Plaster

If you are looking for a quick and inexpensive option for cladding an existing portal, consider plastering. This material is available to everyone and does not require much work.

It should be noted that plastering does not contribute to the weighting of the main fireplace masonry, therefore, strengthening of the base is not required.

7photos

Decorative qualities are achieved by staining with a compound that is resistant to temperature changes.

How is plastering done:

- clean the surface from dirt and old plaster;

- using small nails, fix a reinforcing mesh on the masonry;

- the prepared solution should be applied with a spatula evenly over the entire surface;

- after you finish finishing work on your fireplace, leave the surface to dry for two days. After that, you can apply coloring solutions or decorative putty. If necessary, you can add a water-soluble color.

Types, methods of finishing the fireplace

There are several options for finishing the portal, each of them has its own positive and negative properties. Most often, the hearth is plastered with subsequent staining, revetted with decorative ceramic tiles, natural or artificial stone, and sheathed with metal sheets. The portal itself is often decorated with fire-resistant glass doors, heavy cast-iron gratings, and steel dampers.

Plastering: advantages, disadvantages

Decorating the hearth with plaster is not a complicated and expensive process. Suitable for structures made entirely of bricks and concrete. This design does not make the object heavier, therefore there is no need to further strengthen the foundation. The plaster layer intended for subsequent finishing is slightly different from the decorative option. When changing the interior, the structure can be easily repainted in a different color, corresponding to the color scheme of the situation. The disadvantage of such a finish is that when a thick layer is applied, reinforcement is required, as well as prolonged drying.

Facing the fireplace with tiles - pros, cons

Very often fireplaces are faced with ceramic tiles, porcelain stoneware. The latter is placed both directly on the glue and on metal profiles. With the help of porcelain stoneware, it is easy to mask uneven brickwork, chips, and other surface defects. The material is durable, resistant to frost, open fire, sudden changes in temperature, humidity, physical damage, retains a beautiful appearance for a long time. The downside is not the lowest price.

Facing with ceramic tiles is an inexpensive option, since you can make it yourself or choose from the widest assortment currently presented by most stores. In shape, it is offered square, rectangular, curly, angular, etc. The material is fire-resistant, environmentally friendly, and you can choose it for almost any interior style. The disadvantage of the material is low impact resistance.

Decorating the fireplace with artificial stone - pros and cons

Artificial stone is cheaper than natural stone, outwardly it remotely resembles it. Such material is many times lighter in weight - additional strengthening of the foundation is not needed for it. Frost resistance, resistance to chemicals in most species are also at their best. Fake stone is made of gypsum, stone chips, polymers, imitates granite, marble, onyx, sandstone. The material is easy to install with your own hands, there are flexible options for curved surfaces. Significant disadvantages - a fake stone does not have natural thermal conductivity, as well as the corresponding characteristics of strength, moisture resistance, it is more fragile.

Natural stone finishing: positive, negative qualities

Real natural stone is a heavy, beautiful, completely natural material.Such a finish always looks luxurious, it is voluminous, quite complex in execution, but as durable as possible - the fireplace will serve for more than one generation. It is permissible to install the structure even in a room that is not heated. The stone is resistant to abrasion, shockproof, and the variety of types, shapes, colors allows you to choose it for various interior styles.

The construction device on the first floor of a private house requires a reinforced foundation under it; on the second and subsequent, it is recommended to install the product at the junction of two main walls. Another disadvantage is the high cost of the material. For cladding use:

- marble;

- granite;

- sandstone;

- shell rock;

- talcochlorite;

- tuff;

- limestone.

Metal sheathing - advantages, disadvantages

The design of the hearth by sheathing with metal sheets is suitable for many modern interior styles. The most popular finishes are stainless steel, copper and brass, the decoration technique is broaching, embossing (including hand), artistic etching, plasma cutting. Metals are easy to combine with natural or artificial stone, plaster. The undoubted advantages of this finish are the relatively low weight of the parts, the ability to decorate the fireplace in almost any interior style (retro, classic, hi-tech, etc.) without completely rebuilding it. A freestanding structure, completely made of metal, is easy to connect and place anywhere in the space. The main disadvantages are the likelihood of getting serious burns when touching a metal surface, uneven heating of the room, and rapid cooling.

