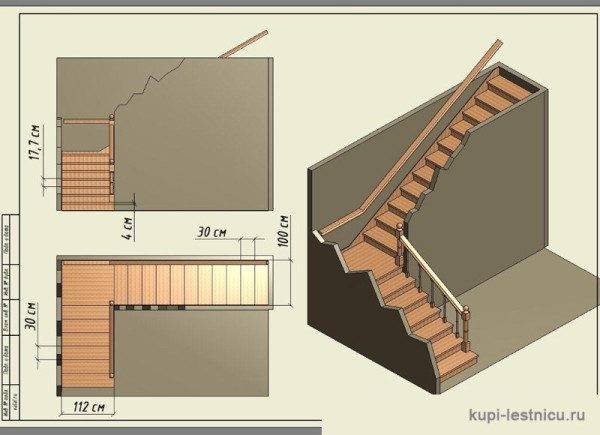

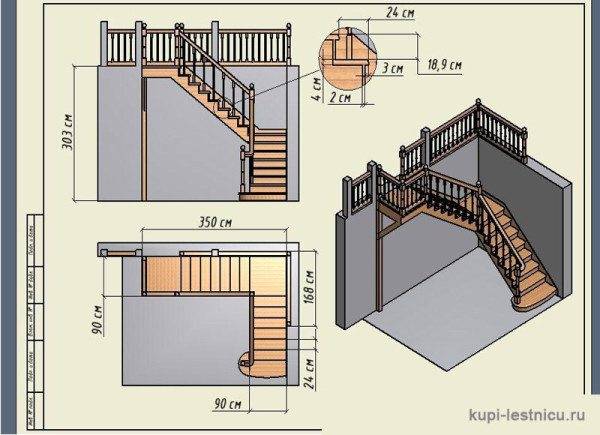

When designing their home, all developers think over the best options and the most rational place for the construction of the stairs, the dimensions of its steps and materials acceptable for this. Of course, corner staircases to the second floor occupy the minimum area.

To successfully select the type, as well as the width of the march, the depth and height of the steps, decorative elements will help us with numerous samples in this article: we can easily clarify the parameters and consumption of specific materials using them.

The successful arrangement of the staircase and appropriate placement will make it a spectacular element of the interior in a small cottage, and in a spacious living room it will be a respectable and decisive accent of the hall.

Step standards

Professionals give ideally comfortable dimensions for such structures:

- stair tread lengthmore than 30 cm in a private house is impractical due to the loss of space;

- step height - up to 15 cm;

- the width of the flight of stairs in a private house or any public building should be 90-120 cm, but the optimal size is 1 meter.

Let's clarify that other sizes will bring us a tangible inconvenience, therefore experts do not advise changing the standards.

- If we increase the height of the step, we will instantly feel this difference in the increased load on the legs when walking on it both up and down.

- Even if we reduce the height of the riser to a minimum, there will be a feeling that we are tiring up the stairs.

Note! Often change the standard of the steps to squeeze instaircase squareexactly in the place reserved for her. And then the owners increase the height of the step to 5 cm, which, of course, will reduce the number of steps and the volume occupied at the same time.

Corner staircase installation technology

Transition platform

- We will make the platform from a strong channel with a width of 14 cm. But the edge of the channel will certainly be inserted into the wall.

- As a result, this transition area touches 2 walls of the house at once, so we will drill 3 holes in these walls and fix the channel.

- Instructions from professionals: pour channel in the wall with concrete is possible even after the entire staircase is completely assembled.

- Such a transition platform is reliably, rigidly clamped by consoles in the wall, so the structure does not need to be reinforced by installing a support at the edge. Of course, unless we want ambitious columns.

Note! The transition platform can be cut in half diagonally to reduce the number of steps. But such a graceful transitional platform of 2 triangles at different heights is not very comfortable when walking.

Staircases

- Weld 2 channels of 14 cm each to the finished transition platform on one side, and on the other, weld the ends of the channel to anchors on a hemp foundation.

- Now we will make steps and treads from a corner 5 cm wide.

- We also note that the flight of stairs may not be close to the wall, because then we will plaster or walk around the walls.

Advice! If the walls for supporting the channel consist of shell rock, foam concrete, aerated concrete or blocks of sawdust, then it is necessary to put bricks under the channel for reliability.

- Similarly, we weld 2 channels of the same size (14 cm) to the transition platform, and fix their other ends on the ceiling.

- Then we make treads and risers from a 5-centimeter corner.

Welding works

- We carry out all welding of the stairs with conventional electric welding.

- In places where wood is in contact with metal, weld a seam from the inside to avoid bumps.

- We carefully cut the end of the corner - and it will not interfere.

Finishing the frame with wood

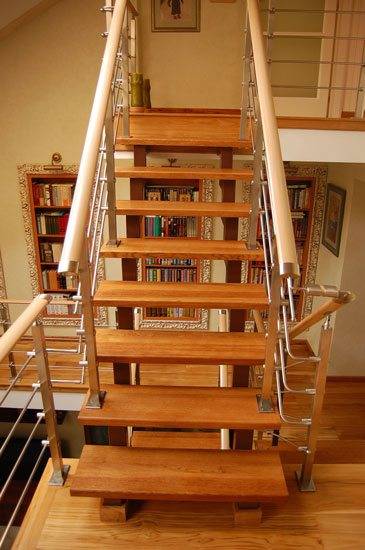

- If we sheathe some of the treads, we get an almost airy and light open structure. Its frame can also be painted to match the color of the wood.

