a diagram to define the angles between the floor (horizontal, like the top of the arch) and the frame (where the arches will be held together). Then cut the metal pieces according to the dimensions in your drawing.

Step 2: welding and grinding

Weld four 10cm nails in the corners of the arch that will hold the wooden handles, and two nails in a rectangle near the wheels.

Step 3: attach the wheels

Weld two nuts on each side. Tighten the bolt to align the holes before welding.

Step 4: make wooden handles

Make several of the same square handles. Their total length should be the same as the width of the main rectangle (25 cm). Sand and varnish.

Step 5: assembly

The build order is very important:

Weld a rectangular frame;

Weld arches and corner nails;

At the same time, and very carefully, hammer the arches into the grooves. Better ask someone for help to keep your feet in balance

Don't worry if the wooden squares are not fully pressed into the corners, this can be corrected later.

Roll up the arches on the frame;

Hold the rack upside down in a vise to set the top cross bar in place;

Tighten the vise until the wooden rods are glued to the two arches, if the crossbeam is too long, loosen the vise, saw off and try again.

Using a piece of wood and a hammer, tap gently so that the squares are clamped in the corners;

Weld the cross member in place.

Step 7: painting

Protect wooden surfaces before cleaning and painting metal parts

The author used newspaper and masking tape to cover the tree, very carefully covering the gaps around the squares.Use fine sandpaper and then wipe off the dust with a damp cloth

Hang the frame from the ceiling if you can to get to all surfaces. For painting, the author used matte black paint to hide the welds.

Step-by-step instruction

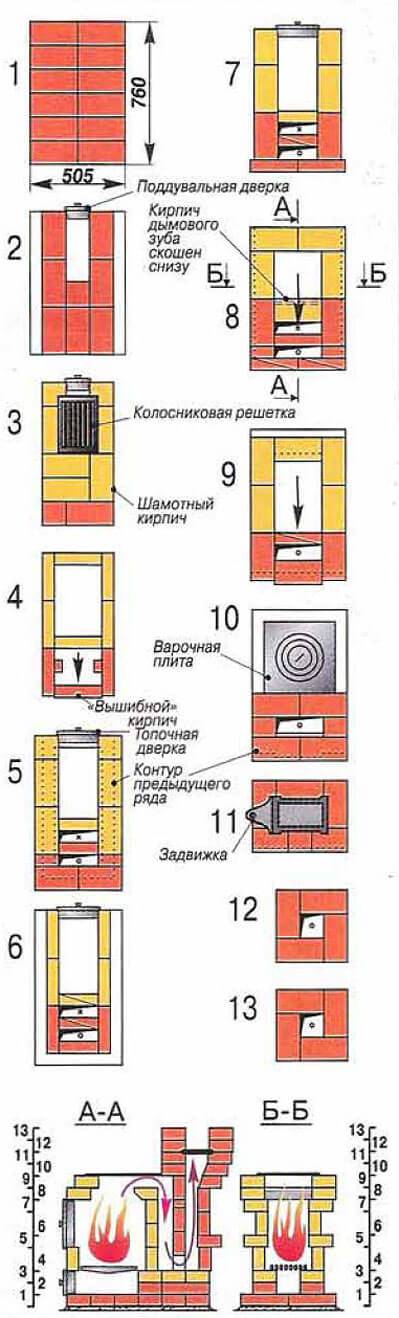

Sorting bricks. Broken, cracked and other non-standard bricks are rejected, they must be used for the construction of the foundation.

The first three rows of bricks are very important because this will be the base of the fireplace. They must be placed strictly according to the level, and limiters are inserted between the bricks for a smoother masonry.

Laying out two rows of bricks without mortar, laying the next on the mortar.

The fourth row is placed around the first three and a hole for the oven begins to form from it.

In the fifth row, it is worth considering the location of the blower. At the same stage, fasteners for a metal lattice are installed in the masonry. You can make them yourself.

The sixth row secures the supports. It also serves as a support for the grate (a cast iron or steel grate that holds the fuel. Ash spills down through it).

The seventh row is the base of the fireplace portal.