Using drywall to decorate an electric fireplace

When performing this type of design, it is worthwhile to first equip the frame. It should be mounted with an accurate calculation. That is, vertical frame racks should allow the drywall to be securely fixed, but at the same time its joints should be neat and invisible. Fastening of plasterboard sheets should be carried out strictly along the frame. Fixing them between profiles is strictly prohibited. Thus, decorating a fireplace with your own hands using drywall includes the following steps:

- clearly plan the structure;

- apply only visible marks on the surface for fixing the profile elements. The markup should be done evenly, clearly and at the same distance;

- fix the vertical profiled frame according to the marks. For this work, ordinary screws are suitable;

- installation of horizontal frame elements;

- sheathe the frame using plasterboard sheets. For fixing, self-tapping screws should be used, which are attached at a distance of no more than 150 mm between themselves;

- close up drywall joints with a special tape dipped in plaster solution;

- to carry out the installation of corners - this will give not only expressiveness to the forms, but also provide the structure with strength;

- to carry out external decoration. You can arrange drywall in different ways, including plastering.

Installation of drywall is not a difficult type of work and does not require special equipment. For this type of work, you only need a screwdriver, which can be found in every home.

Use of decorative or natural stone for cladding

The use of stone for decorating fireplaces is a traditional way of decorating heating structures. This decor is characterized by durability, solidity and graceful creativity. He is not afraid of temperature fluctuations, high humidity levels, significant mechanical influences and most particularly aggressive substances. Stone material can be surface mounted in rooms and rooms for any purpose.

A significant disadvantage of the described cladding is the significant weight of the resulting fireplace, which is typical for finishing with natural stone. It is better to use an artificial material that is lighter in weight. This facilitates transportation and installation work.

Peculiarity!

A decorative facing of a fireplace with a stone (artificial or natural) consists of the following stages:

- preparation of the base, consisting of scrupulous cleaning of the brick surface from unnecessary coating and other dirt. Next, jointing is carried out;

- fixing the masonry mesh. The material should fit tightly around the fireplace;

- the surface is carefully leveled with a solution;

- preliminary laying out of stone plates on the floor is performed. Each element is tried on to the fireplace and an exact layout is formed with trimming in the necessary places;

Wish! To simplify and speed up the work, you must first arrange all the stones into "piles" (in shape, thickness, etc.), and then do the layout!

- the next row of stones must be started from the middle of the first. All elements are stacked so that the seams do not overlap. After the completion of each tier, level control must be carried out with the appropriate tool.

Angles are checked with a plumb line, with special attention to them.

PVC crosses are installed between the stone tiles, creating evenness of the seam gaps.

Important! When the parts to be stacked are very heavy, a special fastening from metal hooks is required. They will hold the stone and prevent it from sliding!

- Grouting is done using a plastic bag with a small hole (for example, a cut corner).

If the jointing is supposed to be done after the stones have been laid, then you must first fill in the joints and let the composition dry a little. Then, on the wet material, plane jointing is carried out.

How to choose a plaster for a fireplace

To decorate a fireplace insert, pipes and other details, you will need to choose the right plaster. The composition is often mixed on its own using the following main ingredients:

- clay - added for heat resistance. It is advisable to choose not too "greasy" - this will quickly crack when the structure is heated;

- sand - he is not afraid of high temperatures, the coating comes out as strong as possible, in terms of volume it is taken about twice as much as clay;

- lime is an excellent plasticizer, improves adhesion to the base, facilitates the application process. It is recommended to purchase ready-made slaked fluff or do it yourself;

- asbestos, fiberglass - increase the density, heat resistance, strength of the coating. It is preferable to add to the solution up to 7-10% of natural fiberglass, asbestos - even less, since it is very toxic;

- cement - as a binder, it is added no more than 50% of the total volume of the mixture, since a larger amount will lead to cracking of the surface.

