Drawings of benches for a summer residence with your own hands: photos and diagrams

When performing the bench, individual needs are taken into account, as well as certain parameters. To create a quality structure, you will need a drawing with all dimensions. An important point is the calculation of the amount of materials, which will depend on the final parameters of the structure. Profiled timber is especially convenient. You can use a special cutter to round off the edges.

Do-it-yourself garden bench with backrest drawings: double structures

Benches can have different capacities. Most often they are designed for 2-4 people. For a two-seater construction, you will need bars and boards. It will take no more than one day to build such a product. Before cutting, you need to find the right drawings.

Small product drawing

Do-it-yourself bench for a summer residence made of wood: how to do it step by step

First of all, the seating boards are being prepared. In this case, the material is cut and processed. A grinder or milling cutter will help in this matter. You can use sandpaper, but it will take much longer. With the help of the bars, you can build strong legs. The areas where the fasteners will be placed should be noted.

Metal pins are used as fasteners. For greater strength, you can use a special glue. The pins are also used to secure the backrest. After completing the markup, you need to measure the distance from the edge.

A simple option for giving

The assembly takes place like this:

- the bars are placed on top of each other;

- all parts are fastened with clamps;

- holes are made in the center and along the edges;

- through the holes made, the parts are fixed with pins.

How to make a simple design, look at the video:

Then the seat boards are attached to the legs with nails. After that, the heads of the nails can be masked with a mixture of mastic and sawdust. Be sure to cover the surface with paint or varnish.

DIY garden bench from scrap materials: from pallets

You can make a do-it-yourself pallet bench. You can see photos of interesting options on our website. Such furniture can be placed not only in the garden, but also in the country house or on the veranda. For installation work, you need three pallets.

Beautiful composition of pallets

This is how the assembly takes place:

- the pallet is divided into two halves. These halves will be used for the back;

- two pallets are connected together with nails;

- then the back is attached to them;

- a mattress of suitable dimensions is placed on top.

Video: how to make a simple pallet bench

Drawings of a garden bench with a back made of wood with your own hands: a transformer option

The transforming structure is independently constructed. For this you need boards and bars.

You can see a variant of a similar design in this diagram.

DIY technology for making a transformer bench

You can build a structure by performing the following steps:

- 3 boards are attached to the supporting part, of which the seat will be made. You need to insert 4 self-tapping screws into each board;

- when assembling units, it is necessary to apply wood glue to these areas;

- the legs for the back support must be sawn down from the front side. Then the legs must be connected in pairs;

- then you need to make a back, which, when transformed, will transform into a tabletop.

- boards are attached so that there is a gap;

- 3 holes with a diameter of 0.8 cm must be made in the support board.

Here's a handy transformer design:

To create the axes of rotation, you need to make two holes on the back leg. The backrest is fastened to the base with bolts.

Related article:

Calculated part

Guided by a previously developed drawing, you can easily calculate the amount of materials and select the necessary tools for work.

Necessary materials

Regardless of the chosen design of the bench, the following materials must be prepared for the manufacture of the product:

-

shaped pipe, the cross-section of which corresponds to the developed documentation. The material is used for the manufacture of the power frame of the bench;

-

planks 20-30 mm thick, made of coniferous wood. Planks or bars are needed to form the base and back;

-

galvanized screws M6-M8 thread and 80–100 mm long, as well as nuts and washers. Hardware with a semicircular head are used to attach strips to a tubular frame.

Let's calculate the amount of materials for making a simple shop.

A minimum of materials are required for manufacturing

To make a bench with a size of 2.3x0.6x0.45, prepare:

- a square pipe 30x30 mm with a total length of 10 meters;

- pine boards 30 mm thick and 100 mm wide - 5 pieces 230 cm long;

- bolts with a semicircular head M8x80 with nuts and washers - 10 sets.

The nomenclature of materials used for the manufacture of a bench with a back is slightly different.

The need for materials is determined by the design of the bench

For self-construction of a bench 1.5x0.44x0.9 you will need:

- rectangular pipe 40x20 mm - 12 meters in total;

- bars 30x30 mm - 9 pieces of 150 cm;

- countersunk screws М8х100 with nuts and washers - 18 sets;

- steel foot pads 2 mm thick measuring 50x50 mm under the bench legs - 4 pieces.

The profiled pipe must be pre-cut into blanks corresponding to the drawing dimensions.