From the eighth to the thirteenth row, the decorative front part of the fireplace is laid out, which is tied together. From the eleventh row, the formation of a "mirror" begins - the inner rear wall of the fireplace, which is located at an angle.

On the fourteenth and fifteenth rows, the portals are again bandaged.

From the sixteenth row, the "mirror" is finished and the "tooth" begins, which is coated with clay soaked a few days earlier. This is to prevent a fire in the house.

From the seventeenth to the nineteenth row, the facade of the fireplace is formed.

On the twenty-second row is the creation of a chimney pipe with access to the street. The accepted dimensions for this hole are 15x28 cm. The wider the chimney, the more heat will be stored, the standard size gives good draft and allows optimal removal of combustion products.

On the twenty-third row, a "swallow's tail" is formed - the shape of a smoke hole.

The last layer of brick is laid.

What is under the fireplace insert

Formed by screens, horizontal and slightly inclined surfaces, the lower part of the firebox is called under. In some materials, it is found as a furnace sump.

As there is no blower near the fire, so in the first fireplaces under the firebox it was solid. But for a quick firewood fire, extra traction does not hurt at all. Therefore, the laying of fireplaces of modern design often provides for a small blower, which is closed after the appearance of a stable fire. The vortex is formed at the moment of closing. Up to this point, all the generated heat flies out into the pipe.

In classic English fireplaces, there was a slight inclination of the hearth towards the floor. This improved the conditions for the occurrence of a thermal vortex, but the burning embers were trying to roll out of the furnace. Therefore, as a protection, the fireplace insert was equipped with a low grate. Today, fire protection is provided by glass doors of a special design. And the grilles are assigned a purely decorative role.

The main types of fireplaces

These heating systems can be divided according to the place of installation:

- Outdoor fireplace designs. They serve for various purposes: for decorating the local area, for cooking as a substitute for various kebabs and barbecues, as a water heating installation for various household needs.

- Homemade. Installed inside a home or other building.

By appointment:

- For heating a specific space.

- For cooking food.

- To create a special interior design.

- For domestic purposes, for example as a boiler.

By the method of installation in the room itself:

- Island fireplace stoves. They can be installed at some distance from the walls or in the center of the room. The rarest and most laborious types to manufacture, but have a number of advantages over others: they are excellent heat accumulators, have a large heat transfer area, and can serve as a full-fledged heating device even in a medium-sized room.

- Built into the wall. Such subspecies are built into the load-bearing wall of the building. Their advantage is their small footprint and some ease of installation. In terms of efficiency, they are inferior to stoves installed in the center of the room, due to the smaller area of the heated surface inside and the heat exchange of the wall with the outside environment.

- Corner models of wood burning fireplaces are the same inside - wall views, but located in the corner of the house. They are more difficult to build than ordinary wall options, but they allow you to create interior solutions that are unique in terms of design delights. Thermal efficiency is approximately equal to the previous version.

By type of execution:

- Standard fireplaces with a square or rectangular fireplace portal made of traditional materials.

- Variants with a D-shaped combustion portal and a top-mounted wooden beam.

- Modern models with various forms of portals. They can be made using glass, metal and polymer materials.

By the design of the firebox:

- With an open firebox. They are widely used due to the visibility of an open flame and the special atmosphere in the house.

- With a closed firebox. More like a traditional oven. Most often they are used not as a piece of furniture, but as a means for heating, drying and cooking food.

When choosing a fireplace model, give preference to the option with a glass door, so the unique surroundings are preserved and fire safety is increased.

Long burning wood stoves-fireplaces for home and summer cottages

A solid fireplace in the house will not only decorate the interior, but also will not create any problems for its owners. Today, manufacturers offer a wide variety of fireplace models that are used as a source of heat, as well as for aesthetic pleasure. Modern fireplaces are a structure that consists directly of a firebox and a chimney, and a portal, which gives the fireplace an attractive appearance. Depending on your preferences and the interior of the room where the fireplace will be installed, you can choose its size and shape.