How to plaster yourself

Plastering the structure yourself is not too difficult

It is only important to choose a special composition - fire-resistant, when heated does not emit harmful substances into the surrounding atmosphere, does not crack under the influence of high temperatures

How to perform plastering step by step:

- before starting work, the walls of the structure are cleaned of dirt, degreased, slightly heated, moistened with water;

- then reinforcement is carried out using a special mesh so that the coating comes out as strong as possible;

- after spraying with a liquid solution - this allows you to fill the pores in the brickwork;

- when the layer has slightly grasped, plastering is performed - a layer of four to six mm is applied. thick.To do this, use a trowel and a polisher;

- then one or three more of the same thin layers are applied, dried;

- Covering is done with the same liquid mixture as spraying, it helps to hide the smallest defects. The plane is leveled until it hardens completely, using a wood trowel;

- it is permissible to heat the stove after three to four days - it is unacceptable to accelerate the drying process with kindling, since the coating often cracks;

- the textured coating is made very thin - 0.3-0.7 cm so that the finish does not make the structure heavier;

- decorative plaster is rarely tinted, so you will have to add the paint yourself. It is selected heat-resistant - up to +650 degrees, organosilicon enamel, which almost never cracks, is best suited.

Stylistic directions in the decoration of the fireplace

Different types of stoves are built into very different interiors

It is important to respect the integrity of the interior, to select an acceptable color scheme. The fireplace is often a zoning piece that neatly divides a spacious room into two functional parts.

Most often, fireplaces are built into the interiors of classicism, baroque, loft, provence, country.

English style

The hearth in the English style is made U-shaped, equipped with a large firebox, a wide mantelpiece. Suitable finishing materials are valuable wood species (wenge, zebrano, stained oak, Karelian birch, etc.) or their high-quality imitation, ceramic tiles, metal (forged elements). Most of the lines here are even, the corners are strictly straight, all the details have a strict regular shape.

Provence style

The Provence fireplace has the simplest possible shape, but every detail is worked out as much as possible. The color of the construction is usually white, other suitable colors are pastel, cream, pale pink, bluish, pale green. As a material, suitable decorative plaster, ceramic tiles with floral patterns, light wood species, including painted, artificially aged. Forging will also have to be in place.

Country style

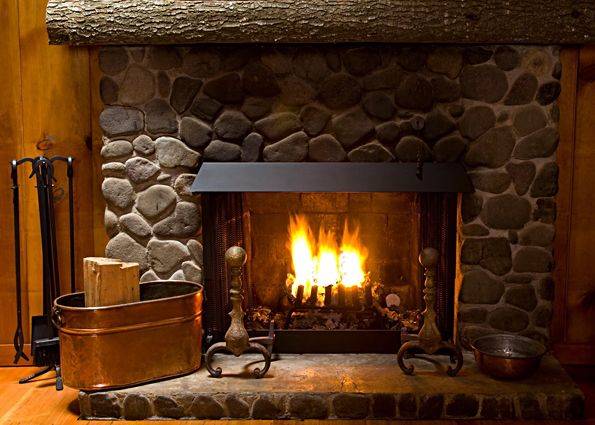

Country is a style associated with rustic simplicity and comfort, that's why the fireplace here is finished “modestly, but tastefully”. This design is heavy, very voluminous, therefore independent finishing is very laborious. The portal itself is made D-shaped, above the firebox there is a thick beam, most often a stone one. Artificially aged natural stone (shell rock, sandstone), brickwork, imitation of stone, brick are suitable for decor.

Classic style

Classics are usually associated with harmony, symmetry, correct geometry, both of the object itself and of the entire room where it is located. A few stucco elements are permissible here - moldings, rosettes, semi-columns, pilasters, corner pieces, and more. Forging, ceramic tiles made in light colors with unobtrusive decor, including imitating wood, are also acceptable.

Hi-tech style

A high-tech fireplace is sure to be sleek and shiny. Rarely it is located against the wall - usually it is located in the corner, island, suspended, rotating structures. The main finishing materials are metal, glass (fireproof, transparent, patterned, partially tinted, etc.).

