Specifications

There are several types of screw piles, but their correct choice depends on the quality, characteristics of the soil in a particular area, on the expected load that will be placed on the foundation. It often happens that during the construction of one pile-screw base, several types of screw piles are used at once. This method of construction makes it possible to distribute the load as evenly as possible.

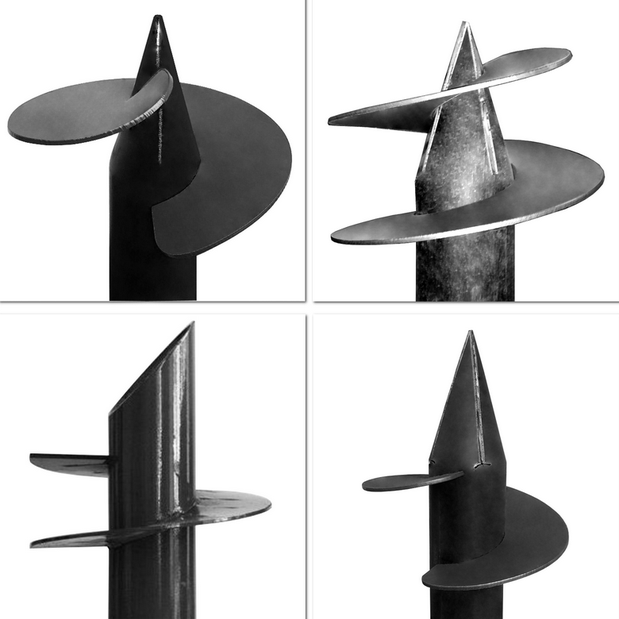

By tip type

This element, which guarantees a relatively quick and easy immersion in the ground, is cast or welded. The first varieties are of great value, so they are used in force majeure circumstances.

They are irreplaceable if the work is carried out on dense soil, including areas of permafrost soils, those that contain massive inclusions of natural or artificial origin. Screw piles equipped with a cast tip pass these layers easily and without any deformation.

By the number of blades

All designs differ in the number of these main elements. Screw piles are available in single and multi-blade design. The maximum possible number of them on one barrel is 6 pieces. Single-blade piles are intended for work on dense soils, characterized by low mobility.

The latter can be considered versatile, but they are more often used on weak soils with a low bearing capacity, since a larger number of blades can withstand any loads: pressing, pulling, horizontal. Efficiency provides a competent selection of the number of blades, their angle of inclination and bending pitch.

By blade size

Products are classified according to this criterion. Screw piles are narrow-bladed or wide-bladed. In the latter species, the diameter is at least 1.5 times greater than this parameter of the trunk. They are optimal for the construction of a foundation on soft soils, where a large support area is the main requirement, ensuring the foundation is reliable and unshakable.

Narrow-blade products have their own "work front" - extremely hard, dense or frozen soil, since it is almost impossible to screw in a pile with large-diameter blades and not deform (or break) it under such conditions. There is an international standard (ICC AC358), according to which the diameter of the blades must fit into a certain range, it is 200-350 mm. Their highly recommended thickness is 9.5-12.5 mm. The exception is temporary and light structures, where blades with a thickness of 5 mm or less are allowed.

Advantages and advantages of the pile-screw foundation

The advantages of this type of foundation are quite obvious and are confirmed by experts in the construction industry.

+ 1. Low price of the foundation. You can accurately calculate how much you will be able to save on construction, taking into account the depth of the laying, the type of soil, the size and average weight of the building itself, and other factors.

+ 2. Water resistance. You don't have to deal with high humidity in your home, even if it is built on soil with a high water content. The structure will be separated from the soil surface by metal piles, so that the appearance of dampness, mold, fungi in living quarters is excluded.

Yes, yes, this is a pile-screw structure.

+ 3. Simplicity and ease of installation. To install the pile-screw foundation, you do not need to fit special equipment or buy expensive tools. Even non-professionals will be able to do this without serious violations of building standards. Just ask a friend or family member to help you; three people will be more than enough to lay the foundation.

Installation can be done even by non-professionals.

+ 4. Affordable repair. Everyone can face poor-quality materials or negligence of craftsmen. If your home is built on a slab or strip foundation, cracking and subsidence will become a serious problem and lead to very high costs.