Fireplace accessories and accessories

You can give a finished look to the fireplace using fireplace accessories. Only they are able to bring a special coziness and that atmosphere of warmth, for the sake of which a fireplace is often installed. Today, fireplace accessories are not only the classic scoop, poker, which are used to clean the fireplace and woodpile, but also many other details. Exquisite candelabra candlesticks, chic mantel clocks in a classic style) - all these interior details, selected with taste, will transform any room, reminding you of the Middle Ages, when the whole family gathered around the fireplace in the evenings. Accessories for the fireplace also play a purely practical role, for example, the firebox allows you to store a small supply of firewood and, at the same time, dust does not fall on the floor, and the screen performs a protective function.

When is a fireplace better than a stove

The fireplace was the first heating device in the history of human civilization. That is why its design repeats the features of an ordinary fire: the presence of an open flame, heating the space only within the line of sight, rather low efficiency.

In the process of evolution, the fireplace gradually turned into a closed stove - a device, undoubtedly, much more complex and efficient for heating a room. Nevertheless, in our time, fireplaces play not only a decorative role, but are also used for heating. And this is due precisely to the peculiarity of their work:

- unlike a stove, a fireplace begins to give off heat almost immediately after a stable flame appears;

- cleaning and maintaining a fireplace is much easier than a stove;

- the construction of a fireplace is not so critical to the mistakes of a bricklayer and therefore can be carried out without the involvement of professional stove-makers;

- there are modern industrial metal fireplaces, the efficiency and safety of which is comparable to the parameters of stoves.

DIY brick fireplace in the interior

Positive features of the fireplace

The weight of a simple fireplace is much less than a stone stove, and given the low heating temperature in the fireplace, ordinary ceramic bricks of good quality may be suitable for its construction.

As a result, the costs of bricks, materials and work are several times less than the cost of building a stone stove. This is the fireplace in the country, the photo of which is shown below.

Simple fireplace in the house with your own hands

Today, there are fireplace designs that are in no way inferior to traditional Dutch or Swedish designs in terms of their thermal and quality indicators. True, it is not possible to achieve these indicators in a brick structure, therefore, these structures are implemented in metal and are presented in the form of ready-made metal fireplaces of industrial production.

Much needs to be considered before building fireplaces: size, location, arrangement, type of materials used. All this is calculated in advance, often using special programs. High efficiency fireplaces are focused on the use of pallets or other similar slow burning biofuel.

Fireplace for summer cottages with open hearth

On the safety of using the fireplace

The use of an open flame in a room is legally prohibited by building and fire-prevention regulations, which greatly limits the use of a classic fireplace. Information can be found in the Fire Safety Rules of the Russian Federation (PPB 01-03, section 3: Rules for human habitation).

A developer who violates the rules of the PPB and lays out an open fireplace in the country with his own hands from bricks is at great risk. Today this issue is easily resolved through the use of glass protection. High-temperature glass easily transmits infrared radiation, providing the effect of the heat of an open flame.

Fireplace layout

The most important thing when erecting a fireplace in an already built cottage is to combine it with all supporting structures: walls, floor and ceiling floors, rafters. Draw a floor plan of your building and combine it with the drawing of the fireplace, make the necessary adjustments and only then start construction work.

When choosing the location of the fireplace, some rules must be taken into account:

- It is not customary to place the fireplace in front of a door or window, this can lead to drafts or smoke.

- There should be no flammable objects and materials near the fireplace.

- Wooden partitions should be insulated with a metal screen and basalt mats.

Step 4 We lay the laying of the fireplace to give

The plinth of the fireplace is about two centimeters above the floor level, so we lay the first row, so that in the future, the attached plinth will cover the plinth masonry and the finished masonry of the fireplace is visible.

The first row of the fireplace is solid. The second row is the main one for laying the combustion chamber and two air ducts of the convection chambers.

In addition, we prepare the door of the blower for installation using oven tapes fixed to the door body with bolts.

On the second row we lay an ash pan and two "pockets" of convection chambers.

Bringing the verticality of the oven out is a very complicated procedure. Let's use the stove-makers' trick to solve this problem. We will stretch two threads, placing them along a plumb line in the corners of the oven and parallel to each other.

The threads are fixed to the ceiling and we attach them to the seam of the first row of masonry exactly in the corner of the fireplace.

On the front wall, we form two air intakes into the convection chambers.

On the third row of masonry, we make a jumper above the air intakes and a blower above the door.