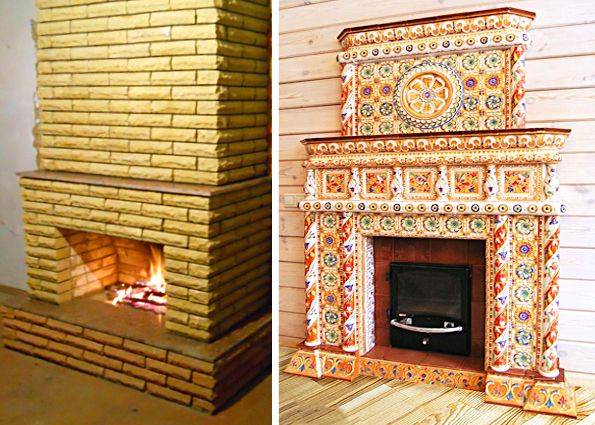

Ethnic style

Ethnic fireplaces are colorful oriental and austere European designs. Less often, it is an imitation of a "Russian stove" inscribed in the corresponding interior. Popular finishing methods are decorative plaster, whitewash with chalk, clay coating mixed with various dyes, mosaic of colored ceramic tiles. Patterns are completely absent here, or are maximally sinuous, multi-colored.

Loft style

The loft hearth is always decorated "semi-antique", finished with brick, stone, dark metal, rough wood, less often - plaster, stucco. The structure is usually placed near the wall, but island, suspended versions are acceptable, the shape is rectangular, rounded, in the form of a barrel, etc. The chimney is not masked here, but is accentuated. Also, the hearth may resemble a slightly modernized "stove-potbelly stove" located in an empty niche.

Dimensions and preparation stage

To create a false fireplace with your own hands, no special design or engineering skills are required.

First of all, you need to clearly understand how you want to see the future fireplace in order to choose the right material, thanks to which the work will be easier and faster.

Make sure to sketch and draft first. Do not be surprised, a sketch will help you better imagine what kind of fireplace will be externally, and the project will display the given dimensions, by which you can calculate how much material is required. When choosing sizes, take into account all the nuances and only then do the project.

An artificial fireplace should be proportional to the size of the room where it will be placed. A massive structure in a small room will look bulky and visually make the room much smaller. A fireplace of modest dimensions in a spacious room will become completely inconspicuous.

In addition, the fireplace should be in the right place so that your household and guests can mix around the room without obstacles.

Types of plaster for finishing

This type of decorative fireplace is considered the most durable and durable. Special fixtures and tools help to create any texture on the surface of the decorative coating.

For decoration, two types of building composition are used. The first one is used for initial or rough coating. It has a dense texture and dark color. The layer thickness should not exceed 5 mm. The building composition allows you to get rid of external defects in brickwork on the surface of the fireplace.

The second type of building composition has a white tint, which can be further changed with the help of special color tints. It is applied in a thin layer and left to dry completely.

To create textured lines, use a decorative roller or spatula. The decorative plaster contains refractory substances. They prevent excessive accumulation of soot and soot during wood burning.

In addition, they reduce the risk of possible deformation. Most often, their surface has a moisture resistant coating. This allows the plane to be cleaned as it gets dirty.

Using stone to decorate a brick fireplace

Finishing with natural stone allows you to make the fireplace especially elegant and chic. Natural material, like no other, fits into any room design, allowing you to emphasize the nobility and sophistication of the owner. In addition, natural stone has unique performance characteristics.

With special equipment, you can create real masterpieces of art. If you do not have devices for processing natural stone, then you can use shell rock, limestone, rubble stone. Such a fireplace with your own hands will become the pride of every owner of the house.

Artificial decorative stone can also be used to decorate the fireplace. It is outwardly similar to natural, easy to install and has a long period of use, during which it does not lose its appearance. Modern technologies allow you to choose an artificial material for any natural fossil. In addition, artificial stone can be made by yourself.To prepare a mixture for making a stone, it is necessary to mix cement, sand and pigment. Pour the finished mixture into special silicone molds, leave for a certain time until it hardens completely. Remove the finished artificial stones from the mold. They are ready for facing work.

Cladding with both natural and artificial materials is exactly the same: using a special adhesive for ceramic tiles, you need to fix the stones on the surface of the fireplace. To create a beautiful pattern, stones can be laid out on a flat surface, choosing the most advantageous options for their placement. Thus, when they are fixed already on the surface of the product, there will be no troubles associated with the size or shape.

Finishing features

One of the most important requirements for finishing a real fireplace is the fire resistance of the facing material. The structure consists of a hearth (the place where the fire burns) and a portal (decorative outer part) with a chimney. The object is carried out most often from clinker - a special heat-resistant oven brick.