+ 5. High speed of screw pile installation. Unlike other types of foundations, screw piles can be installed in just 1-2 days. This is due to the absence of such costly and complex steps as pouring concrete, digging a hole, arranging formwork and reinforcement. The exact installation time is determined by the qualifications of the workers, the type of soil and the depth of the screw piles.

+ 6. Ease of building up the pile-screw foundation. If the owner of the house decided to make a redevelopment or add a new room, in this case it will be possible to increase the area of the foundation with minimal financial costs and efforts.

An extension to a house with a pile-screw foundation is a much simpler solution than in the case of a tape or slab option.

+ 7. Possibility of installation on a site with uneven terrain. A large slope of the site with a height difference of 5-8 m is not an obstacle to the installation of a pile-screw foundation. A reinforced concrete foundation for such a construction is categorically not suitable, and a strip foundation will cost much more.

Installation of a pile-screw foundation on slopes does not differ from erection on a plain either in cost or in terms.

+8. Cleanliness of the site after laying the foundation.

At the same time, you do not have to take out excess soil and pay extra for this service.

+ 9. Warm floor at no additional cost. The specificity of the pile-screw foundation is such that there is an air gap between the soil and the floor of the building, which is a natural heat insulator. Therefore, even in the coldest winter, residents will not freeze, walking around the house in light slippers.

+ 10. Installation in any season. Making concrete and reinforced concrete foundations in late autumn or winter, when the air temperature drops significantly below zero, is quite problematic. The owner of the building will have to spend money on various antifreeze additives, think about heating the concrete, etc. The pile-screw foundation, in contrast to them, allows installation even in the cold season: we have prepared a separate article about this, read it !.

SVF, erected in winter.

+ 11. Increased resistance to winter "swelling" of the soil. This guarantees the durability of the foundation, erected on heaving soils, with the sharpest temperature changes.

+ 12. Long service life. Screw piles are made of high-grade steel and treated with special anti-corrosion agents, so the foundation does not need to be replaced for a very long time - up to 150 years.

+ 13. Environmental friendliness. During the installation process, soil compaction and serious changes in the surrounding landscape do not occur, as is the case with other types of foundations.

Advantages and disadvantages

The following advantages of strip foundations can be distinguished:

- the indisputable advantage of this type of warp is the basement. In addition to the fact that it is possible to hide all communication systems in it, it contributes to less heat loss from the interior of the house;

- a simple device allows you to build a foundation on your own, without resorting to hiring specialized equipment;

- the base has increased strength characteristics and therefore will last for many decades;

- this foundation is very resistant to the negative effects of groundwater on it.

Despite the fact that such a base for a house is one of the most popular today, it also has its drawbacks. The disadvantages of strip foundations are as follows:

- When arranging such a foundation, you will have to perform a fairly large amount of excavation work.

- If the foundation is arranged independently, then the construction time can become quite long, since in addition to digging a trench, it is necessary to install formwork and pour concrete.

- The base should be poured with concrete immediately.If the solution is poured over several days, butt joints will form, which reduce the strength characteristics of the base.

- It is impractical to arrange a strip foundation on problem soils and peat soils.

- More costly in terms of materials than pile foundations, and also more laborious.

Characteristics of the main elements of the pile-screw foundation

Screw pile installation

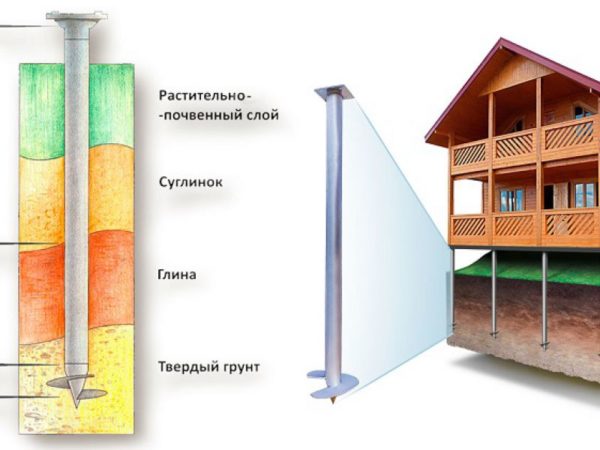

The screw pile is a steel pipe with a sharp, closed tip and blades. In fact, this is a drill screwed into the ground. The screw tip is the main working element, which acts as a functional part, support and anchor. Heads are sold in addition to the piles. They cover the upper part of the structure and serve as a platform for further strapping work. Also, the head is used for screwing, clinging to it, and not to the base of the pile. The blades hold the building under the influence of frost heaving forces.