We make a decorative shelf above the door. It is done very simply. ¼ part of the length is cut off from the brick. We put it "poking forward" and ¼ part of the brick length protrudes above the fireplace wall.

We start laying the decorative shelf from the center of the brickwork. The total length of the shelf will be 7 bricks.

We measure the horizontality of the masonry, and correct the identified deviations using the thickness of the masonry seam.

The procedure for laying a brick oven with your own hands

The next stage is the construction of the stove itself:

- In the first row, the solution is not applied. 12 pieces are laid out strictly horizontally on the sand. A blower is placed on the clay-sand mortar. The door is wrapped with asbestos cardboard, wrapped with a cord. Fastening is done with wire.

- Then the laying of the second row is made.

- In the third row, lined with refractory bricks, strictly above the blower, a grate is placed.

- The bricks in the fourth row go to the edge.

- The chimney is provided with a support for the partition. The back wall is laid out without the use of mortar. These bricks will then need to be removed. Then they put the fire door, wrapping it with an asbestos cord. A couple of bricks are temporarily used for fastening. Secure with wire.

- The fifth row is laid out flat, like the fourth.

- The bricks of the sixth row go to the edge.

- The bricks in the seventh row are laid flat again. For inter-row bundling, you need to start with a brick chipped off three-quarters in size. Having placed two bricks on the edge, they begin to build the back wall.

- The eighth row will close the firebox door. To direct the fire towards the center of the hob, the brick is placed at an angle. Tightness is ensured with a wetted asbestos cord.

- The ninth row is also laid using an asbestos cord. The peculiarity of this row is that it is slightly shifted back so that the door remains open.

The beginning of the chimney is formed in the tenth row. There will be a place to attach the iron pipe. In the eleventh row, a chimney valve is installed. At this stage, step-by-step instructions will come in handy - how to fold the stove with your own hands, which will help you not to get confused in the details.

Fireplace masonry

The question of how to build a fireplace in the country is not so simple, since not everyone can do the work with their own hands, but controlling the process, understanding what is happening, is a very real task.

Fireplace base

Fireplaces of light structures, which are often installed in the country, are placed directly on the floor, large ones (over 700 kg) are built on a foundation with a depth of about 0.5–0.7 m. In the construction of fireplaces, two types of foundations are distinguished:

- Pouring foundation, in which concrete with fillers (crushed stone, crushed brick, etc.) or liquid concrete is used. For particularly heavy fireplaces, reinforcement fittings can be used. The surface of the flood foundation is usually made at floor level or 10-15 centimeters lower. Formwork is used for casting.

- Brick foundation, which is designed for small fireplaces. It is laid out in the form of bricks placed on the edges. For the mortar, high-strength cement (grade M300 or higher) is used. Rows should be from 4 to 6.

To protect the foundation from moisture, roofing material is used, for which the bottom and walls of the formwork are covered with roofing material, and the joints with bitumen. We wash the attachment points, and cover the bottom of the foundation with a thin layer of expanded clay.

If a heavy fireplace is placed on the second floor, the foundation is built anyway, except for the presence of a wooden floor. In such a situation, a 15 cm layer of refractory material covered with a sheet of iron is placed on the floor.The lower brick layer is laid on a cement-clay mortar.

After the foundation is made, it takes 5-6 days until it dries up.

Chimney

Basic moments:

- The pipe walls must be thick enough to reduce heat loss. When the fireplace is located against the inner wall, the chimney is laid out in one brick. If the fireplace is next to the outer wall - one and a half or two bricks. The normal section of the pipe is 1 / 10–1 / 15 of the width of the furnace opening. The minimum pipe dimensions are 14 × 25 cm.

- It is unsafe to support a heavy pipe on a light fireplace, so it is better to use ceramic or metal pipes. They need to be insulated from the outside by laying a brick over the pipe and filling the space between the brick and the pipe with expanded clay.

- The quality of traction directly depends on the height of the pipe. The optimal height option is 5–7 meters. Above the damper, the pipe looks like a tapering pyramid, and the transition at the top into the chimney. The front wall of the smoke box is raised, tightly joining it with the chimney. The vertical rear goes straight into the chimney.