The color of the finish also matters. When the fireplace is intended primarily to heat the room, and not to decorate it, the darkest matte colors are preferred. The more textured, embossed the surface is, the stronger the heat transfer, which means the higher the temperature in the room with such a stove.

Decorating the fireplace with decorative tiles

A particularly popular solution is finishing with ceramic tiles. The fireplace she decorated looks really amazing. In addition, the material is strong, durable, easy to clean (even with aggressive agents) and, moreover, is resistant to regular temperature extremes.

Heating structures are usually clad with the following materials:

- clinker tiles;

- glazed ornamented tiles or majolica;

- terracotta elements or unglazed cladding;

- porcelain stoneware.

Exception! Clinker tiles should be fixed to the fireplace surface using a special mortar. This is due to the ability of clinker tiles to actively absorb water from the fixing compound. Specialty mixes are sold separately and labeled accordingly!

The decorative design is best done with small-sized plates, since they are easier to adjust to various protrusions and niches.

Also, if deformations begin to appear, they will most likely remain intact. Large ones, in such a situation, will crack and will move away (fall off) from the surface.

The tile gluing technique is as follows:

- the surface of the fireplace is being prepared for facing - you need to clean off the old finishing material and join the masonry joints;

- the mounting mesh is fixed on the base and the surface is carefully leveled with an adhesive mass;

Nuance! It is required to leave the fireplace alone until the glue and the underlying base are completely dry!

- installation must be started from the bottom row of tiles. A layer of adhesive is applied to each element with a notched trowel. Then, the tile is tightly, with effort pressed against the prepared base and to improve adhesion it should be gently “tapped” with a rubber mallet or rubber hammer. Excess adhesive solution protruding through the tile joints is immediately removed.

To maintain the evenness and conformity of the seams, special PVC crosses are used, which are installed between the corners of the tiles or in the middle between them. According to this technology, row by row, the entire planned surface of the fireplace is filled with tiles;

- after waiting for the fixing compound to dry completely, you can start the grouting process.The inter-tile joint spaces are filled with a color-matched mineral paste-like grouting mixture. Until the composition has set, it should be leveled with a damp, dense sponge. With a soft cloth soaked in water, you need to clean the surface of the tiles from the remains of grout and other dirt;

- after a day, each seam must be treated with a special compound that repels all kinds of dirt.

Construction stages

Many people build a drywall false fireplace because they perfectly understand how to do it and do not see any difficulties in work. Indeed, to carry out all the work, a minimum skill in handling a construction tool is sufficient.

Conventionally, the entire construction scheme can be divided into three stages:

- Preparatory stage - sketch development, selection and purchase of tools and materials, site preparation.

- The stage of creating the base, base - construction of the frame of the structure from a metal profile or bar, finishing the fireplace with plasterboard.

- Finishing - decorating the appearance of a false fireplace, working with a firebox, creating a suitable space around it through the use of suitable accessories (pokers, candelabra, candles).

If you have creative potential, then you can develop a drawing of your false fireplace yourself, for others it is easier to find it on the Internet. Presenting the general image of the future structure, one should evaluate how it will fit into the interior of the room. If everything is fine, we calculate the dimensions of the future structure, estimate how much drywall and metal profile will be required, we buy them in a hardware store.

Large artificial fireplace in a private house

The construction of the frame should be started by transferring the drawing to the walls and floor. Then the base is attached to the surfaces, and the frame is already assembled on it. Depending on the type of fireplace chosen, the frame can be simple or complex. It is convenient to build very complex frames from a bar, since it is easier to fasten. Make sure that the frame is built on a level, and its racks are in the right places and strictly upright.

When the frame of the structure is assembled, the fireplace is lined with plasterboard. At this stage of work, the main thing is to be careful, because gypsum is a rather fragile material that breaks under excessive mechanical stress. Sheathing is done using wood screws, they perfectly hold drywall sheets on a metal or wooden frame. Decorating a fireplace with plasterboard with your own hands is a very laborious task, but with the proper approach, it is quite doable.

When the structure is built, it should be finished with plaster or putty. The main places requiring processing are the joints of sheets, corners, caps of self-tapping screws recessed into drywall. All these areas are putty and leveled. For this, a universal putty sold in every hardware store is quite suitable. After the putty has dried, the fireplace is ready for finishing work.