To increase the service life of manufactured products, you will need:

- paint to protect the metal frame of the bench from corrosion;

- material for antiseptic wood processing;

- wood stain or varnish for finishing wood planks.

These materials will increase the resistance of the bench frame to corrosion, and will ensure the safety of the wood when used in high humidity conditions.

Applied tools and equipment

To carry out work on the manufacture of a bench of any level of complexity, you will need the following equipment and tools:

- welding machine complete with electrodes 3 mm in diameter;

- grinder with a cutting wheel for metal;

- electric drill with drills;

- sander (you can use a file and sandpaper);

- roulette;

- building level.

If radius blanks are used in the design of the future bench, then it is necessary to prepare a device for bending shaped pipes.

The device allows you to smoothly bend the profile pipe

Decor for country benches made of metal

Since just a metal frame and boards are boring, craftsmen tend to diversify their products with interesting additions. Most often, forged elements act as such additions. They simultaneously serve as a decoration for outdoor furniture and at the same time increase the rigidity of the structure by creating additional points of support.

For example, in this model, the curls from the square bar act as side crossbars and support the wooden armrests.

Here, the curved profile tube completely replaces the standard sidewall and backrest support elements.

And in this model, there is no decor as such, but polished stainless steel with a crosshair made from a bar on the side looks elegant on its own.

The creators of such products prefer minimalism, therefore, the benches are not supplied with decor. The shape of the models is interesting, the use of only brushed metal or the original design.

Asymmetry, curved contours and original shapes also help to make ordinary benches from a profiled pipe the best addition to a garden or park.

Manufacturing steps

One of the main reasons that makes metal a popular material for the manufacture of such structures is its availability, because it can be purchased at any hardware store. In addition to this, you can significantly save on the manufacture of such a product if there are old metal parts in your area, for example, from water pipes or clamshells. They can also serve as the basis for making metal benches.

Materials and tools

A metal pipe is not the only material that you need to make a do-it-yourself garden bench. You should also have pine planks available, one of which is 35 mm thick to fit the seat, and the other 25 mm to be used to create the back. All your expenses for the purchase of materials will amount to a maximum of 1000 rubles. You will also have to take care of the availability of a number of tools:

- Bulgarian;

- welding machine;

- corrosion protection paint;

- woodworking tool.

Bolts, nuts, gloves and glasses, as well as a hammer and a hacksaw must be present.

A bending tool will be useful, for the manufacture of which you can use the brake disc of a car. By using it, you can avoid damage to the pipe when bending.

Pipe bending

The bending procedure itself is performed as follows: first you need to take a cork and plug the end of the tube with it. After that, fine sand is collected in the pipe and closed on the other side.

Next, the pipe is fixed in the bending device so that it is securely fixed between the protrusion on the disc and the pin. You can then start bending the pipe to the desired angle.

Recent Entries

Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives make Secrets of growing seedlings from the Japanese, who are very sensitive to the earth

p> It is not always possible to give the pipe the required angle at the first attempt. To simplify the procedure, you can heat the bend using a blowtorch. By following this recommendation, you can bend the pipe effortlessly.

Next, they begin to fasten the constituent elements of the structure. To do this, you can use threaded connections or resort to welding.

If you have to work with duralumin pipes, then only one option is possible to connect them to each other - a connection based on screws and bolts. Welding for such pipes will be useless, since they do not lend themselves to it.

The process of making a garden bench from a profile pipe ends with the processing of seams. You need a sander to do this, but if you don't have one, you can also use a file.

It is necessary to carry out grinding until the joint zone acquires a flat surface. Even before finishing the frame, it is necessary to remove the scale from it, which may appear after welding.

Having followed exactly all of the above steps, you will create a frame for the future garden bench. If everything worked out right, then you will have more reason to be proud, since you completed the most difficult part of the work without the help of specialists.

The last step will be to install the frame for the seat, for which the corners are used, fastened with self-tapping screws. After that, your bench is ready for use.

To make the armrests, you will have to use a pipe: you need to divide it into two pieces, each of which should be 75 cm long.Next, they need to be bent using a pipe bending device.

Then these parts must be welded to the metal frame, after which they must be processed using a grinder or file. Finally, the armrests are painted.

After completing all the above work, your bench will take on a more presentable look. Thus, few people will have the idea that you made it yourself.