Pile-screw foundation

Pile-screw foundation

In winter, swelling on clayey water-saturated soils, especially for light timber structures, can lead to squeezing out of the foundation. The problem cannot be solved by deepening the supports below the freezing zone due to the forces acting on the side part. But if you lower the support below the freezing level, with an anchor, then a layer of solid soil will hold the foundation.

Screw piles are designed to erect a lightweight and inexpensive foundation. Moreover, each building has its own standard size, shown in the table.

| Type / size | Application area | Bearing capacity (kg) |

|---|---|---|

| SV76X122 | The most lightweight structures are fences, sheds and utility blocks, playgrounds. | 350 |

| SV89X250 | Non-residential premises - garden houses, arbours (gazebos), lightweight berths and piers | 1450 |

| SV108X300 | Residential buildings of light weight - houses made of timber, logs and SIP panels. | 2200 |

| SV133H350 | The heaviest of the possible structures made of foam concrete, expanded clay concrete blocks. | 2900 |

Pile types

There are two main types of supports, they are distinguished by the way the tip is created:

- Welded tip.

- Molded tip.

The first option is cheap, for which you have to pay for reliability. The disadvantage is that the blades are welded to the tip without observing technological standards, using a handicraft method. As a result, when screwing in, the pile can move away from the vertical. The blade may break off, this is noticeable by the decrease in resistance when screwing in. Such a pile can no longer fulfill the role of a full-fledged support, some of its load-bearing duties are assumed by neighboring points, as a result of which their wear is accelerated. The worst option is the breakage of the pile after the construction of the house. The foundation grillage is deformed, and the structure becomes emergency.

Cast head for screw pile

Cast head for screw pile

More reliable lugs made by precision casting are more reliable. They are more expensive, but durable and can withstand up to 6 tons of load.

Separately, it is worth considering piles from a tubing with an increased wall thickness. Their reliability is comparable to cast ones, thanks to the thick-walled pipe. Special steel can withstand aggressive environments without a protective coating up to 7 times longer. The use of such piles allows you to get rid of their main drawback - metal corrosion in the soil.

Important pile parameters

When choosing screw piles, one should be guided by the type of tip and a number of auxiliary parameters:

- wall thickness is an individual parameter, depending on the type of soil, the weight of the structure, and a number of other requirements;

- characteristics of steel - each alloy has a number of operational parameters that should be considered when purchasing piles;

- type of strapping - strong, steel foundation strapping distributes the loads between the supports better than its counterparts from a bar;

- methods of anti-corrosion treatment - there is a choice between galvanized metal and polymer coating; if the processing is done according to the requirements, the polymer will be preferred.

When buying piles, ask the seller for all the necessary regulatory documents. They will be a guarantee that, under the guise of reliable supports, the handicraft product has not been sold to you. Otherwise, there is a risk of collapse of the building in the first years of operation.

Stilt house

Stilt house

Types of piles used for the foundation

Today, there are several types of piles that can be used for the construction of a pile foundation. Among them:

- Driven piles.

- Screw piles.

- Bored piles.

Let's consider each of these types in more detail.

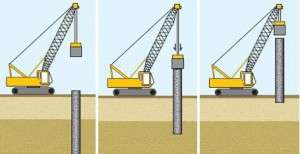

Driven piles

This type of pile gives the foundation the greatest stability. The thing is that during the design of the future structure, the designers calculate the future weight of the building and divide it between all the piles. During their installation, such a force acts on each pile, which then it will have to withstand. When the pile stops sinking into the ground, this may mean that it has reached the ground on which the structure can already withstand.

The compacted soil around it gives additional stability to the pile. It is possible to hammer such piles only with the use of a special pneumatic hammer, which is very expensive to use in private housing construction. That is why this type of pile is not recommended for self-erection of such a foundation.

Screw piles

This type of pile is an ordinary steel pipe, at the end of which elements that resemble threads are welded. In fact, this type of pile can be compared with a self-tapping screw, that is, they are screwed into the ground according to the same principle as a self-tapping screw. Thanks to its blades at the ends, the support area is increased, which in turn increases the strength and reliability of the structure. If the soil at the construction site is not dense enough and even unstable, then piles can be used, on which blades are welded along their entire length.