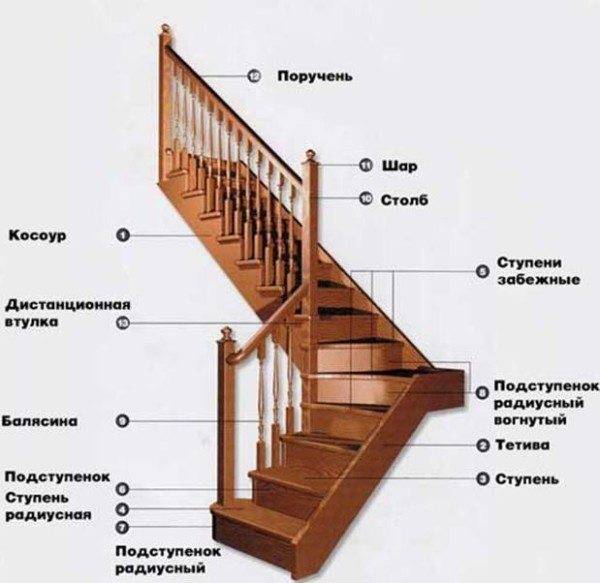

- Balusters, railings are also made of metal or wood.

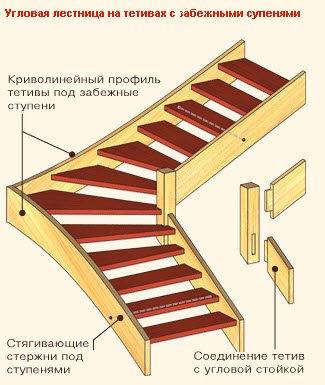

Corner structures on bowstrings

We make the wall strings of the winder ladder from a curved profile. Outer bowstrings are either straight or curved. The question of what angle the staircase should be is decided by the owner together with the designer.

Mounting options

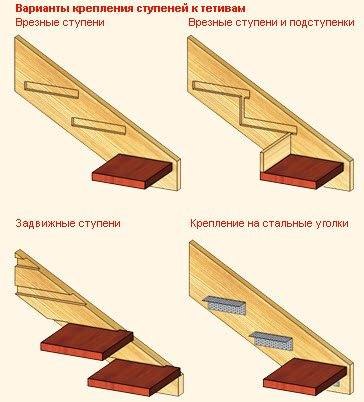

There are 2 ways to mount steps and risers directly to the bowstrings.

- The treads enter the grooves to a depth 3 cm... These are mortise or insert steps.

- We insert the sliding steps into the groove with open edges into the ready-made bowstrings. The edges protrude slightly over the edges here.

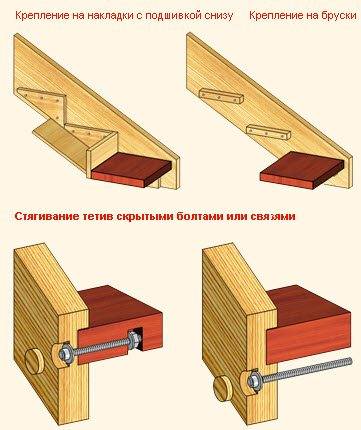

For the screed, we will use threaded steel rods every 5 steps. Tightening rods can be replaced with countersunk bolts inserted inside the steps - so the tie will become invisible.

An alternative - fastening steps to bars, corners, bowstrings - this does not require milling work and tension rods. A staircase from a corner with your own hands is an easy task. But such elements are visible and do not decorate the flight of stairs.

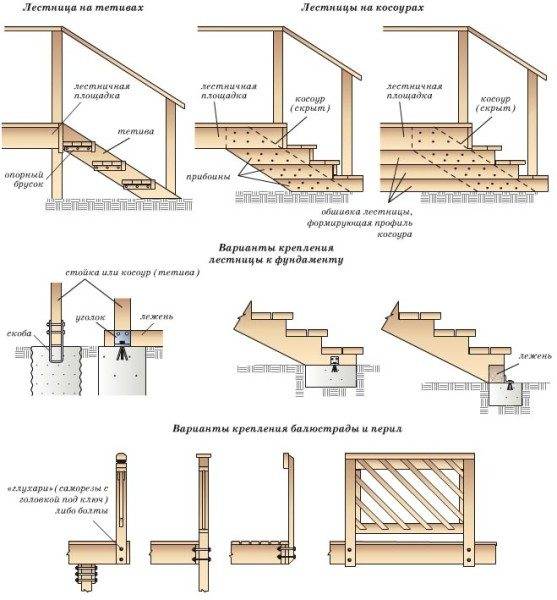

Belyasines (railing posts) are installed on the bowstring, but on the kosoura they are placed directly on the steps, while we use glue on the dowels. Half of the dowel is in the bowstring, and half is outside, for the baluster.

Output

A staircase with 1 transition platform is very effective, unfortunately, it takes up more living space than its usual counterpart, and the price is much higher.

The most acceptable option is a combined structure, consisting of a metal frame, which is sheathed with wood.

Her undoubted advantages:

- such an element can be of any configuration and size;

- the metal frame never creaks or shrinks.

The only difference between ladders on bowstrings is that we set the steps on the stringers from above, and their edges sometimes protrude. And on bowstrings, all the steps are between 2 supports, while they are attached to them only with their ends. Therefore, the bowstrings aesthetically hide the ends and form an inclined straight profile.

The video in this article will help you understand this topic.