Bench with backrest

A garden bench with a back requires more time to make with your own hands, but it is convenient because you can always lean on it. Using a detailed drawing, you can create a comfortable, beautiful bench without much effort and material costs.

This will require the following materials:

- 8 meters of pipes with a section of 25x25mm;

- boards with a thickness of 30-35 mm for the seat and 25 mm for the back.

From the profile pipes, you need to prepare the frame parts. This will require a grinder for metal and a tape measure.

- 1 piece of pipe 1550 mm long for the crossbeam between the supports;

- 2 bent with a span of 100 mm, sections 780 mm high for the back and rear of the supports;

- 2 pieces of 350 mm each will be the base of the seat;

- 2 pieces of 390 mm to create the front of the supports;

- 2 pieces of 200 mm to strengthen them;

- 4 metal plates 40x40 mm will serve as a stand on the supports;

- 2 bent metal strips 450 mm for connecting supports on each side.

Next, we prepare:

- 3 boards 1600 mm long, 60 mm wide, 30 mm thick - for the seat;

- 3 boards of the same length and width 25 mm thick - for the back;

- 24 bolts and nuts for screwing the boards to the frame.

After preparing the frame, it remains to assemble the bench. To do this, it is necessary to connect the crossbeam and 2 sections 350 mm long

It is important to take into account that the crossbar must be installed in the center of each segment, perpendicular to them. Then weld 2 bent segments 780 mm long to the structure

Weld at the bend of the pipes. After that, the front parts of the supports are welded to the frame. Please note that the connection point of the supports should be located 9 cm from the base of the seat. In order to increase the strength of the bench, the front supports must be connected to the crossbar.

At the last stage, 2 arcs are welded between the supports and fixed at the ends of the legs. The finished product is polished at the welding points and painted. After the paint has dried, the wooden elements are installed to serve as the seat and backrest. The boards are pre-treated with a plane, polished, varnished or painted.

Making a bench with your own hands is a feasible task that does not require large expenses. All it takes is tools, materials, blueprints and a little patience. The product, in which strength and soul are invested, will be a real decoration of a suburban area or courtyard of a private house.

Metal benches for the garden: how to make?

The bench can be built entirely of metal or in combination with other building materials. For example: wood + metal. This type of bench has advantages that cannot be overlooked:

- The construction of a combined bench requires minimal costs.

- The design is practical and reliable.

- A seat made of wood does not heat up as much as a metal one, due to this, it is comfortable to spend time on such a bench even on a sunny day.

- A bench with a metal frame will last a very long time.

Most often, builders choose steel to create the frame. The material is practically not subject to corrosion, it lends itself well to processing, due to which you can add beautiful forged elements to the structure. In addition to forged elements for decoration, profile pipes are used for benches.

Compared to concrete structures, a metal bench is lightweight and easy to install. Benches made of stone are inferior to metal products in a variety of design solutions, and stone is much more expensive than metal. A universal material for construction is wood.The main disadvantage of wood is its vulnerability to weather conditions, which cannot be said about metal.

Creating a bench and benches from shaped pipes yourself

The cross section of the pipe can be different. In the construction market, you can find a suitable option for the job. To create a bench, in addition to pipes, you will need wooden beams, an apparatus for welding, drilling and grinding wood. Additionally, you need to purchase paint for metal, wood stain or any other paint for wood processing. You will also need nuts, bolts, pliers, a hammer, a tape measure and a building meter, if you do not have it on the farm, you will have to purchase it along with the material. Professionals advise using a groove to create symmetrically curved pipes. Before bending the heated part of the pipe, it is necessary to pour sand into it. The pipe is bent by hand.

Instead of a bench, you can build a bench. The difference between a bench and a bench is the absence of a back. The absence of this element helps to reduce money costs, save time and effort for construction. You can replace the back of the bench by placing the bench in the gazebo, where the wall plays the role of the back. You can use profile pipes to design other buildings, for example, gates, or include a decorative element from this material in the construction of a gazebo. So all the buildings on the site will look harmonious, create a single style and complete the composition.

Creation of a structure. For this design, you need to purchase 24 bolts and the same number of nuts. The seat of the future bench is formed by three metal rectangles. The rectangles are interconnected by a pair of shaped pipes. The shop is easy to install and design, therefore it does not require a detailed drawing. To create it, you can use a photo from the network, which you liked the most.