This type of pile can be used for both private construction and industrial construction. Piles can be screwed in either manually or using a special technique. In the case of screwing in the pile yourself, this will require several strong people

As a rule, at the other end of the pile, there are two holes that allow you to connect them with the twisting technique, while it is very important that when the pile is twisted, it is located strictly vertically. When the pile is completely screwed in to the desired level, concrete is poured into the pile pipe and the head is welded, on which the grillage is subsequently installed

Some disadvantages of such piles should also be noted:

- A screw foundation requires an accurate calculation of the depth of solid soil, otherwise the pile will not be stable, especially during heaving of the soil.

- The piles must have high-quality welded seams, otherwise, during the screwing of the pile, the blades may come off or be damaged. This can lead to a loss of bearing capacity.

- The piles must be covered with a high-quality layer of factory paint, otherwise a poor-quality coating can lead to corrosion.

Bored piles

This type of pile is often used in private housing construction. In order to carry them out, it is required to make pile wells with a hand drill, after which formwork is performed in the case of loose soil that crumbles.

Such piles are waterproofed with roofing material or any other insulating material (asbestos-cement pipes can be used), reinforced, after which concrete is poured directly into the well.Piles are installed along the entire perimeter of the future foundation, that is, in the corners, along the outer and inner walls. The number of piles depends on the total weight of the future structure.

Among the disadvantages of these piles, it can be noted that it is impossible to accurately determine whether the pile has reached solid ground or not.

What properties should screw piles have?

The rods are highly durable. All elements are treated with sandblasting equipment and are additionally treated with an anti-corrosion coating. Welded tip piles are an economical option.

Cast lugs are produced in a production environment by precision casting in a vacuum space. The disadvantages of screw structures lead to instability of the entire building.

When arranging the foundation, it is worth considering certain structural features of the piles:

- Propeller blades are used on soils with poor bearing capacity. In the northern regions, structures with imitation of threading along the length of the rod are often used. This makes it possible not to have a large impact on the permafrost areas.

- Various pipe diameters. The larger the diameter, the greater the weight of the structure the trunk can support.

- Piles with a diameter of more than 100 mm cannot be screwed in manually.

- The blade diameter is taken larger for water-saturated soils. For dense soils, the pipe section may be smaller.

Advantages of the pile-screw foundation

Screw piles used as a foundation have a complex of positive aspects:

- They can be used on problem soils with a high concentration of moisture, as well as soils with an increased content of sand and clay inclusions.

- Correctly calculated and executed in compliance with construction requirements, the pile field is resistant to soil erosion, soil shrinkage and heaving associated with temperature fluctuations.

In practice, a device of this type of base is, on average, 30% more economical than a shallow reinforced tape.

- They do not require significant financial costs when arranging the foundation. The budget of the support structure allows the developer to mount the field from spiral supports, having received three times the savings in money compared to the strip base.

- They allow you to quickly start the construction of a building by quickly assembling a pile foundation. Within 1-2 days, a group of qualified builders can install pile supports for a building with an area of 150-200 m². This is a significant advantage compared to a concrete foundation, which hardens within a month.

- Screw piles are installed regardless of the season and weather conditions. This provides an opportunity not to be tied to weather factors while performing work, while concreting at negative temperatures is difficult and requires additional costs.

- Supports are installed both manually and with the use of small-scale mechanization. The absence of the need to use special equipment allows you to equip pile foundations on your own in areas with a difficult climate and relief, where it is problematic to send construction equipment, for example, for digging a pit for a strip base or mixing increased volumes of concrete.

Stages of construction and installation of a screw foundation

The technology for arranging such a base is simple and does not require digging trenches. Step by step:

- Work begins with marking the land plot, installing pegs around the perimeter - these will be the places for screwing in the supports.

- Next, they pull the cord between them - this is the outline of the future foundation of the house.

- Next, the soil is removed by 10-15 centimeters under each support, based on the diameter of the blades.

- According to the markings, you need to screw the supports into the ground. For this purpose, holes are made in the upper part of the pile - scrap or pipes are inserted into them (depending on the diameter of the piles), they will be levers for twisting.

- The pile must be screwed in strictly perpendicular to the soil surface. The pile is not completely screwed in - some margin remains.