- The chimney provides a damper (rotary or slide), with the help of which the fireplace is closed for heating. It is also needed to adjust the traction force. The damper should be 20-30 cm (maximum 80-100 cm) above the firebox opening, at a distance of about 2 meters from the floor.

- If the chimney is less than 5 meters, then without a damper, cold outside air will quickly fill the room. If the pipe exceeds 7 meters, you do not need to install the damper, although in any case it will not be superfluous.

Step 5 we start laying the firebox of our fireplace for a summer residence

The inner part of the firebox is made of fireclay bricks. We put two metal corners above the ash pan, on which we lay the grate.

We leave an air gap between the fireclay brick and the ceramic brick so that there is no contact overheating (in the photo behind).

For now, we leave the masonry alone and proceed to preparing the fireplace door for installation. Firstly, we remove the glass from the mounting sinuses and glue the outer part of the frame with building masking tape.

Construction tape on the frame of the fireplace door will prevent it from possible damage during door installation.

We fasten the fastening oven tape to the side pillars of the door using bolts.

The length of each tape must be at least 50 cm. The fact is that the door is quite massive and must be securely fixed.

We install the door. We fasten the lower edge of the door using tapes, hiding them in a row of masonry. To prevent the door from wobbling, we make temporary stands in order to fix it in a certain position.

We fix the upper tapes in the racks laid out "dry" on the inner walls of the fireplace.

As soon as the door is secured, we proceed to the process of raising the rows of masonry on the outer sides.

We hide the upper tapes in a row of masonry, which completes the process of installing the door.

Monitor the control of the falling solution inside the combustion chamber, removing it so that it does not cause the impossibility of accurate installation of the fireclay bricks of the combustion chamber.

The mistake of many is that they hide the fastening tape in the horizontal seam of the row, it would be better to do it this way.

After the door is in place, be sure to clean the convection chambers. The fact is that a width of 12 cm and a depth of 70 cm is critical in order to reach the bottom.

The convection chamber has been cleaned. The rest of the fastening tape is bent along the masonry of the transverse wall of the fireplace and is attached to it with self-tapping screws screwed into the groove.

We proceed to the thermal insulation of the combustion chamber. The simplest and most effective method is to use a flat sheet of asbestos. We use a sheet with a thickness of 10 mm.

We cut the sheet to the required size.

Before starting the laying of fireclay bricks, it is necessary to make thermal insulation with asbestos. We install sheets on both sides.

We press the sheet of asbestos cement against the inner wall of the ceramic brick masonry.

Similarly, we install the asbestos sheet to the other wall of the masonry.

The front part of the combustion chamber must also be thermally insulated against overheating. For this purpose, it is best to use basalt cardboard. Its thickness is 5 mm, we cut it out along the width of the front part of the brickwork.

Basalt cardboard is installed on the front wall. So that it does not interfere with work, it is best to press its upper part against the brickwork.

We begin to lay out the combustion chamber. It is necessary to use a kiln mixture that can withstand high temperatures. So that the firebox does not lose much in the internal space, you can use the technique of laying fireclay bricks placed on the edge.

Pay attention to the fireplace door so that it is more hermetically "planted" in the masonry, its frame is wrapped with a basalt cord with a diameter of 8 mm. Firebox masonry rows: the first row is the base, the second ¾ the width of the brick, the third row is placed on the edge

Firebox masonry rows: the first row is the base, the second ¾ the width of the brick, the third row is placed on the edge.

For now, at this stage, we stop laying the firebox and start preparing the bricks to create a wedge lock, which we will beat and make as a decorative element of the front part of the fireplace

Continued in the next article.

Final activities

Three more a number of brickwork is performed for pipe connections. Having taken out the "knock-out" bricks, the channels of the furnace are immediately cleaned of construction debris. The perimeter of the structure is neatly covered with a plinth.

The whitewashing or facing of the stove is done after a test ignition.

Only after the whitewashed or tiled mini-oven is completely dry can it be used. In order for the mini stove for the summer residence to please for a long time, you should not rush to kindle it. Let it stand for a week or two with the doors open.

It is not recommended to use coal immediately; it is necessary to give the stove time to initially warm up with chips.