Bench creation. First of all, a frame is created for seating the future bench. To create it, you will need pipe segments. With the help of guides, these segments take the shape of a rectangle. In order to achieve a right angle between the profile pipes, use a square. By adding additional supports to the original structure, you can increase the size of the bench. After welding the elements, the wooden beams are adjusted.

Assembly of all forged elements, treatment of welds and coating them with a primer. After installation and painting of the frame, 8 holes must be drilled in each of the elements for the installation of a piece of wood (seat). The holes must be symmetrically positioned. It is imperative to treat the wood with wood stain to prevent the process of darkening, decay, and also to protect the material from various insects. After the tree has dried, the seat is mounted to the frame part of the bench. Additionally, a canopy can be built above the bench or a single structure can be created. This solution allows you to stay on the bench in rainy weather.

Advantages of benches and benches made of profiled pipes:

- Strength and reliability of the design.

- Withstands any weight load.

- Low cost of materials to create a structure.

- Light weight of the finished product: benches or benches.

- Ease of installation.

- Durability.

Preparation for construction

Making a sophisticated bench with lots of ornaments is difficult. Actually, we did not set ourselves such a task.

Model selection

We chose for work a simple bench with a seat and back made of narrow boards, the only highlight of which is the curved armrests. However, if you do not have the skills to work with a "pipe bender" or do not have the device itself, or you do not know how to bend metal with a welding machine, you can easily refuse them, this will not affect the functionality of your bench.

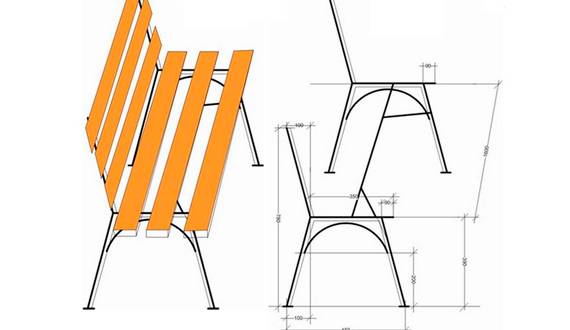

Drawing of our future bench

Material selection

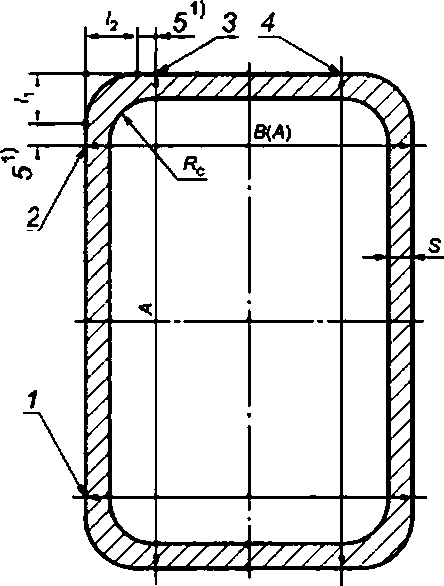

Select the pipe profile. An oval profile is best suited for our purposes.