- The supports are made the same in length - the excess is cut off with a grinder.

During work, it is very important to check the perpendicularity with a level. After the performed actions, the support must be filled with concrete to exclude moisture ingress, increase the strength of the product and the rigidity of the entire structure

After the performed actions, the support must be filled with concrete to exclude moisture ingress, increase the strength of the product and the rigidity of the entire structure.

Further, an additional element is welded - the head. It is on it that the slab or grillage beam will be installed. In this case, any distortions are unacceptable!

After that, the strapping is already made, which is done on wooden or metal jumpers. In one case or another, treatment with an antiseptic or anti-corrosion agent, respectively, is necessary.

With some experience, you can not resort to the services of special teams, but do the work yourself - just look at how it is done correctly at least once, and also have at least minimal construction skills.

Advantages and disadvantages of the tape type foundation

It got its name because it looks like a reinforced concrete tape buried in the ground. The outer and inner walls of the building with their entire lower plane rest on the surface of this tape. By the type of deepening into the ground, the strip type of foundation is deepened (from 1.45 to 1.65 m) and with shallow deepening (less than 1.4 m). The first type is being built for large structures and multi-storey buildings, and the second for low-rise buildings. In structure, it can be monolithic and prefabricated. Monolithic is poured from concrete mortar, and precast is made from separate reinforced concrete blocks.

An example of arranging a strip foundation for a house from a wooden frame

For the construction of a monolithic foundation, the following materials can be used:

- Portland cement;

- sand;

- crushed stone;

- fragmentation rock;

- broken brick;

- steel reinforcement;

- water.

The need for these materials can be pre-calculated using a concrete strip foundation calculator or manually.

An example of a strip foundation with shallow deepening

The strip foundation has a number of advantages that make it truly popular among all other types of bases:

- weak susceptibility to heavy loads;

- simple construction without the use of heavy technical means;

- structural reliability;

- the possibility of building on soils of heterogeneous density;

- the walls of the structure can simultaneously serve as walls in the basement of the house.

He also has disadvantages:

- a lot of materials are needed for construction;

- waterproofing work is required.

For the construction of the strip foundation, wooden formwork, steel reinforcement, concrete are used

With all its advantages and disadvantages, this type of foundation is widespread, especially in private construction.

Plinth finish

Given the multidirectional use of screw piles, it is possible to close the basement space in various ways.

False plinth device

For this, sheets of flat slate are used, fastened to a previously prepared wooden frame or bolted to the piles themselves. Such a base does not look very presentable, but to hide the technological space near the shed, this will be quite enough.

Decorative finishing

But for finishing the basement in a residential building, this approach is unacceptable.The foundation of the building should look beautiful, and you can use here, different types of tiles made of natural or artificial stone.

OSB boards can serve as the basis for finishing. They have good binding capacity due to the use of various polymer resins in their production. In addition, they are distinguished by good strength, impervious to moisture and do not require preliminary priming. The tiles can be glued even to an unprepared surface.

A good option for decorating the basement of the pile foundation is finishing with cladding panels or bricks. When using the latter, it will be enough to make a masonry in half a brick.

An important point when finishing the basement of pile foundations is the observance of the technological gap, calculated to compensate for the height of the foundation due to the natural shrinkage of the building.

Pile - the main bearing link of the foundation

Pile driving scheme

The pile field takes on the entire load of building structures, furniture, equipment, and the weight of people. The working element consists of a metal pipe (barrel), a tapered base (cast or welded tip), blades. The design resembles an auger. The blades (screws) are made of heavy-duty material - titanium and other alloys. Their purpose: to screw into the soil to the depth of the location of hard rocks, to be fixed in it and held under load. On top of the pipe there is a grillage, or a head is welded on. The house rests on this structural detail.

The work is performed by rotating the barrel, deepening the base, which is wrapped around the vertical axis of the blades until a predetermined level is reached. The elements of the pile element are calculated based on the type of soil, the geological features of the site, the load, and the installation method. This is how the size, pitch and number of blades, pipe diameter, etc. are selected. When penetrating into the ground to a depth not exceeding 5.0 m, the structural element can be screwed in manually. At deeper depths, special mechanisms are used for this. Piles are installed at a certain interval. Mandatory places are the intersection and abutment of wall structures. Like any other method of arranging foundations, the use of piles has its positive points and disadvantages.