Pipe profile with nominal dimensions

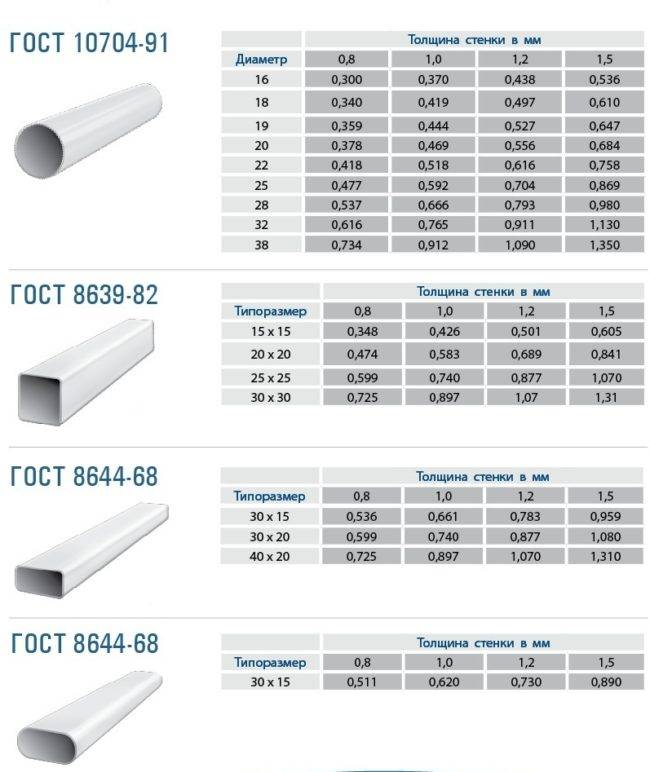

We select the required section of the pipe. Since no overloading is foreseen, you can choose a pipe with a rectangular cross-section and a small wall thickness of 1.5 mm. The section will fit 40x20 mm - this is exactly what to ensure strength and not make the structure heavier.

GOSTs for profile pipes that make it easier for us to choose

Pine can be used perfectly for the back and seat. It is cheap, well planed without scoring, elastic and does not give splinters and chips, due to some resinousness it is less susceptible to fungus and rotting, therefore it is durable. A wide board dries for a long time after rain, it is inconvenient to sit on a narrow one, it requires a lot of work with a drill and self-tapping screws, or bolts and nuts, to fasten each strip. As a compromise, we choose a board 25x100 mm.

Pine board, untreated

Drawings and dimensions

We draw a drawing. You can search the Internet and find a ready-made one. We did just that, taking a drawing from the site "Industrial metal structures".

Bench drawing with specification and dimensions

Required tools

- Welding machine

- "Pipe bender" or "snail" from a car disk for bending pipes

- Grinder with grinding and cutting wheels for metal (or a hacksaw for metal)

- Electric saw (or hacksaw for wood)

- Drill with metal drills and attachments for grinding metal and wood (or a file and a set of sandpaper)

- Hydro level

- Roulette

- Gon

- Planer, jointer

- Set of screwdrivers and keys

- Hammer

- Pliers

Tools (photo gallery)

| Name | Specification | Quantity |

| Regular profile pipe made of low-alloy steel | 40x20x1.5x6000 mm | About 14 kilograms plus 2 kilograms of stock |

| Metal sheet for "dimes" under the legs | Thickness 4 mm | A small flap, sufficient to cut 4 "dimes" 70x70 mm |

| Back and seat boards | 25x100x3000 mm | 4 boards (provided that the boards are free from defects; if the board is defective, then a margin for rejection is needed)) |

| Welding electrodes | 3 mm | 1 pack |

| Anti-corrosion primer for metal | According to the consumption per 1 m2 indicated on the package | |

| Anti-corrosion paint for metal | According to the consumption per 1 m2 indicated on the package | |

| Anti-rotting impregnation for wood | According to the consumption per 1 m2 indicated on the package | |

| Wood primer | According to the consumption per 1 m2 indicated on the package | |

| Weatherproof colored or transparent varnish, or weatherproof paint, or wood stain | According to the consumption per 1 m2 indicated on the package | |

| Waterproof glue | 1 tube | |

| Bolts with washers and nuts (preferably a semicircular head). Or self-tapping screws | М6х35 | Not less than 30 pieces |

| Plastic caps for profile ends | If home use of the bench is planned - 6 pieces, if outdoor - 4 pieces | |

| Furniture plastic caps | Not less than 30 pieces | |

| Sand | Finely dispersed | 10 kilograms |

Product stability

This is a safety issue: the bench should not tip over when sat on it. Stability is ensured in various ways, which are taken into account at the stage of drawing development. They depend on the types of products, which can be portable and stationary.

Stationary garden benches are firmly fixed in place. Additional mounting elements need to be made in the design of their legs:

If the bench is installed on a hard and level surface (asphalt or concrete), then it can be fixed with anchor bolts. For this purpose, brackets with holes are welded to the legs.

When installed on the ground, the legs are fixed using local concreting. Their length must be calculated taking into account the part that goes underground. Rods that increase their length are attached to the legs of finished products that were not installed permanently.

The portable bench is convenient in that it can be used anywhere and on any surface without the need for installation. But this is also its disadvantage: it becomes much more difficult to ensure sustainability.

It is necessary to ensure that the bases of the legs are located in the same plane parallel to the seat. For accurate installation, you need to do it yourself or purchase ready-made fixtures. You can also use regular clamps, a bench square, and a large workbench with a flat surface.

All specified parameters should be strictly adhered to: lengths, distances, angles, alignment, etc. Therefore, it is better to use drawings prepared by professionals. Finding them on the Internet is not so difficult. And if you want to make an exclusive with your own hands, it is much easier to do this by making changes to the finished assembly scheme. Nobody discourages you from realizing your creative potential, but by working on the model, you will make fewer mistakes. Having many options in front of your eyes is useful for developing your own ideas.

Tips for making decorative items

Profile pipes bend well with the simplest home-made bending devices. There are two ways to bend, each of them has its own characteristics.

-

Cold. The most common, used in all bending machines, including industrial ones. It has several disadvantages: great efforts are required, bending must be done in several steps, there are great risks of wrinkling. The advantages are safety and availability.

-

Hot. A little more complicated, it is rarely used at home and only for the manufacture of small parts. The pipe or other rolled products are heated with a blowtorch or gas torch to a bright red color; safety rules should be observed during bending. The hot method eliminates the appearance of cracks and folds on the surfaces, makes it possible to bend the metal at a large angle in one pass.

Curved parts are manufactured in various sizes and at the same time perform load-bearing and decorative functions. Come up with patterns yourself, any of them will be completely original

It is the exclusivity that attracts the attention of home-made benches.

With the help of bending from shaped pipes, you can create a variety of curly elements for the bench

Metal profile as a material for a bench

Benches made on the basis of metal pipes have several advantages:

- relatively low weight, in contrast to cast iron and concrete products, suitable only for parks;

- low cost and wide design possibilities, which cannot be said about structures made of stone;

- extraordinary durability, which differs from wooden benches, which deteriorate under the influence of weather conditions, bugs and mold.

A significant drawback of the metal pipes used to create the bench is their unaesthetic appearance. However, you can ignore this drawback, because there are many ways to decorate a metal product. No wonder the most popular benches are made on the basis of rust-resistant steel pipes and supplemented with wooden elements. A seat is usually made from wood, so that the bench does not heat up in the sun.

DIY metal garden benches: drawings and photos, characteristics

Despite the fact that this type of structure belongs to the category of metal, in most cases in the photo of do-it-yourself metal benches that are found on the Internet, products of a combined type are shown. In them, the frame part is made of metal, and wood is used as the material for the seat and backrest.

Successful application of metal elements in garden benches

Thus, not only the construction of a bench is reduced in price, but the construction itself becomes more practical and comfortable, since a wooden seat, unlike a metal one, does not heat up under the sun.

The advantages of a do-it-yourself bench made of metal over products from other materials

Metal supports are devoid of those drawbacks that are inherent in the frame parts of benches made of other materials:

cast iron is the heaviest type of structures, which is suitable for installation exclusively in park areas (products are characterized by high cost, decorativeness and complex manufacturing technology);

Bright and creative bench design

- concrete - benches are heavy and are accompanied by a number of difficulties during installation on the site;

- stone - products have a high cost and are significantly limited in terms of design;

- wood - despite the beauty, availability and low weight, the supports in these structures quickly become unusable, since the material is extremely vulnerable to the influence of weather and climatic conditions, as well as negative environmental factors (fungi, insects, mold).

Original metal bench made from the headboard of an old bed

Often steel is used as a raw material to create a metal frame. It is this material that is considered the most suitable for benches and benches intended for installation in country-type plots and adjacent areas of country cottages. Steel is practically unaffected by corrosion processes and destruction. It offers many design options through the use of the decorative forging method.

Combination of metal and wood in an original design

Features of creating unusual designs

Profile pipes are also used to create decorative elements that can be added to a finished bench or bench. If you decide to create a unique design, you will need to add a few more items to the general list of required tools.

To form a steel decor, you will need to use:

locksmith vice;

The metal structure is a wonderful decoration for the tree in the garden

- pipe bending instrumentation;

- mini-machine called "Snail".

To obtain symmetrical pipe bends, it is recommended to use a plasma. The basis for its manufacture is a piece of plywood sheet. On top of it, apply the contour part of the decorative element that you want to get. To create graceful and even bends, you should use the capabilities of a blowtorch, which softens the material and makes it pliable to bend. To do this, it is enough to act with the lamp on the required area.

Unusual butterfly-shaped metal bench for children

The filled bending pipes must be placed on the machine by placing them between the stop and the shoulder located in the center. Then you can get to work. The pipe bending process is carried out manually.

A bench with a reliable metal frame will last for many years